Underwater hollow hub-free propeller

A thruster, hollow technology, applied in the directions of rotary thrusters, rotating propellers, controlling mechanical energy, etc., to achieve the effect of improving efficiency, increasing the number of poles, and being easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

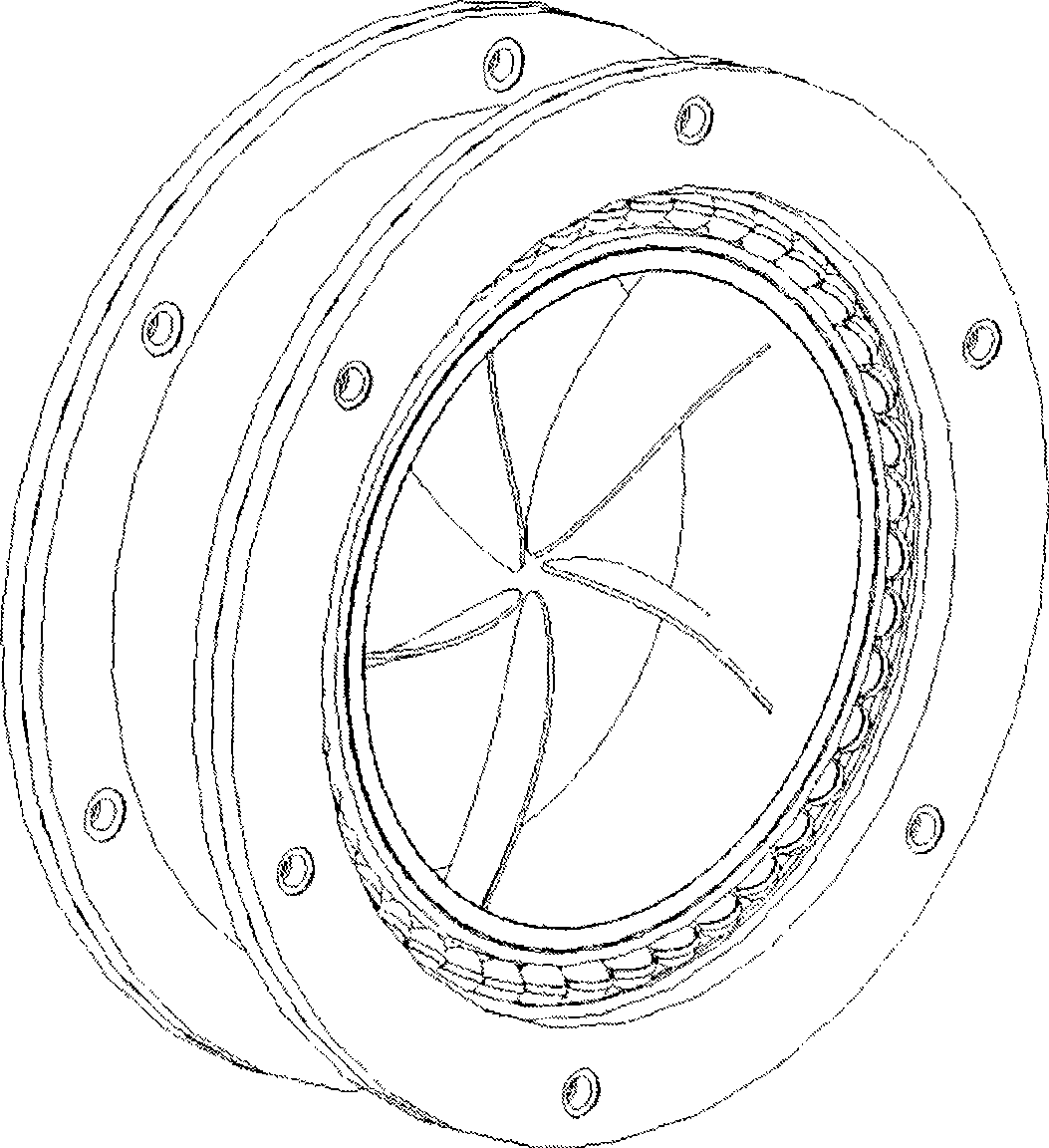

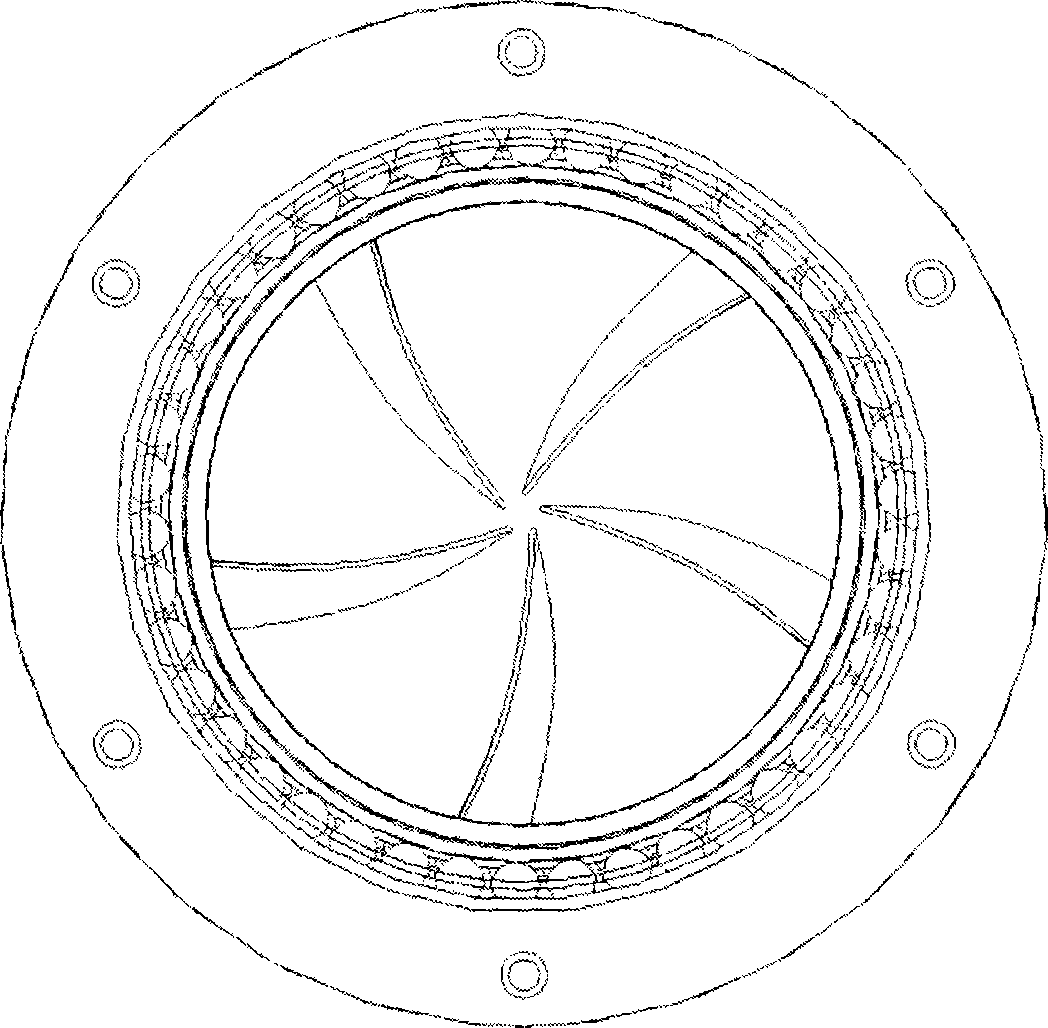

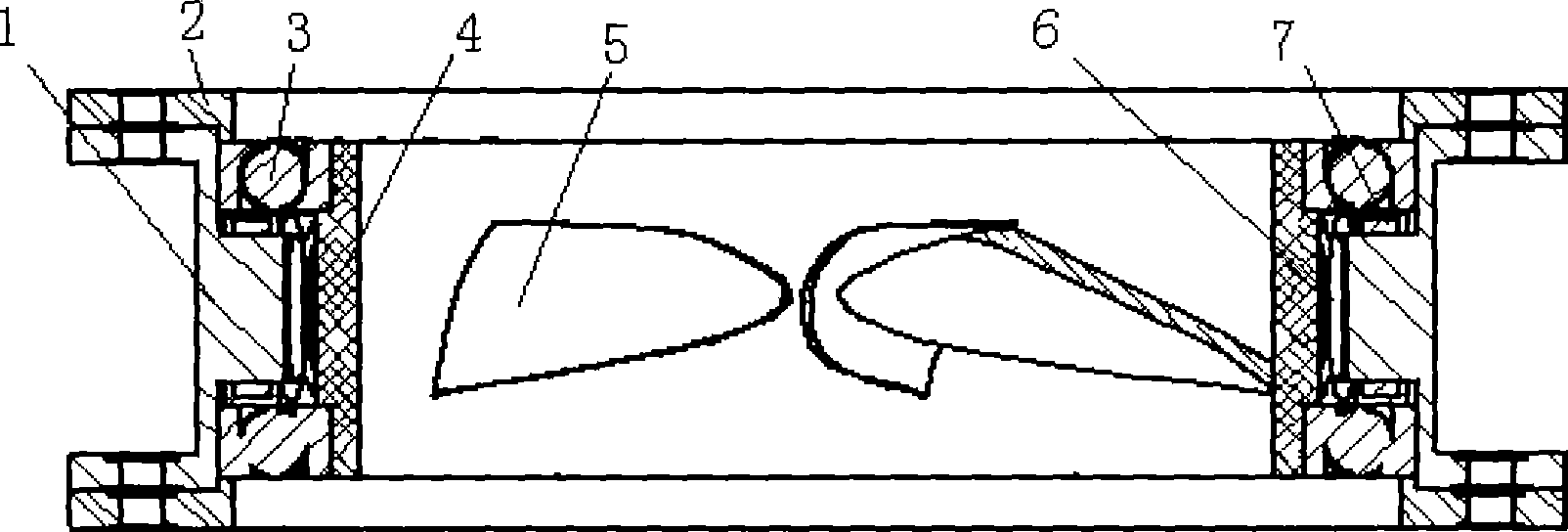

[0017] to combine Figure 1 to Figure 3 , The composition of the underwater hollow hollow propeller includes a motor electronic housing 1, an end cover 2, a ceramic angular contact bearing 3, a rotor 4, a propeller blade 5, a cured outer skin 6, and a stator coil 7.

[0018] The motor housing 1, the stator coil 7 is wound on the silicon steel sheet of the stator motor stator housing 1, and then put it into the center of the motor housing 1, the rotor 4 is designed as a hollow ring structure, and the rotor permanent magnets are fixed on the rotor 4 in poles, forming Rotor with a hollow structure, the propeller blade 5 is fixed inside the hollow rotor 4, so that the propeller blade 5 and the rotor 4 are combined into a whole, and the rotor 4 is fixed in the motor by two ceramic angular contact bearings 3, which can be installed in the motor according to the applicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com