Power plant of water surface ship

A technology for power plants and ships, applied in the field of engines, can solve the problems of limited power and low thermal cycle efficiency, and achieve the effect of reducing the incidence of failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

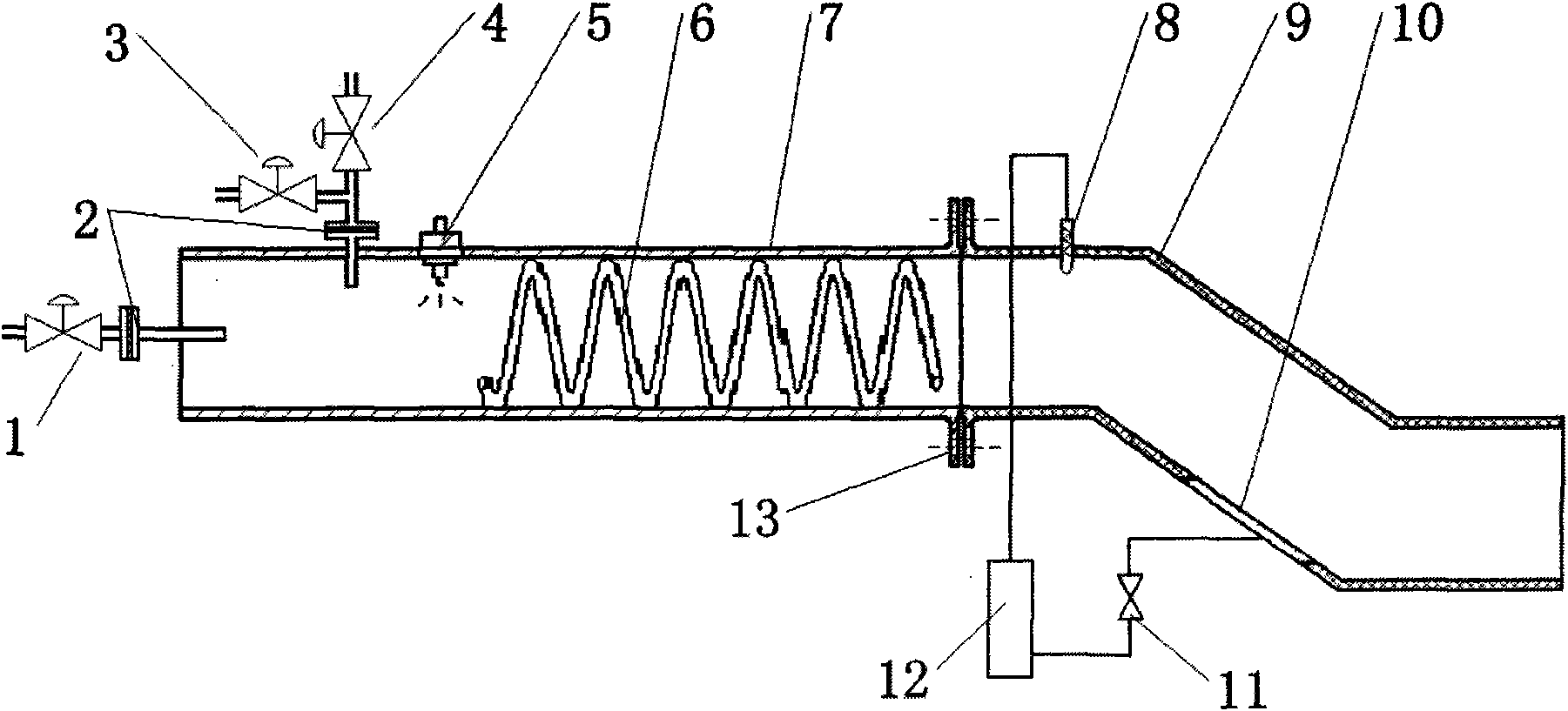

[0022] The power device of a surface vessel described in this embodiment includes a pulse detonation tube 7 and an engine inclined tube body 9 .

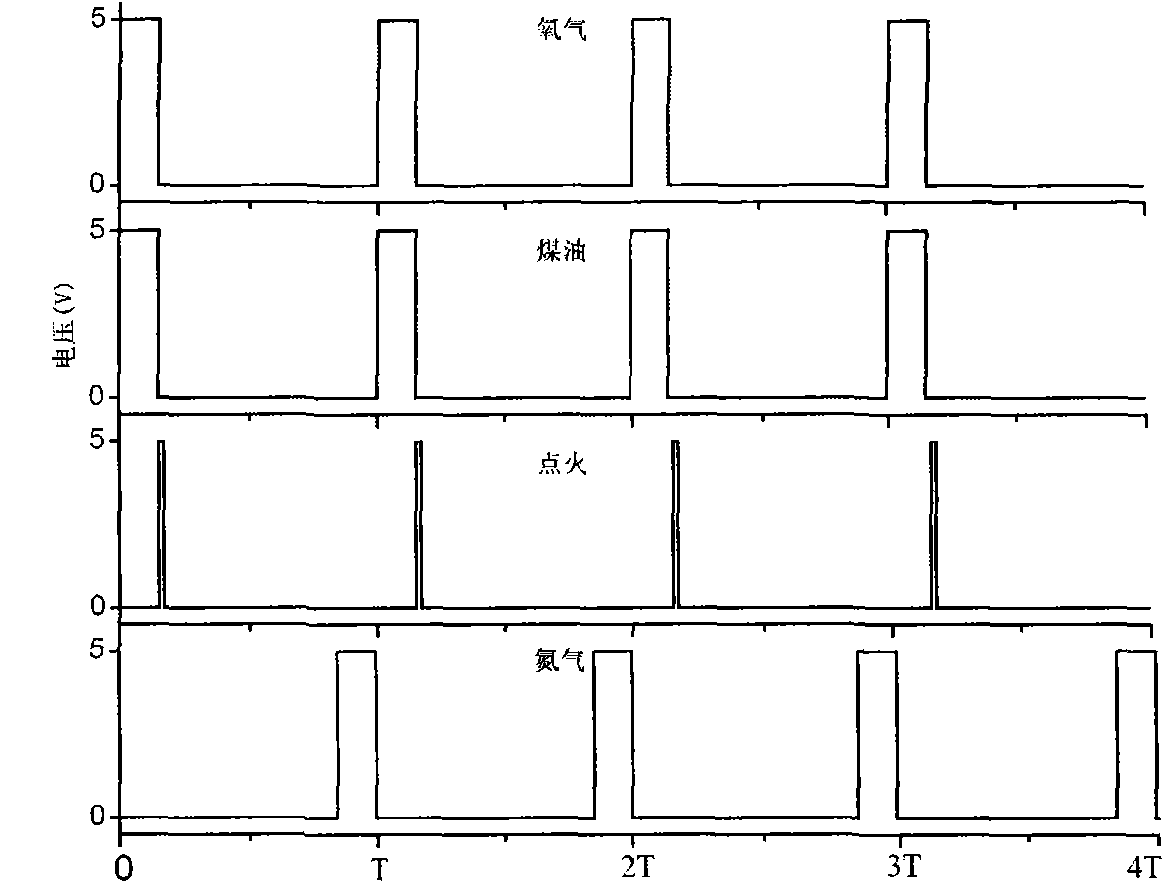

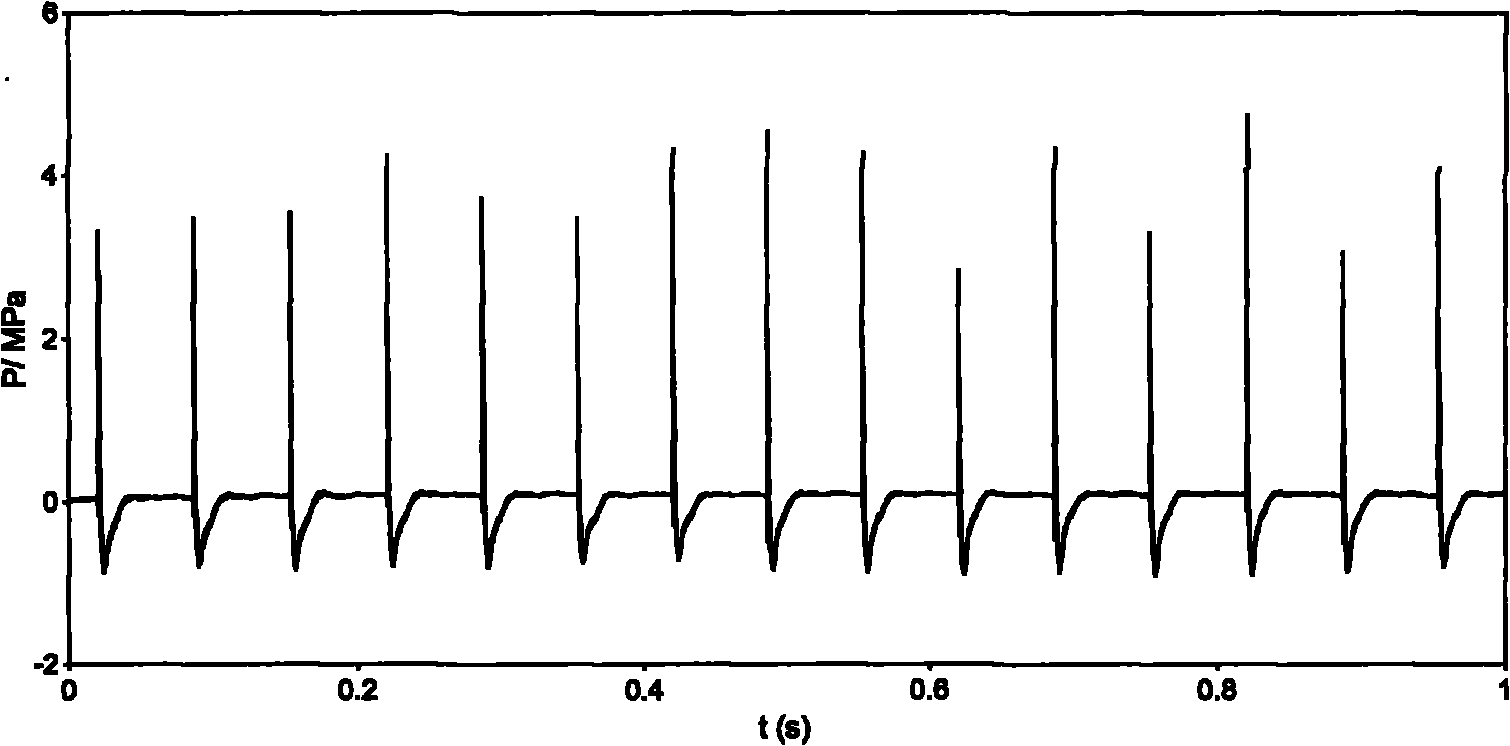

[0023] The fuel used in the pulse detonation tube 7 is aviation kerosene, the supply pressure is 0.5MPa, the oxidant is compressed oxygen, the supply pressure is 1.5MPa, the supply pressure of fuel and oxidant is greater than the water pressure at the outlet of the inclined tube body of the engine, and the liquid kerosene / oxygen mixture The equivalence ratio is about 1.0, the isolation gas is compressed nitrogen, the inner diameter of the tube is 30mm, and the length is 0.9m. The fuel inlet of the pulse detonation tube 7 is opened on the closed end of the pulse detonation tube 7, and the fuel inlet is externally connected to the fuel solenoid valve 1. On the wall of the pulse detonation tube 7, an oxidizer solenoid valve 3 and an isolation gas solenoid valve 4 are respectively connected to the oxidant pipeline and the isolation gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com