Multifunctional industrial paint spraying waste gas environment-friendly treatment equipment

A technology for environmental protection treatment and waste gas treatment, which is applied in gas treatment, water/sewage multi-stage treatment, gaseous discharge wastewater treatment, etc. Improve emission standards, avoid pollution, and discharge environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

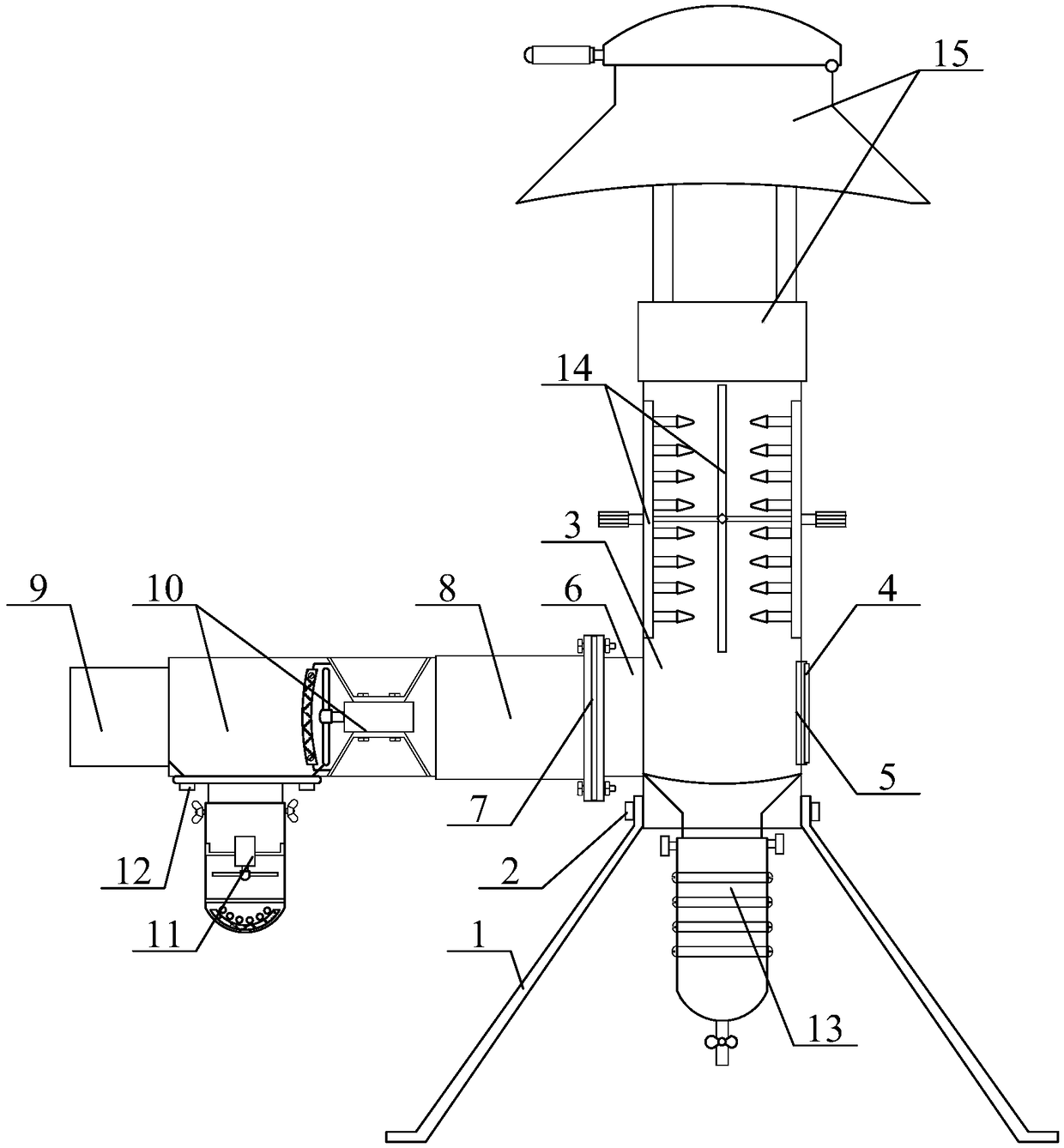

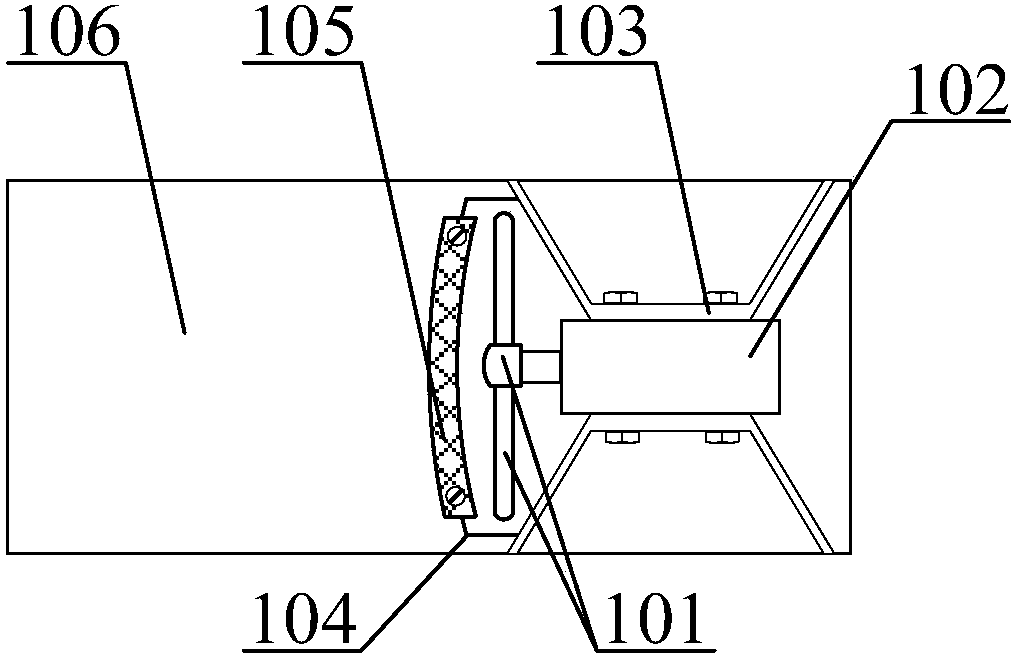

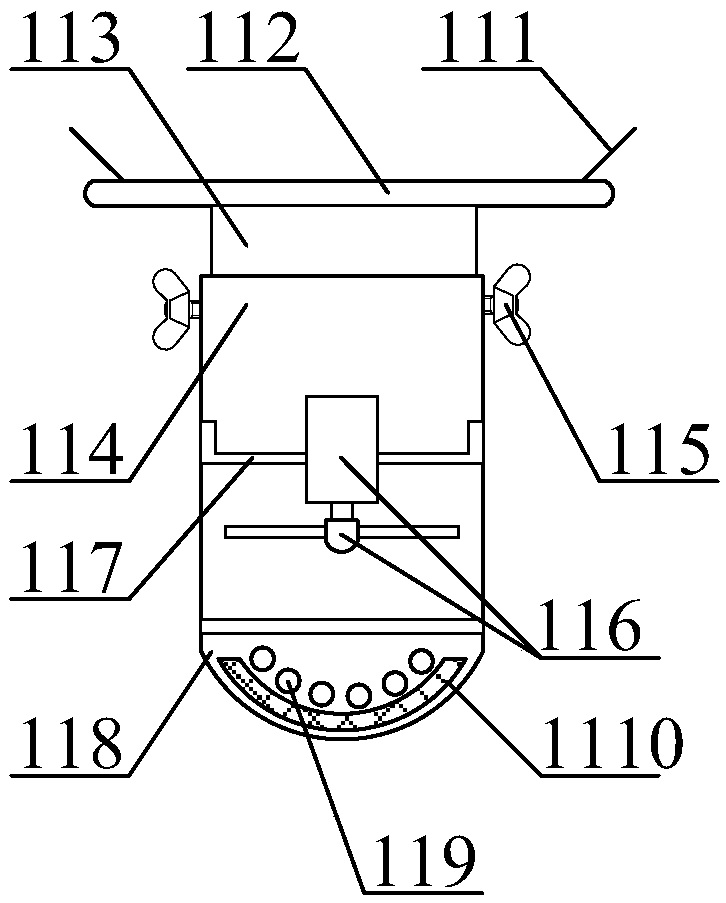

[0049] as attached figure 1 to attach Figure 6 shown

[0050] The invention provides a multi-functional environmental protection treatment equipment for industrial painting waste gas, which includes support legs 1, fixing bolts 2, waste gas treatment outlet pipe 3, observation piece 4, fixed frame 5, air intake pipe 6, connecting flange 7, and flow guide Pipe 8, waste gas introduction pipe 9, waste gas rapid suction primary processor structure 10, odor treatment machine structure 11, square head bolts 12, waste water recovery and treatment barrel structure 13, waste gas ultimate shower treatment head structure 14 and openable rainproof guide The gas cover structure 15, the support legs 1 are respectively installed at the four corners of the lower side of the exhaust gas treatment outlet pipe 3 through the fixing bolts 2; the observation piece 4 is embedded in the middle position inside the fixed frame 5; the fixed frame 5 is embedded in the lower right part of the exhaust g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com