Graphene-based carbohydrazide metal complex crystal energetic material and preparation method thereof

A technology of metal complexes and alkenyl carbohydrazides, applied in explosives and other directions, can solve the problems of low laser ignition efficiency and complex preparation process, and achieve the effects of reduced nitrogen content, high crystal density and low laser ignition energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

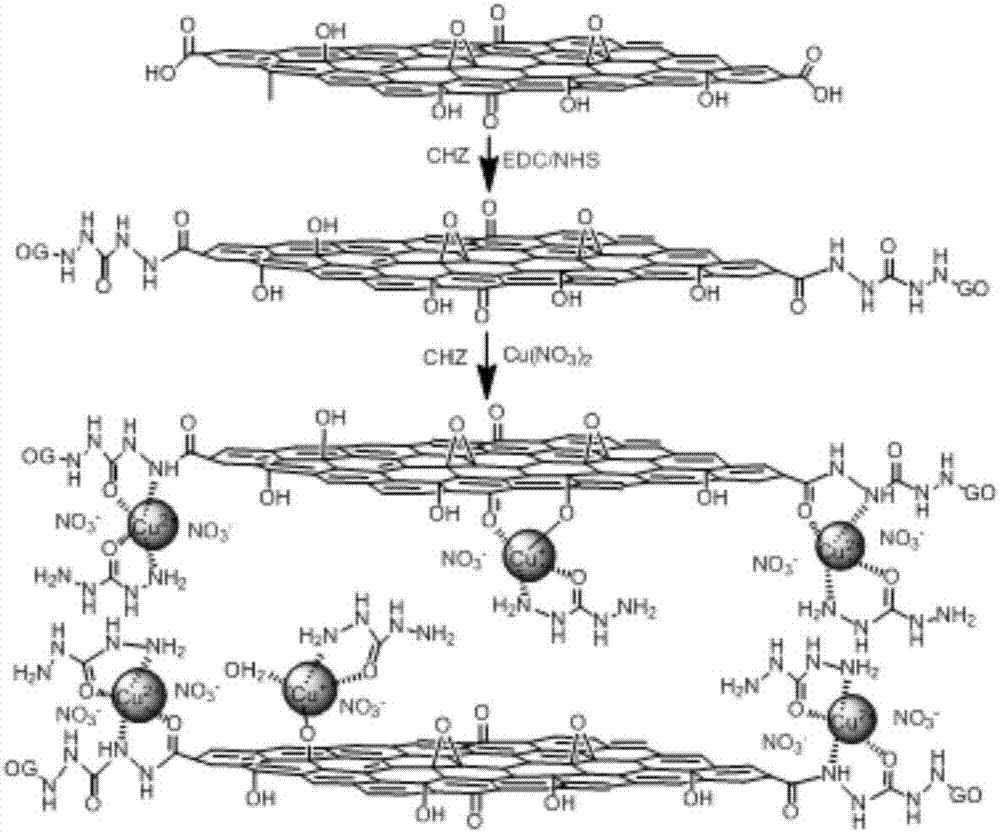

[0040] The preparation method of graphene-based carbohydrazide copper nitrate complex crystal comprises the following process steps:

[0041] Preparation of graphene oxide: Add 1g of natural flake graphite powder with a particle size of 120 mesh to 25mL of concentrated sulfuric acid at 0°C, then add 3g of potassium permanganate, control the temperature of the mixture below 10°C and stir for 2h, then stir at room temperature for 24h Finally, 100 mL of deionized water was slowly added dropwise under ice bath conditions. After about 20 min, 300 mL of deionized water (containing 5 mL of 30% hydrogen peroxide) was added. After the mixture turns bright yellow, perform suction filtration, then wash with 500ml of 10% hydrochloric acid, and vacuum dry at 60°C for 48 hours to obtain graphite oxide; in addition, graphite oxide can also be purchased as industrial grade graphite oxide, but it contains Oxygen needs ≥ 45%.

[0042] Preparation of graphene oxide suspension:

[0043] Graphe...

Embodiment 2

[0056] The preparation method of graphene-based carbohydrazide cobalt nitrate complex crystal comprises the following process steps:

[0057] Preparation of graphite oxide: Add 1g of natural flake graphite powder with a particle size of 120 mesh to 25mL of concentrated sulfuric acid at 0°C, then add 3g of potassium permanganate, control the temperature of the mixture below 10°C and stir for 2h, then stir at room temperature for 24h Finally, 100 mL of deionized water was slowly added dropwise under ice bath conditions. After about 20 min, 300 mL of deionized water (containing 5 mL of 30% hydrogen peroxide) was added. Suction filtration was performed after the mixture turned bright yellow, washed with 500 ml of 10% hydrochloric acid, and vacuum-dried at 60° C. for 48 hours to obtain graphene oxide.

[0058] Preparation of graphene oxide suspension: weigh 28.1 mg of the above graphene oxide into 30 mL of water, and ultrasonically disperse for 30 minutes to obtain graphene oxide ...

Embodiment 3

[0066] A method for preparing graphene-based carbohydrazide nickel nitrate complex crystals, comprising the following process steps:

[0067] Preparation of graphite oxide: see Example 1.

[0068] Preparation of graphene oxide suspension: Add 28.1 mg of graphene oxide into 30 mL of dimethylformamide (DMF), ultrasonically disperse for 1 hour, and form the graphene oxide suspension.

[0069] First add 10 mg of 1-ethyl-3-(3-dimethylaminopropyl) carbodiimide (EDC) to the graphene oxide suspension, and then add 5 mg of N-hydroxysulfosuccinyl after reacting for 1 h imine, after 30 minutes of reaction, the activated precursor of graphene oxide was obtained;

[0070] Disperse the activated graphene oxide precursor in water for 30 minutes by ultrasonic dispersion, add 15 mg of carbohydrazide, and react for 4 hours after ultrasonic dispersion for 10 minutes. The reaction temperature is controlled at about 65 ° C. Finally, it is washed and filtered with deionized water, and dried in vac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com