Folding coaxial cavity microwave igniter for engine of automobile

A technology of automobile engine and coaxial cavity, which is applied in the direction of engine ignition, engine components, machine/engine, etc., can solve the problems that cannot meet the actual needs of microwave ignition technology, and achieve the coupling degree that is easy to adjust, easy to design, and structurally symmetrical Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

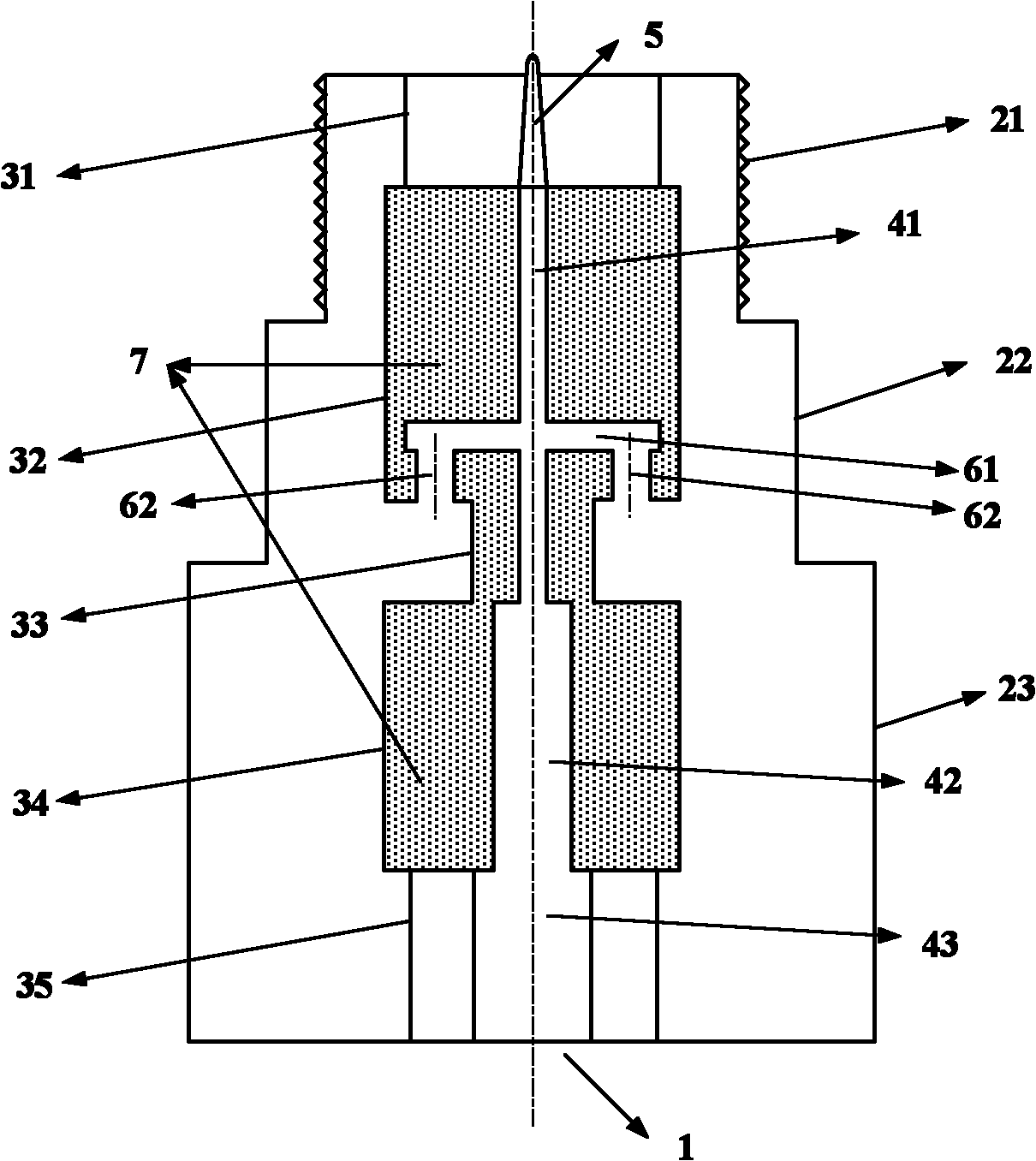

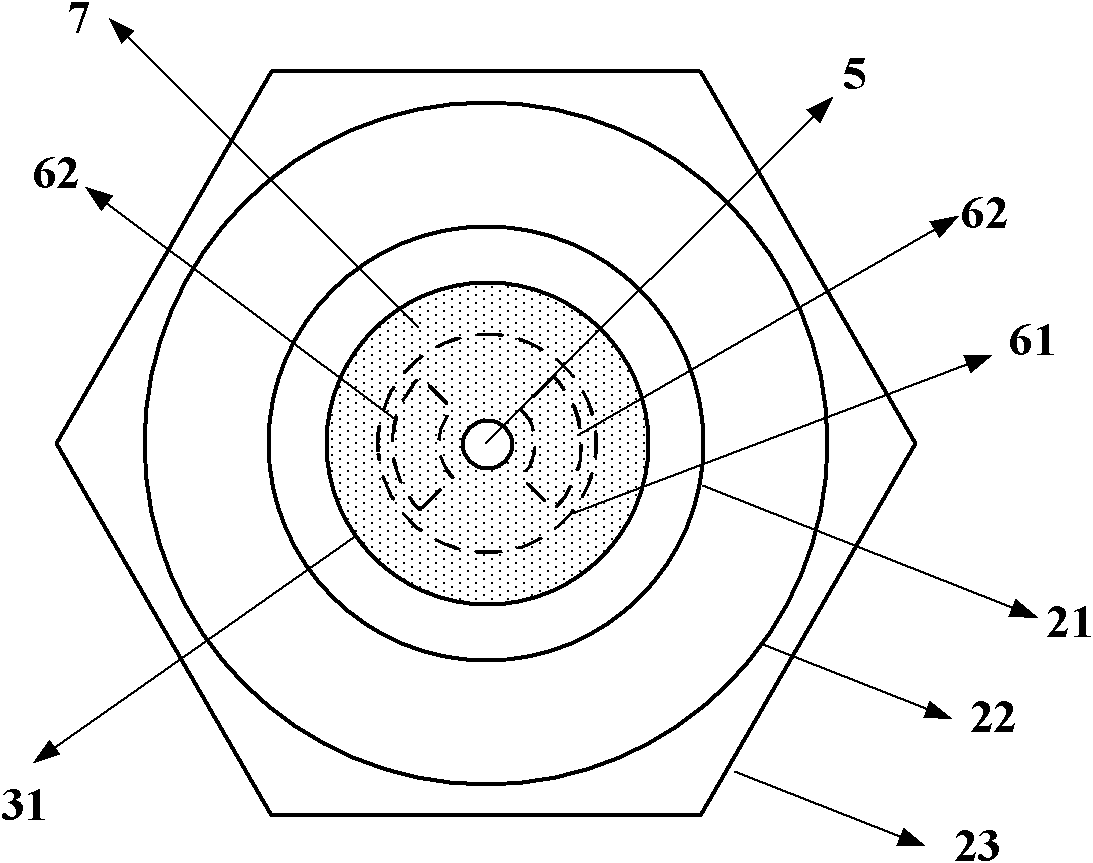

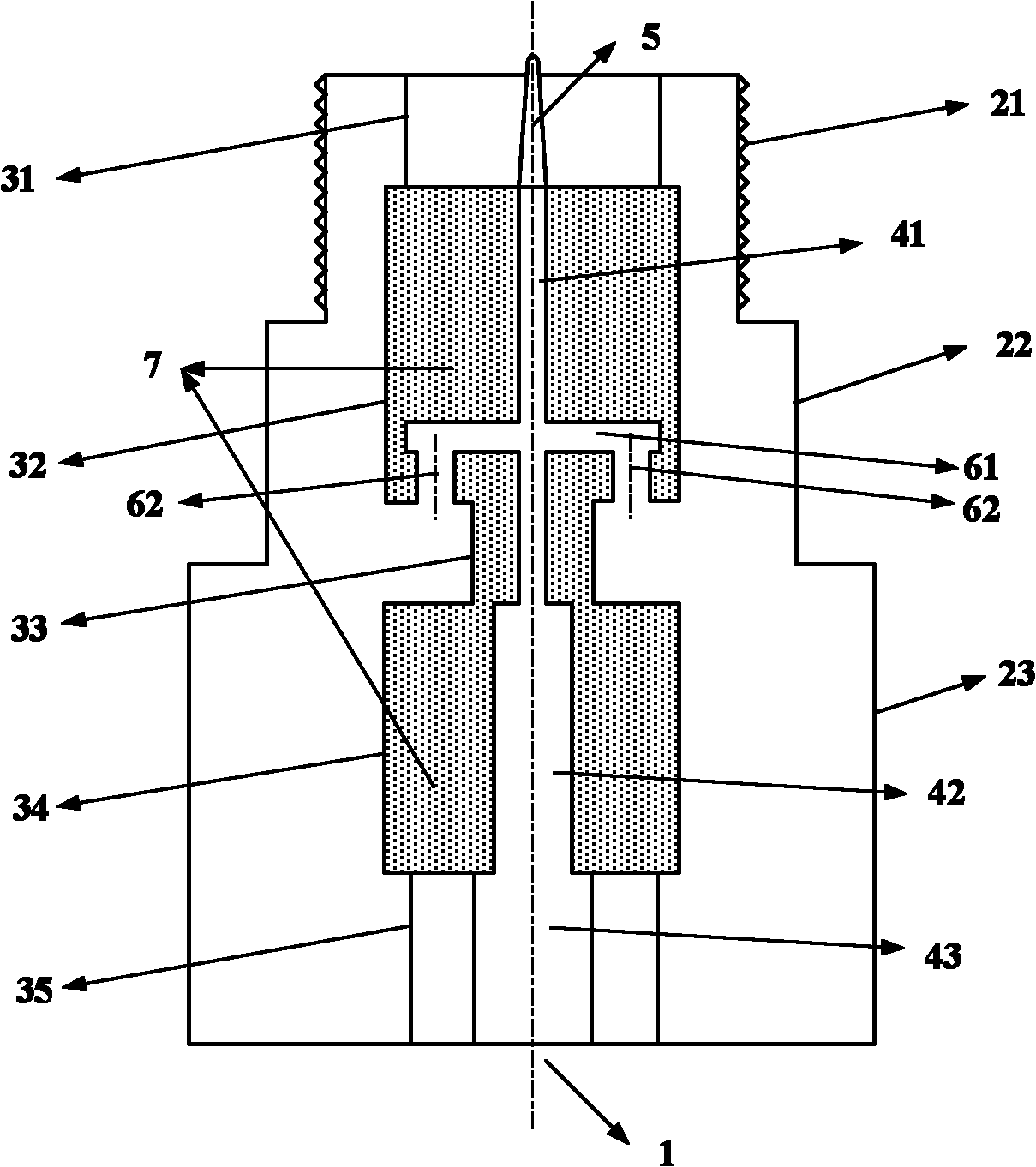

[0020] A folded coaxial cavity microwave igniter for an automobile engine, comprising an inner conductor and an outer conductor; the outer conductor is formed by sealing the outer contour of the outer conductor and the inner contour of the outer conductor; the outer contour of the outer conductor includes at least one The external thread 21 connected to the cylinder and a hexagonal prism working surface 23 for easy disassembly and installation; the inner contour of the outer conductor is a cylindrical surface structure with different radii, including the outer conductor inner contour-31 corresponding to the inner conductor tip 5 respectively , outer conductor inner contour two 32 corresponding to inner conductor one 41 and outer conductor inner contour three 33, outer conductor inner contour four 34 corresponding to inner conductor two 42, outer conductor inner contour corresponding to inner conductor three 43 Five 35; the inner conductor is composed of inner conductor one 41, ...

Embodiment 2

[0024] A folded coaxial cavity microwave igniter for an automobile engine, comprising an inner conductor and an outer conductor; the outer conductor is formed by sealing the outer contour of the outer conductor and the inner contour of the outer conductor; the outer contour of the outer conductor includes at least one The external thread 21 connected to the cylinder and a hexagonal prism working surface 23 for easy disassembly and installation; the inner contour of the outer conductor is a cylindrical surface structure with different radii, including the outer conductor inner contour-31 corresponding to the inner conductor tip 5 respectively , outer conductor inner contour two 32 corresponding to inner conductor one 41 and outer conductor inner contour three 33, outer conductor inner contour four 34 corresponding to inner conductor two 42, outer conductor inner contour corresponding to inner conductor three 43 Five 35; the inner conductor is composed of inner conductor one 41, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com