Pressurization and ignition device and method

A technology of ignition device and fire rod, which is applied in the directions of combustion ignition, combustion method, lighting and heating equipment, etc., to achieve the effect of improving ignition success rate, improving ignition efficiency and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below with reference to the accompanying drawings.

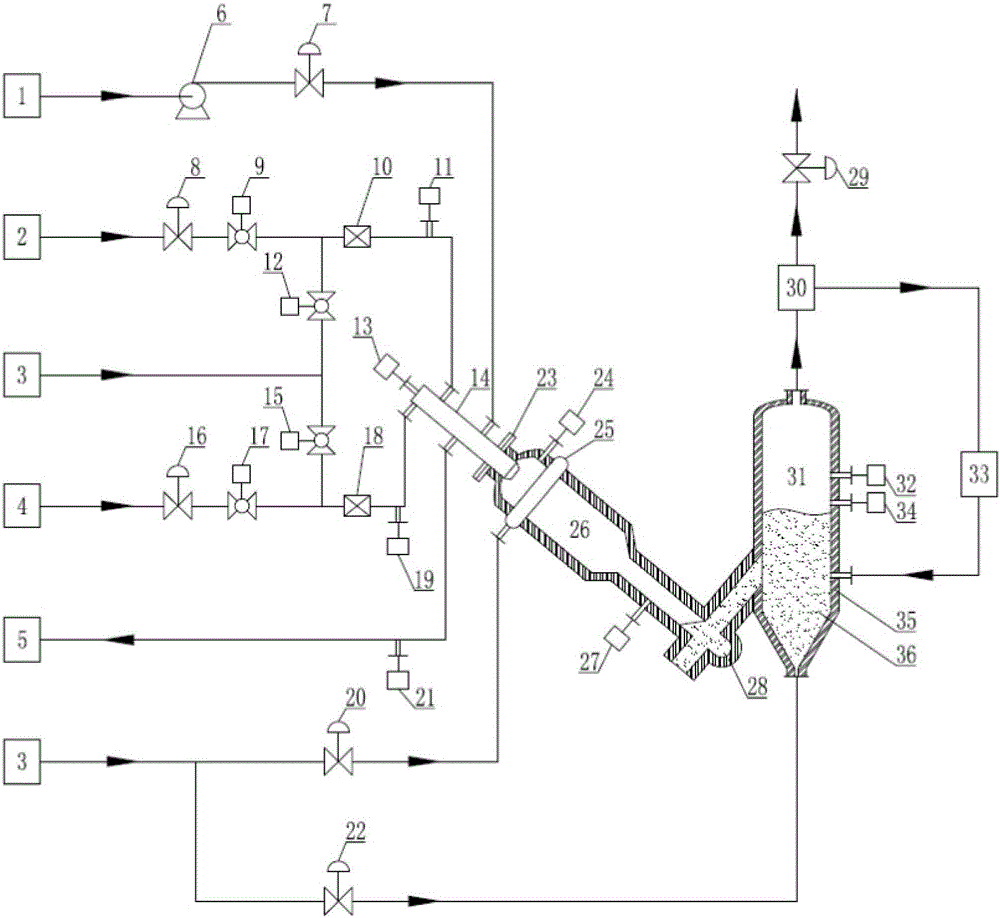

[0032] see figure 1 , the present invention includes the burner 14 provided with the electronic ignition rod 13, the working time of the electronic ignition rod 13 should include at least the options of 10 seconds and 20 seconds, the burner 14 is connected with the inlet of the rectifier furnace 26 through the flange 23, and the rectifier furnace The outlet of 26 is connected with the reaction furnace 31 through the tee 28. The rectifier furnace 26 is provided with a flame monitor 24, an air distribution ring pipe 25 and a flue gas thermometer 27. The air distribution ring pipe 25 passes through the pipeline and is installed on the pipeline. The first nitrogen flow regulating valve 20 is connected to the nitrogen gas 3, and the inner wall of the rectifier furnace 26 is provided with a refractory and heat-insulating material layer, the interior of the reaction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com