Positive ceramic wrapped type multipole spark plug

A wrap-type, spark plug technology, applied in spark plugs, electrical components, circuits, etc., can solve the problems of reducing fuel utilization efficiency, difficult to start the engine, increasing the difficulty of ignition, etc., to improve power performance, increase the average effective pressure in the cylinder, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

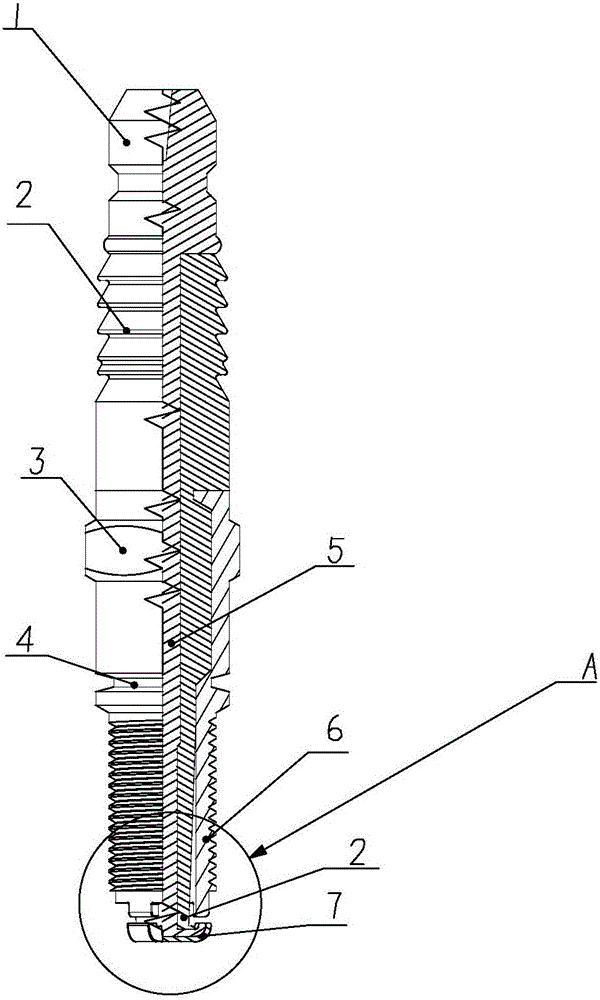

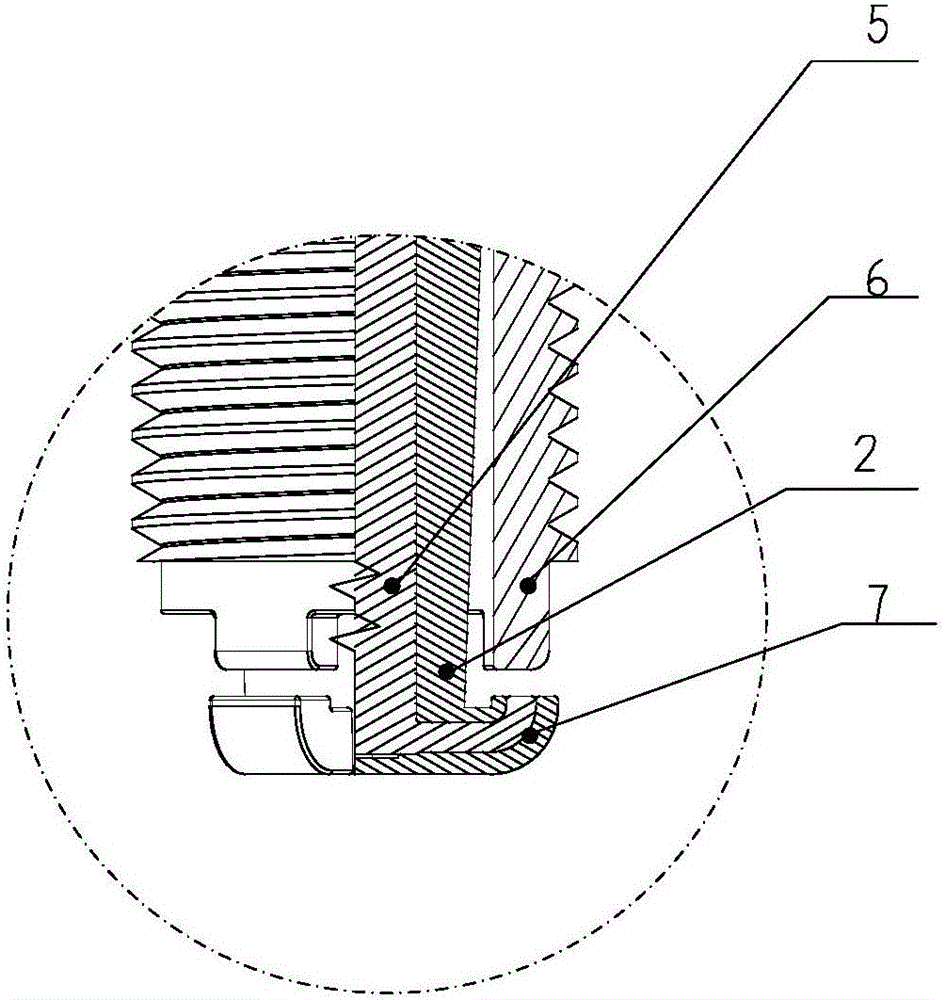

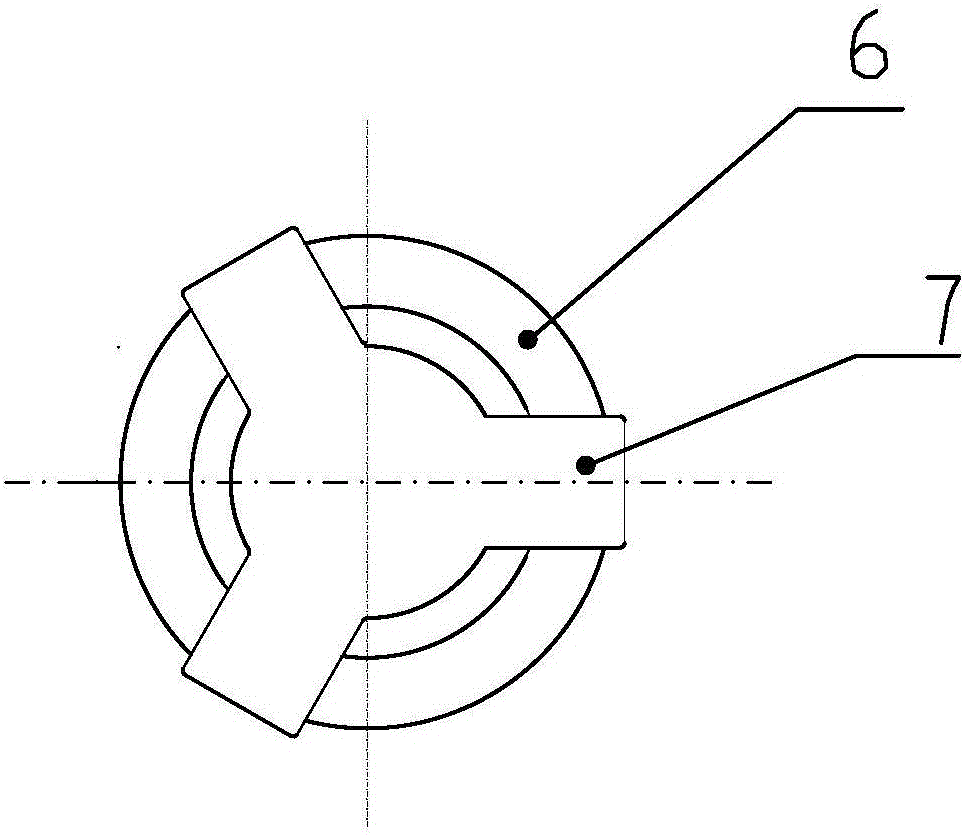

[0023] Such as figure 1 , 2 , 3, and 4, the spark plug mainly includes a ground nut 1, a ceramic insulator 2, a connection screw, a shell 3, a gasket 4, a center electrode 5 and a side electrode 6, and the thread is processed on the connection screw, which is roughly the same as the existing general spark plug structure unanimous. The center electrode is wrapped inside a ceramic insulator, and the side electrodes are in a circular tubular structure and coaxially fixed with the center electrode wrapped in the ceramic insulator; the bottom end of the center electrode is lower than the bottom end of the side electrodes, and the center electrode The bottom end is welded with three L-shaped ignition electrodes arranged at equal intervals. The front end of the L-shaped ignition electrode is bent upward and the end face of the front end is guaranteed to be horizontal. Ceramic coating 7 is sprayed on the surface of the ignition electrode except the front end end face; the bottom of t...

Embodiment 2

[0026] Such as Figure 5 , 6 , 7, the spark plug mainly includes a ground nut, a ceramic insulator, a terminal screw, a shell, a gasket, a center electrode and a side electrode, the center electrode is wrapped inside the ceramic insulator, and the side electrode is a circular tubular structure and is wrapped with the The central electrode in the ceramic insulator is coaxially socketed and fixed; the bottom end of the central electrode is lower than the bottom end of the side electrodes, and three metal sheet-shaped ignition electrodes arranged at equal intervals are welded on the bottom end of the central electrode, and the metal sheet-shaped The ignition electrode and the center electrode are in a vertical state; the metal sheet-shaped ignition electrode and the center positive electrode are integrally sprayed with a ceramic coating, and the front end faces of the three ignition electrodes are polished to expose the metal end faces; the bottom ends of the side electrodes are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com