Split type high-voltage arc ignition device for experiment

A high-voltage arc and ignition device technology, which is applied in the direction of ignition by electric spark, combustion ignition, and combustion methods, can solve the problems of poor applicability, low ignition efficiency, and poor stability of arc ignition devices, and is beneficial to experimental ignition and use. Flexible, precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

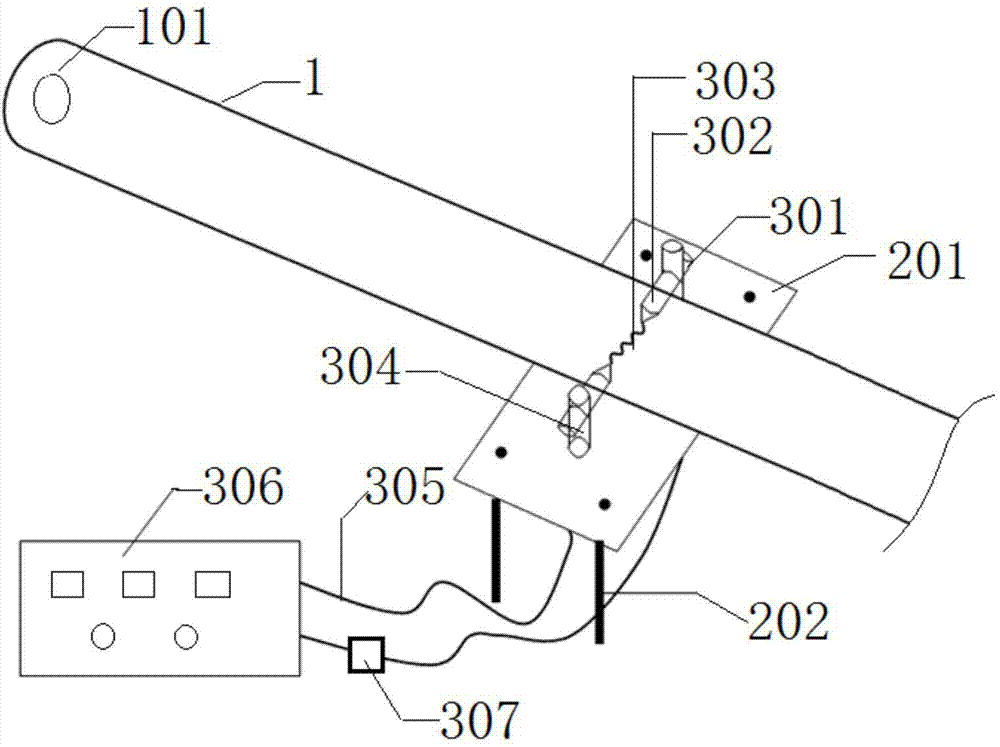

[0026] combine figure 1 , an experimental split-type high-voltage arc ignition device of this embodiment is mainly composed of an arc generating mechanism and a supporting device, wherein: the supporting device includes a supporting seat 201 and a scale-type adjusting rod 202, and four scale-type adjusting rods 202 are installed The lower surface of the support base 201 serves as a support; the scale-type adjustment rod 202 used can be adjusted in millimeter scales to change the height of the support base 201 .

[0027] The arc generating mechanism in this embodiment includes a voltage boosting device and an arc starting device. The arc starting device is installed on the upper surface of the support base 201 and includes a discharge electrode 302, a scale-type adjusting disc 301 and an electrode support 304. The two electrode supports 304 are vertically fixed. On the upper surface of the support base 201, a coaxial round hole is opened at the same height as the two electrode ...

Embodiment 2

[0033] An experimental split-type high-voltage arc ignition device of this embodiment has the same basic structure as that of Embodiment 1, the difference being that: the scale-type adjusting disc 301 is cylindrical, and the tail of the scale-type adjusting disc 301 is provided with The knob is marked with a scale along the circumference of the knob. Every time the knob rotates, the crossbar extends or retracts by a millimeter, and the corresponding discharge electrode 302 advances or retreats by a millimeter, thereby achieving the purpose of adjusting the distance between the discharge electrodes 302.

[0034] The scale-type adjusting dial 301 in this embodiment is similar to the adjusting structure of a spiral micrometer, and its adjustment accuracy is higher, and the distance between the discharge electrodes 302 can be fine-tuned, thereby changing its energy density, realizing the adjustability of the ignition device, Scalability and increased applicability

Embodiment 3

[0036] An experimental split-type high-voltage arc ignition device of this embodiment has the same basic structure as that of Embodiment 2, except that there are three graduated adjustment rods 202 installed on the lower surface of the support base 201 in this embodiment. , its main purpose is to support the supporting seat 201.

[0037] Based on the above embodiments, when the arc ignition experiment is performed on pulverized coal in the laboratory, different types of pulverized coal have different ignition characteristics and different ignition energies. After adopting the experimental split-type high-voltage arc ignition device of the present invention, it no longer depends on the traditional metal heating ignition and the ignition method of using an open flame to ignite, and can be applied to the combustion and ignition experiments of pulverized coal with different components, and it is energy-saving and environmentally friendly. Small impact. In the present invention, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com