Gas well blowout prevention ignition ball

A technology of natural gas and fire bombs, which is applied in the field of natural gas well blowout ignition bombs, which can solve the problems of low probability of igniting natural gas, short launch distance, and high personnel costs, and achieve high ignition efficiency, improved safety, and large spreading area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

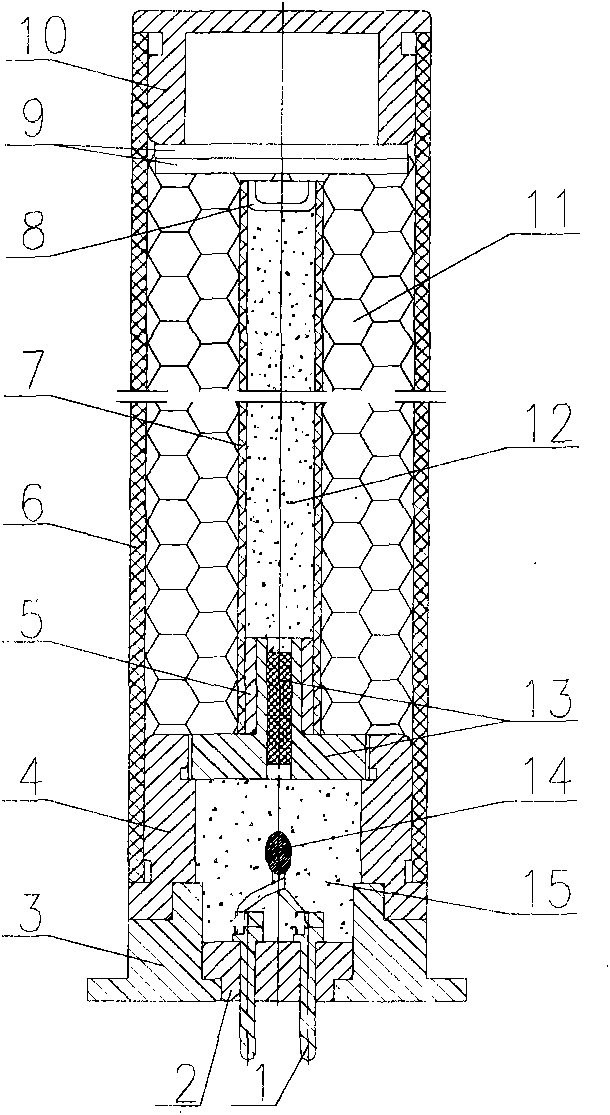

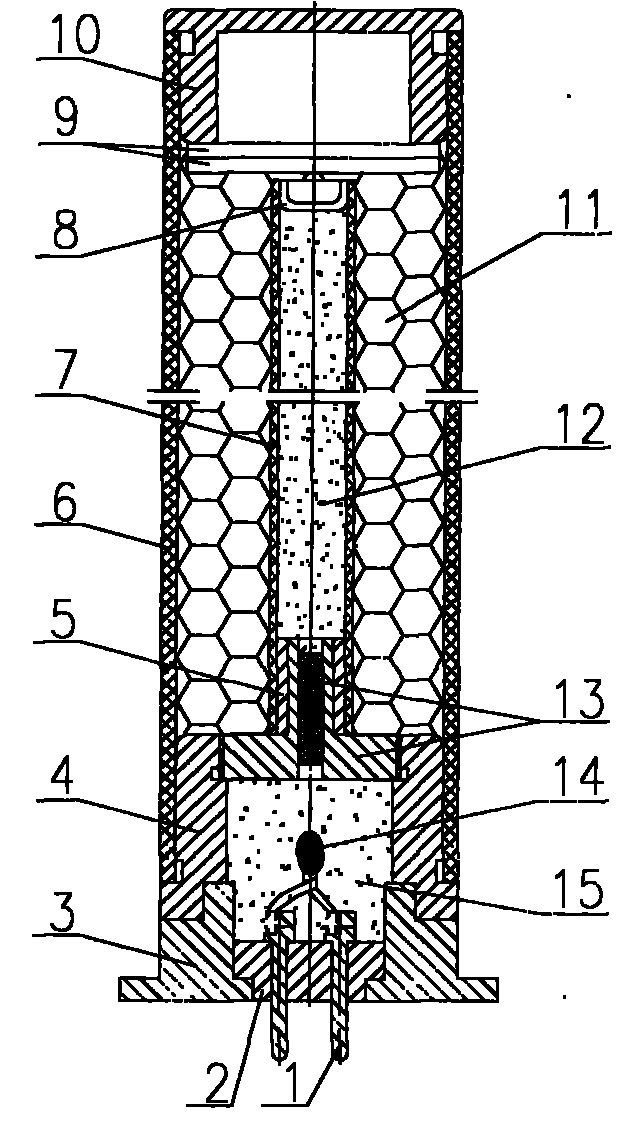

[0007] A natural gas well blowout ignition bomb, including a plug core 1, an insulating base 2, a base 3, a connecting body 4, a collar 5, a tube shell 6, a central tube 7, a cap 8, an adjustment piece 9, a blocking cover 10, and an ignition bullet 11. Projectile charge 12, delay mechanism 13, ignition head 14, propellant charge 15; plug core 1 is connected with insulating base 2, insulating base 2 is connected with base 3, one side of plug core 1 is connected with ignition head 14, and base 3 is connected A connecting body 4 is provided, a tube shell 6 is provided on the outside of the connecting body 4, an extension mechanism 13 is arranged on the inside of the connecting body 4, a collar 5 is arranged on the extension mechanism 13, a center tube 7 is arranged on the collar 5, and a center tube 7 is arranged on the center tube 7 is provided with propellant 12, central tube 7 is provided with block cap 8, is provided with ignition bullet 11 between central tube 7 and pipe shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com