Heat-storing combustion apparatus and biomass gas heating system

A combustion device and heating system technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of burner loss, affect the service life of the burner, and cannot directly ignite gas, so as to prolong the service life and improve the ignition efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

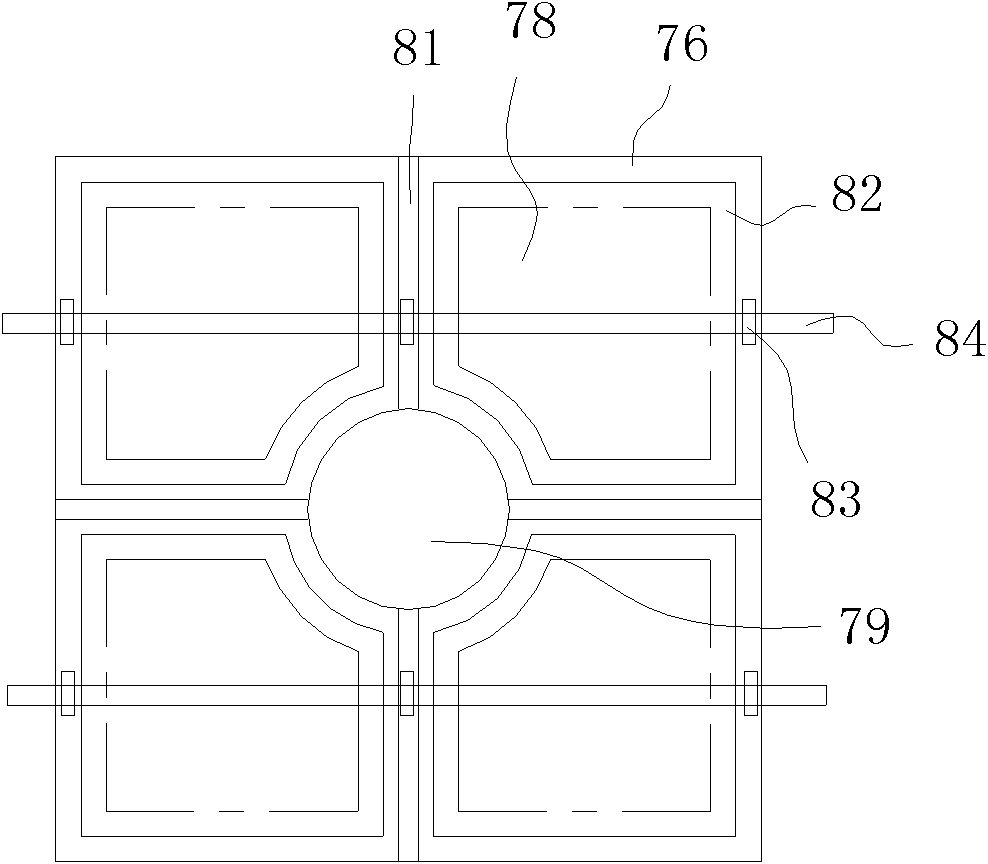

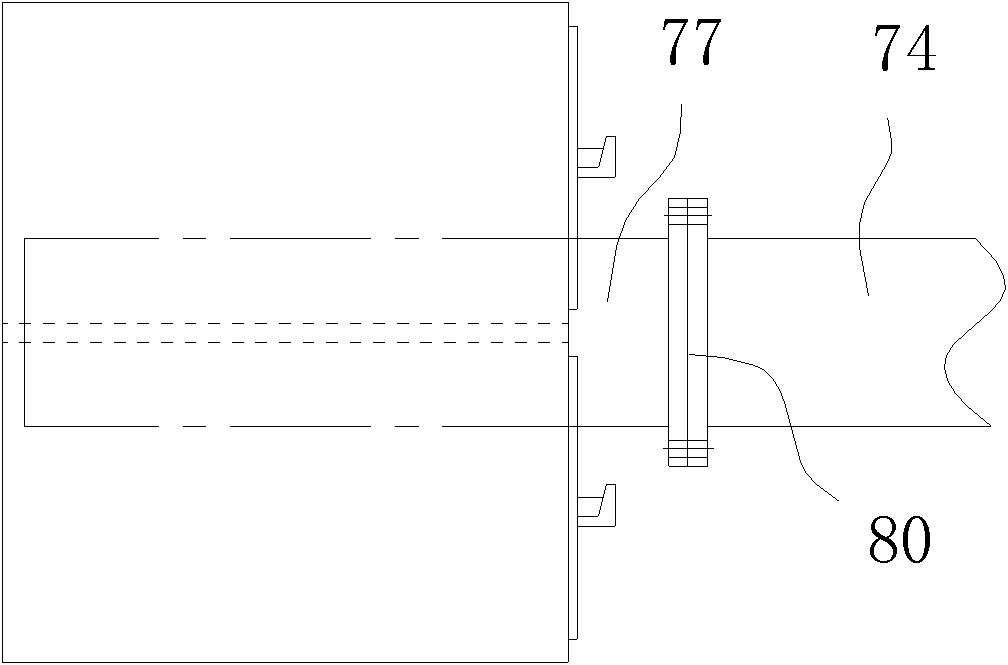

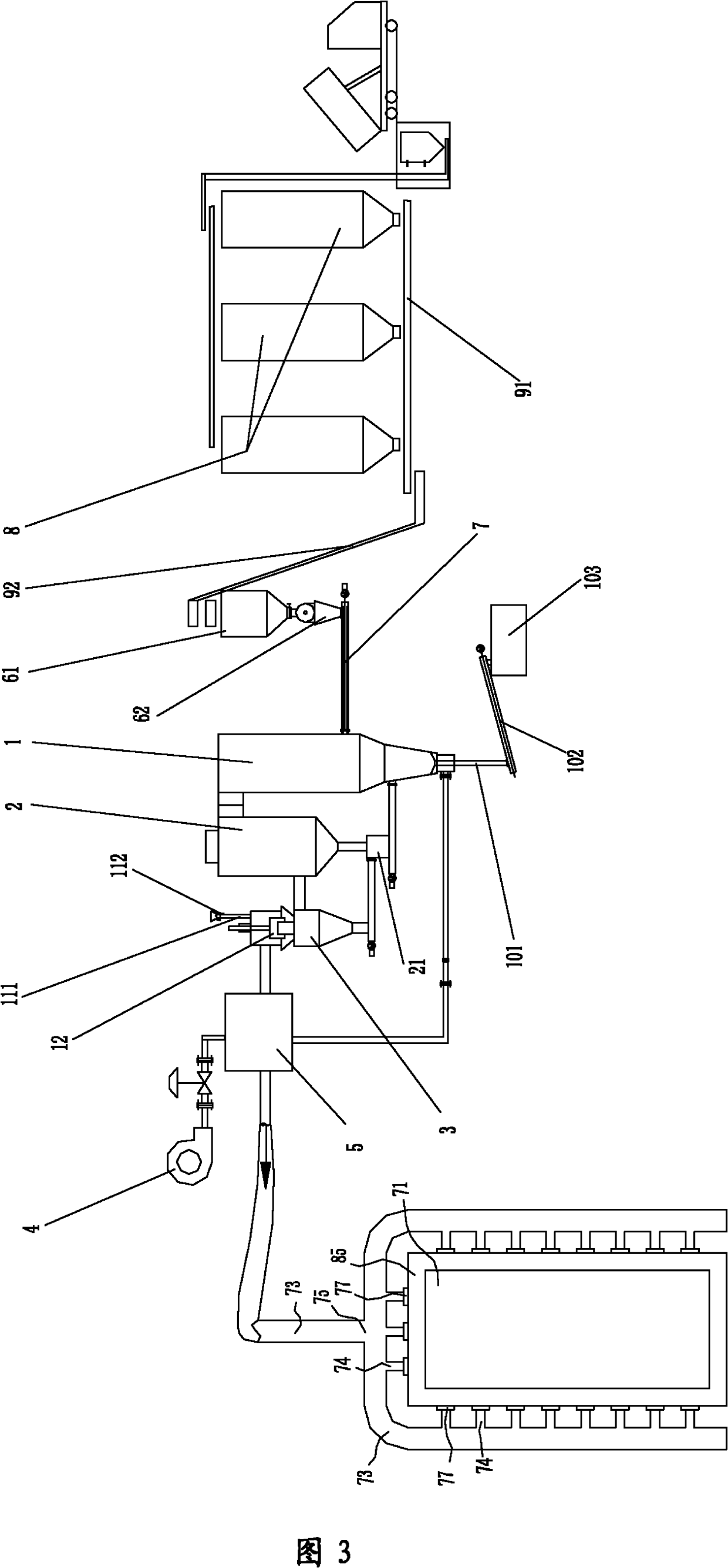

[0027] see figure 1 , figure 2 and image 3 The biomass combustible gas regenerative combustion device in this embodiment includes a regenerator 76, a burner 77, and a biomass gasification reaction system connected to the burner 77. The regenerator 76 is square and has four accumulators inside. The thermal body treatment holes 78 are arranged axially adjacent to the four corners of the regenerator chamber 76 respectively, and the burner hole 79 is arranged axially in the middle of the regenerator chamber 76, that is, between the four heat storage body treatment holes 78. The burner hole 79, the regenerator processing hole 78 is in radial communication with the burner hole 79, the ceramic regenerator is placed in the regenerator processing hole 78, the burner 77 is placed in the burner hole 79, and the burner 77 passes through The flange 80 is connected to the gas branch pipe 74, and the gas branch pipe 74 is connected to the biomass gasification reaction system through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com