Heterotopic flameless burning treatment apparatus and method for oily sludge

A treatment device and technology for sludge, applied in the field of ectopic sludge flameless smouldering treatment devices, can solve the problems of low ignition time and air transmission efficiency, limited treatment efficiency of smoldering technology, poor sludge effect, etc., so as to improve combustion repair efficiency, shorten the processing cycle, improve the effect of ignition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

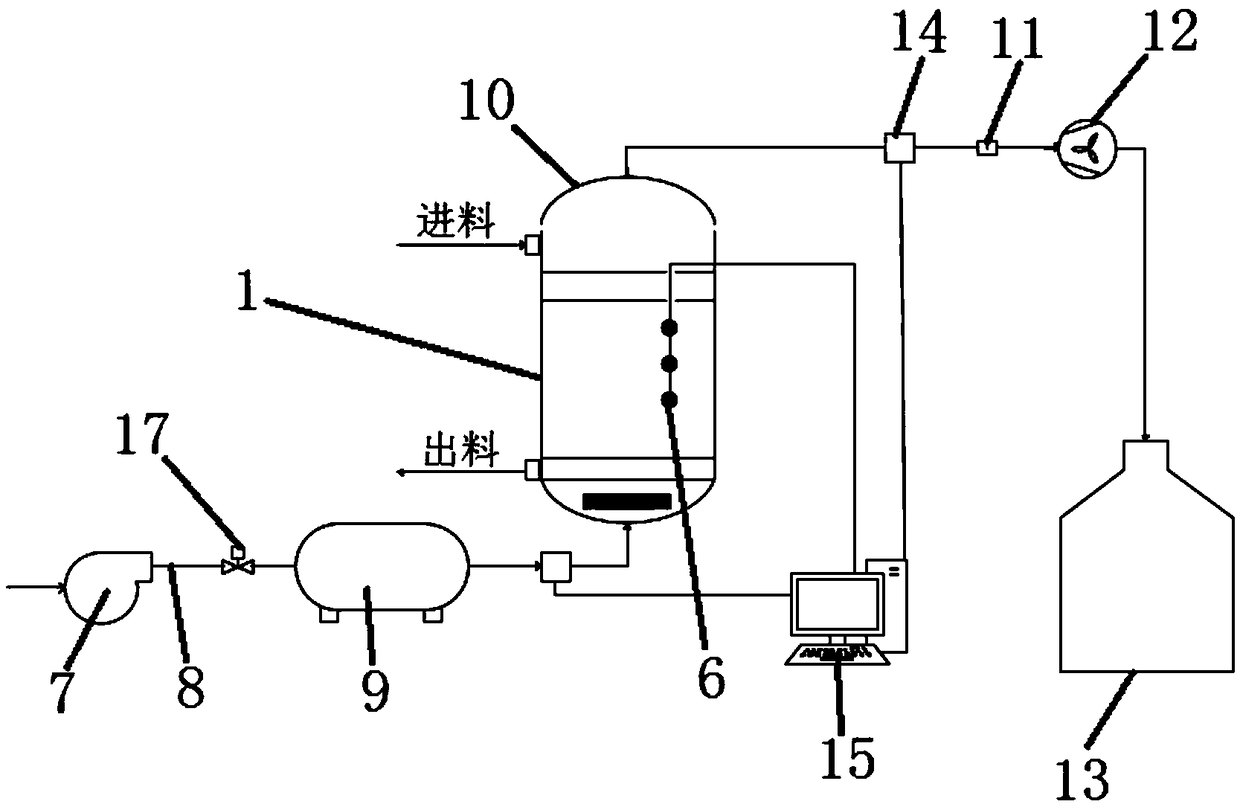

[0042] Such as figure 1 A flameless and smoldering treatment device for heterotopic oil sludge shown includes a reaction system, an air injection system connected to the inside of the reaction system, an exhaust gas treatment system adapted to the top of the reaction system, and the reaction system and air injection system respectively. The monitoring and regulating system for the electrical connection of the system and the exhaust gas treatment system.

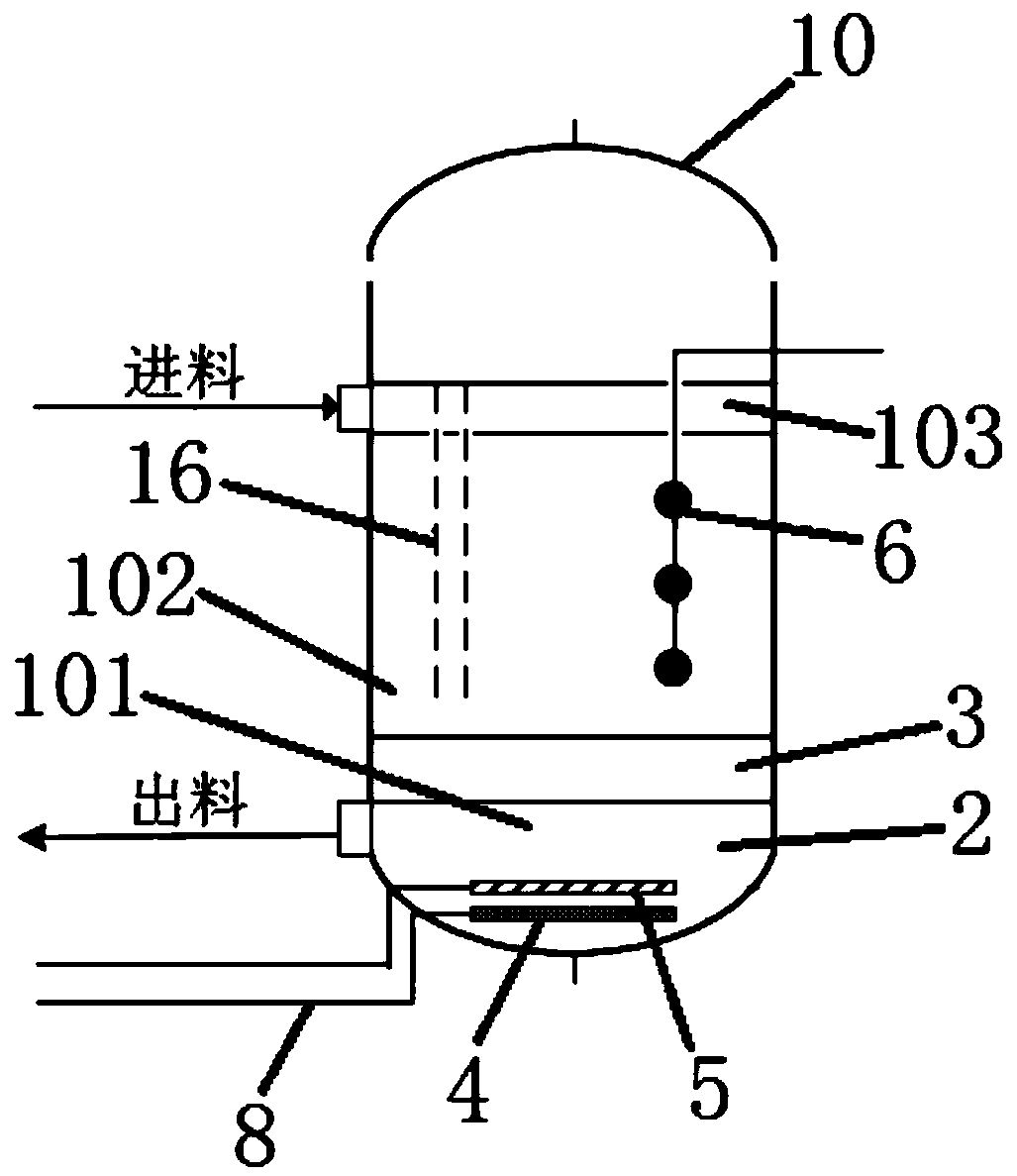

[0043] Such as figure 2 As shown, the reaction system includes a reactor shell 1 with an open top and a temperature monitoring mechanism arranged in the reactor shell 1. The reactor shell 1 is sequentially provided with an ignition start-up area 101 and a reaction area 102 from bottom to top. And the coverage area 103 , the temperature monitoring mechanism is set in the reaction area 102 . Sand layer 2 and igniter layer 3 are respectively arranged in the ignition starting area 101. The sand layer 2 is embedded with an air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com