Ignition device, particularly for an atomizer burner of a motor vehicle heating appliance

a technology for atomizer burners and heating appliances, which is applied in vehicle heating/cooling devices, combustion processes, vehicle components, etc., and can solve problems such as the inability to produce glow ignition components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

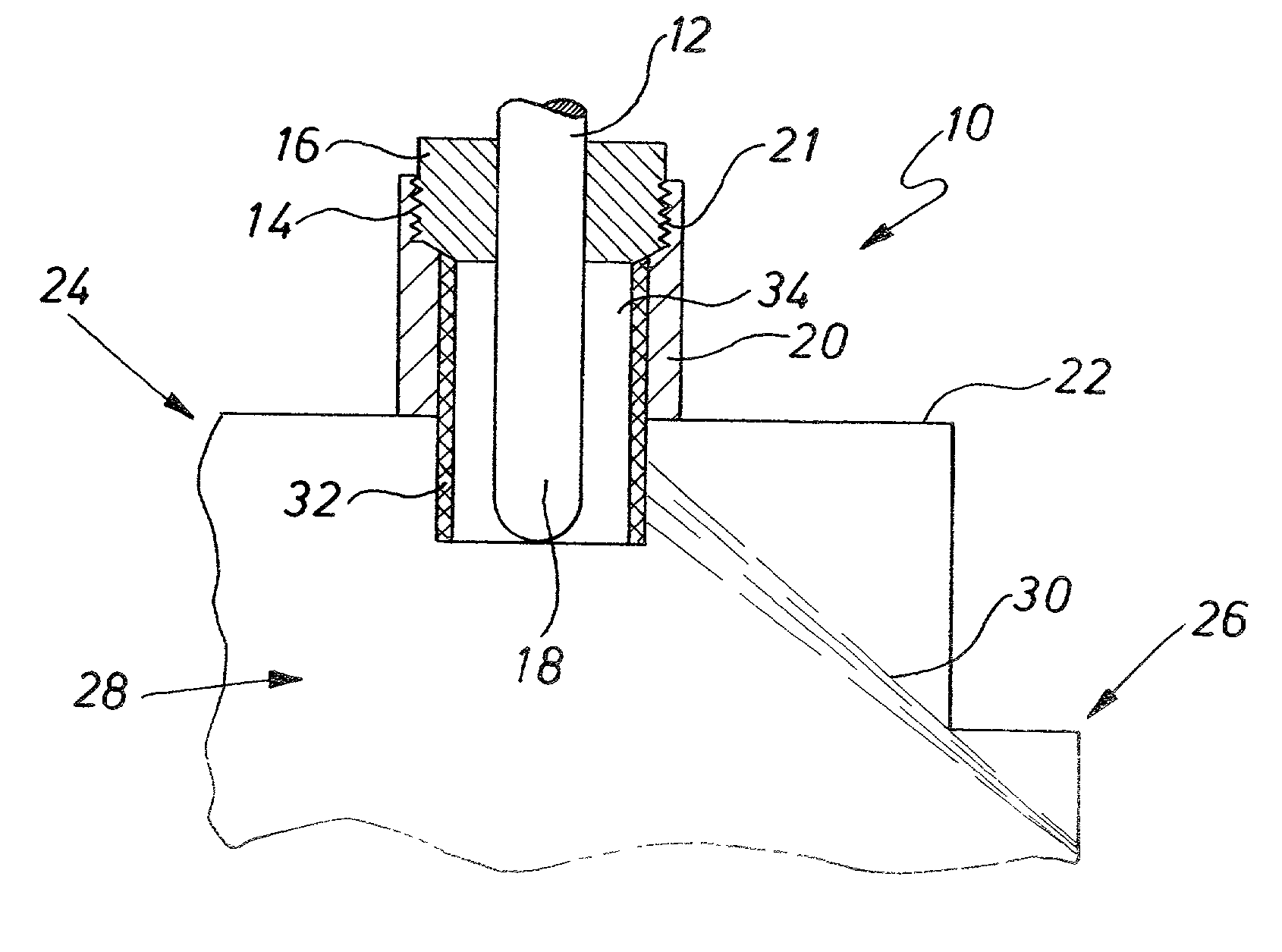

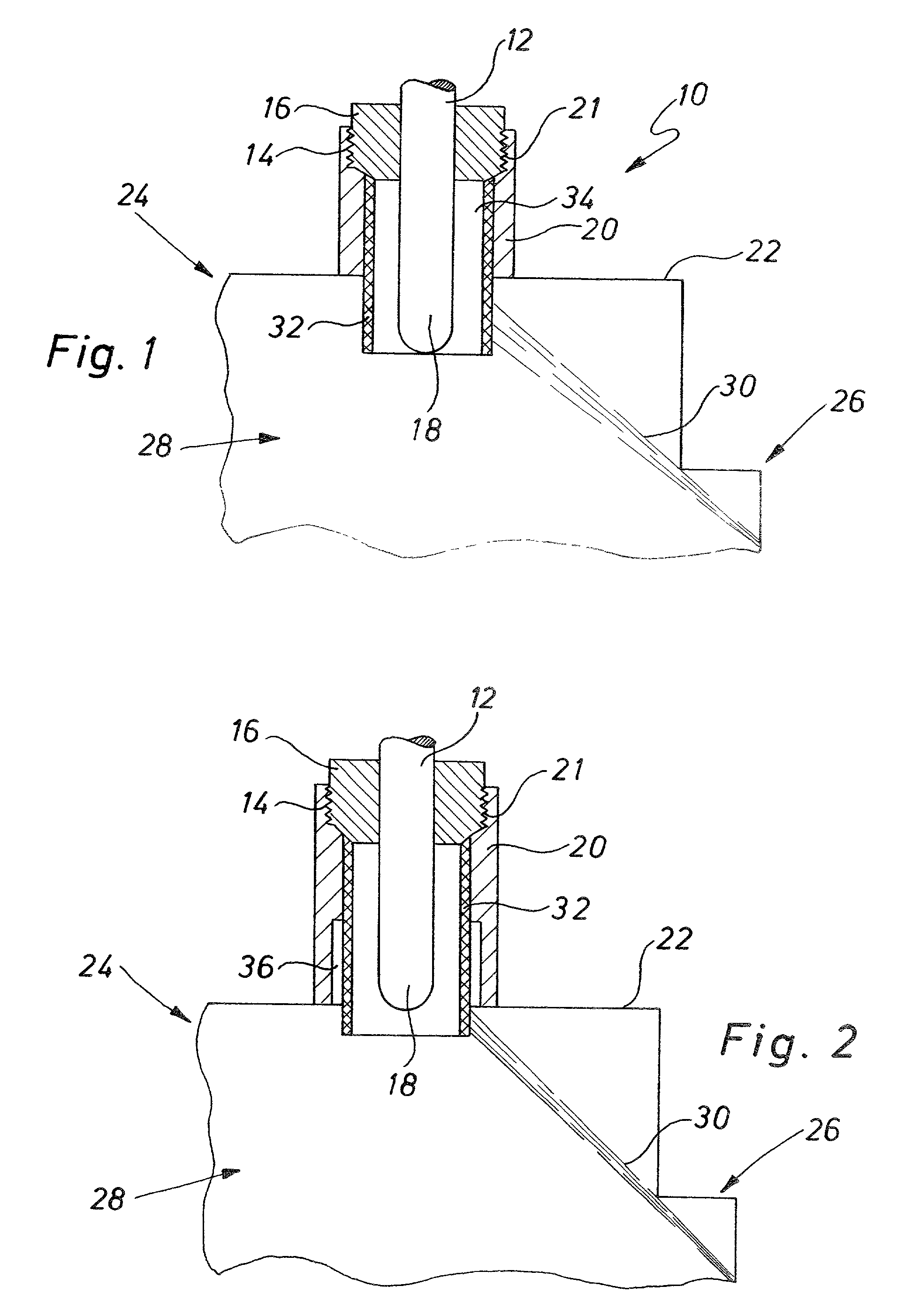

[0019] A glow ignition member is generally denoted in FIG. 1 by the numeral 10. The glow ignition member 10 comprises a glow plug or a glow pin 12 of conventional construction, which can thus have, for example, a heating coil and if necessary a control coil as well as insulating powder or the like, in a heat-resistant glow tube. The glow pin 12 is supported in a support member 16 provided with an external thread 14, and projects over this support portion 16 with its free end region 18, which for example then contains the heating coil. The support member 16 is supported in a substantially cylindrical support sleeve 20 with an internal thread 21. The support sleeve 20 can be installed on a housing 22, shown schematically, of a heating burner 24. This heating burner 24 furthermore has an atomizer nozzle 26, shown schematically. Combustion air is introduced at high speed into the combustion chamber 28 of the heating burner 24 by means of the atomizer nozzle 26. The combustion air, flowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com