Titanium alloy combustion test device and test method thereof

A combustion test, titanium alloy technology, applied in the field of aero-engine, can solve the problems of unsatisfactory control parameters, large overall structure and high energy consumption, and achieve the effects of compact structure, low test cost and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

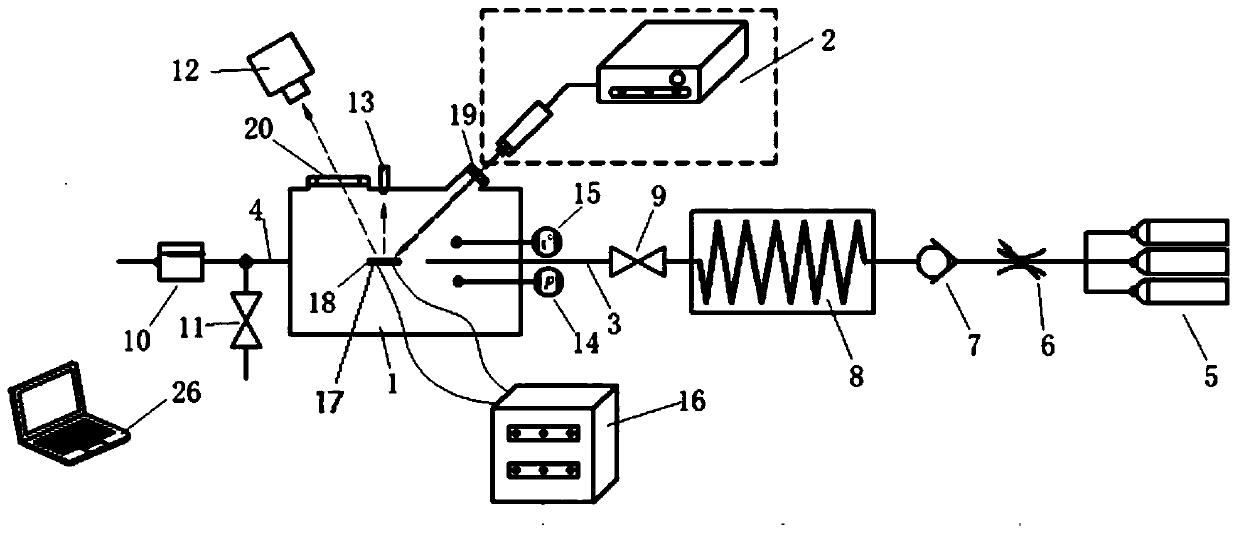

[0046] A titanium alloy combustion test device under simulated service conditions, including a combustion chamber (1), a fiber laser (2), a gas supply pipe (3), an exhaust pipe (4), a gas cylinder group (5), a mass flow controller ( 6), one-way valve (7), gas heater (8), intake valve (9), pressure control valve (10), exhaust valve (11), camera (12), temperature sensor (13), pressure Sensor (14), thermocouple (15), sample heating device (16), sample holder (17) and computer (26).

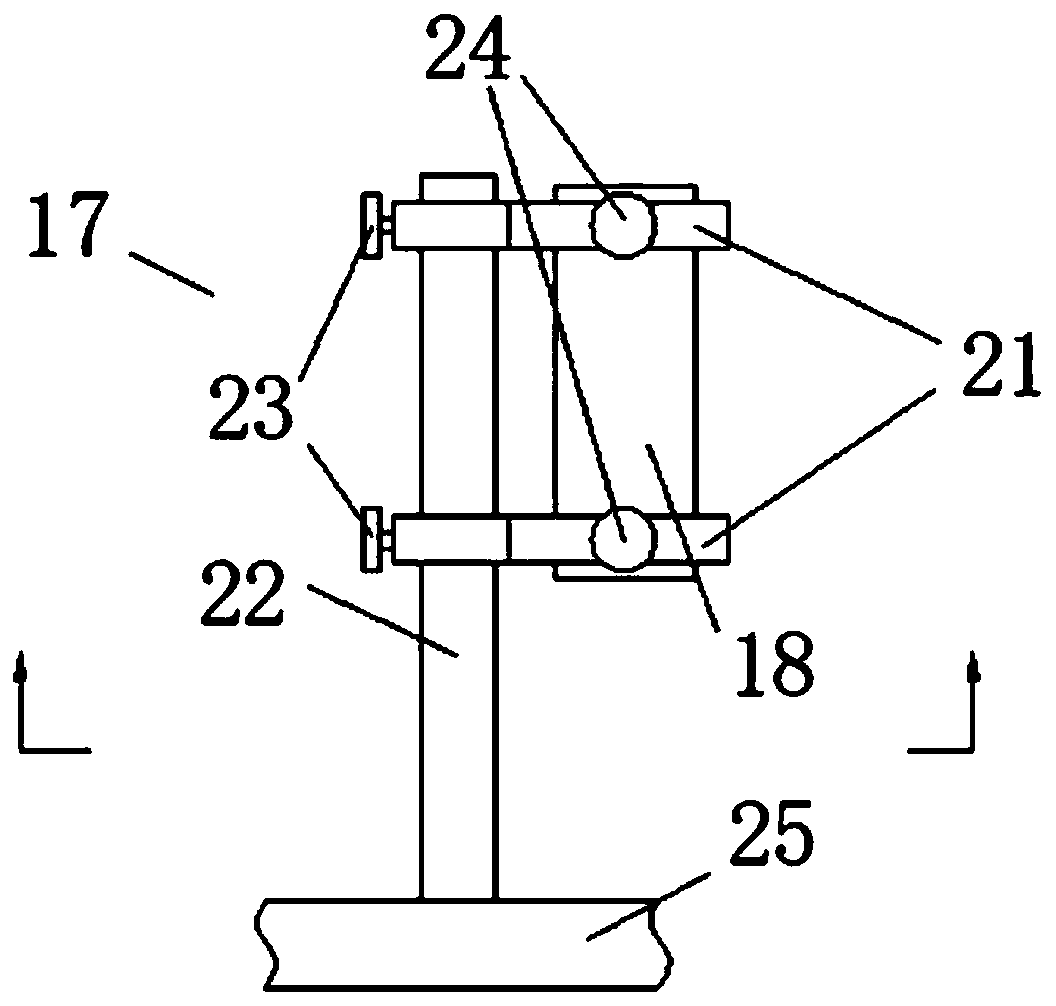

[0047] The sample fixture (17) includes two copper electrodes (21), insulating rods (22), electrode fixing screws (23), sample fixing screws (24) and flanges (25). One end of the copper electrode (21) has a round hole, which is sleeved on the insulating rod (22), so that it can rotate around the insulating rod (22), fixed by the electrode fixing screw (23), and the other end has a rectangular groove. The sample (18) is put into the rectangular groove, and the sample fixing screw (24) presses the upp...

Embodiment 2

[0067] A titanium alloy combustion test device under simulated service conditions, including a combustion chamber (1), a fiber laser (2), a gas supply pipe (3), an exhaust pipe (4), a gas cylinder group (5), a mass flow controller ( 6), one-way valve (7), gas heater (8), intake valve (9), pressure control valve (10), exhaust valve (11), camera (12), temperature sensor (13), pressure Sensor (14), thermocouple (15), sample heating device (16), sample holder (17) and computer (26).

[0068]The sample fixture (17) includes two copper electrodes (21), insulating rods (22), electrode fixing screws (23), sample fixing screws (24) and flanges (25). One end of the copper electrode (21) has a round hole, which is sleeved on the insulating rod (22), so that it can rotate around the insulating rod (22), fixed by the electrode fixing screw (23), and the other end has a rectangular groove. The sample (18) is put into the rectangular groove, and the sample fixing screw (24) presses the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com