Periodic oxygen-enriched sintering of iron ore

A technology of iron ore and mixture, applied in the direction of improving process efficiency, etc., can solve the problems of poor surface layer quality of sintered body, incomplete coke combustion, poor reducibility and permeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

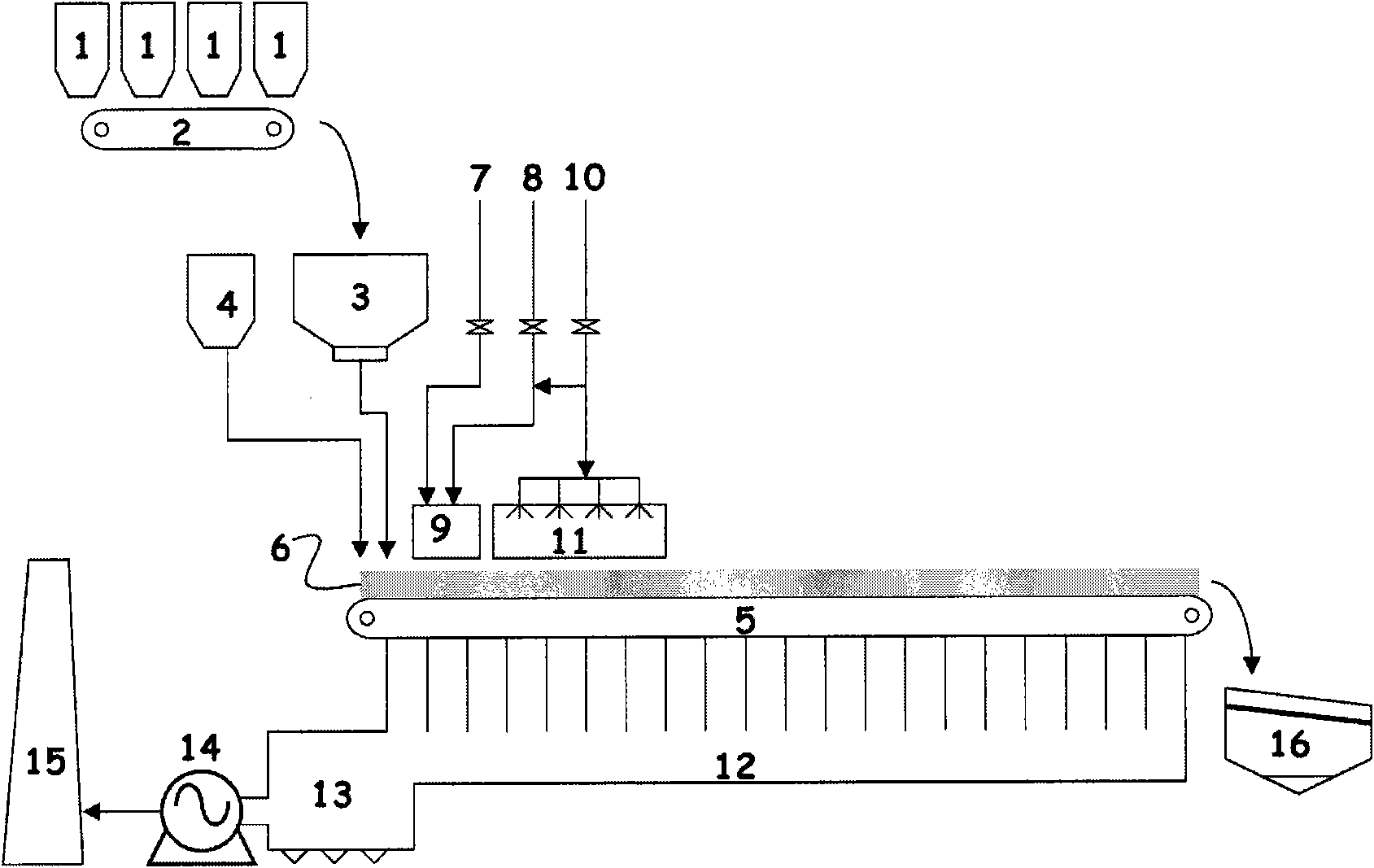

[0039] The following is a practical example of the use of oxygen in iron ore sintering according to the invention, wherein the oxygen is introduced at the same flow rate across the entire length of the bed.

Happening

[0040] The following is an example of the practice of using oxygen in the sintering of iron ore according to the invention, where at the start of sintering (that is to say, from the end of the bed where the material to be sintered is initially fed into The oxygen flow rate to the bed) is higher than the oxygen flow rate further along the bed length.

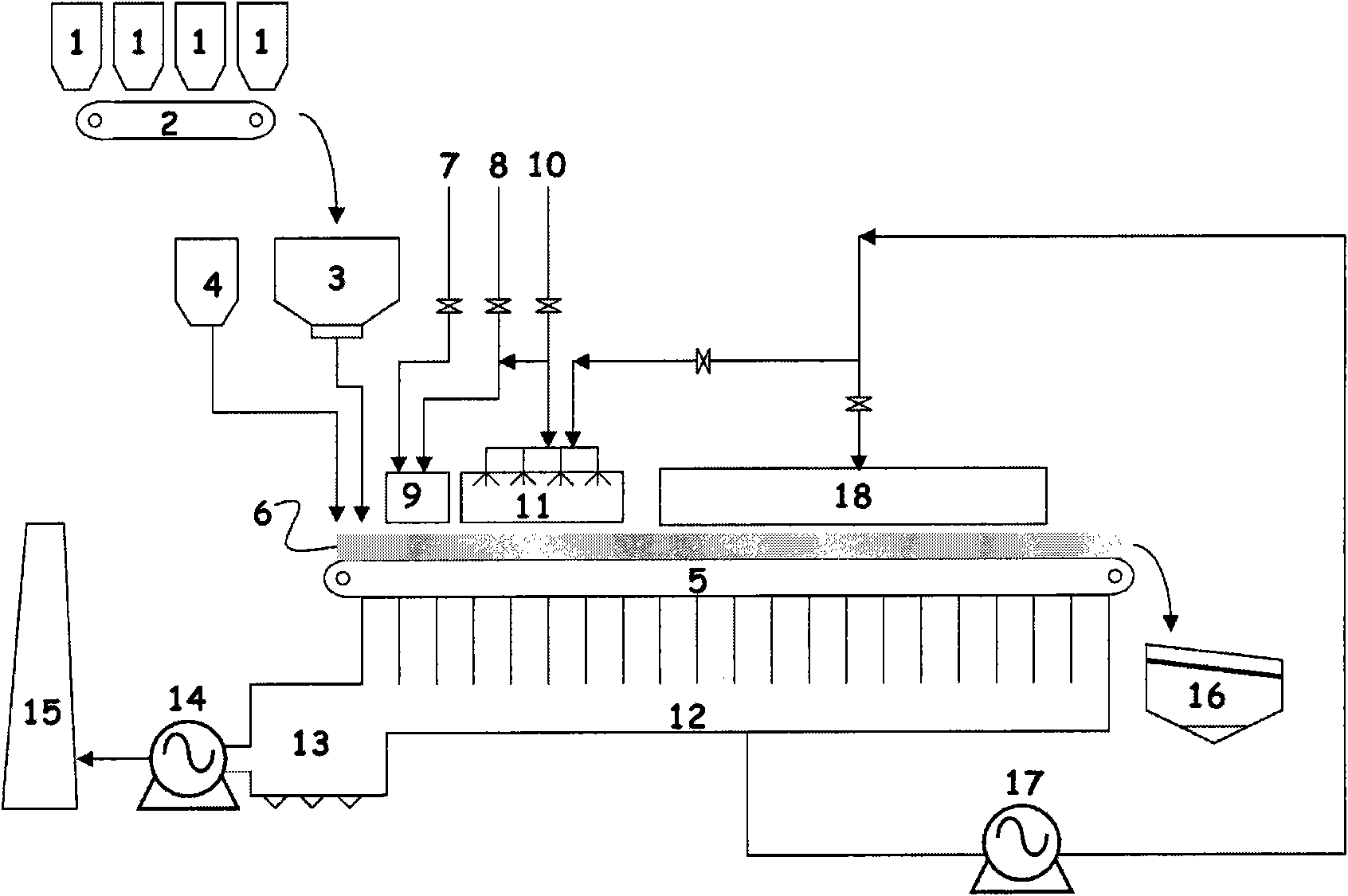

[0041] Provided below according to the present invention in iron ore sintering such as image 3 An example of practice using oxygen and recirculating the flue gas is shown.

degree, meter

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com