Combustion head and alcohol-based low-nitrogen combustion device

A combustion head and combustion chamber technology, applied in the direction of burners, combustion chambers, combustion ignition, etc., can solve the problem of non-compliance of flue gas nitrogen oxide emissions, to ensure ignition stability and reliability, realize variable load regulation, Effects for special needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

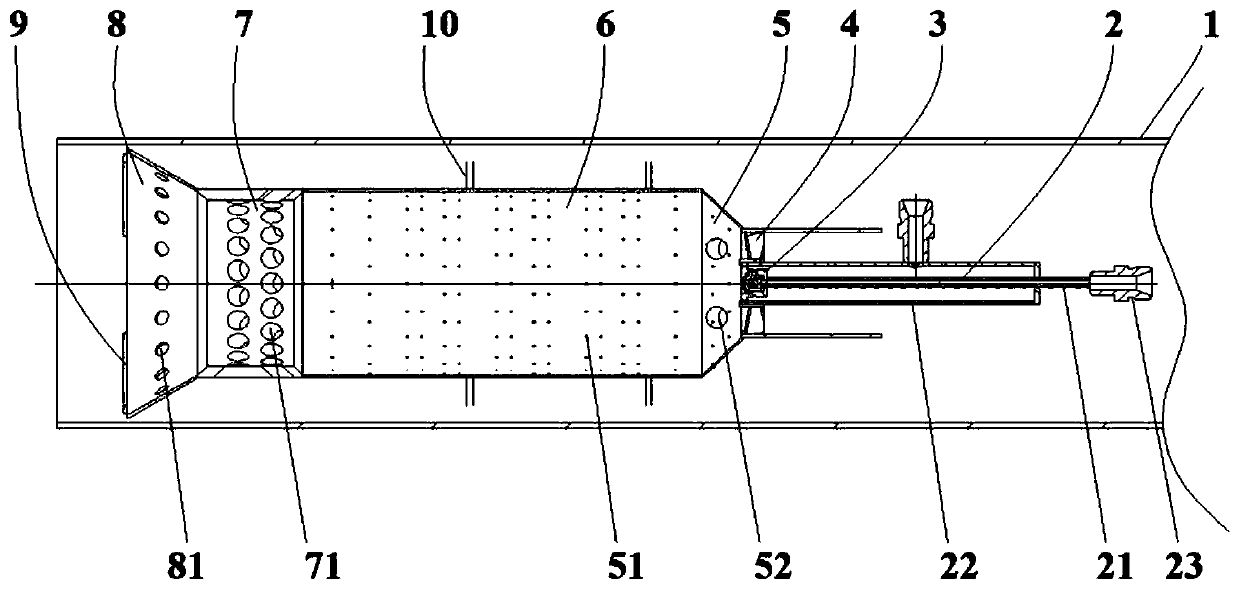

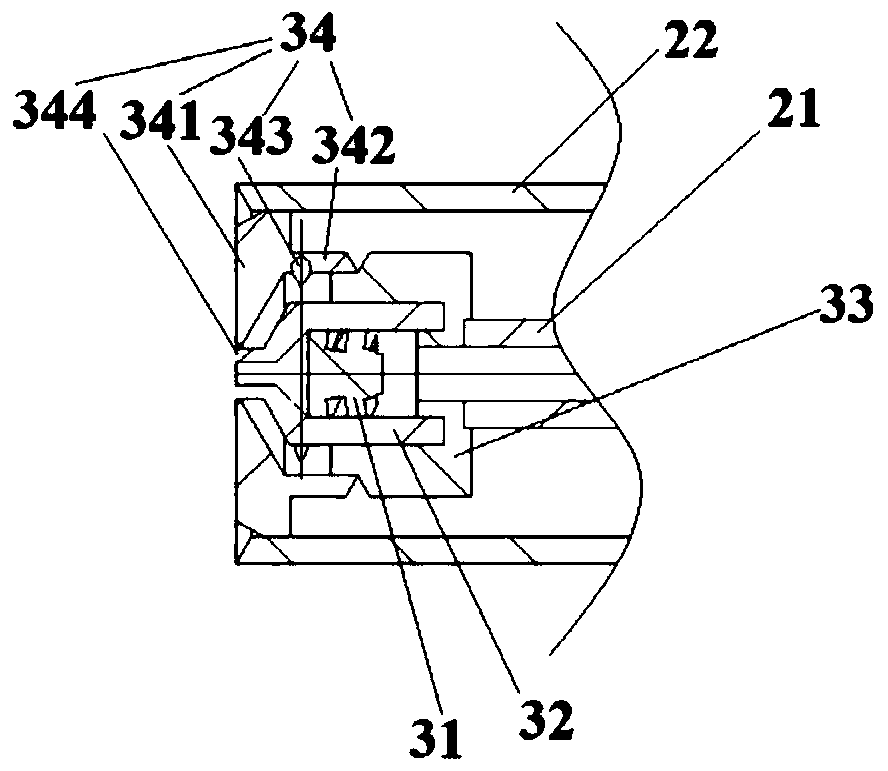

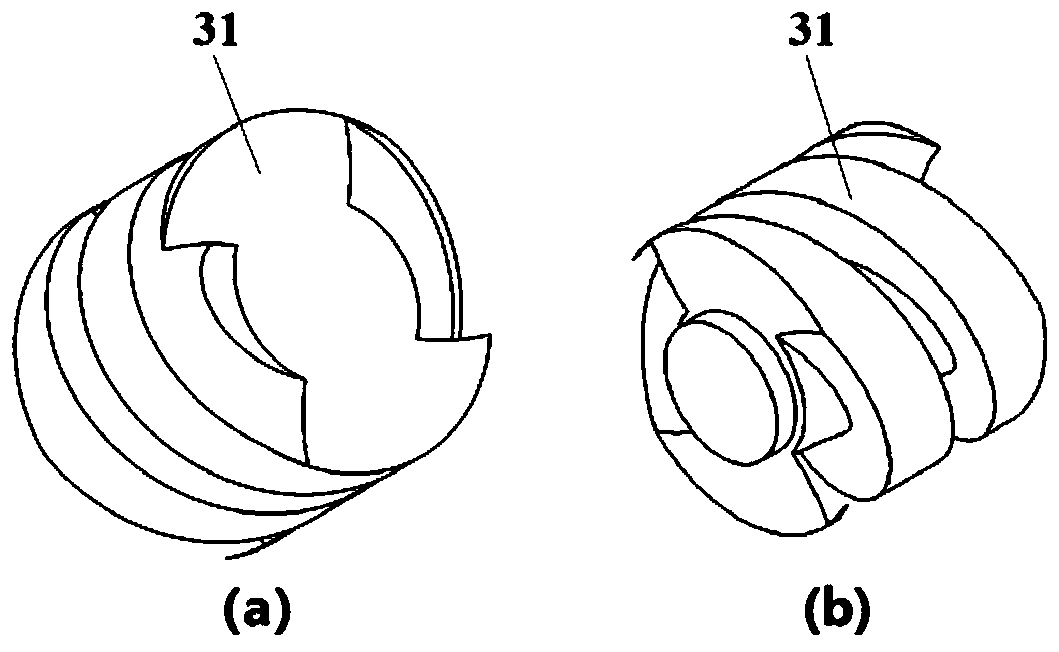

[0043] Such as Figure 1 to Figure 7 As shown, the present embodiment provides a combustion head, which includes a cylindrical housing 1, in which there are: a fuel supply pipe 2 arranged axially along the housing 1, and a fuel supply pipe 2 arranged at the end of the fuel supply pipe 2. The fuel nozzle unit 3, the cylindrical swirler 4 sleeved outside the end of the fuel supply pipe 2, and the expansion section 5, the central combustion chamber 6, the narrowing section 7 and the The mouth cone section 8; the expansion section 5 and the mouth cone section 8 are both cone-shaped structures, the necking end of the expansion section 5 is connected to the cyclone 4, and the necking end of the mouth cone section 8 is connected to the shrinking section 7 connected, and cooling holes 51 and electrode installation holes 52 are provided on the expansion section 5, and a plurality of through holes 81 distributed in the circumferential direction are provided on the mouth cone section 8; ...

Embodiment 2

[0055] Such as Figure 1 to Figure 9 As shown, this embodiment provides an alcohol-based low-nitrogen combustion device, including an air supply system 100, a fuel supply system 200 located at the air inlet of the air supply system 100, and a programmer 300 for controlling the air supply system 100 and the fuel supply system 200 ; Also includes the combustion head 400 in Embodiment 1, the connection end of the casing of the combustion head 400 and the air outlet of the air supply system 100 are in sealed communication through the variable diameter pipe 500 .

[0056] Specifically, both ends of the variable-diameter pipe 500 are in detachable and sealed communication with the casing connection end of the combustion head 400 and the air outlet of the air supply system 100 respectively through flanges, and the flange connections are fixed by a number of screws evenly distributed around the circumference. The outer diameter of the combustion head 400 can be docked with any size of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com