Pulse wave fracturing device and method

A pulse wave and fracturing technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of single hydraulic fracture shape, small oil drainage area, weak stimulation effect, etc., and achieve large adjustable space , The effect of performance safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

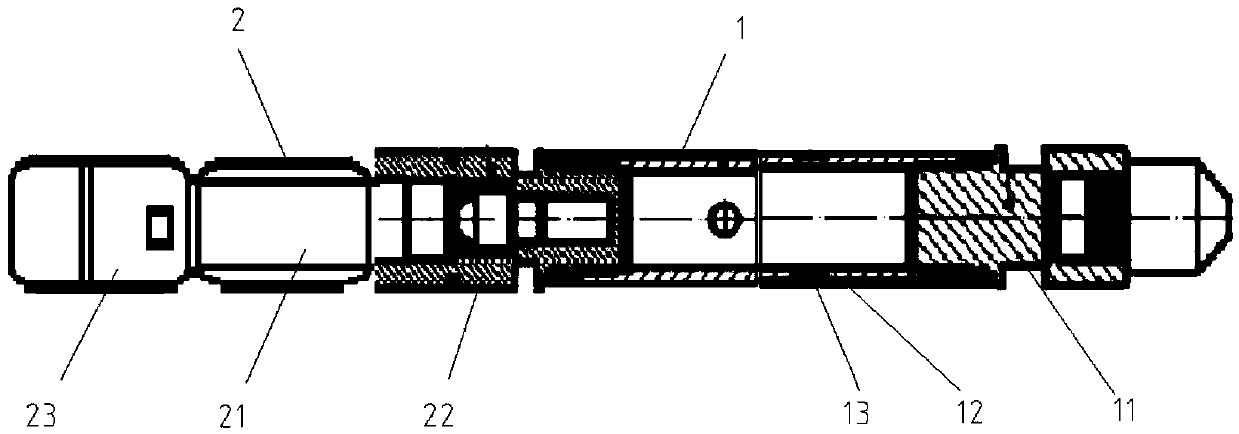

[0027] figure 1 It schematically shows the pulse wave fracturing device according to an embodiment of the present invention. According to the pulse wave fracturing device of the present invention, it can meet the operation of relatively deep wells, and at the same time, it is equipped with a delay ignition device, which leaves enough operation time for the operation after pressing, so that the operations such as opening and closing valves on the ground after pressing, and firing guns in abnormal situations are easier. Safety.

[0028] Such as figure 1 As shown, the pulse wave fracturing device described in this embodiment includes a pulse wave fracturing gun 1 . The pulse fracturing gun can release high-pressure gas, and the pulse wave generated by the high-pressure gas can effectively fracture the bottom layer. The pulse wave fracturing gun 1 is filled with fuel, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com