Centrifugal compressor asymmetric self-circulation treatment casing based on varied notching width

A technology for centrifugal compressors and casings, which is applied to components of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., can solve the problem of non-axisymmetric and non-axisymmetric flow fields in the compressor that cannot be considered. It can improve the stability of the working range, optimize the stability expansion effect, and maintain the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principle, structure and working process of the present invention will be further described below in conjunction with the accompanying drawings.

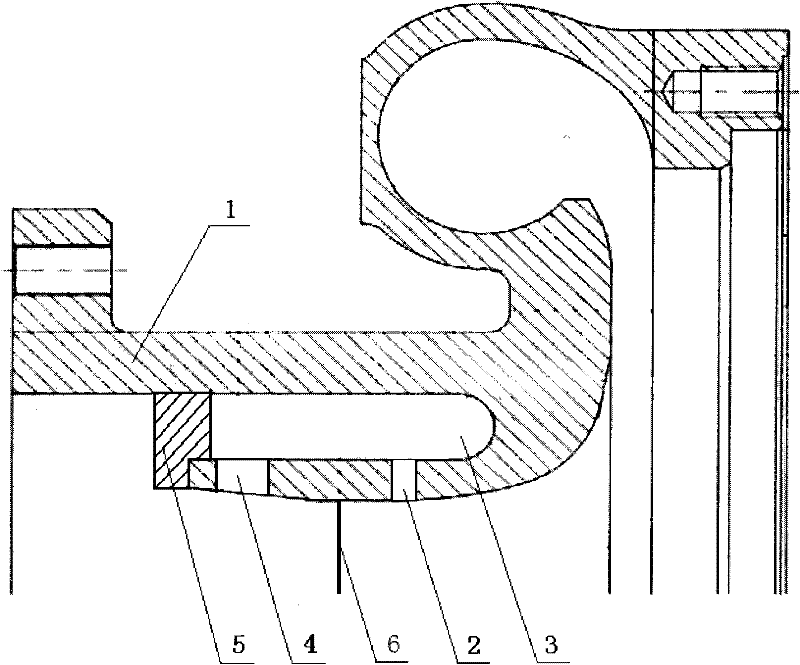

[0015] figure 1 It is a schematic cross-sectional view of the self-circulating processing casing structure.

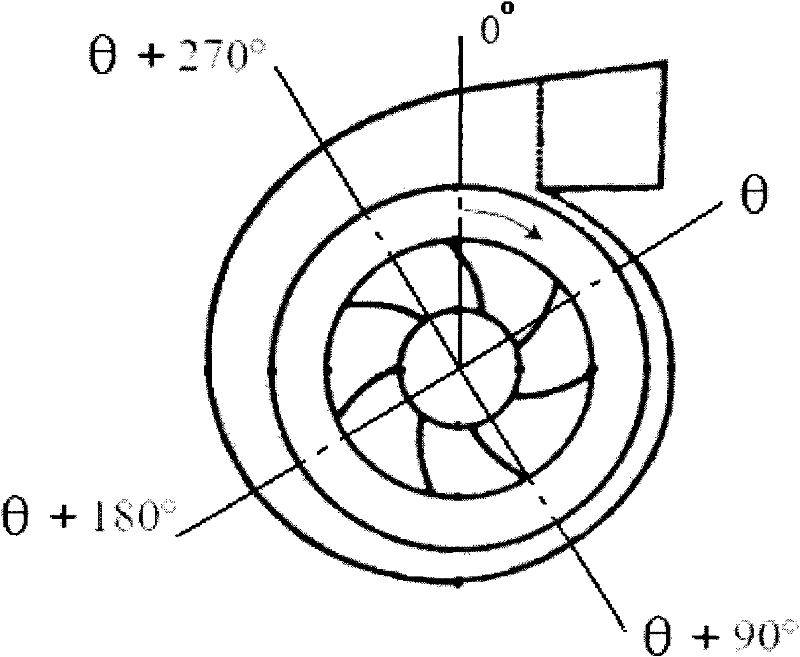

[0016] Based on the asymmetric self-circulation processing casing of the centrifugal compressor with variable slotting position, a self-circulation channel is opened in the circumferential direction of the wall surface of the processing casing 1, and the channel is composed of a suction ring groove 2, a guide ring groove 3, a return The ring groove 4 and the blocking block 5 are composed, and the distance S between the front end surface of the suction ring groove 2 and the leading edge 6 of the compressor impeller mainstream blade r The distribution in the circumferential direction of the casing is non-axisymmetric.

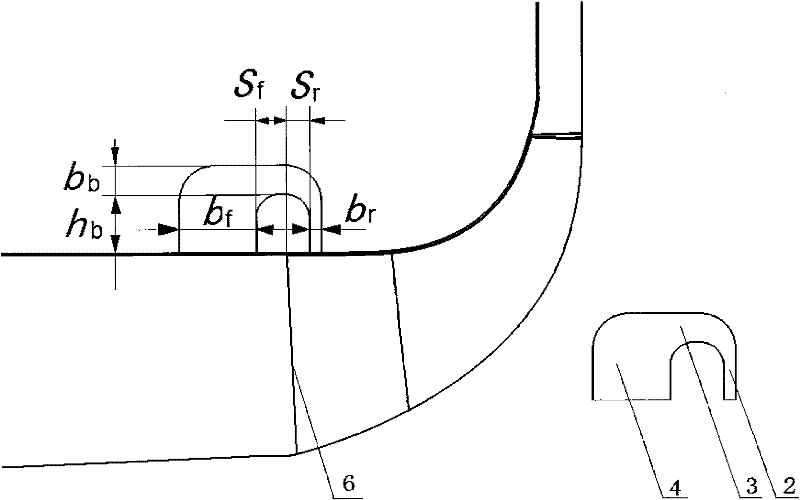

[0017] figure 2 A schematic diagram of a self-circulating channel.

[0018] The main structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com