Zigzag gas burner

A gas burner, zigzag technology, applied in the direction of burners, burners, gas fuel burners, etc., can solve the problems of flame defiring, tempering, fire extinguishing, etc., and achieve ignition and combustion stability, strong adaptability, and combustion high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

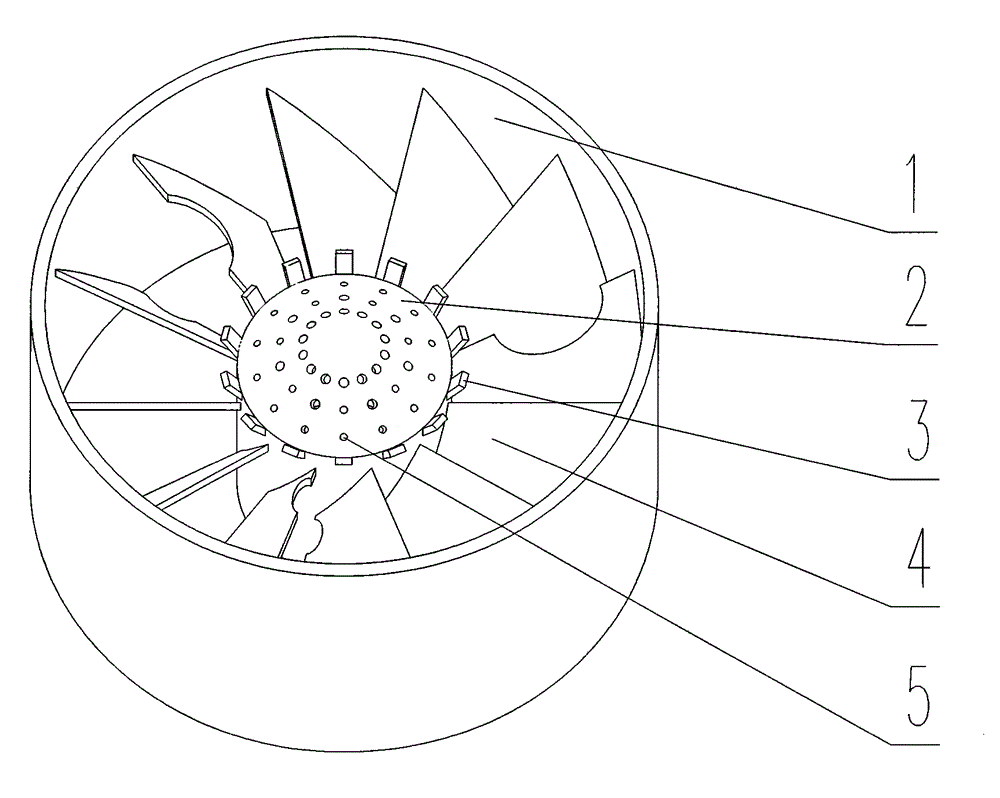

[0020] Referring to the accompanying drawings, a gas burner with a zigzag flame stabilizer is composed of a nozzle 1, a conical gas nozzle 2, a zigzag flame stabilizer 3, and an air distribution vane 4. The center of the nozzle 1 is provided with a conical gas burner The nozzle 2 is provided with air distribution blades 4 in the circumferential direction between the nozzle 1 and the conical gas nozzle 2, and the sawtooth-shaped flame stabilizer 3 is provided in the circumferential direction of the cone of the conical gas nozzle 2, and the conical gas nozzle 2 is provided with a gas injection hole 5 . The nozzle 1 is made of heat-resistant steel and is a cylindrical cylinder; the conical gas nozzle 2 is made of heat-resistant steel. The front section is a cone with a certain taper, and the rear section is a cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com