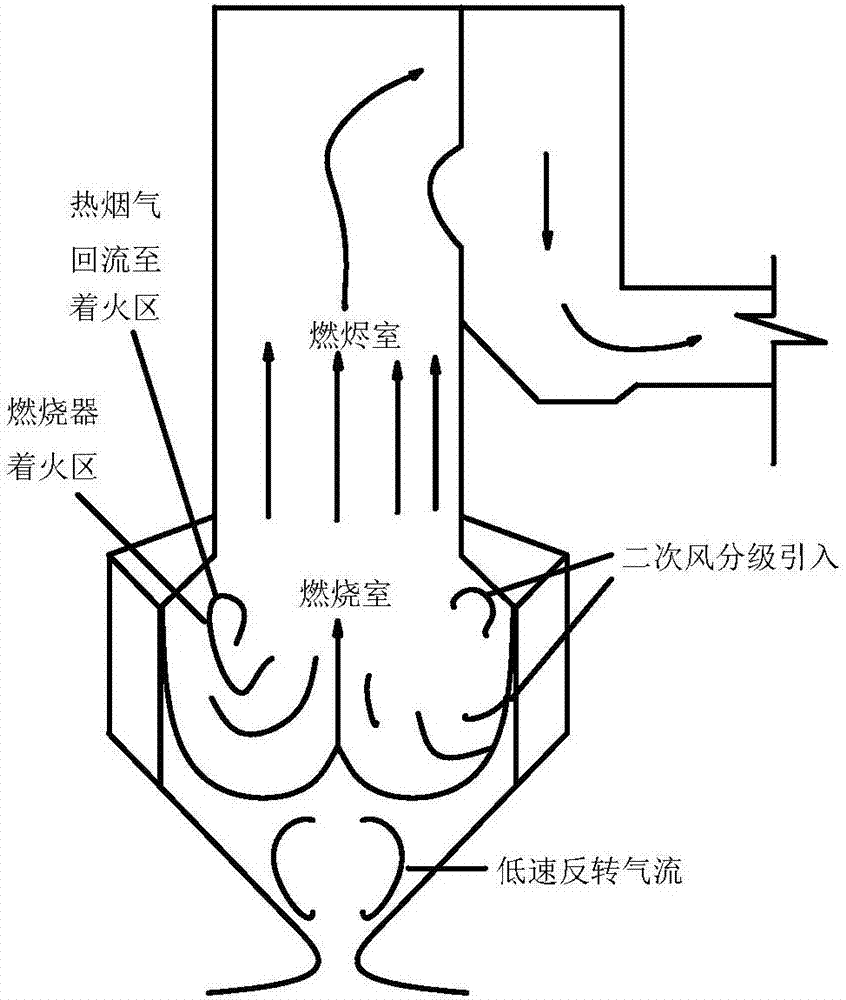

W-shaped flame boiler air distribution way optimization method

An optimization method and boiler technology, applied in the direction of combustion method, combustion type, air supply adjustment, etc., can solve the problems of poor stability and poor burnout of W flame boilers, and achieve the effect of improving stability and improving the adaptability of coal types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

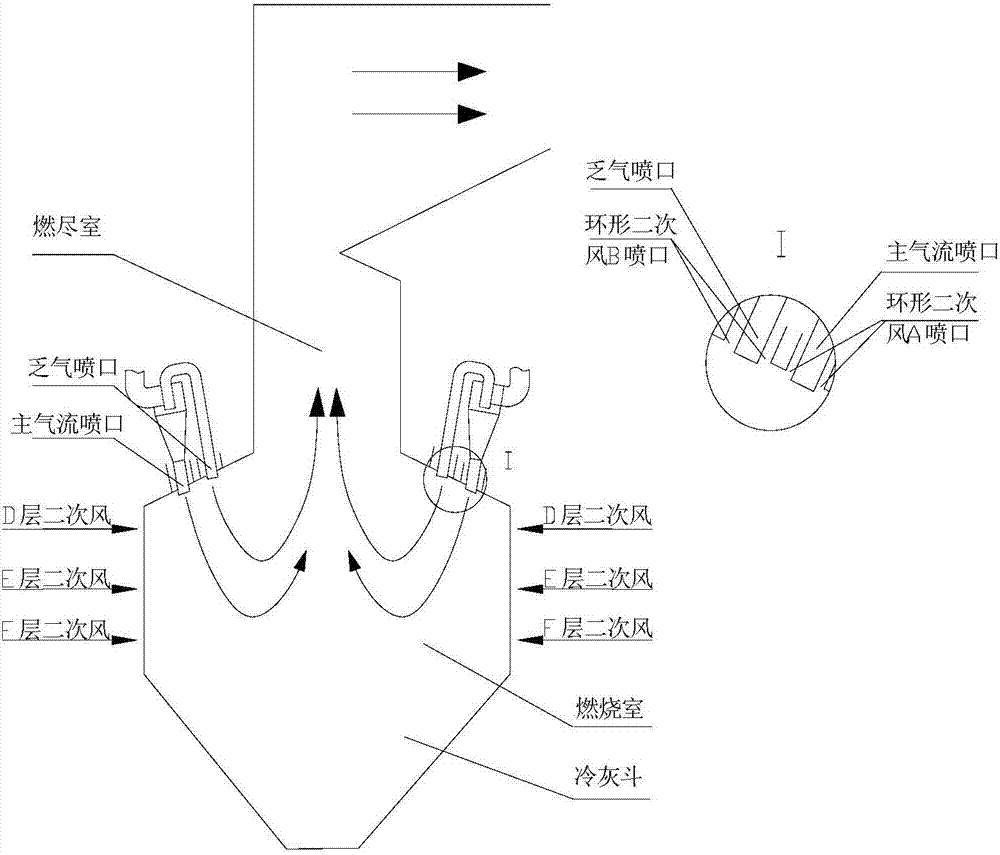

Embodiment 1

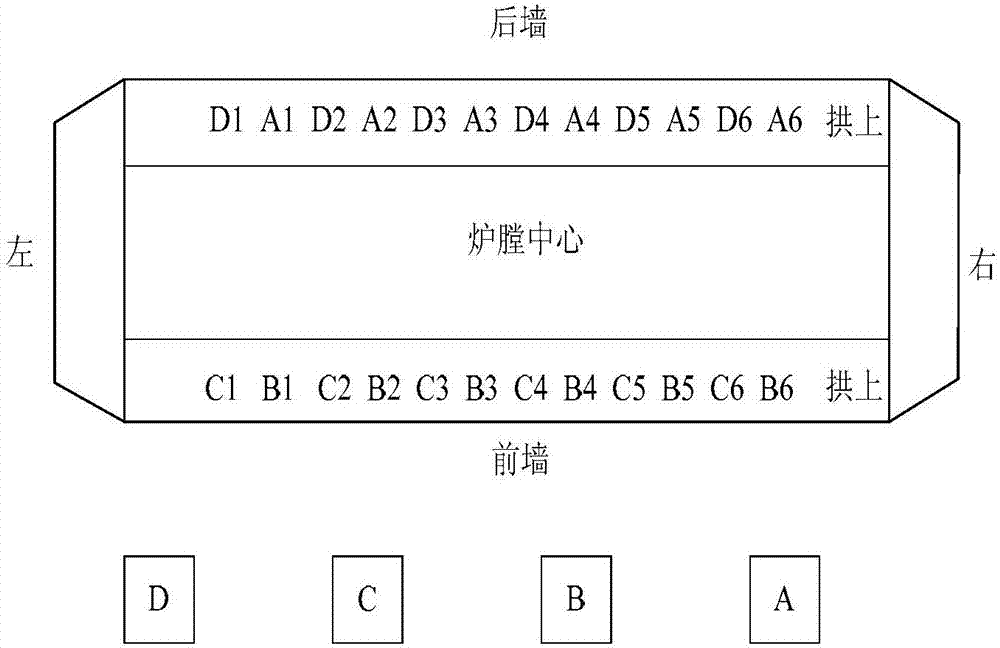

[0062] Such as image 3 As shown, the method for optimizing the air distribution mode of a W-flame boiler in this embodiment is characterized in that, at about 1 / 3 of the furnace height, the front wall and the rear wall form a furnace arch inward, and 2×12 double cyclones are arranged on the arch. Burner; there are secondary air chambers on the front and rear walls of the lower furnace, which are divided into the secondary air chamber on the arch and the secondary air chamber under the arch through the partition plate. Separated by partitions to form independent secondary air chambers, there are twelve independent air chambers on the front and rear walls; the double cyclone burners correspond to the independent air chambers one by one, and the front wall is burner C1 and burner C1 from left to right. B1, burner C2, burner B2, burner C3, burner B3, burner C4, burner B4, burner C5, burner B5, burner C6, burner B6; the rear wall from left to right is Burner D1, Burner A1, Burner...

Embodiment 2

[0071] The method for optimizing the air distribution mode of the W-shaped flame boiler in this embodiment, on the basis of Embodiment 1, also includes SOFA nozzles on the arch, four on the front and rear walls, three and three of which are opposed, the right side of the front wall and the left side of the rear wall They are arranged in such a way that one spout is provided respectively.

[0072] Due to the relatively serious over-temperature phenomenon in the boiler reheater, the method of shutting down the burner in the over-temperature area is used to solve the over-temperature problem of the reheater in normal operation.

[0073] It is believed that the energy in the middle position of the boiler is relatively concentrated, and this symptom can be alleviated by adjusting the downtilt angle of the F wind and the air distribution of the F wind.

[0074] F wind downtilt angle and D, E wind opening degrees adopt the formulation method described in the table below. This operati...

Embodiment 3

[0077] The method for optimizing the air distribution mode of a W-shaped flame boiler in this embodiment, the W-shaped boiler adopts a staged combustion method to burn coal types, which specifically includes: selecting a predetermined proportion of combustible coal types and anthracite, and using the combustible coal types to react with oxygen , becoming the first-stage combustion; the high-temperature flue gas atmosphere formed in the first stage, under the coercion of high-temperature flue gas, ignites anthracite to form a second-stage combustion, in which the volatile content of combustible coal is higher than that of anthracite, and the volatile The proportion of bituminous coal and anthracite is greater than 1:1. Preferably, the ratio of bituminous coal to anthracite is 3:1.

[0078] In this embodiment, the W-shaped flame boiler is equipped with four coal mills, the first coal mill and the third coal mill are used for grinding anthracite, the second coal mill and the four...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com