Patents

Literature

90 results about "Embodied carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Embodied carbon assessment. Embodied carbon is the carbon footprint of a material. It considers how many greenhouse gases (GHGs) are released throughout the supply chain and is often measured from cradle to (factory) gate, or cradle to site (of use).

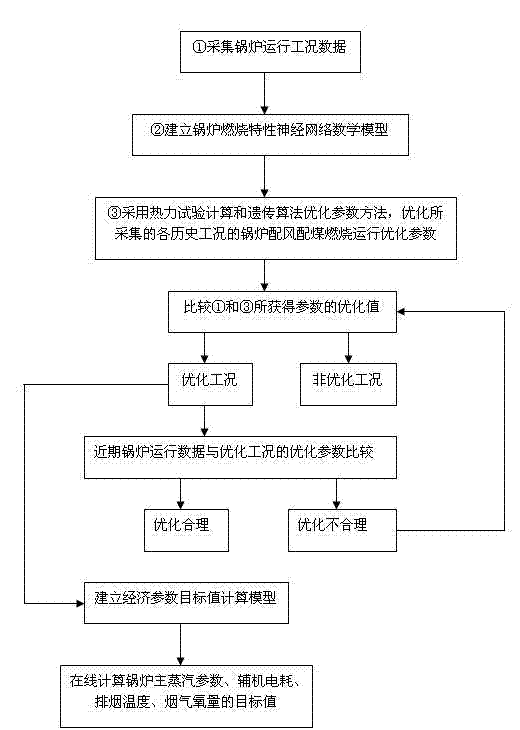

Method for acquiring target values of boiler optimized operation economic parameters

The invention discloses a method for acquiring target values of boiler optimized operation economic parameters. The method comprises the following steps of: establishing a boiler combustion characteristic neural network mathematical model by using a neural network technology according to boiler variable coal type combustion optimized operation working condition data; according to the boiler combustion characteristic neural network mathematical model, optimizing air distribution and coal distribution combustion operation parameters of each historic working condition of a boiler by using an optimized combination method of a thermal test algorithm and a genetic algorithm and by taking the maximization of boiler comprehensive efficiency as an optimization target; comparing the air distribution and coal distribution combustion operation parameters of each historic working condition with corresponding optimized values, determining an optimized working condition, and establishing a target value calculation model for boiler main steam parameters, auxiliary engine power consumption, smoke exhaust temperature, fume oxygen content and fly-ash carbon content by taking data of a historic working condition which is marked as the optimized working condition as a sample and by using the neural network technology; and calculating a boiler main steam parameter target value, an auxiliary engine power consumption target value, a smoke exhaust temperature target value and a fume oxygen content target value under the conditions of different loads and different coals by using the obtained target value calculation model.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

Sludge bagasse active carbon and preparation method thereof

ActiveCN103241737AImprove adsorption capacitySolve the defect of poor adsorption performanceSludge treatmentOther chemical processesSludgeSugar refining

The invention relates to sludge bagasse active carbon and a preparation method thereof. The sludge bagasse active carbon is prepared from sewage treatment sludge and sugar refining industrial waste bagasse. The bagasse is added into the sludge to improve the carbon content of the sludge and the adsorptive property of sludge base active carbon, so that the problem that the adsorptive property of the sludge base active carbon is poor is solved; and the sludge is subjected to heavy metal removal to improve the using safety of the sludge base active carbon. The process comprises the following steps of: carrying out heavy metal removal on the sludge by adopting a certain technical means; drying the sludge and the bagasse, and then uniformly mixing the sludge and the bagasse according to a certain proportion; adding an activating agent ZnCl2 solution with a certain concentration to carry out immersion and activation; then carrying out pyrolysis under the protection of an inert gas; and washing and drying to obtain the active carbon. According to the preparation method, the active carbon is prepared from the sludge and the bagasse, the active carbon with good adsorptive property is prepared, and the resource utilization of the two types of industrial solid wastes is achieved at the same time, so that the sludge bagasse active carbon has good economic, social and ecological benefits.

Owner:GUANGXI UNIV

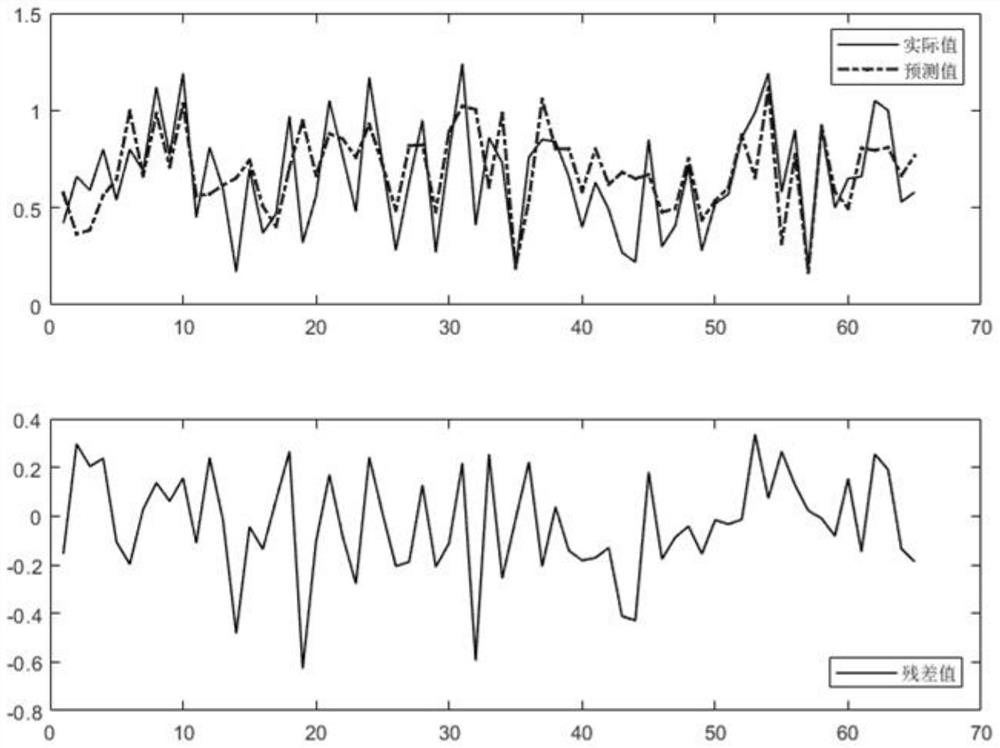

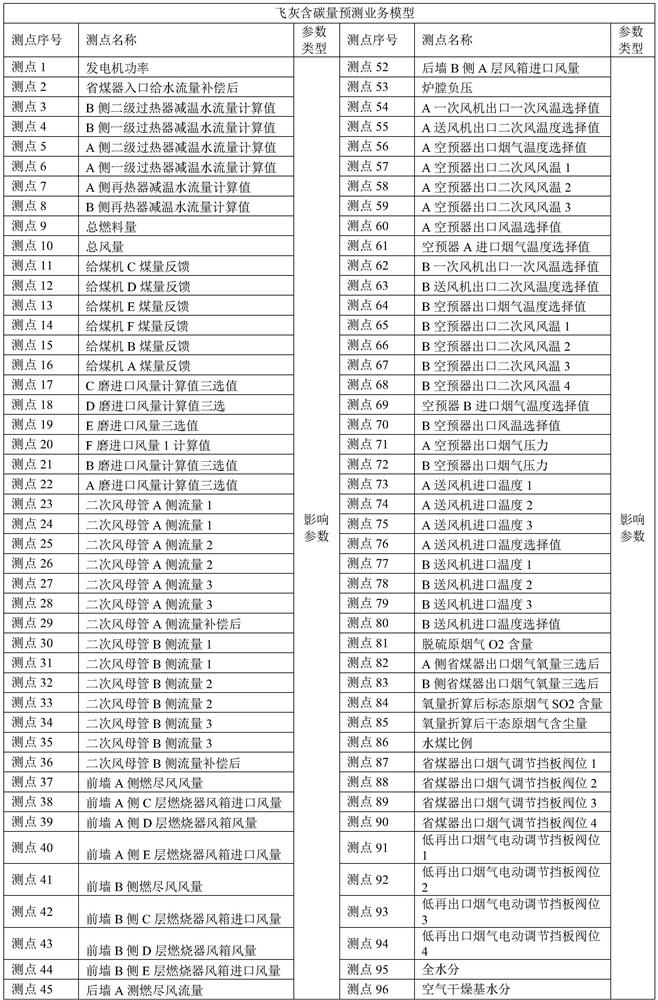

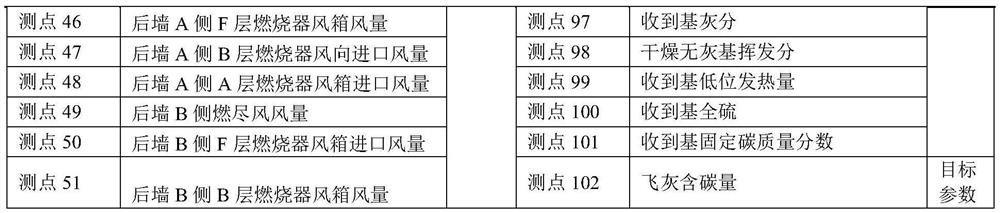

Fly ash carbon content prediction method based on coal quality prediction and PSO-SVM

PendingCN111754093AImprove predictive performanceRealize online predictionKernel methodsNeural architecturesSupport vector machinePredictive methods

The invention relates to a fly ash carbon content prediction method based on coal quality prediction and PSO-SVM, and the method comprises the steps: 1, selecting and constructing proper coal qualityinfluence parameters and coal quality feature parameters, constructing a coal quality prediction model based on a BP neural network, and carrying out the soft measurement of the coal quality of coal as fired through coal type matching; 2, constructing a support vector machine (SVM)-based fly ash carbon content prediction model. The method has the beneficial effects that the method can be used forsoft measurement of the carbon content of the fly ash, the model is optimized, and the prediction performance of the soft measurement model of the carbon content of the fly ash is further improved. Firstly, a BP neural network model is constructed for coal quality prediction by utilizing coal quality influence parameters so as to obtain relatively accurate coal quality test data; the fly ash carbon content prediction model provided by the invention integrates two technologies of coal quality prediction and fly ash carbon content prediction, realizes accurate measurement of the fly ash carbon content, and has important significance for improving the combustion economy of a boiler, reducing the coal consumption and improving the environment.

Owner:ZHEJIANG ZHENENG TECHN RES INST +1

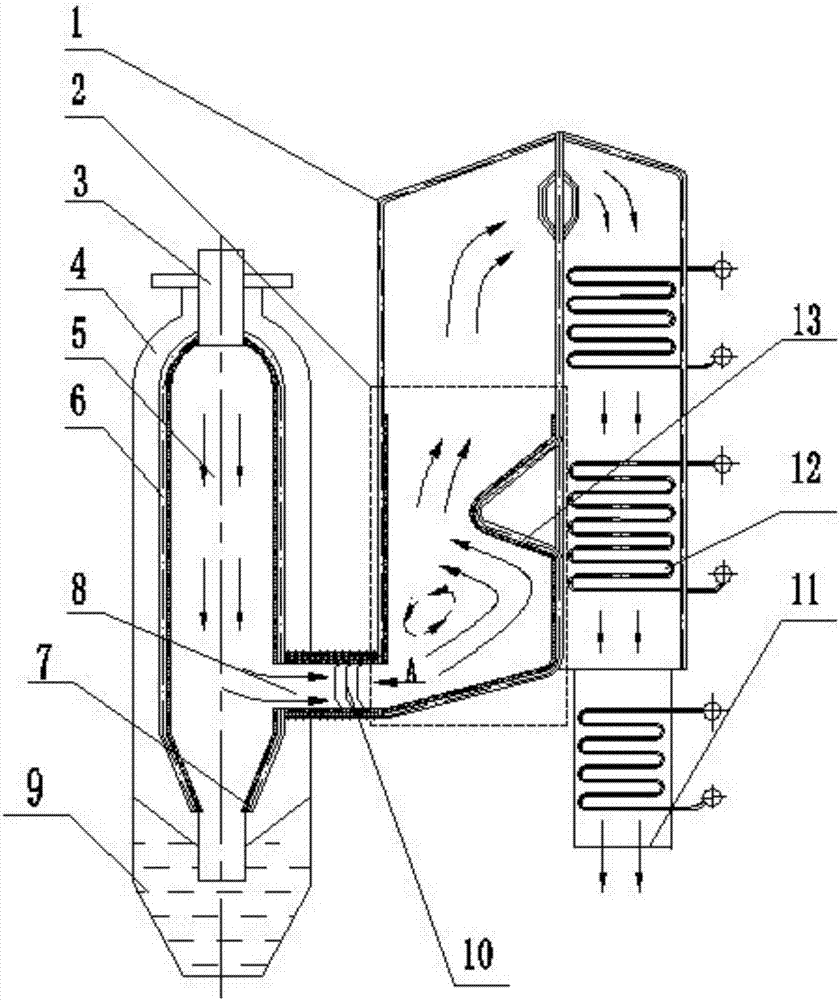

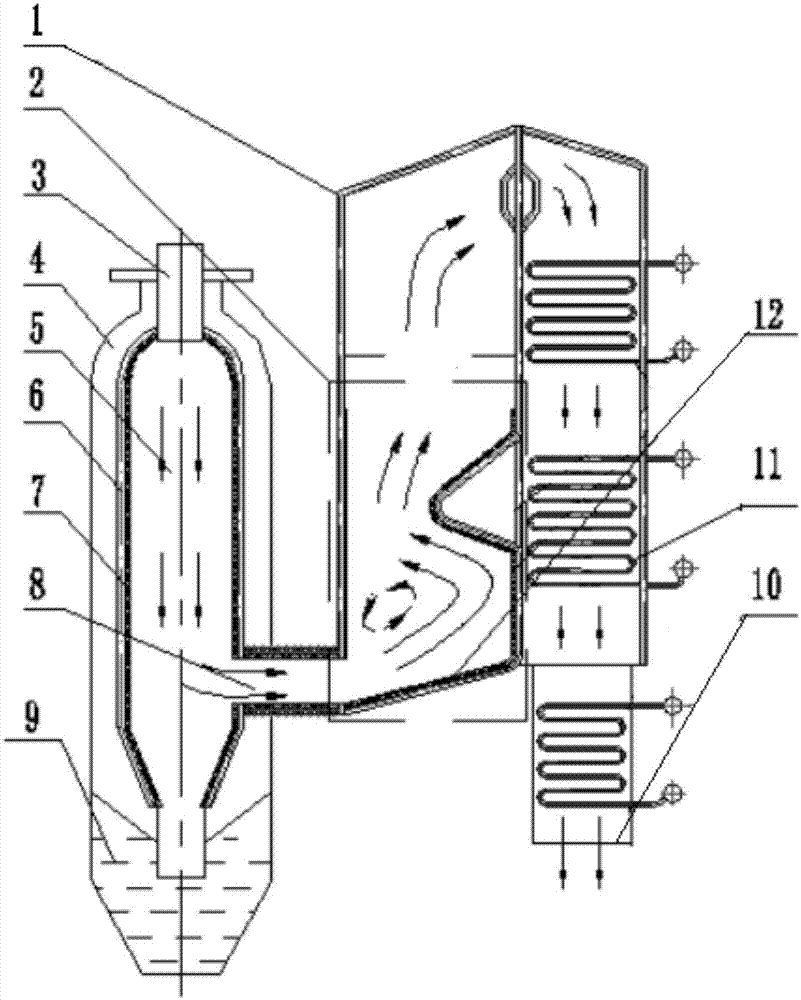

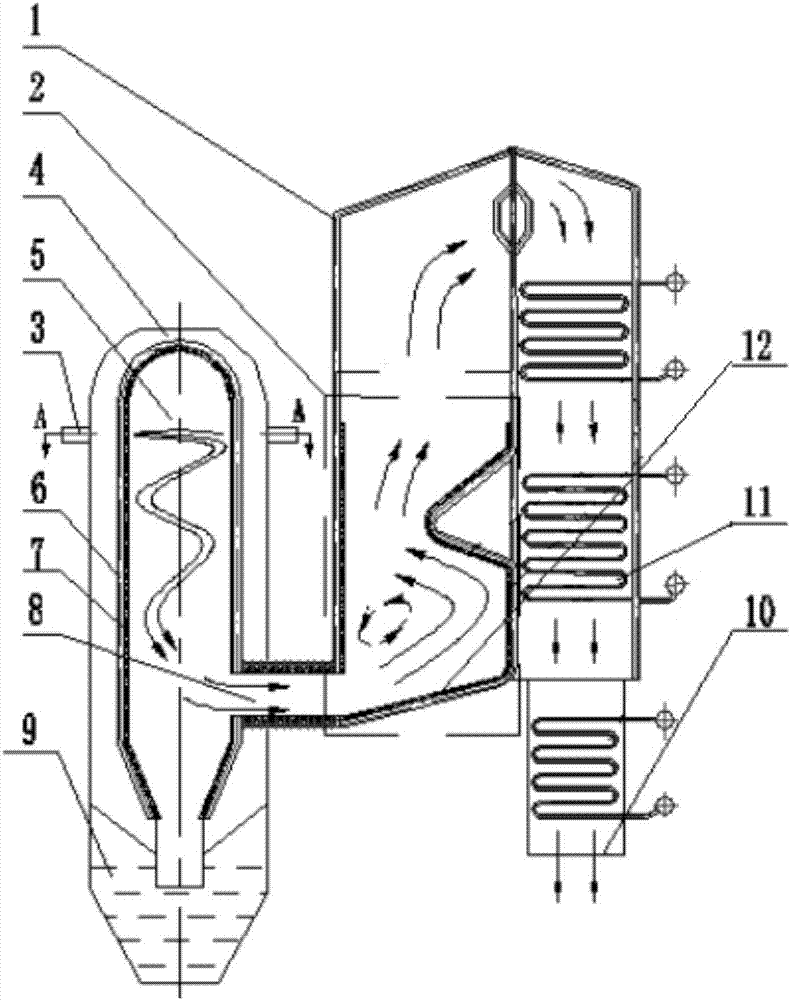

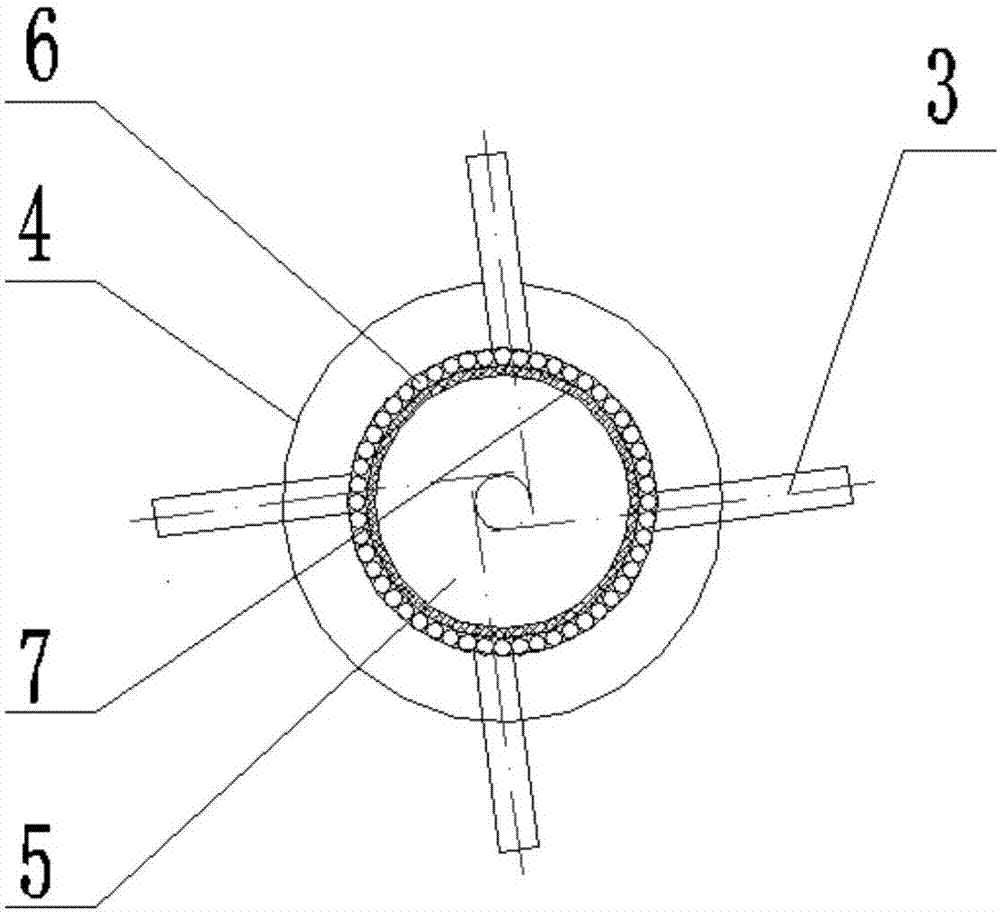

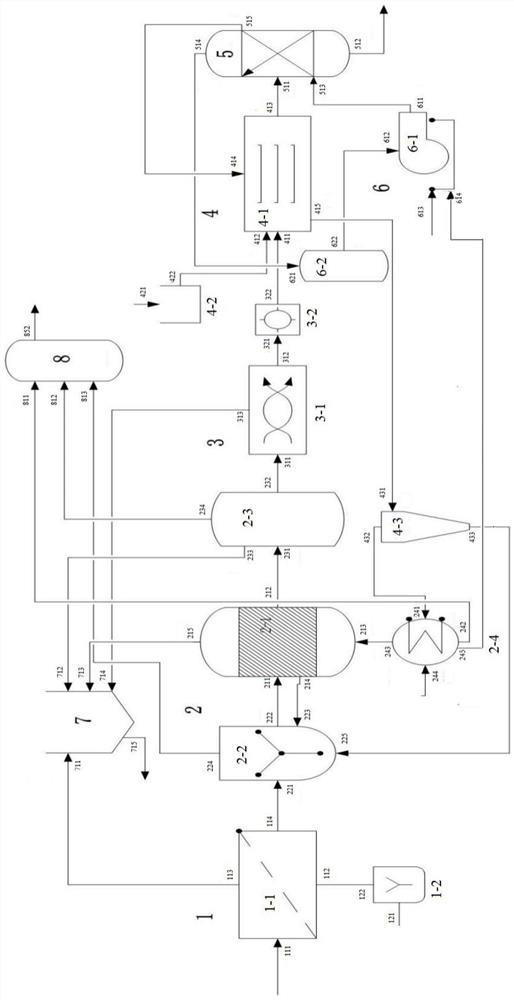

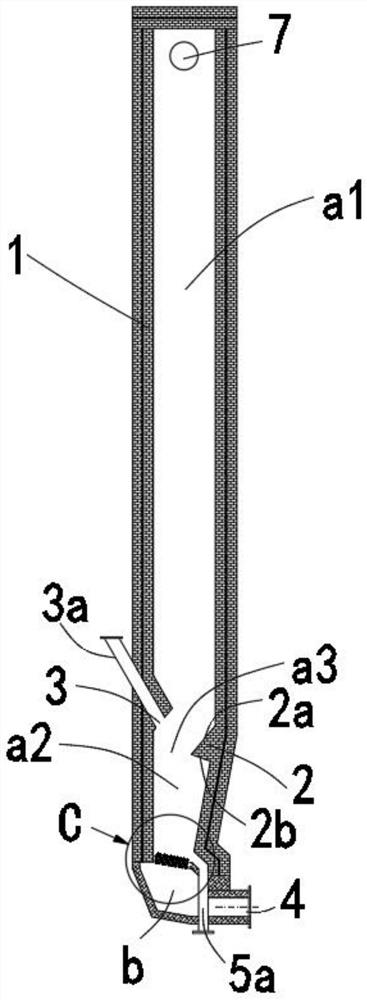

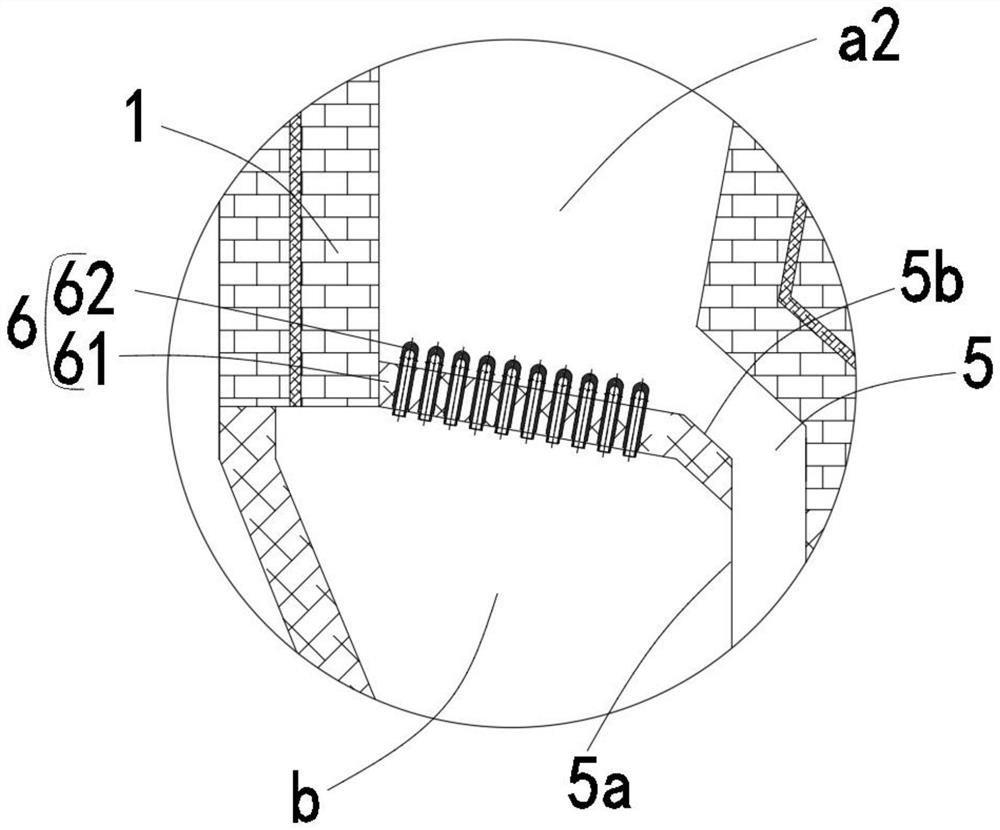

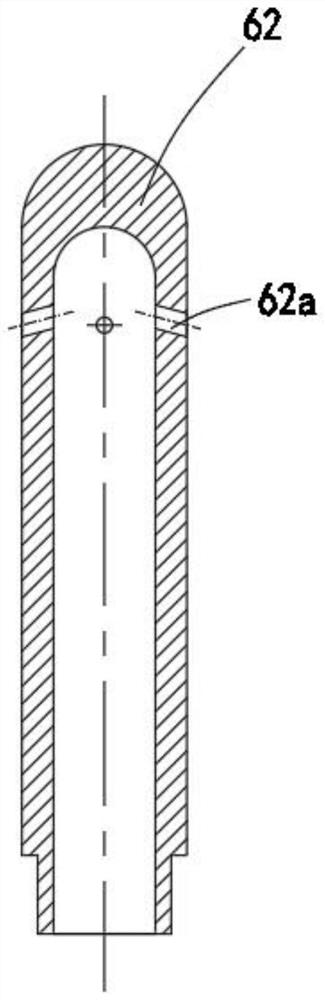

U-shaped coal gasification reaction device used for secondarily separating and deslagging and coal gasification process implementing secondary separating and deslagging by using device

InactiveCN106987279AImprove slag collection efficiencyLarge amount of fly ashGasification processes detailsGranular/pulverulent flues gasificationSlagProcess engineering

The invention relates to a U-shaped coal gasification reaction device used for secondarily separating and deslagging and a coal gasification process implementing secondary separating and deslagging by using the device, and solves the problems of high production of flue dust, high content of unburned carbon in flue dust, low carbon conversion rate and low energy utilization ratio of the existing entrained flow gasifier. The U-shaped coal gasification reaction device used for secondarily separating and deslagging comprises a gasification furnace body, a horizontal flue and a waste kettle; the gasification furnace body comprises a gasification furnace nozzle, a gasification furnace hearth, a water wall tube, a cooling water pipe and a slag basin; the waste kettle is partitioned by a middle furnace wall into a radiation heat transfer chamber and a heat convection chamber; and the gasification furnace body, the horizontal flue and a secondary gasification chamber form a U-shaped coal gasification reaction region. The U-shaped coal gasification reaction device is used for coal gasification.

Owner:HARBIN INST OF TECH

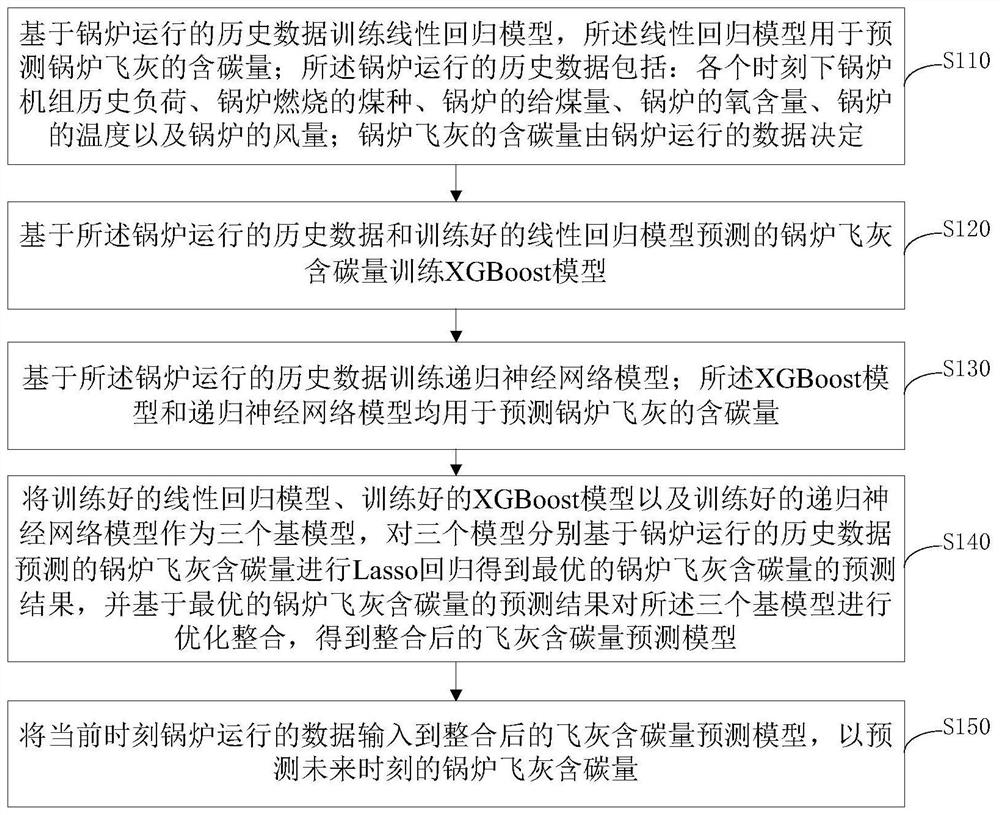

Boiler fly ash carbon content prediction method and system

InactiveCN112232373AMeet needsCharacter and pattern recognitionNeural architecturesData setPredictive methods

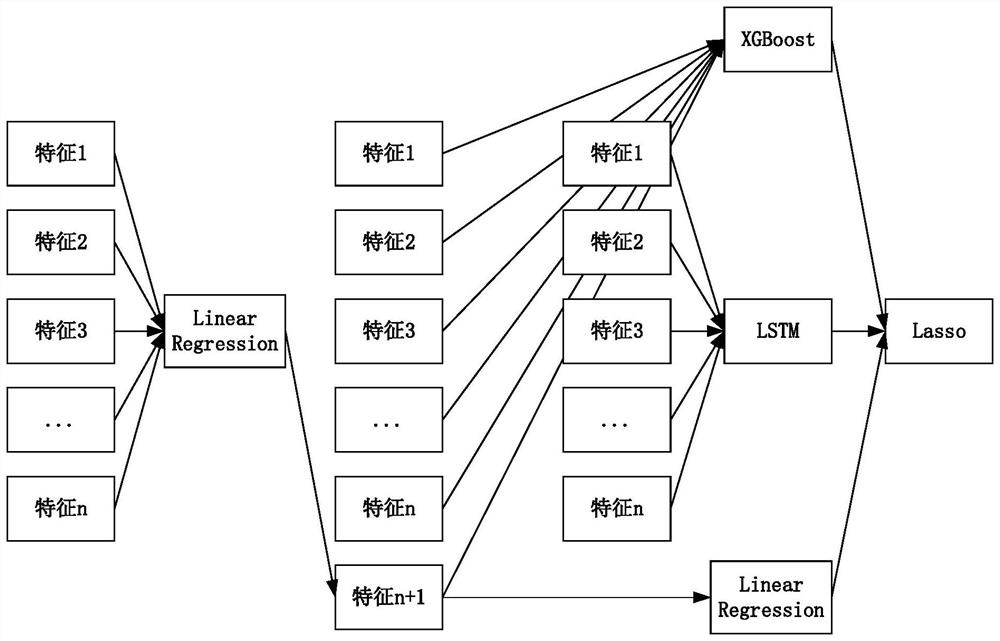

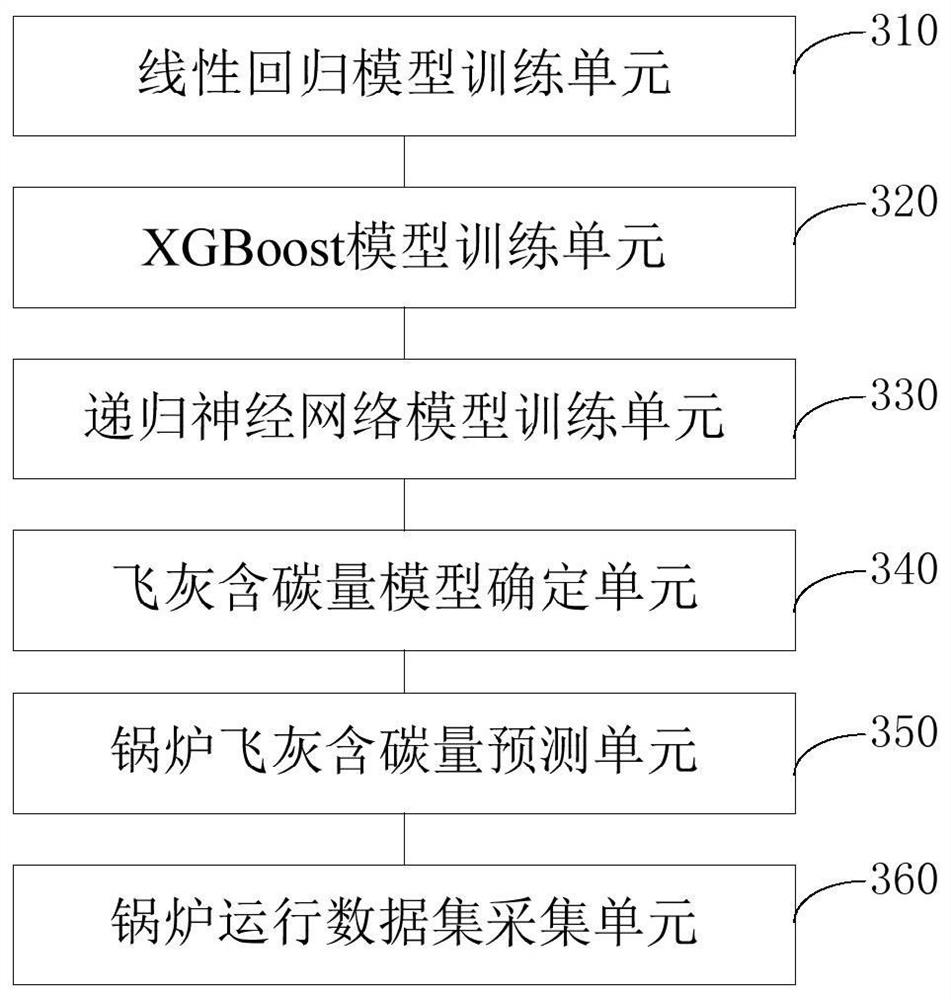

The invention discloses a boiler fly ash carbon content prediction method and system, and the method comprises the steps: obtaining and standardizing a historical data set of boiler operation, and enabling a standard data set to serve as a sample point; inputting the standard data set into a linear regression model, correspondingly outputting the carbon content of the flue gas fly ash, and training to obtain the linear regression model; inputting the standard data set and the obtained characteristics of the carbon content of the flue gas fly ash into an XGBoost model, correspondingly outputting the carbon content of the flue gas fly ash to obtain an initial XGBoost prediction model, and performing parameter optimization on the initial XGBoost model to obtain an optimal XGBoost prediction model; and inputting the standard data set into a recurrent neural network, correspondingly outputting the carbon content of the flue gas fly ash, training to obtain an initial neural network model, and performing parameter optimization on the initial neural network to obtain an optimal recurrent neural network. The outputs of the three models are subjected to linear regression to obtain a fusion model, the fusion model is used for predicting the carbon content of the flue gas fly ash generated by the boiler, and the prediction precision of the emission concentration of the carbon content of the fly ash is improved.

Owner:HUAZHONG NORMAL UNIV

Method and device using high temperature air and high temperature steam as gasification agents for coal gas production

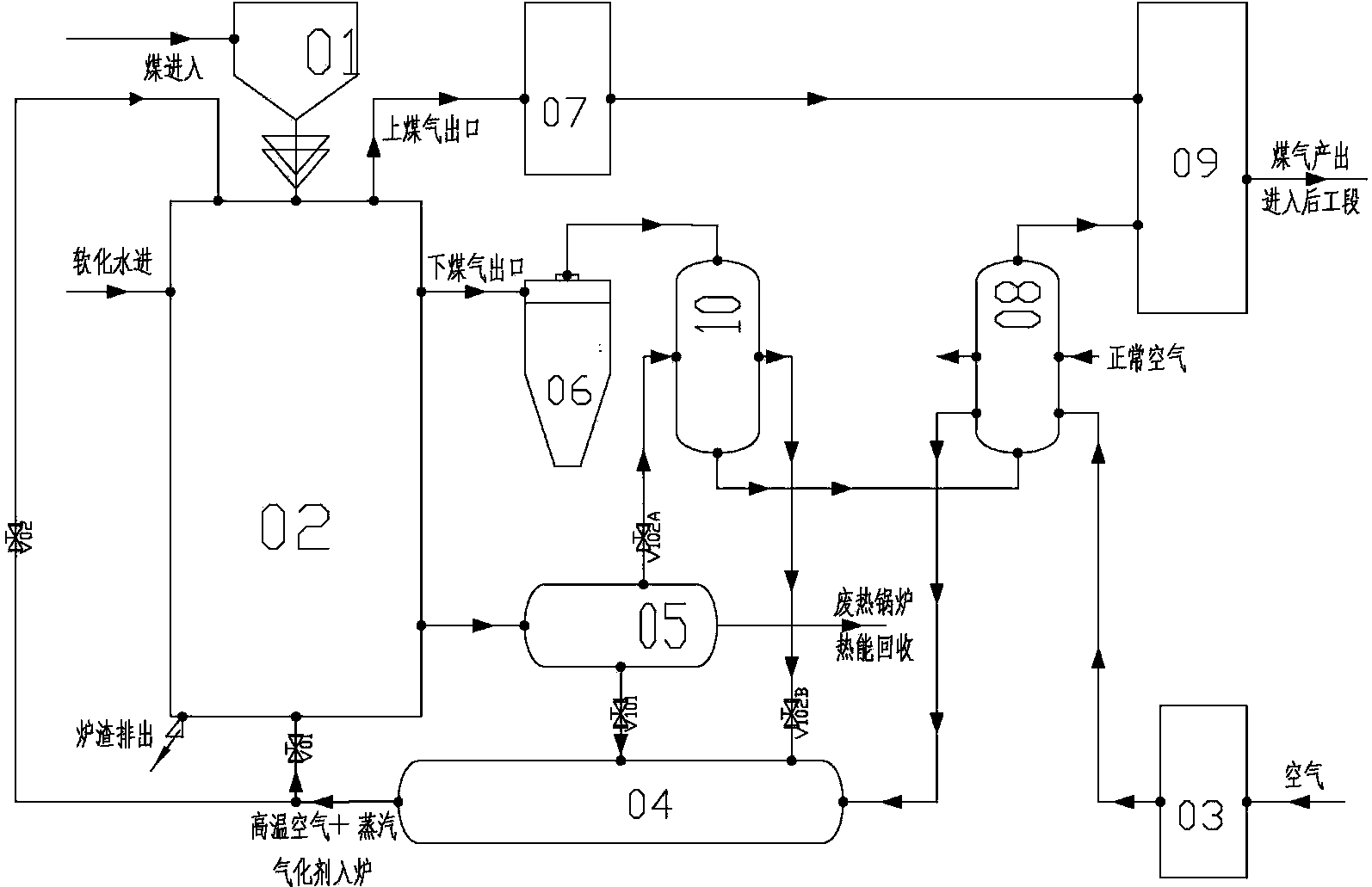

ActiveCN103509605AReduce unit consumptionOvercoming technical defects of furnace gas productionCombustible gas productionFixed bedEngineering

The invention belongs to the technical field of chemical coal gases, in particular to a method and a device using high temperature air and high temperature steam as gasification agents for coal gas production. According to the invention, coal gases are produced by using the air with a temperature of 120 to 220 DEG C and oxygen content of 20.93 percent (v / v) and the high temperature steam with a temperature of 120 to 220 DEG C as the gasification agents. Correspondingly, a heat exchanger, a control valve and a pipeline are additionally arranged in an original coal gas production device. According to the invention, the technical defects of gas production of a conventional normal-pressure fixed bed gas producer are well overcome; yield of a gas furnace and the calorific value of the coal gases are improved; carbon content in ash is reduced; sensible heat loss is reduced; standard coal consumption under the unit calorific value is reduced to 5 to 15 percent.

Owner:上海穗杉实业股份有限公司

U-shaped coal gasification reaction device and process for coal gasification by using device

InactiveCN107099337AImprove slag collection efficiencyReduce the amount of fly ashChemical industryGasification processes detailsFlueSlag

The invention relates to a U-shaped coal gasification reaction device and a process for coal gasification by using the device, and aims to solve the problems of large flying ash generation amount, high flying ash carbon content, low carbon conversion rate and low energy utilization rate of an existing entrained flow gasifier. The U-shaped coal gasification reaction device consists of a gasifier body, a horizontal flue and a waste pan, wherein the gasifier consists of a gasifier nozzle, a gasifier hearth, a water cooling wall pipe and a slag basin; the waste pan is divided into a radiation heat exchange chamber and a convection heat exchange chamber through a middle furnace wall; the gasifier body, the horizontal flue and a second gasification chamber form a U-shaped coal gasification reaction region. The U-shaped coal gasification reaction device is used for coal gasification.

Owner:HARBIN INST OF TECH

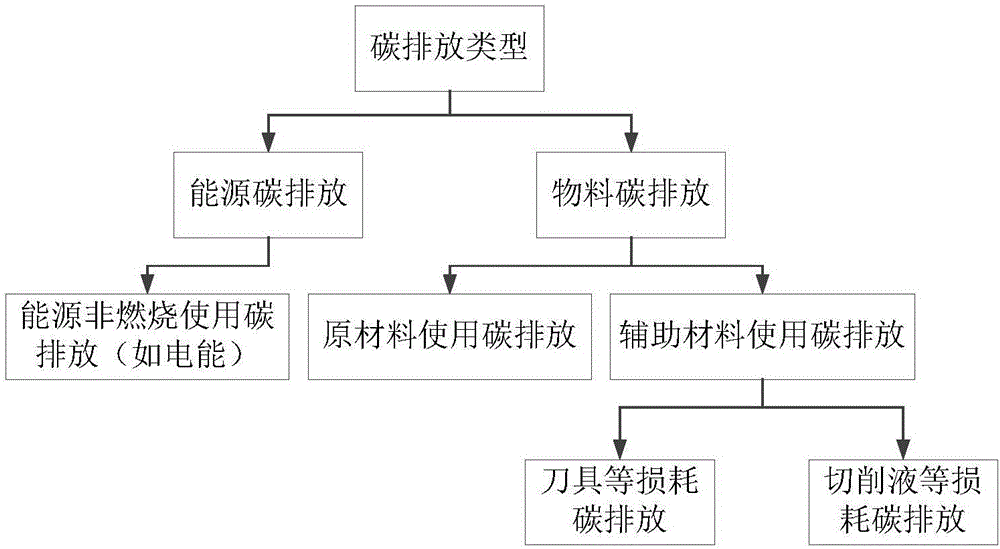

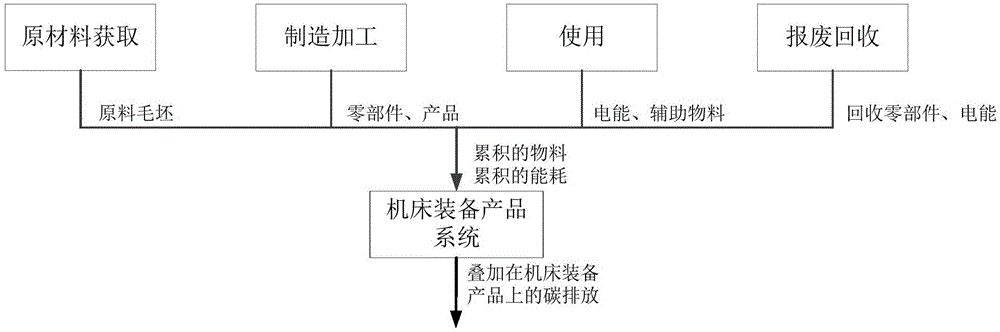

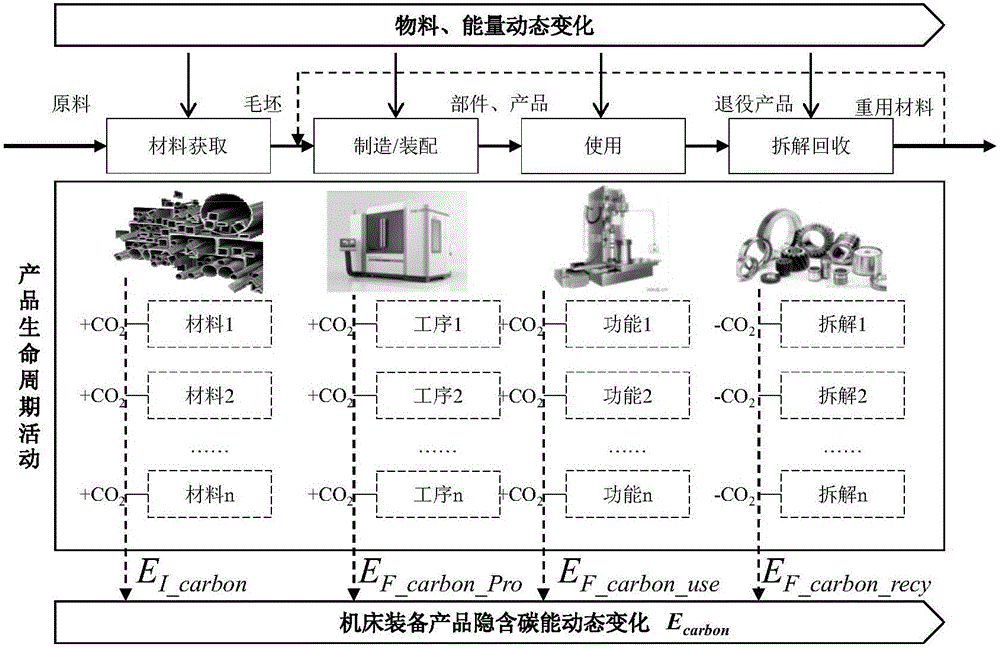

Embodied carbon energy-based machine tool equipment product carbon emission quantification method

ActiveCN106777877AGuaranteed practicalityEnsure consistencyTechnology managementInformaticsEnergy basedEnergy flow analysis

The invention provides an embodied carbon energy-based machine tool equipment product carbon emission quantification method. The method comprises three parts, i.e., machine tool equipment product material flow and energy flow analysis, a machine tool equipment product carbon emission quantification model and an embodied carbon energy-based carbon emission quantification method. A machine tool equipment product material flow and energy flow superposition principle is provided by analyzing the characteristics of energy flow and material flow; a carbon emission boundary model at a main lifecycle stage is established, and a machine tool equipment product carbon emission quantification principle is given based on an embodied carbon energy concept; an embodied carbon energy-based specific carbon emission calculation formula is obtained according to the characteristics of the main lifecycle stage. The invention adopts an embodied carbon energy quantification method, which takes a product as the boundary, for providing data support for a low carbon design, and is more close to the target object requirements of actual low-carbon optimization improvement, so that the practicality and consistency of the carbon emission boundary and a calculation result are guaranteed, and an effective basis and theoretical support are provided for energy conservation and emission reduction of products manufactured by machine tool equipment.

Owner:XI AN JIAOTONG UNIV

Method for realizing energy-saving running of coal burning boiler

The invention relates to a method for realizing energy-saving running of a coal burning boiler. The method comprises the following steps of: arranging grid measuring points on furnace walls around a hearth combustion region in horizontal and vertical directions at the intervals of 1-2 meters, and monitoring the carbon monoxide concentration C<CO> and carbon dioxide concentration C<CO2> of a coal dust burning product in the hearth combustion region at the grid measuring points in real time by using an online monitoring system; taking fly ash generated by combustion from each measuring point every half or one hour, and analyzing the carbon content FC<ash> of the fly ash; and summarizing monitoring data of each measuring point within 24 hours, calculating a comprehensive combustion index r, judging the combustion state of the boiler according to a combustion state distribution figure of an entire hearth drawn on the basis of comprehensive combustion indexes, and performing corresponding combustion adjustment on the boiler. Due to the adoption of the method, the combustion of the boiler can be monitored and adjusted, so that the problems of coking, fire extinguishment, incomplete local combustion, corrosion of a water-cooled walls and the like existing in the boiler are further prevented, and energy-saving running of the boiler is realized.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

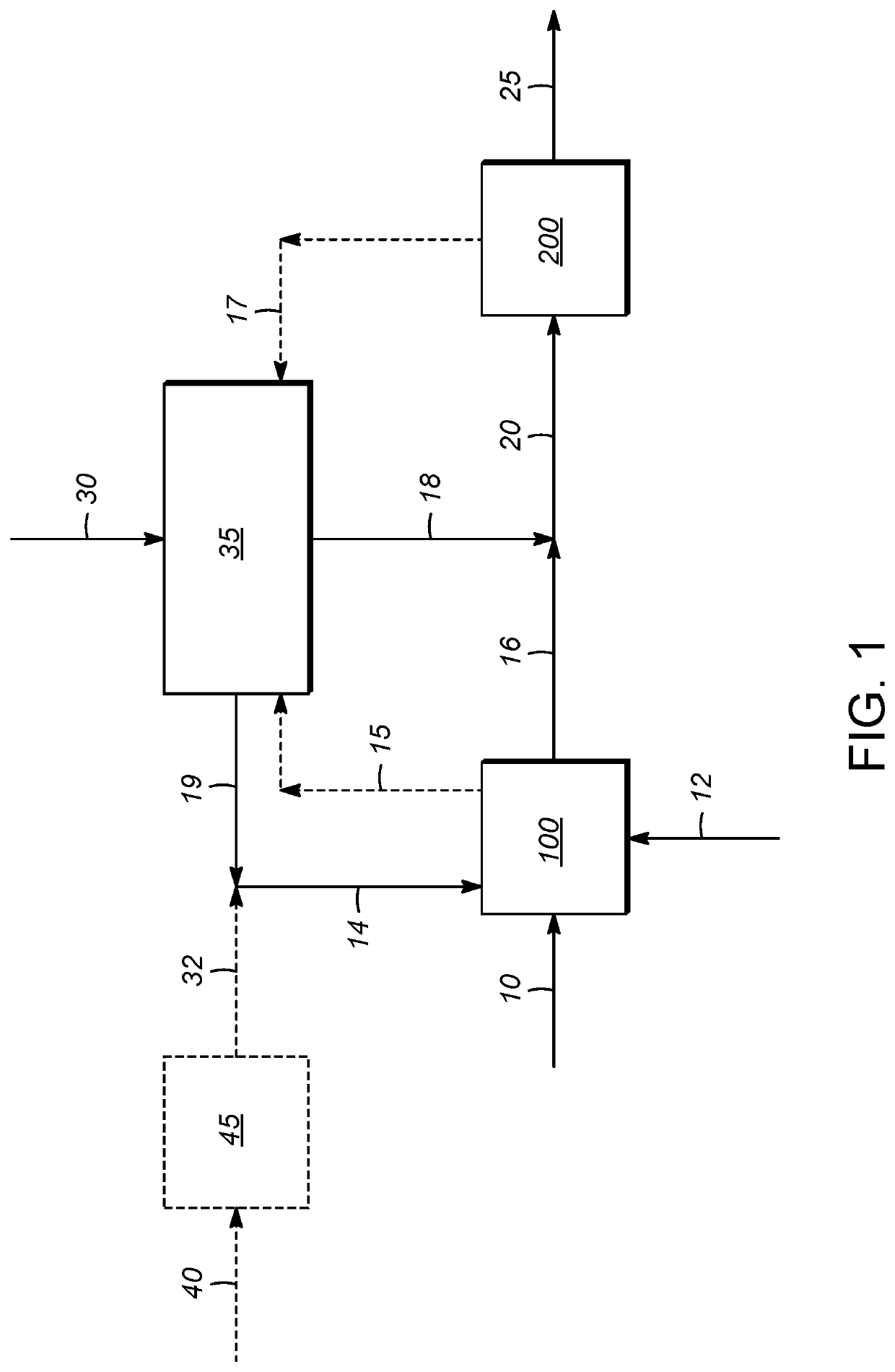

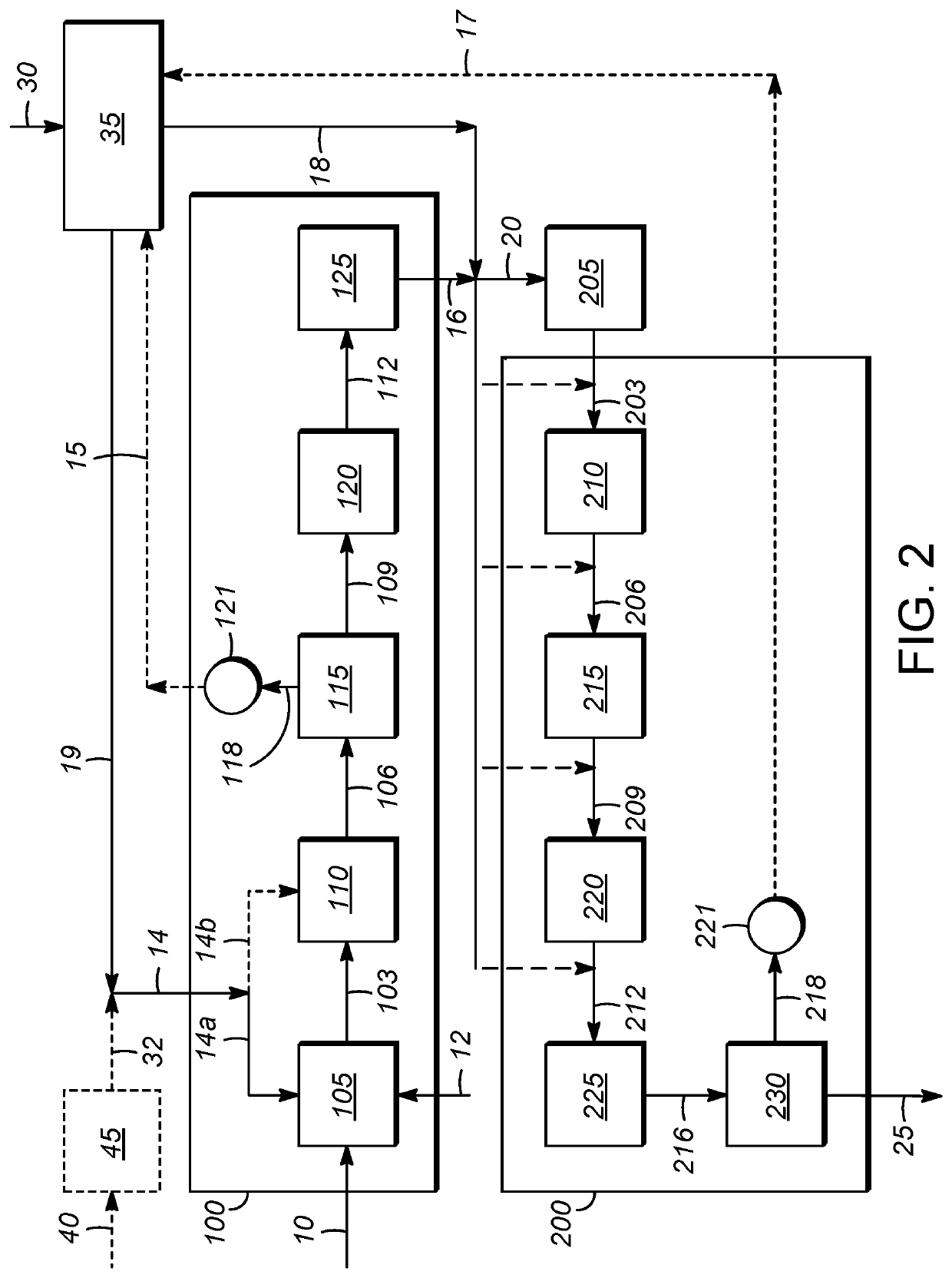

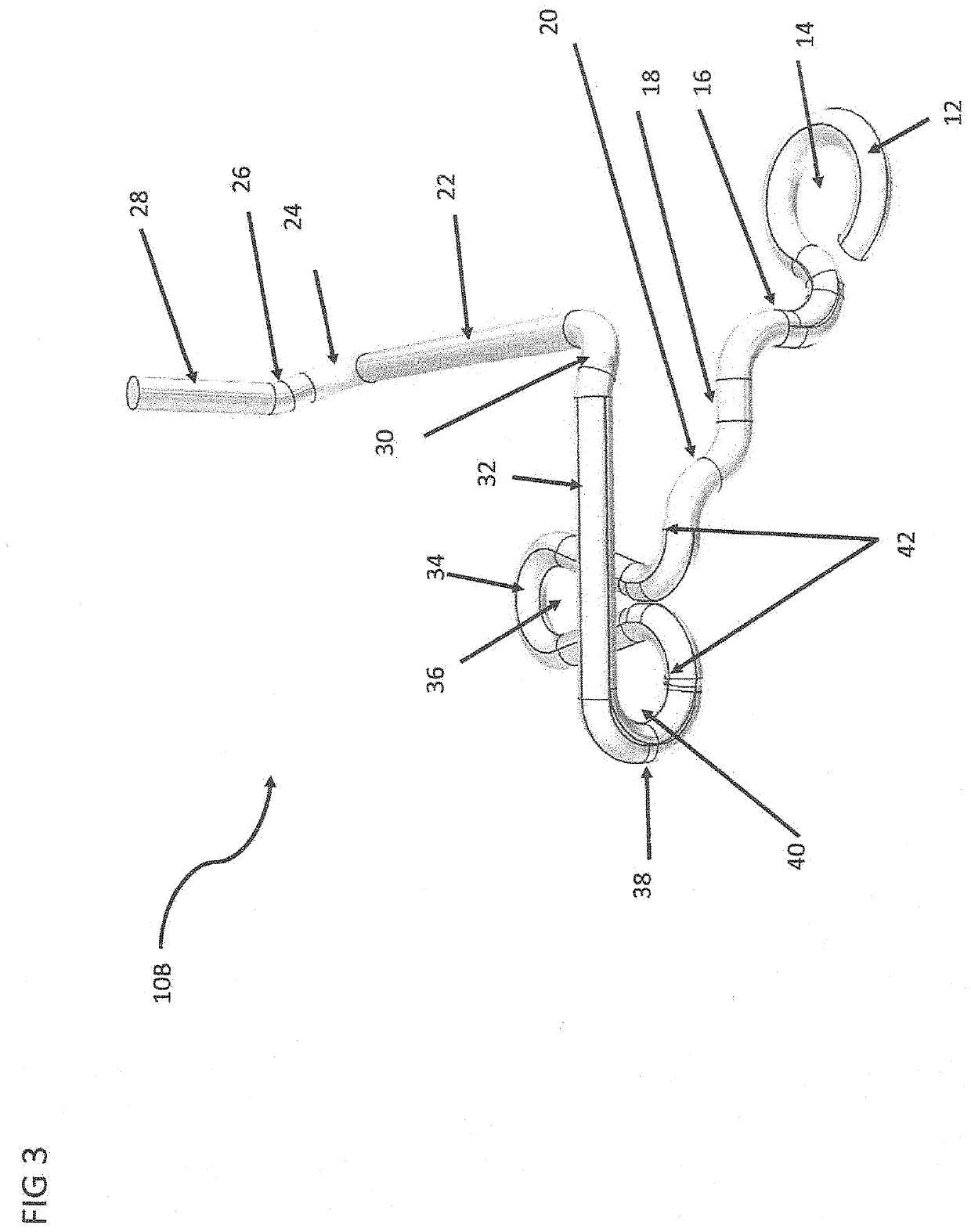

Integrated gasification and electrolysis process

ActiveUS20200017422A1Efficient managementReduce carbon footprintHydrocarbon from carbon oxidesGaseous fuelsThermodynamicsElectrolysis

Aspects of the invention relate to improvements in the flexibility with which oxygen and hydrogen, for example from electrolysis, may be supplied to processes having both gasification and methanation steps, as well as improvements in how such processes may be operated in response to variations in carbonaceous feeds. Offsets, between the ideal quantity of hydrogen and the quantity available from a given source may be compensated for by adjusting one or more operations of the process, and in particular such operation(s) that ultimately impact the quantity of CO and / or CO2 available downstream of the gasifier for conversion to methane in an RNG product stream.

Owner:GAS TECH INST

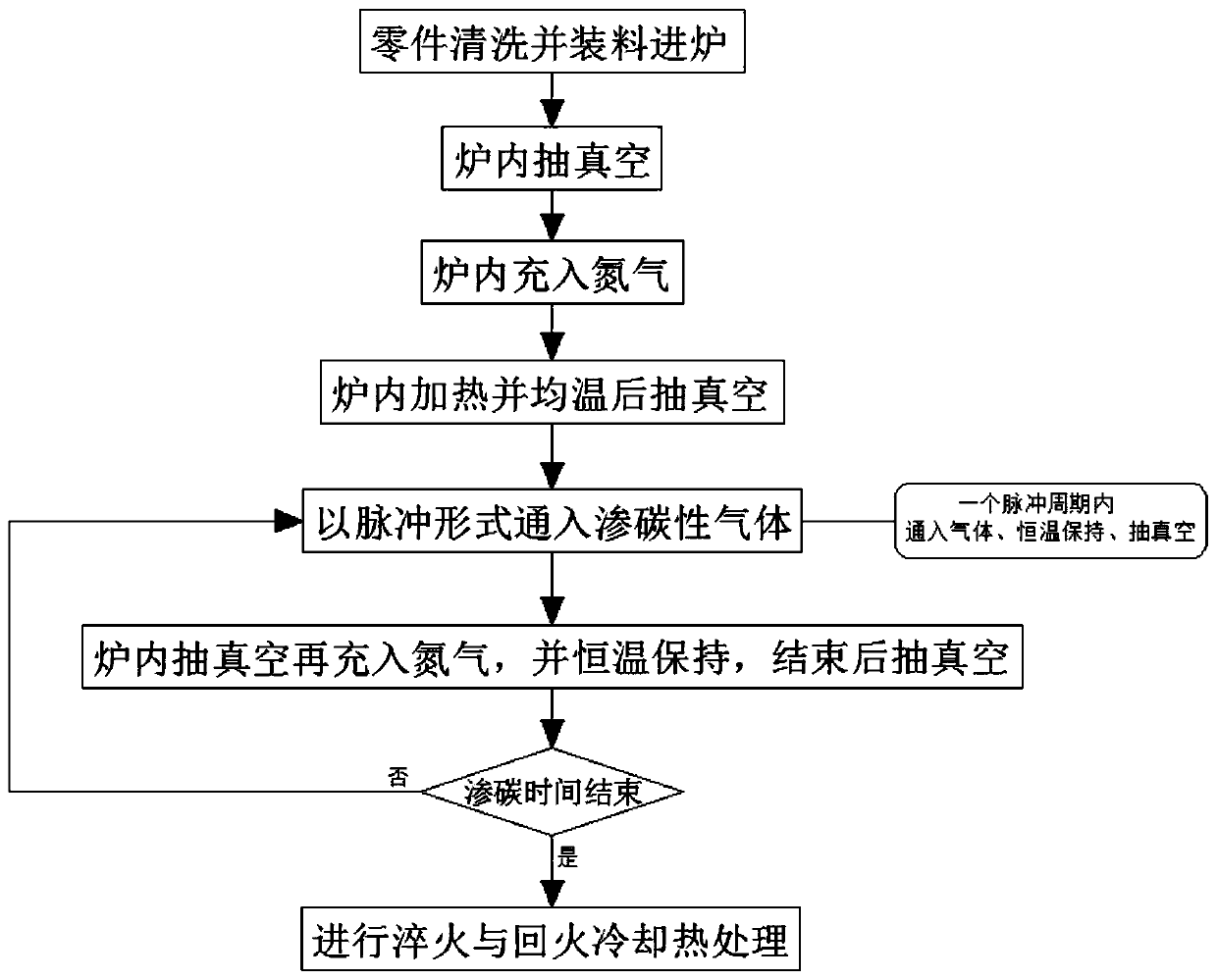

Vacuum carbonization heat treatment machining process

PendingCN110846612AMaintain temperatureMaintain concentrationSolid state diffusion coatingCarbonizationNitrogen gas

The invention relates to the technical field of metal surface heat treatment, and discloses a vacuum carbonization heat treatment machining process. The internal of a furnace is vacuumized, and partsin the furnace are heated; the heating temperature is 930-950 DEG C; after the parts are heated to a set temperature, the temperature is homogenized by 30 min; carbonization gas is introduced in the furnace in a pulse form, and is maintained at a constant temperature of 930-950 DEG C; in a dispersion phase, the internal of the furnace is firstly vacuumized; then, nitrogen is injected in the furnace to reach the gas pressure in the furnace of not higher than 80 Pa for constant-temperature maintenance; and the internal of the furnace is vacuumized after maintenance. The low-pressure protective nitrogen is injected in the furnace in the carbonization dispersion phase, so that the pressure can be provided into the furnace to improve the dispersion efficiency, and high-concentration carbon content nearby the surfaces of parts is prevented; and under the condition of maintaining the carbonization temperature and the carbonization concentration in the furnace, the pressure in the furnace is increased, the carbonization efficiency is improved, the dispersion time is shortened, the production efficiency is improved, and the setting contradiction problems among the carbonization temperature,the carbonization concentration and the carbonization efficiency are effectively solved.

Owner:SHANGHAI FENGDONG HEAT TREATMENT ENGINEERING CO LTD

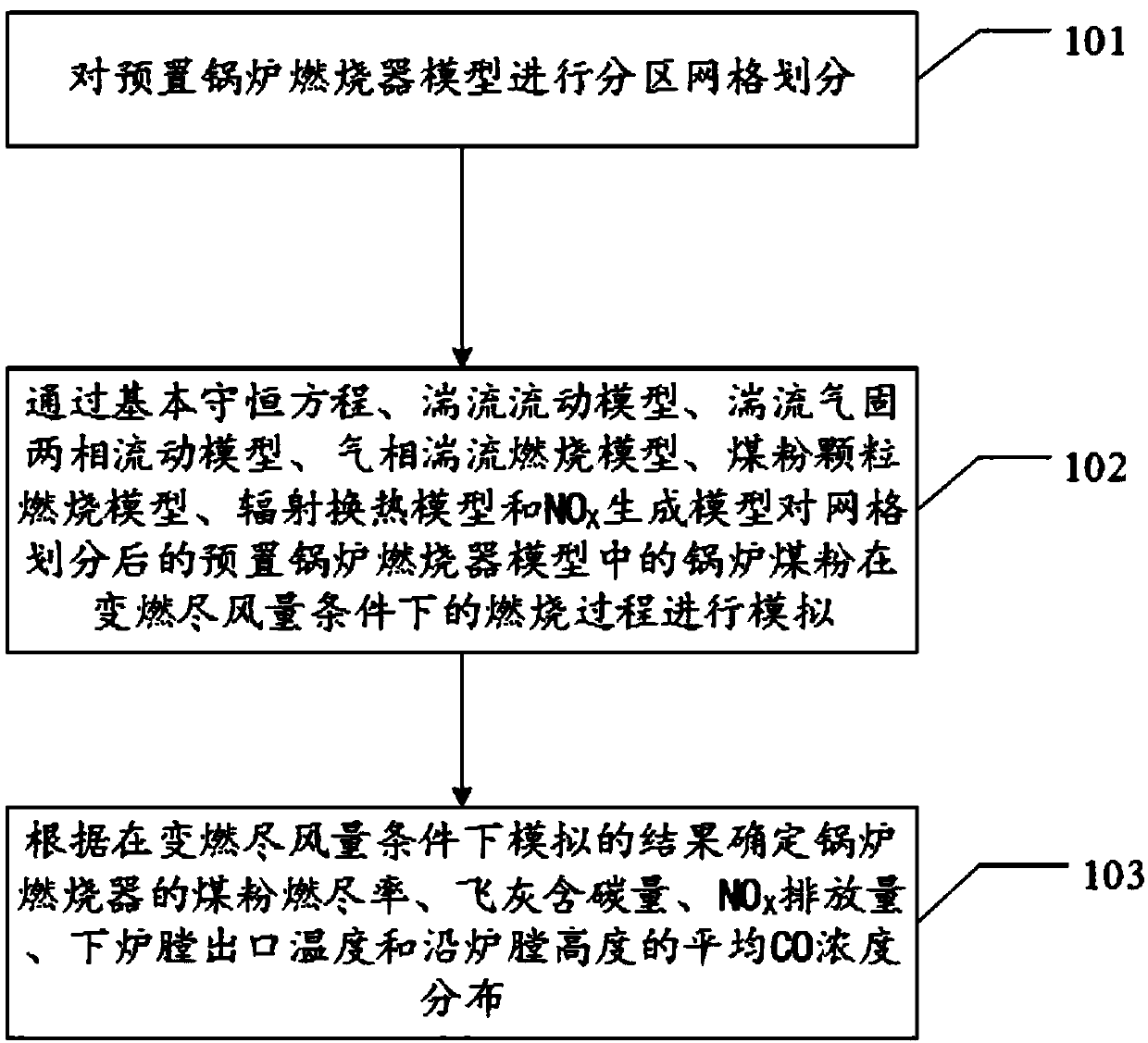

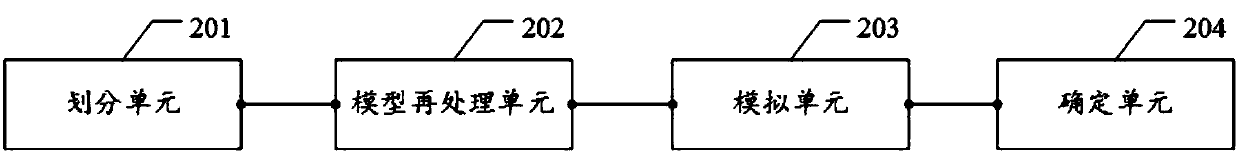

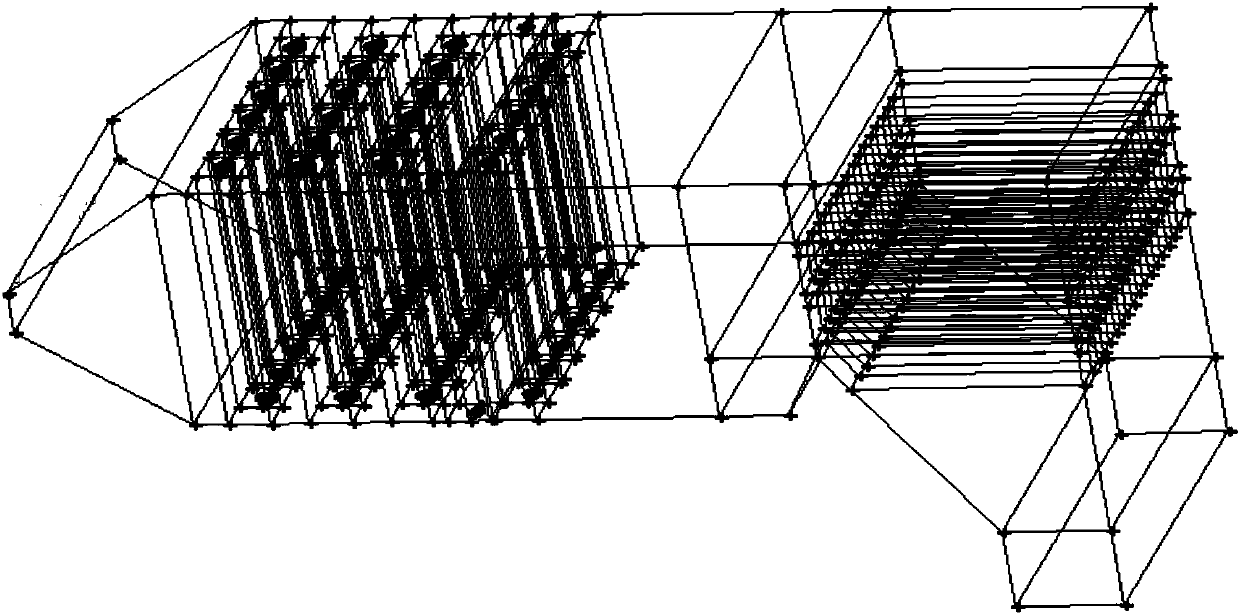

Simulation method and device of combustion characteristic generation numerical value of utility boiler pulverized coal under variable over fire air volume

InactiveCN106383944ADesign optimisation/simulationSpecial data processing applicationsAir volumeCombustor

The embodiment of the invention discloses a simulation method and device of a combustion characteristic generation numerical value of utility boiler pulverized coal under a variable over fire air volume, and solves the technical problems that the whole rule characteristics of combustion, flowing and heat transfer in a furnace can not be measured since the manufacture of the testbed of a full-size model is unrealistic because the size of a hearth is larger and larger at present. The method comprises the following steps of: on the basis of a base conservation equation, a turbulence flow model, a turbulence gas-solid two-phase flow model, a gas phase turbulence combustion model, a pulverized coal particle combustion model, a radiation heat exchange model and a NOX generation model, simulating the boiler pulverized coal in a preset boiler combustor model subjected to mesh generation in a combustion process under a condition of variable over fire air volume; and according to a simulation result under the condition of variable over fire air volume, determining the pulverized coal burn-off rate, the unburned carbon in flue dust, the NOX discharge amount, the lower-hearth outlet temperature and average CO concentration distribution along hearth height of the boiler combustor.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

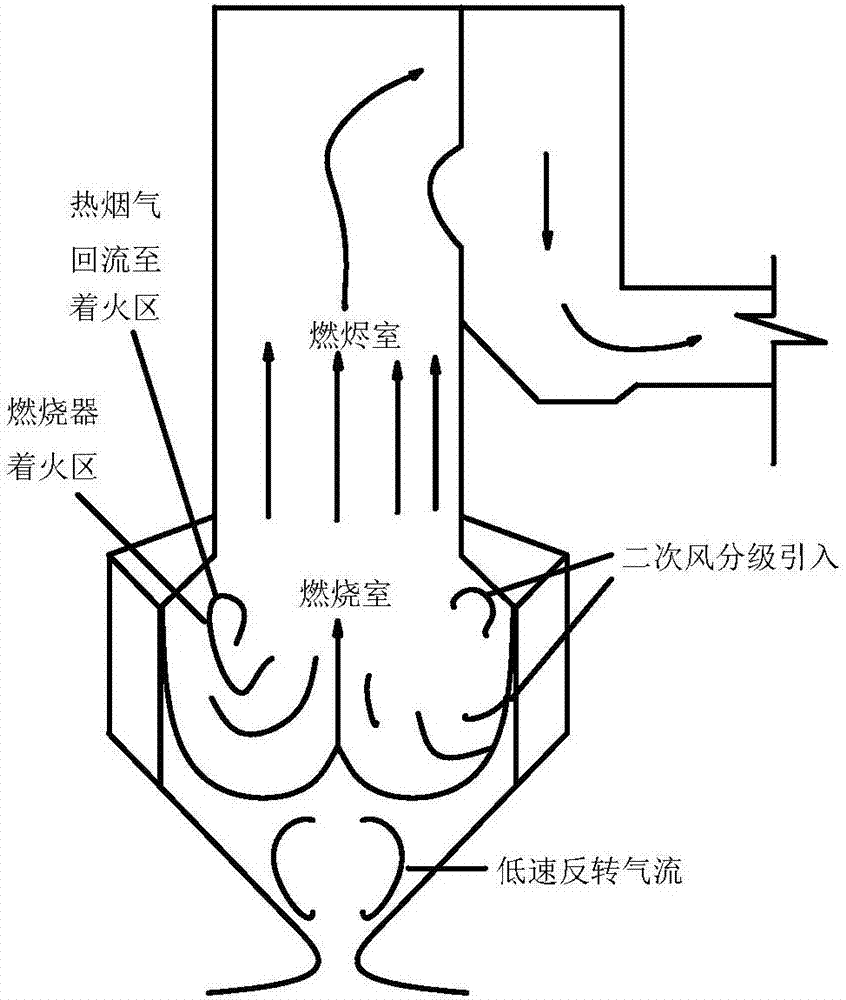

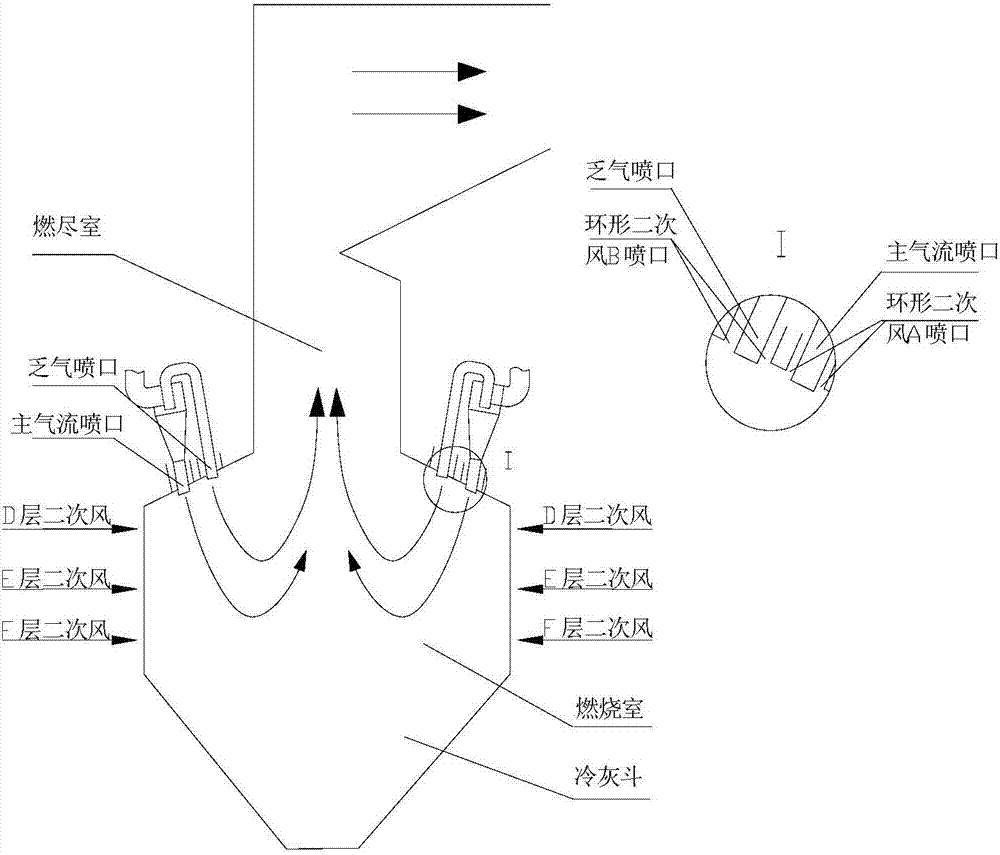

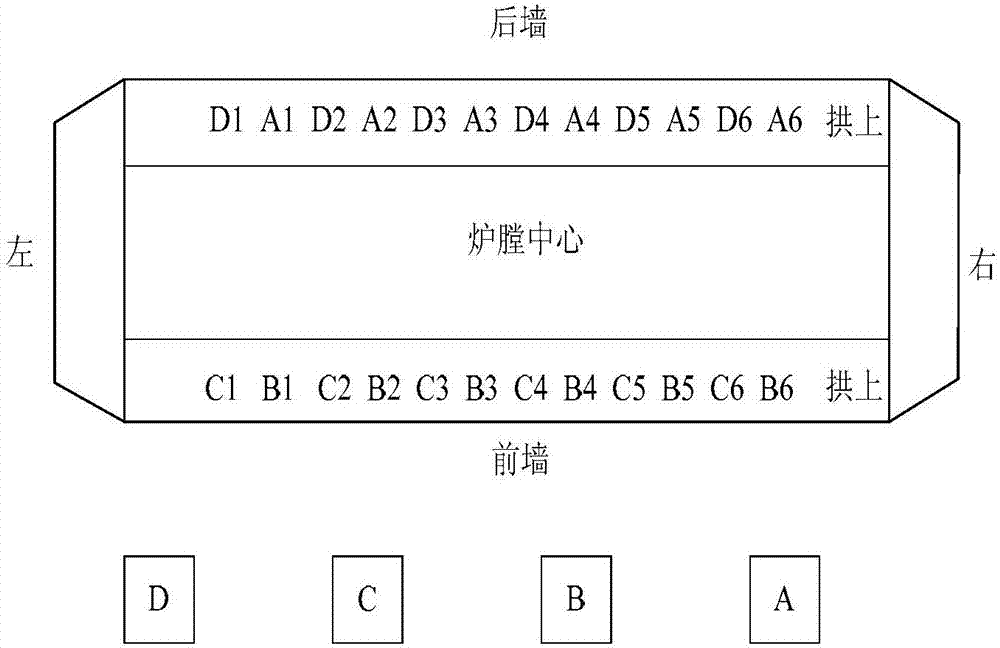

W-shaped flame boiler air distribution way optimization method

ActiveCN107355807AImprove adaptabilityImprove stabilitySolid fuel pretreatmentStaged combustionCombustionEngineering

The invention relates to a W-shaped flame boiler air distribution way optimization method. The method comprises steps of analyzing an acquired boiler operation condition, determining an F wind downward inclination angle and D,E wind opening degree, in which for a back wall, the F wind downward inclination angle is 25,25,5,5,30,30,30,30,5,5,25,25, the E wind opening degree is 25,25,5,20,20,20,20,20,5,5,10,10, the D wind opening degree is 5,5,5,5,5,5,5,5,5,5,5,5 and for a front wall, the F wind downward inclination angle is 25,25,5,5,30,30,30,30,5,5,25,25, the E wind opening degree is 25,25,5,20,20,20,20,20,5,5,10,10 and the D wind opening degree is 5,5,5,5,5,5,5,5,5,5,5,5. An in-furnace combustion work condition can be improved; and CO can be reduced and flying ash carbon content can be also reduced at the same time.

Owner:中国大唐集团科学技术研究总院有限公司

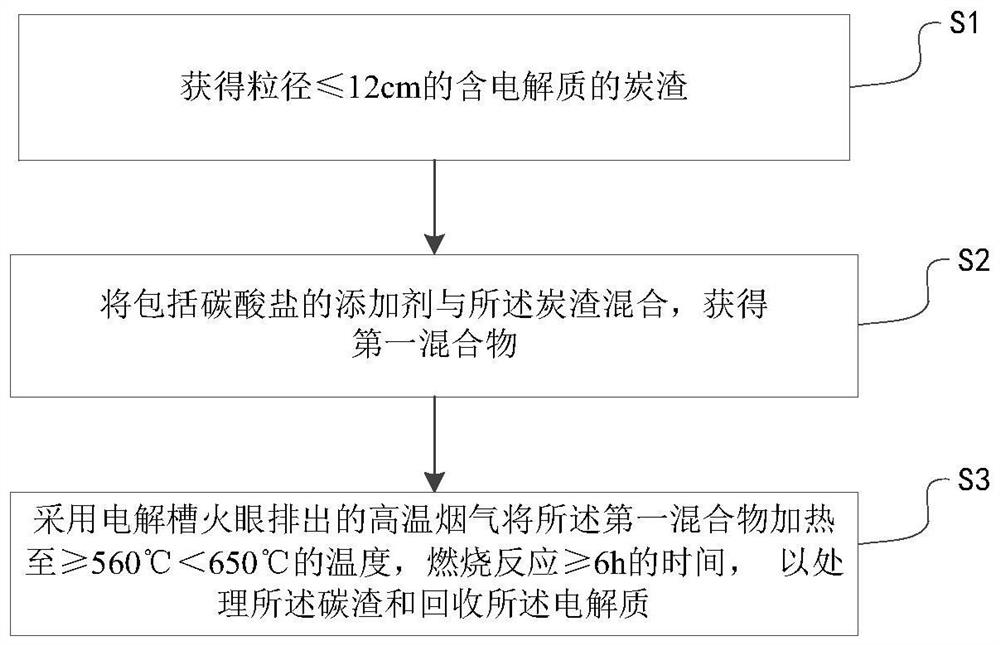

Method and device for treating carbon residues and recycling electrolyte

ActiveCN113481542AIncrease the reaction areaOvercoming hurdles of difficult-to-combust reactionsIncreasing energy efficiencyWaste heat treatmentFlue gasPhysical chemistry

The invention discloses a method and a device for treating carbon residues and recycling electrolyte. The method comprises the following steps: obtaining the electrolyte-containing carbon residues with the particle size of less than or equal to 12cm; mixing an additive containing carbonate with the carbon residues to obtain a first mixture; and heating the first mixture to the temperature larger than or equal to 560 DEG C and smaller than 650 DEG C through high-temperature flue gas exhausted by a fire hole of an electrolytic cell, the combustion reaction time is larger than or equal to 6 h, and therefore the carbon residues are treated, and the electrolyte is recycled. By adopting the method disclosed by the invention, the recovery rate of the electrolyte in the carbon residues is 98.07-98.68%, the recovery rate is high, the carbon content is 0.18-0.2%, the impurity content is low, and an electrolytic aluminum workshop does not discharge hazardous waste of the carbon residues; and the method fully utilizes the waste heat of the electrolytic cell and does not generate secondary pollution, so that the method is energy-saving, environment-friendly and pollution-free.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

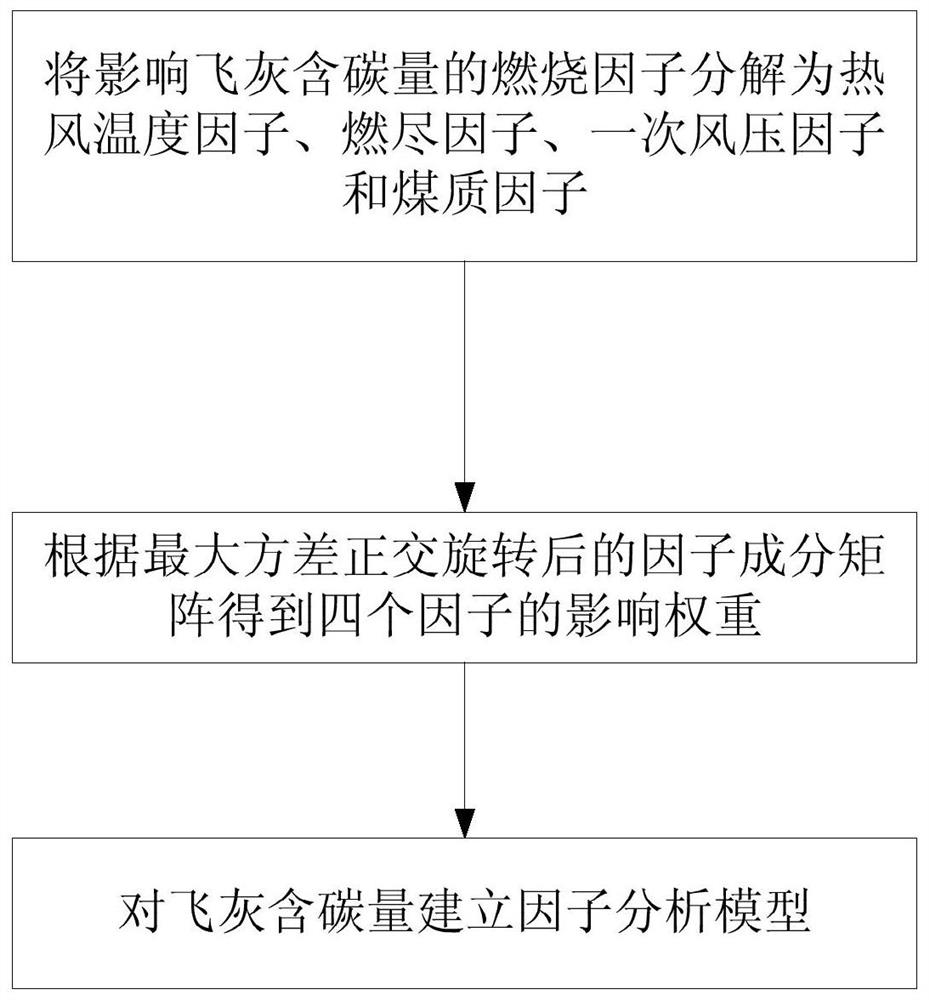

Method for measuring carbon content of power station boiler fly ash based on hearth fly ash residence time

ActiveCN112446156AVersatilityAdvancedDesign optimisation/simulationSpecial data processing applicationsHearthElectric power

The invention discloses a method for measuring carbon content of a power station boiler fly ash based on hearth fly ash residence time. The method is characterized by comprising the steps that step 1,combustion factors influencing the fly ash carbon content are decomposed into a hot air temperature factor, a burnout factor, a primary air pressure factor and a coal quality factor; step 2, according to an orthogonal rotation method, influence weights of four factors are acquired by utilizing the factor component matrix after the maximum variance orthogonal rotation; a factor analysis model is created for the carbon content of the fly ash; compared with other modeling methods, the modeling method adopted by the invention is not limited by an algorithm, and is relatively high in practicability in a DCS system; the data is more comprehensive than other single algorithms; compared with hardware measurement, the parameter adaptability is higher; the invention has the characteristics of advancement, high sensitivity, good stability, high measurement accuracy and strong universality, and can be widely applied to the fields of electric power and the like.

Owner:CHONGQING DATANG INTL SHIZHU POWER GENERATION CO LTD

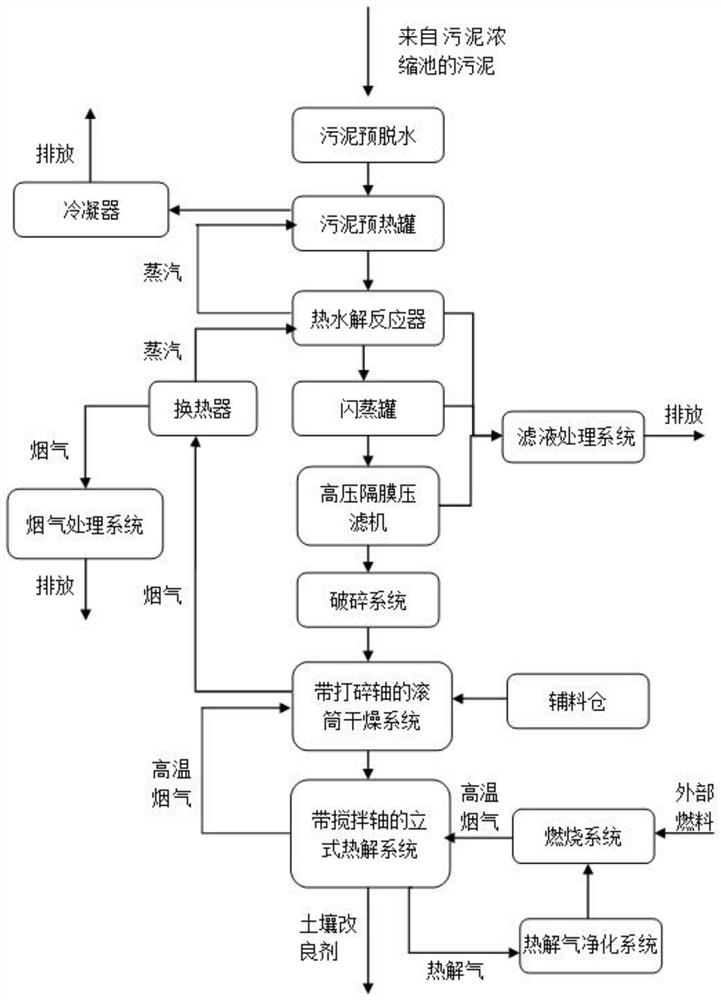

A kind of sludge soil conditioner and its preparation method and device

ActiveCN110358541BReduce loadReduce demandSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSolid carbonForest industry

The invention provides a sludge soil conditioner and a preparation method and application thereof, belonging to the technical field of sludge treatment. The preparation method of the sludge soil conditioner comprises the following steps: pre-dehydrating sludge to obtain first sludge; carrying out thermal hydrolysis reaction on the first sludge to obtain second sludge; sequentially carrying out filter pressing dehydration, crushing and drying on the second sludge to obtain sludge particles; mixing the sludge particles and biomass auxiliary materials, and performing pyrolysis reaction to obtainthe sludge soil conditioner. The preparation method meets the principles of reduction, harmlessness, stabilization and resource utilization, and has low cost and high efficiency. By adding the biomassauxiliary materials, the content of organic matters in the material is increased, a large amount of pyrolysis gas can be generated, the self-balance of system heat is realized, the dependence on an external fuel is reduced, and the operation cost is greatly reduced; the carbon content in solid carbon slag is improved, and the requirement of the soil conditioner for forestry is met.

Owner:科蓝博(北京)环境技术有限公司

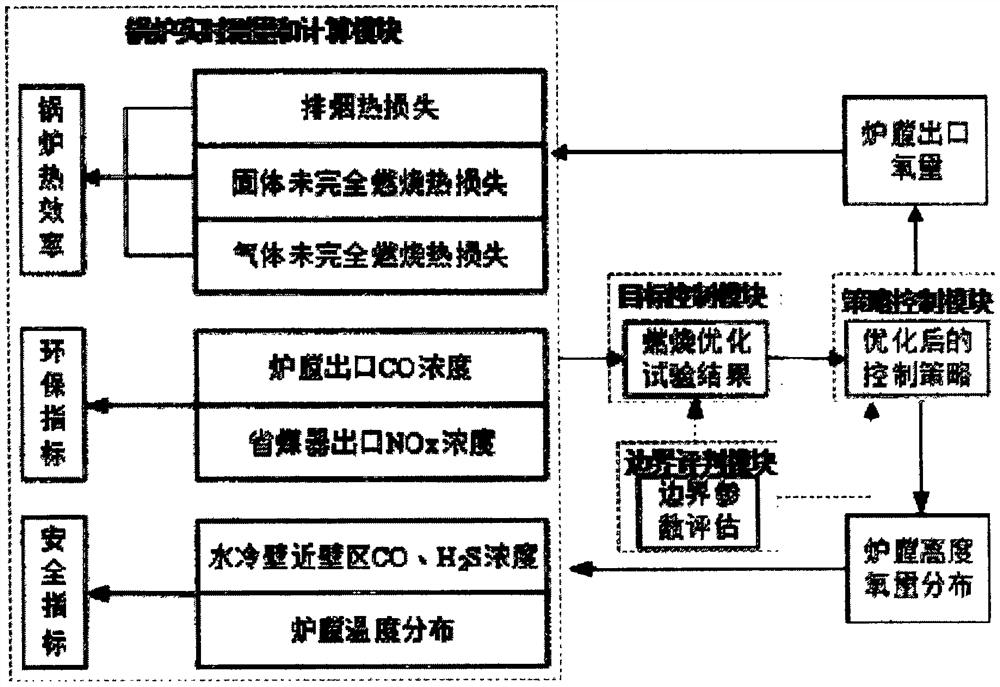

Thermal power plant boiler combustion efficiency intelligent analysis system and method

PendingCN112555896AImprove combustion efficiencyIntelligent analysis to improve combustion efficiencyCombustion regulationLoop controlLoad following power plant

The invention discloses a thermal power plant boiler combustion efficiency intelligent analysis system and method. The thermal power plant boiler combustion efficiency intelligent analysis system andmethod adopt a mode of combining open-loop control and closed-loop control. The thermal power plant boiler combustion efficiency intelligent analysis system comprises a boiler real-time measurement and calculation module, a target control module, a strategy control module and a boundary judgment module. The thermal power plant boiler combustion efficiency intelligent analysis method is based on anO2 / CO coupling relationship, boiler heat efficiency is taken as a main control target, and NOx and CO concentration is balanced; through a combustion optimization test, the relevance between the O2 / CO concentration and the carbon content and NOx concentration of ash is determined, and powder making system operation parameters and boiler O2 / CO optimal cooperative operation parameters under different loads are determined; and according to experimental research, an O2 / CO optimal cooperative operation scheme is formulated, related control logic is modified on a DCS, a set of intelligent combustion efficiency analysis system with independent intellectual property rights is formed, the current optimal operation scheme is intelligently prompted, an operator is guided to carry out combustion adjustment and operate according to the scheme, and the boiler efficiency is improved by more than 1%.

Owner:国家能源菏泽发电有限公司

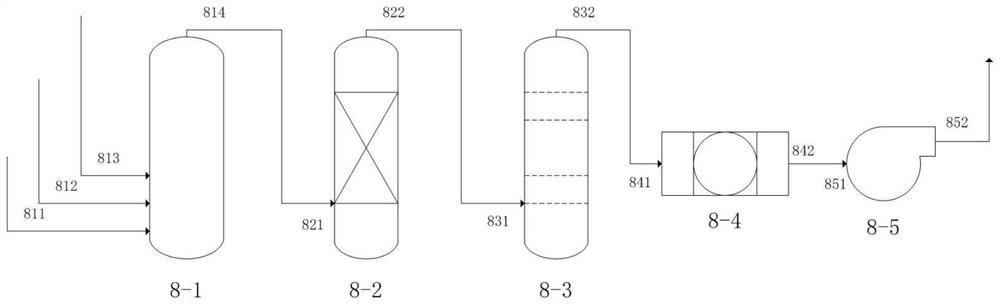

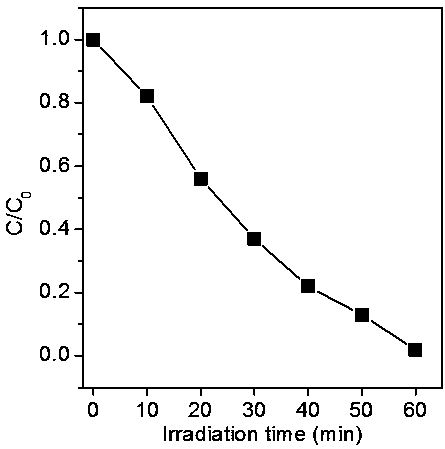

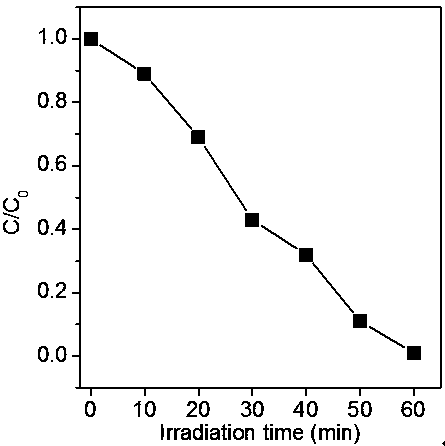

Method for preparing composite photocatalyst containing metal simple substance particles from carbon-containing solid waste

ActiveCN111085196AAdequate adsorptionFully degradableWater/sewage treatment by irradiationWater treatment compoundsPtru catalystPhysical chemistry

The invention discloses a method for preparing a composite photocatalyst containing metal elementary substance particles from carbon-containing solid waste. The method specifically comprises the following steps: adding solid waste with a carbon content of 2-98% and a metal precursor solid raw material into an aqueous solution with a pH value of 1-6 according to the total solid-to-liquid ratio of 1:(10-30), and uniformly mixing; continuously stirring for 1-24 hours at a temperature of 20-90 DEG C, filtering, drying, and preparing into powder particles; and under the condition of introducing protective gas, carrying out a high-temperature reaction for 10-1440 minutes to obtain the composite photocatalyst containing the metal elementary substance particles. The method is simple in preparationprocess and easy to implement and operate, the specific properties of the carbon-containing solid waste are fully utilized, and the prepared composite photocatalyst has a remarkable effect when applied to organic wastewater treatment.

Owner:JIANGSU UNIV OF TECH

Horizontal type circulating fluidized bed gasification method and device

PendingCN107513437AOvercoming high carbon contentOvercoming the large amount of fly ash in the gasGasification processes detailsGranular/pulverulent flues gasificationSolid carbonSlag

The invention provides a horizontal type circulating fluidized bed gasification method and device and relates to the technical field of solid carbon-containing fuel gasification. The method comprises the following steps: by adopting gasification in partitions, carrying out gasification reaction on solid carbon-containing fuel added into a first gasification chamber and a first gasifying agent in the first gasification chamber to generate raw coal gas, conveying the raw coal gas into a second gasification chamber, and separating unreacted carbon-containing solid substances and coal gas by virtue of an inertia separator; enabling the carbon-containing solid substances to fall into the second gasification chamber to be further gasified with a second gasifying agent in the second gasification chamber at gasification temperature higher than that of the first gasification chamber, so as to generate coal gas, then carrying out cyclone separation, then forming purified coal gas, outputting the purified coal gas, and returning a separated solid material to the first gasification chamber by virtue of a material returning device; and carrying out solid-state deslagging at the bottom of the first gasification chamber. The device mainly comprises the first gasification chamber, the second gasification chamber, the inertia separator, the cyclone separator, a vertical tube and the material returning device. The method and device which are provided by the invention have the advantages that the problems that carbon content of solid slag of an existing circulating fluidized bed gasification furnace is relatively high, fly ash content of coal gas is high and fly ash carbon content is high can be solved, carbon conversion rate and coal gas cooling efficiency are improved, and the carbon-containing fuel is utilized more effectively.

Owner:国科洁能(北京)科技有限公司

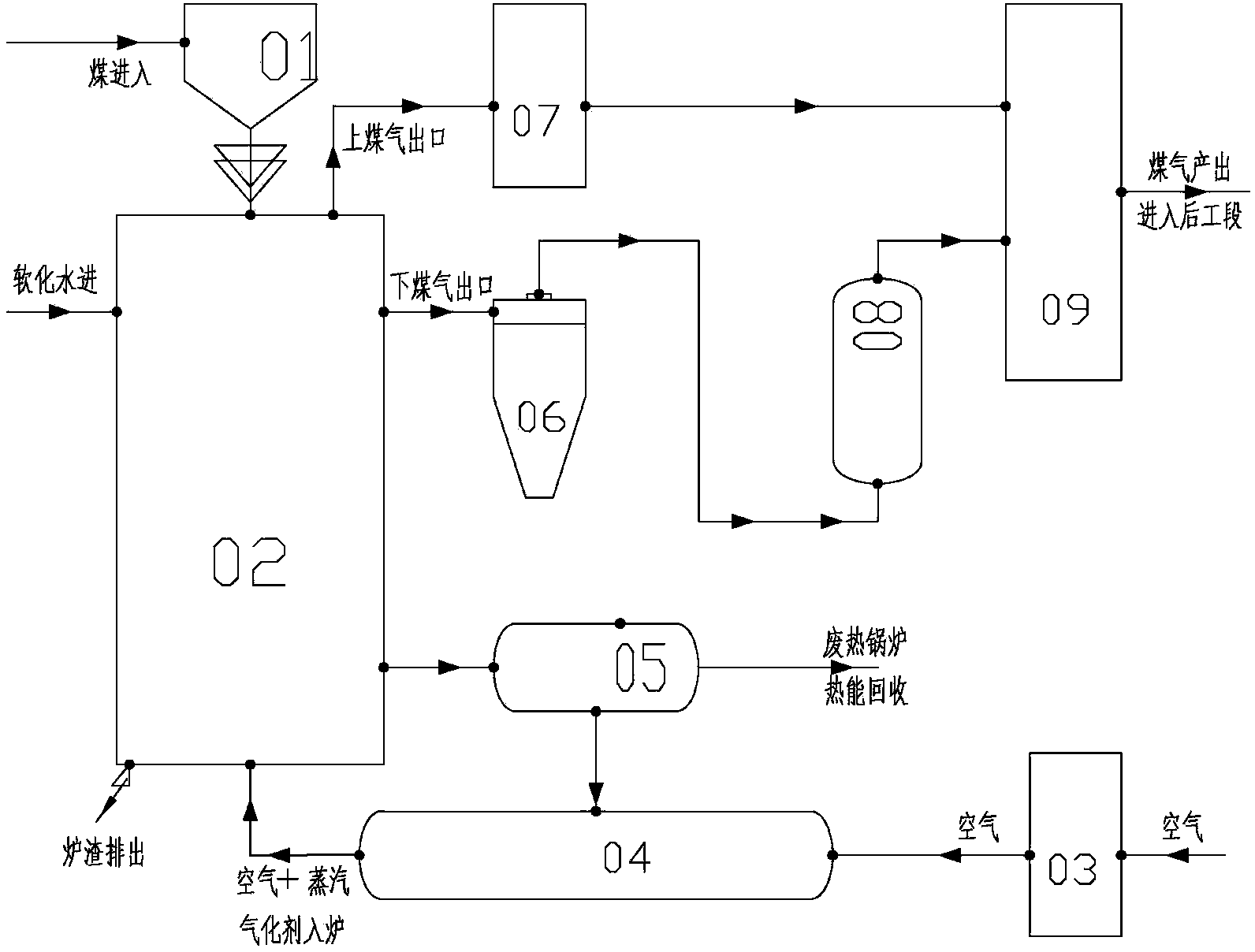

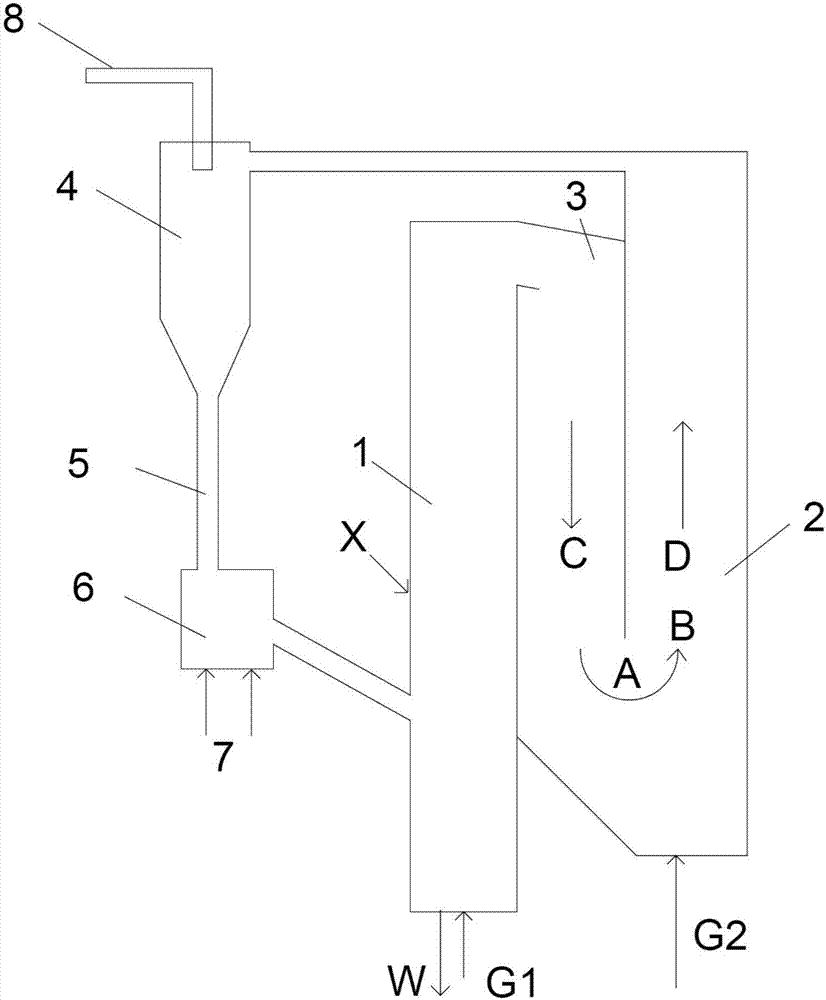

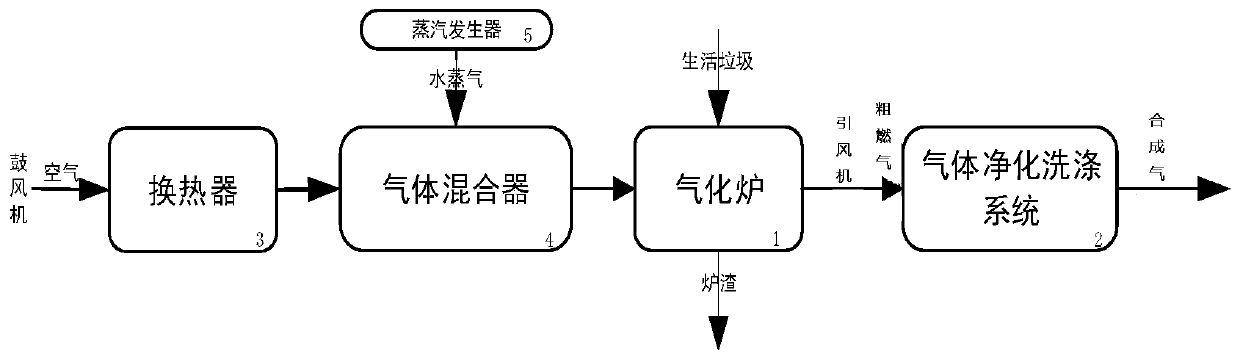

Garbage gasification system using air and steam as gasification agents

PendingCN110684558AReduce carbon contentOvercoming technical defects of furnace gas productionGasification processes detailsCombustible gas productionThermodynamicsSlag

The invention belongs to a domestic garbage treatment gasification system, in particular to a garbage gasification system using air and steam as gasification agents. The invention adopts air and watervapor to mix, and the mixed gas with a temperature of 120-220 DEG C is used as a gasification agent to produce, while ensuring that the air content in the gasification agent is 0.2%-0.35% of the theoretically required air amount, the mass ratio of steam / solid fuel in gasification agent should be controlled at 0-0.35. According to the invention, by changing the gasification agent, the gasificationgas output and the gas calorific value are improved, the carbon content of ash slag is reduced, the sensible heat loss is reduced, and the gasification energy utilization rate can be increased by 10-30%.

Owner:深圳龙澄高科技环保股份有限公司

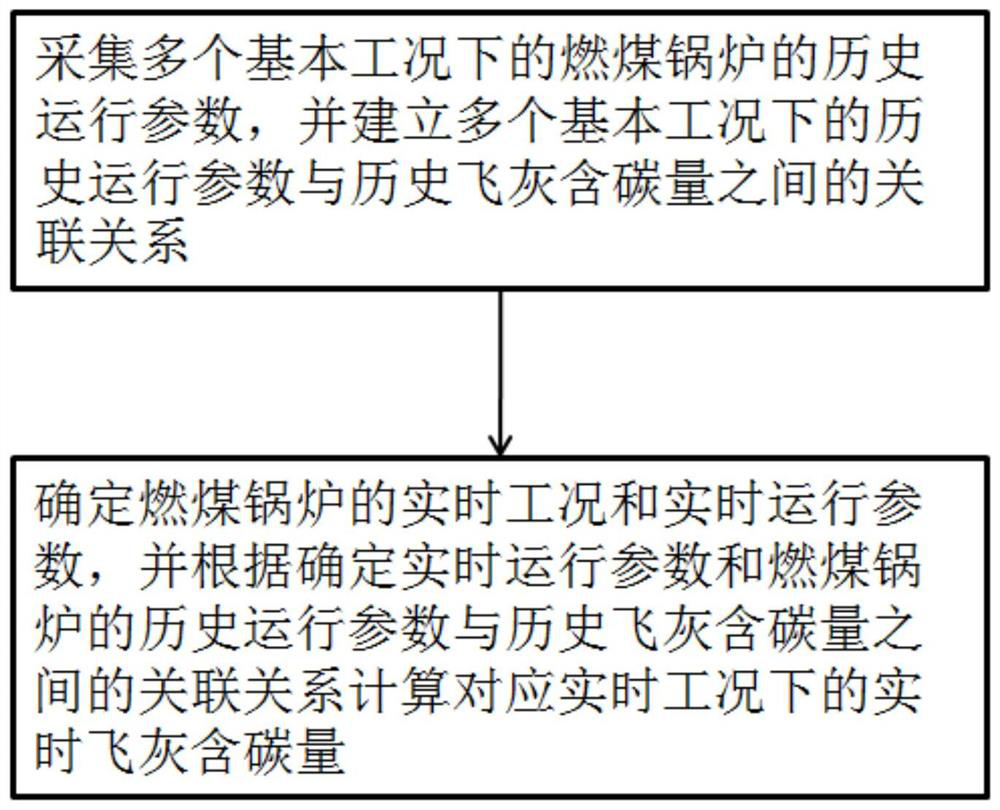

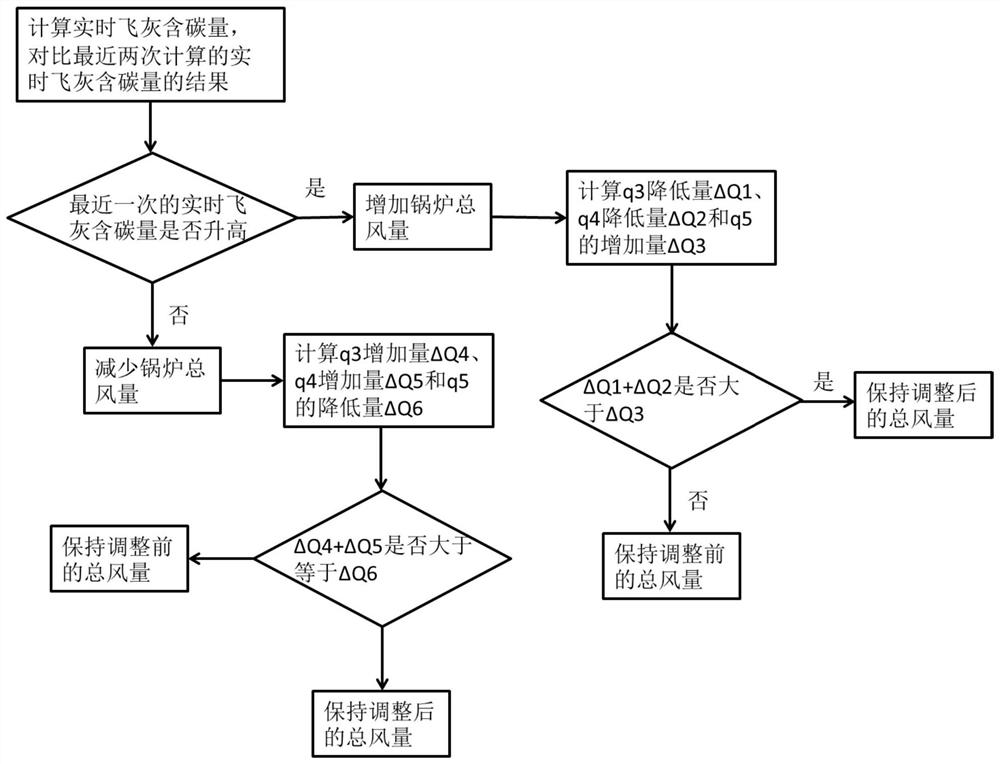

Fly ash carbon content soft measurement method and coal-fired boiler combustion optimization method and system

PendingCN113283052APromote combustionImprove combustion effectDesign optimisation/simulationSpecial data processing applicationsAir volumeThermodynamics

The invention discloses a fly ash carbon content soft measurement method and a coal-fired boiler combustion optimization method and system. The fly ash carbon content soft measurement method comprises the following steps: 1, collecting historical operation parameters of a coal-fired boiler under multiple basic working conditions, and establishing an association relationship between the historical flue CO concentration and the historical fly ash carbon content under a plurality of basic working conditions; and 2, determining real-time working conditions and real-time operation parameters of the coal-fired boiler, and calculating the real-time fly ash carbon content under the corresponding real-time working conditions according to the real-time operation parameters and the association relationship established in the step 1. The boiler combustion optimization method is provided based on the fly ash carbon content of the coal-fired boiler, so that the total air volume of the boiler is adjusted according to the real-time fly ash carbon content of the coal-fired boiler, optimization of boiler combustion is finally achieved, and the combustion performance of the boiler is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

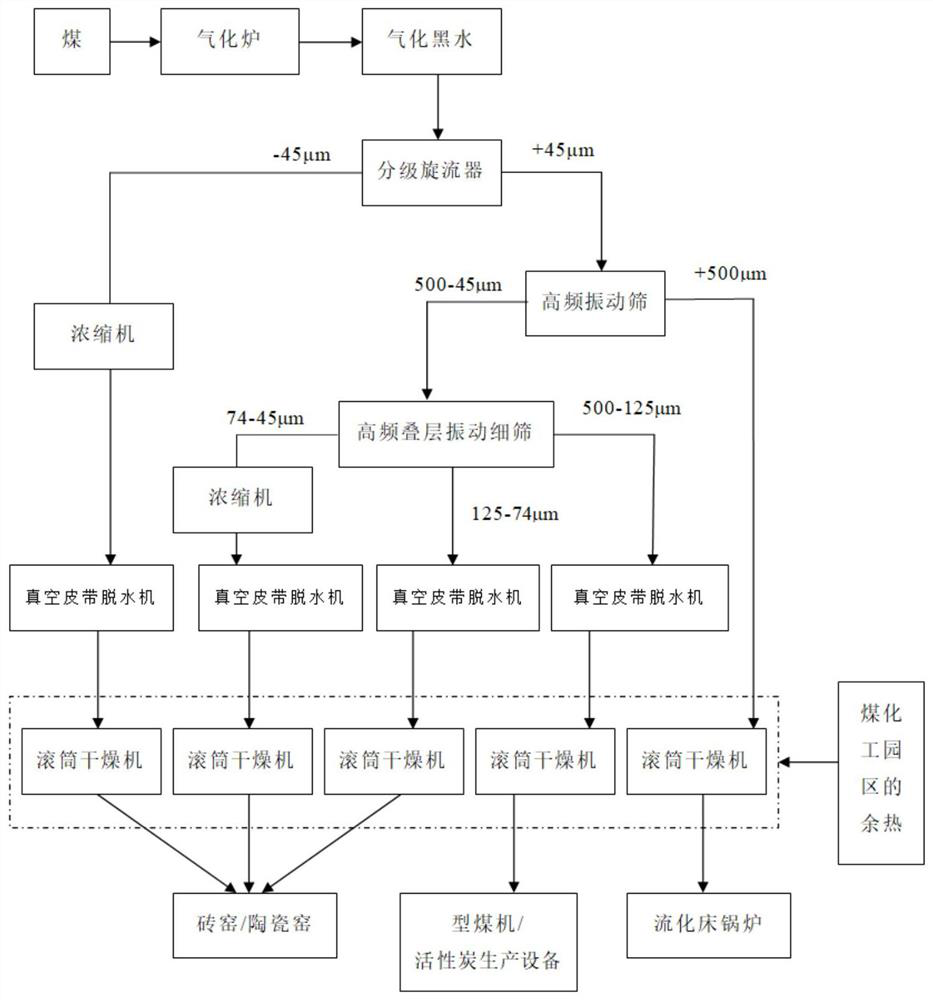

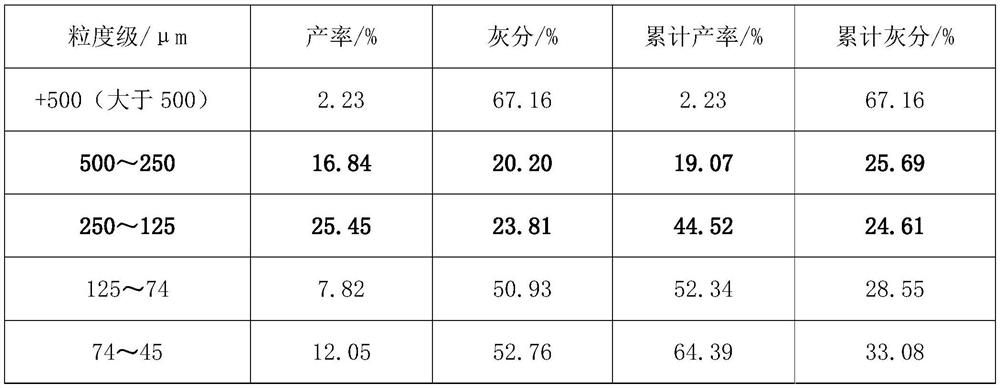

System and method for upgrading and utilizing coal gasification fine slag based on particle size classification

InactiveCN111715678AImprove the level of resource utilizationReduce pollutionSolid waste disposalTransportation and packagingSlagDrum drying

The invention discloses a system and method for upgrading and utilizing coal gasification fine slag based on particle size classification. The method includes the steps that the coal gasification fineslag is fed into a classifying cyclone, a high-frequency vibrating screen, and a high-frequency laminated vibration fine screen for classification, classified products are respectively fed to a filter press and a drum dryer for dry dehydration, and the dried products are respectively fed to a brick kiln / ceramic kiln, a coal machine / activated carbon production equipment and a fluidized bed boilerfor comprehensive utilization. Comprehensive utilization by classification and quality is carried out based on the general law that the carbon content of different granular products in the coal gasification fine slag continuously decreases with the decrease of the particle size and according to the granularity and carbon characteristics of different granular products, the process is simple, the quality improvement effect is good, the resource utilization level of the gasification fine slag can be effectively improved, and the pollution of the gasification fine slag to the environment is reduced.

Owner:山东茵温特节能环保科技有限公司

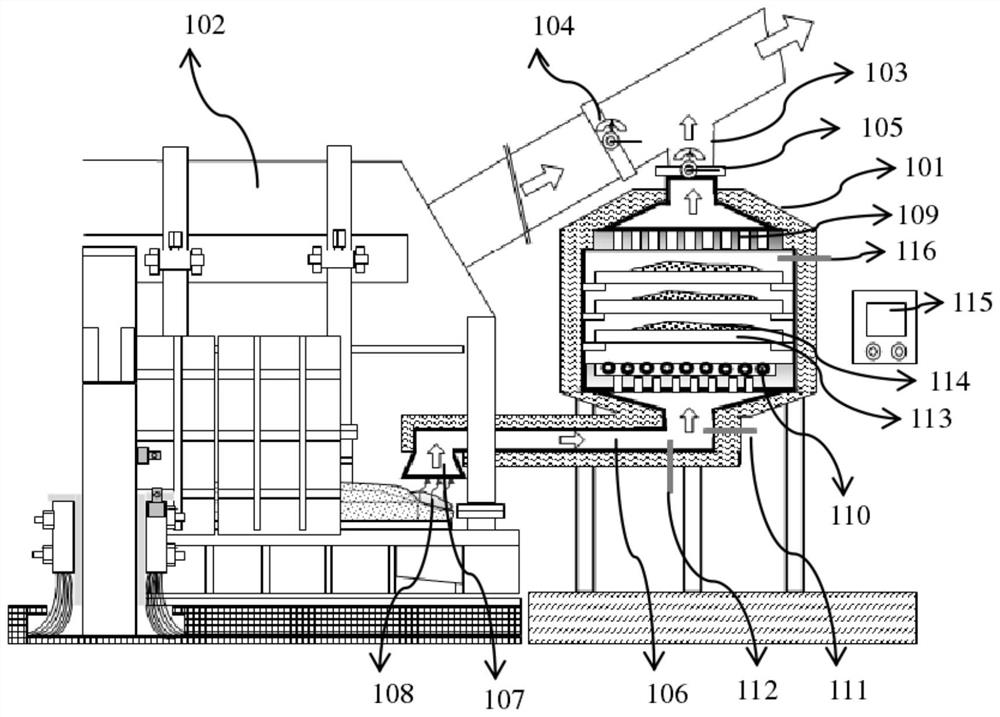

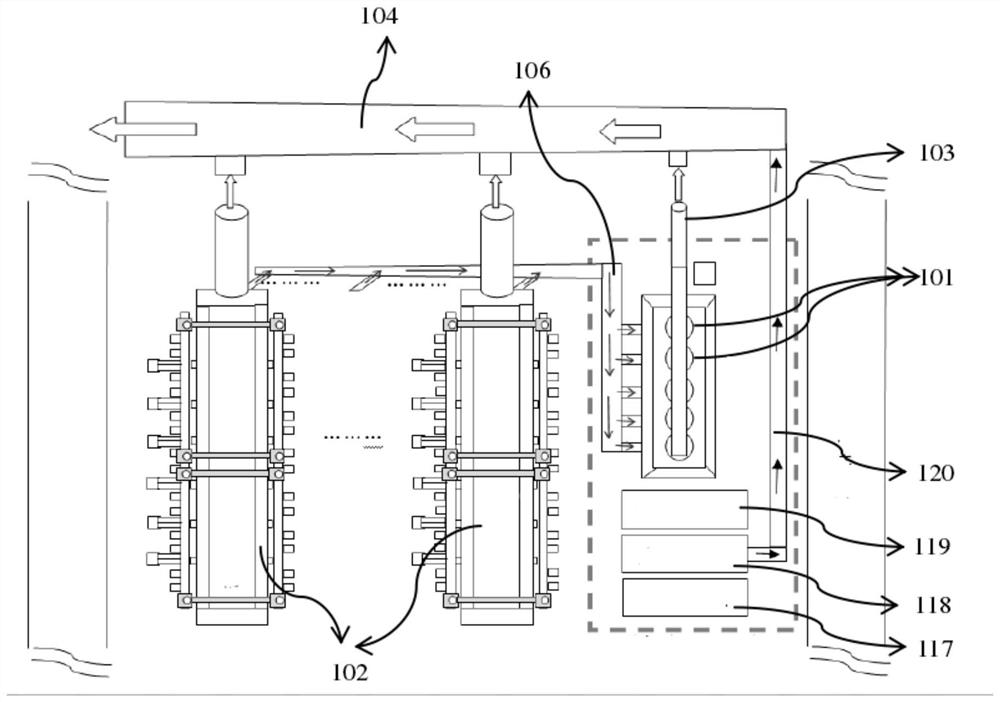

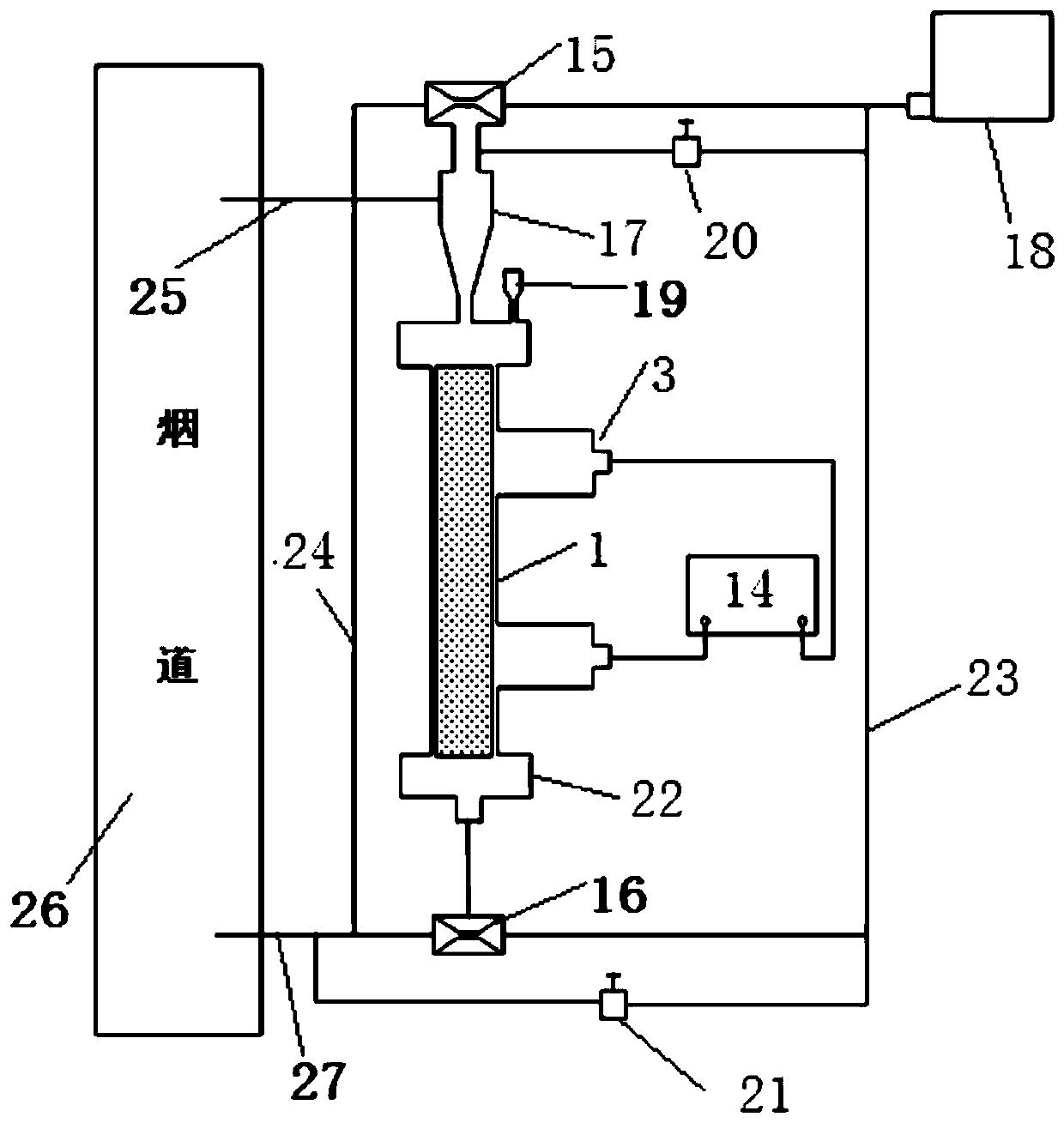

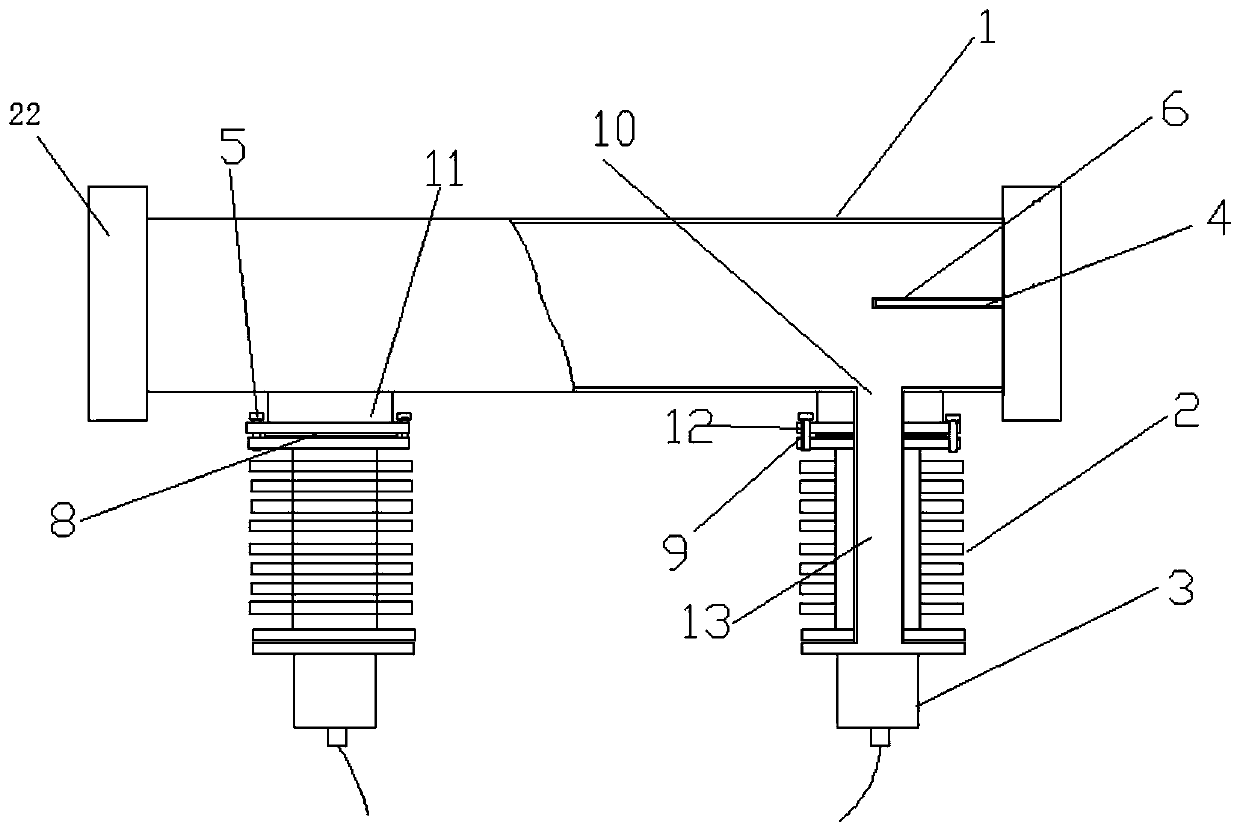

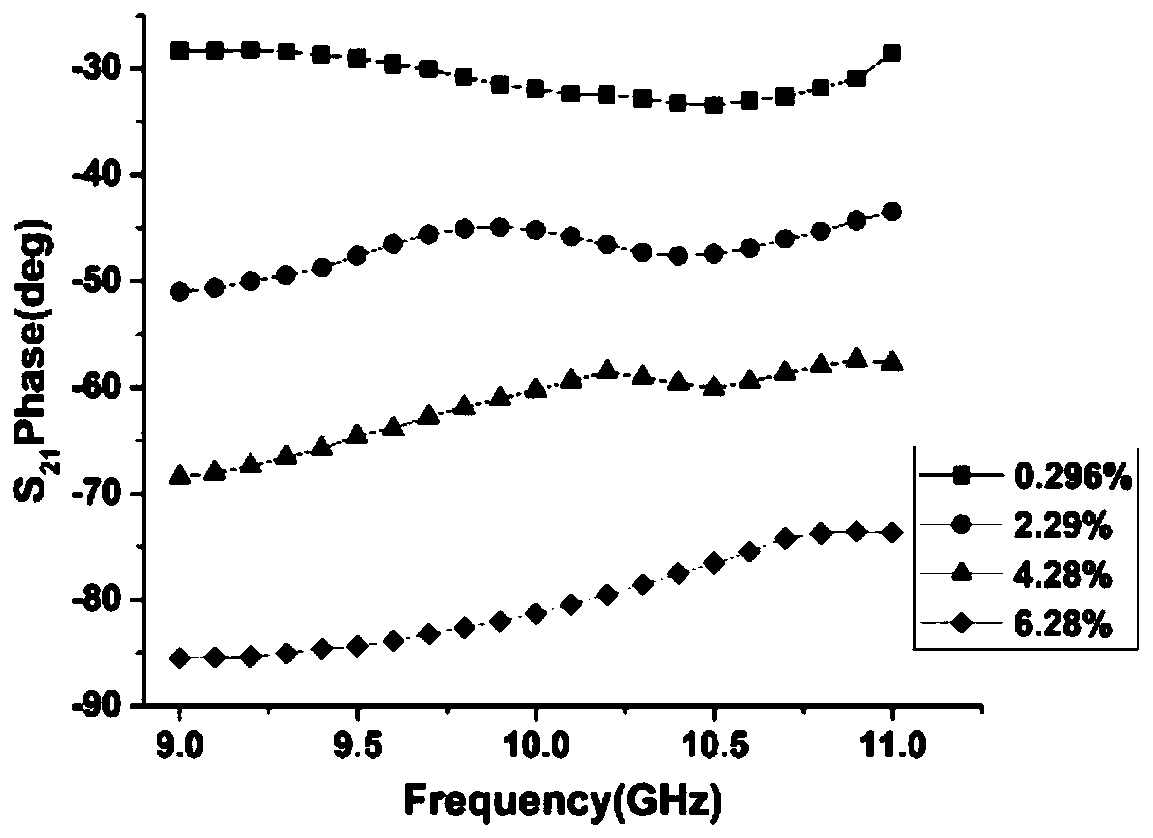

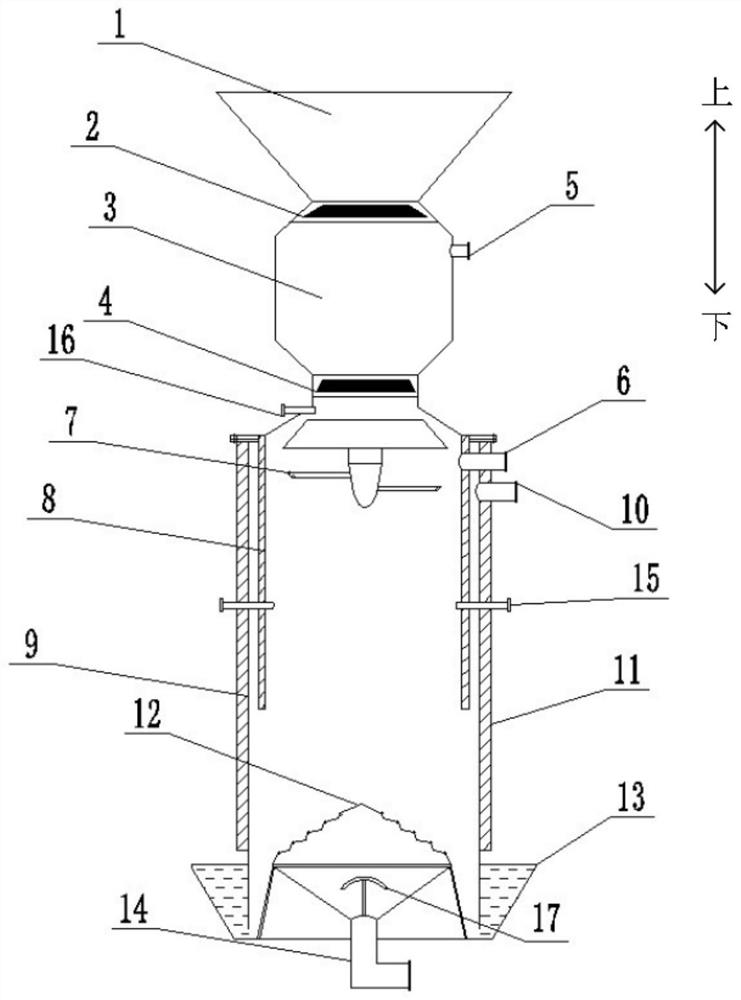

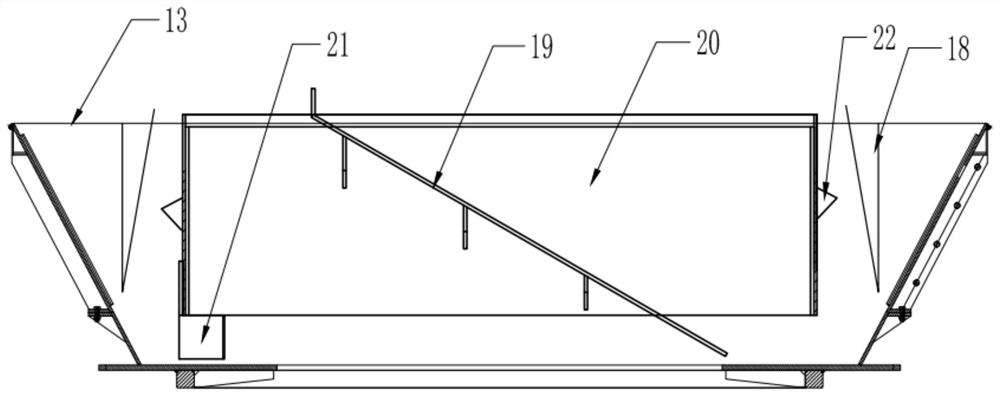

System and method for detecting carbon content of fly ash under dynamic condition of hollow metal waveguide

ActiveCN111060532AHigh resolutionImprove test accuracyMaterial analysis using microwave meansMeasurement deviceAir compressor

The invention provides a system and method for detecting the carbon content of fly ash under the dynamic condition of a hollow metal waveguide. The system comprises a bypass measuring unit and a measuring device, wherein the bypass measuring unit and the measuring device can measure the fly ash from a flue in real time. The measurement method comprises the steps of introducing a standard ash sample of the same kind of coal into the hollow metal waveguide for measurement to obtain S21 amplitude or phase data of the standard ash sample, and fitting the data to obtain a fitting relational expression of the standard ash sample at different frequency points; starting an air compressor to introduce the fly ash in the flue into the hollow metal waveguide through an ejector and a cyclone separator, selecting any frequency point through a vector network analyzer to test the introduced fly ash to obtain S21 amplitude or phase data of the measured ash sample, and substituting the S21 amplitude orphase data into the relational expression to calculate the carbon content. Compared with the prior art, the method has higher resolution and test precision, test results of different carbon contentsare stably and obviously distinguished, the carbon content is increased every 2%, the corresponding S21 amplitude parameter is changed by 15-20 degrees, and the precision is better.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

Internal circulating fluidized bed gasification furnace adapted to organic solid waste treatment

PendingCN112113222AGood dispersionWell mixedAir/fuel supply for combustionIncinerator apparatusSlagHearth

The invention discloses an internal circulating fluidized bed gasification furnace adapted to organic solid waste treatment which comprises a gasification furnace body, a furnace arch, a feeding hole,a blower nozzle and a slag discharging opening. A hearth is arranged in the gasification furnace body; the furnace arch is arranged on one side of the interior of the hearth; the feeding hole is formed in the other side of the interior of the hearth; the blower nozzle communicates with the hearth, and is arranged below the furnace arch; and the slag discharging opening is formed in the lower endof the hearth. Uniform air distribution can be realized in a high-flow-velocity fluidization area at the lower part of the hearth; through an internal circulation enhanced reaction zone in the middleof the hearth, the internal circulation of particles can be realized, the gasification reaction intensity is improved, the residence time is prolonged, and the conversion rate is improved; and in a dilute phase area at the upper part of the hearth, a proper height-diameter ratio is adopted, so that the reduction reaction time of gasified synthesis gas is prolonged, combustible gas with higher quality is obtained, the carbon content of fly ash is reduced, and the emission of dioxin and NOx is reduced.

Owner:HUBEI JIADE TECH

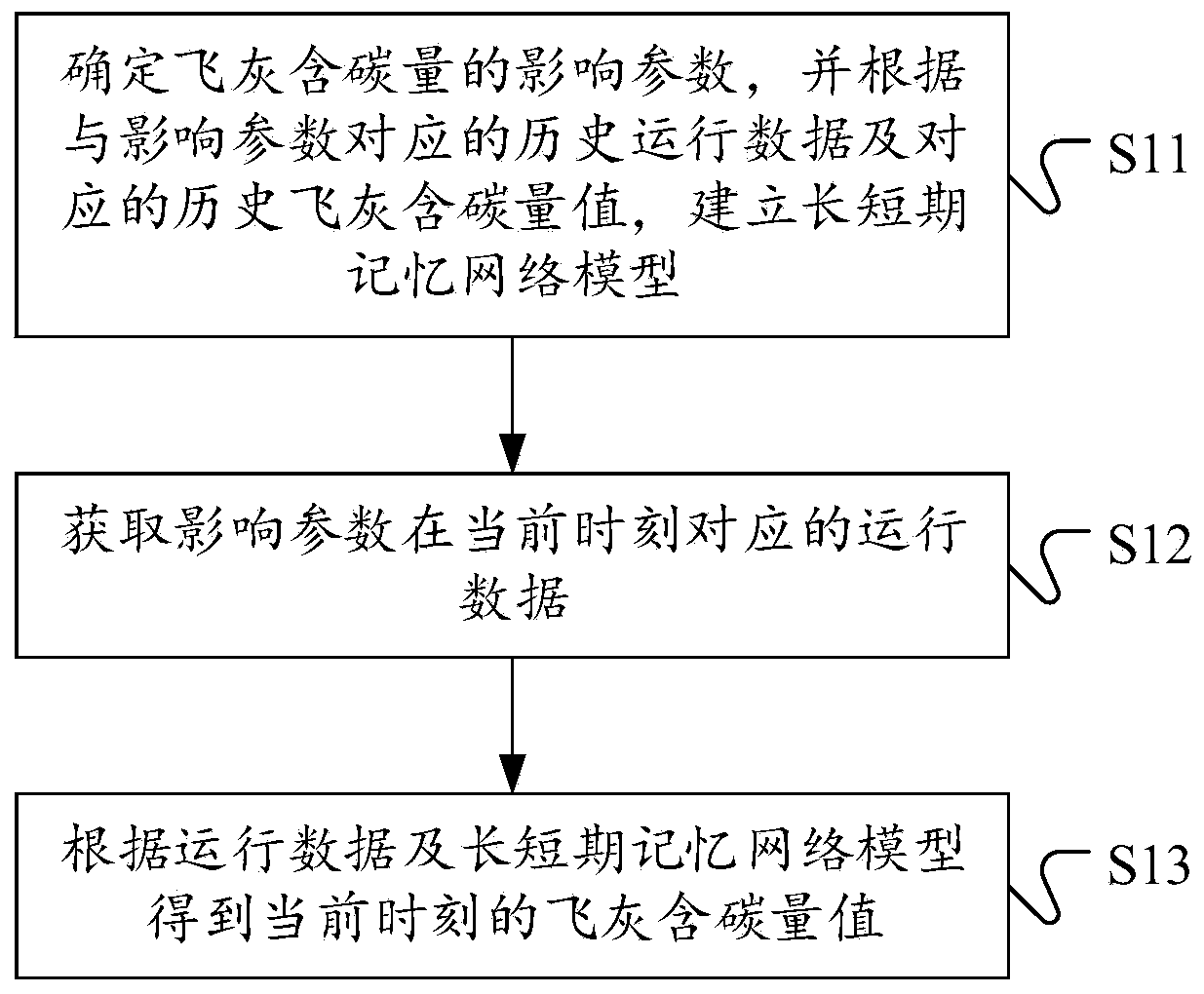

Fly ash carbon content prediction method, device and apparatus and readable storage medium

The invention discloses a fly ash carbon content prediction method, device and apparatus and a computer readable storage medium, and the method comprises the steps: determining an influence parameterof fly ash carbon content, and building a long-term and short-term memory network model according to historical operation data corresponding to the influence parameter and a corresponding historical fly ash carbon content value; obtaining operation data corresponding to the influence parameters at the current moment; and obtaining the fly ash carbon content value at the current moment according tothe operation data and the long-term and short-term memory network model. According to the technical scheme, the long-term and short-term memory network model is a time recurrent neural network. Historical information can be used for helping a current decision, so that the dynamic prediction of the carbon content of the fly ash can be realized through the established long-term and short-term memory network model and the operation data of the influence parameters at the current moment, and the accuracy of the prediction of the carbon content of the fly ash can be improved.

Owner:华润电力技术研究院有限公司

Organic solid waste double-layer furnace body wet ash discharge fixed bed gasification furnace and gasification method

PendingCN112694915ALower gas temperaturePrevent slaggingGasification processes detailsCombustible gas productionThermodynamicsSlag

The invention discloses an organic solid waste double-layer furnace body wet ash discharge fixed bed gasification furnace and a gasification method, the gasification furnace comprises a feeding device, a reaction zone furnace body comprising an upper section furnace body and a lower section furnace body, a furnace top gasification agent gas inlet, a middle section gasification agent gas inlet, a furnace bottom gasification agent gas inlet, a coal gas outlet and a deslagging device, an annular cavity is formed between the upper section furnace body and the lower section furnace body, the coal gas outlet is formed in the side wall, corresponding to the annular cavity, of the lower section furnace body and located between the furnace top gasifying agent inlet and the middle section gasifying agent inlet, and the slag discharging device is arranged in water and comprises an ash tray, a slag crushing ring, a fire grate supporting piece and a first ash knife. The gasification furnace can be applied to gasification treatment of various carbon-containing organic solids, solves the problems of high tar content and gas leakage at a feeding hole of a reverse-flow type gasification device capable of moving in opposite directions of coal gas and a material layer, and also solves the problem of high carbon content in solid-phase ash of a co-current gasification device with coal gas and material layer moving in the same direction.

Owner:苏州允清环境能源科技有限公司 +1

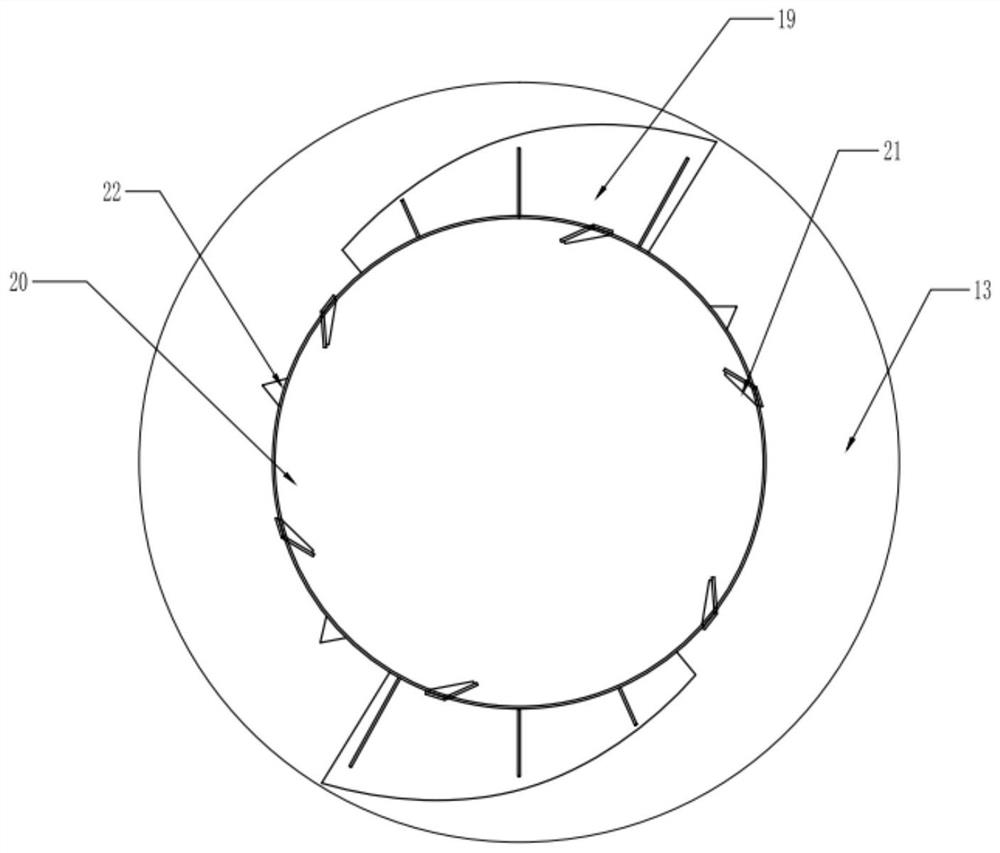

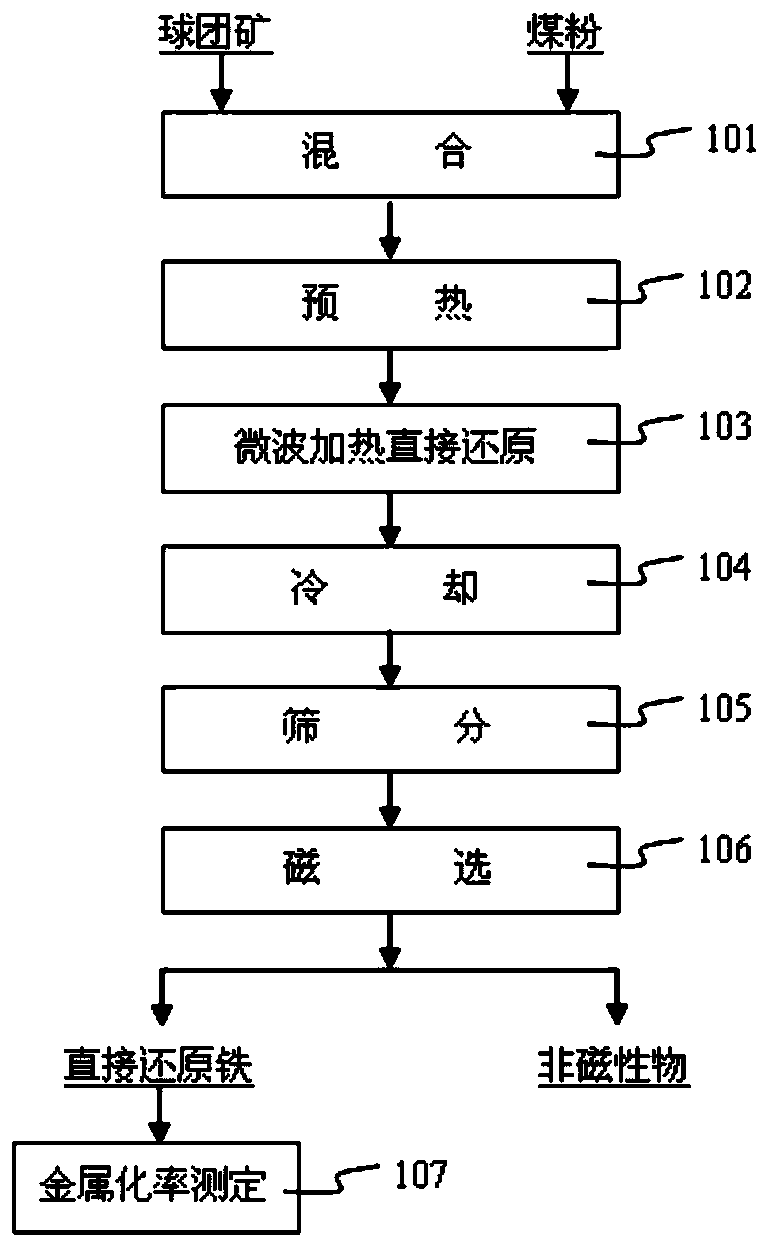

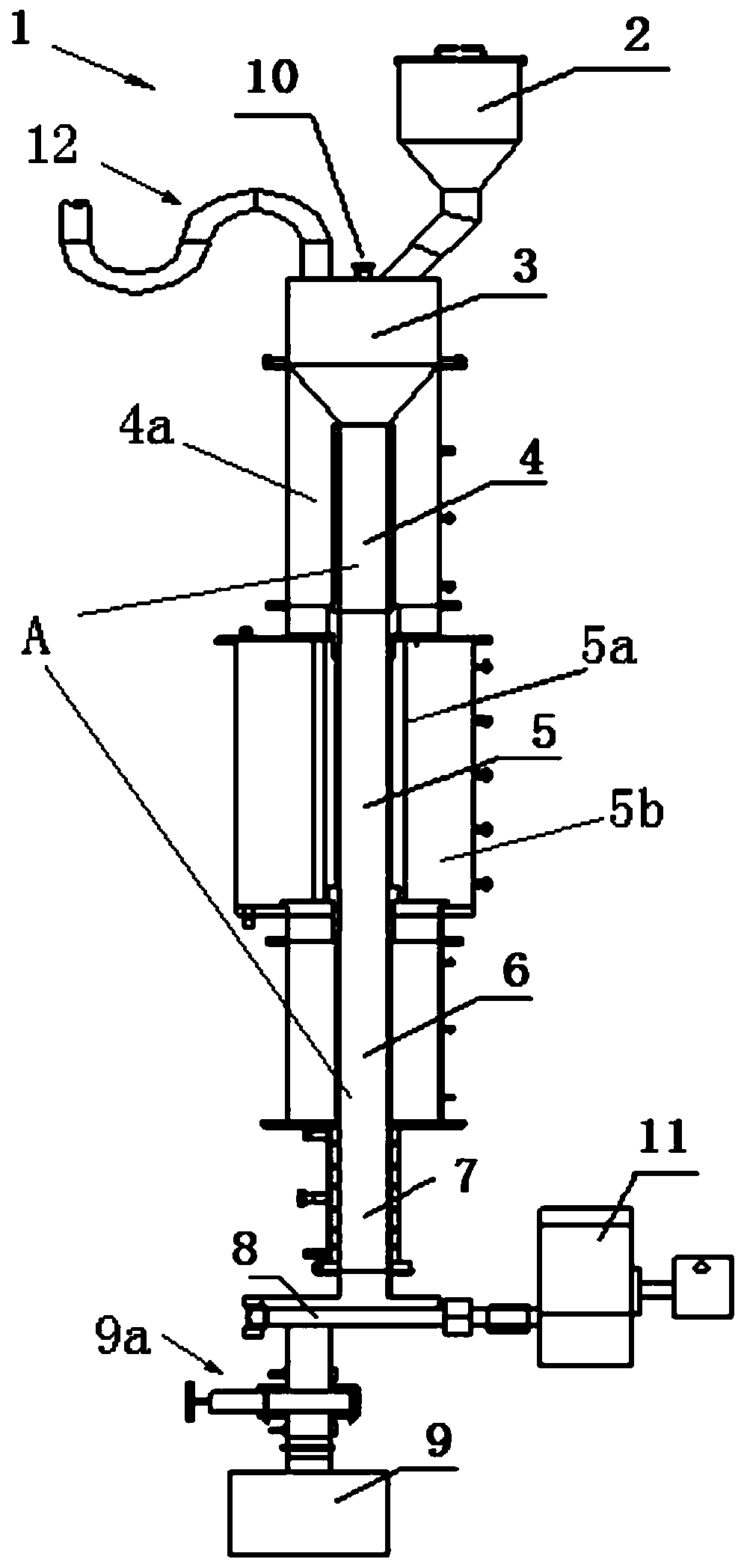

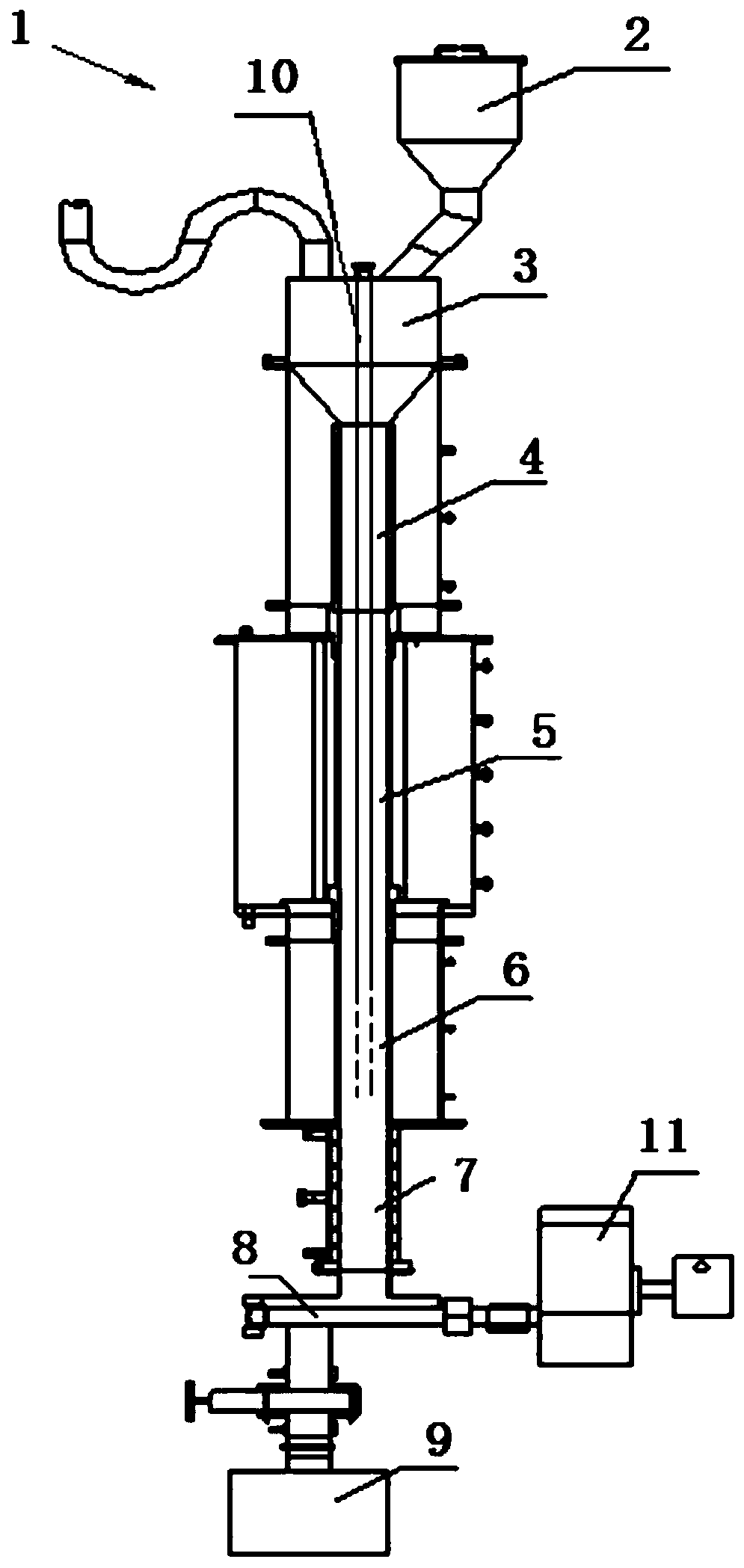

A method and device for producing direct reduced iron

ActiveCN107779536BReduce the temperatureLower requirementShaft furnaceProcess efficiency improvementChemical reactionShaft furnace

The invention relates to a microwave shaft furnace direct reduction process adopting pellets and coal powder. According to the process, direct reduced iron is produced from raw material pellets and external matched material coal powder in a continuous microwave shaft furnace, selection heating, rapid heating, volume heating, activated metallurgical chemical reaction and other features of the microwave are fully utilized, gasification of fixed carbon is accelerated, and iron oxide is further reduced, so that the reduction temperature is lowered and the reaction time is shortened. The coal powder can serve as both a reducing agent and a heating element in the process, a gas-solid-heat exchange step is simplified, energy is saved and emission is reduced. The process contains low free oxygen content, and can produce CO with high purity of 95% or above; and the process is compact in structure, high in metallization degree, which is 94-98%, low in carbon content, which is less than 0.2%, andis low in quality requirements on coal powder, thereby being an environment-friendly iron making process.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

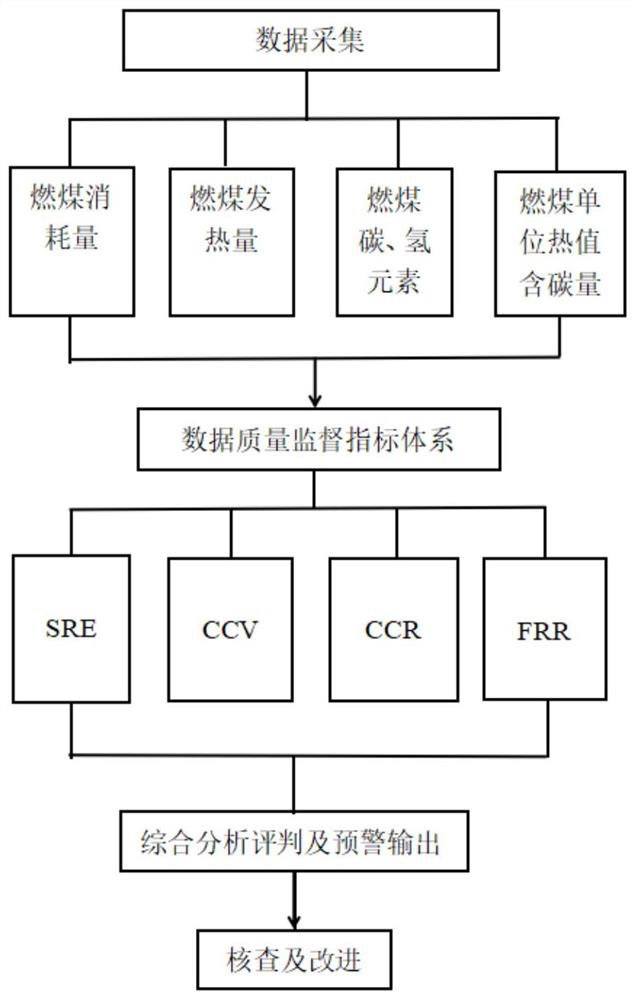

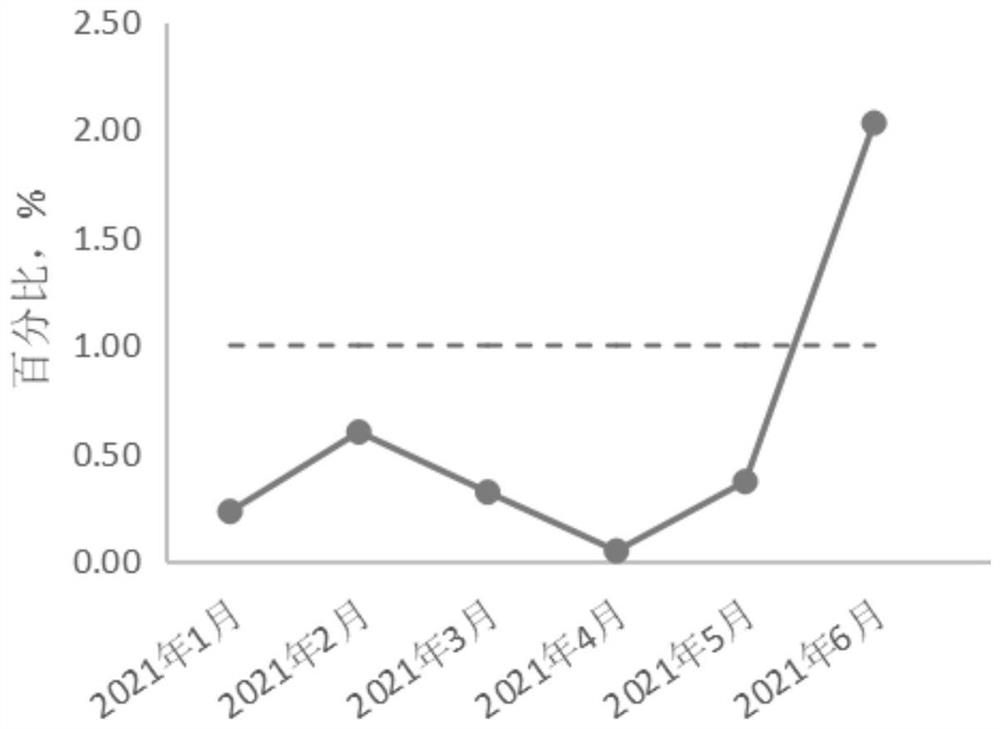

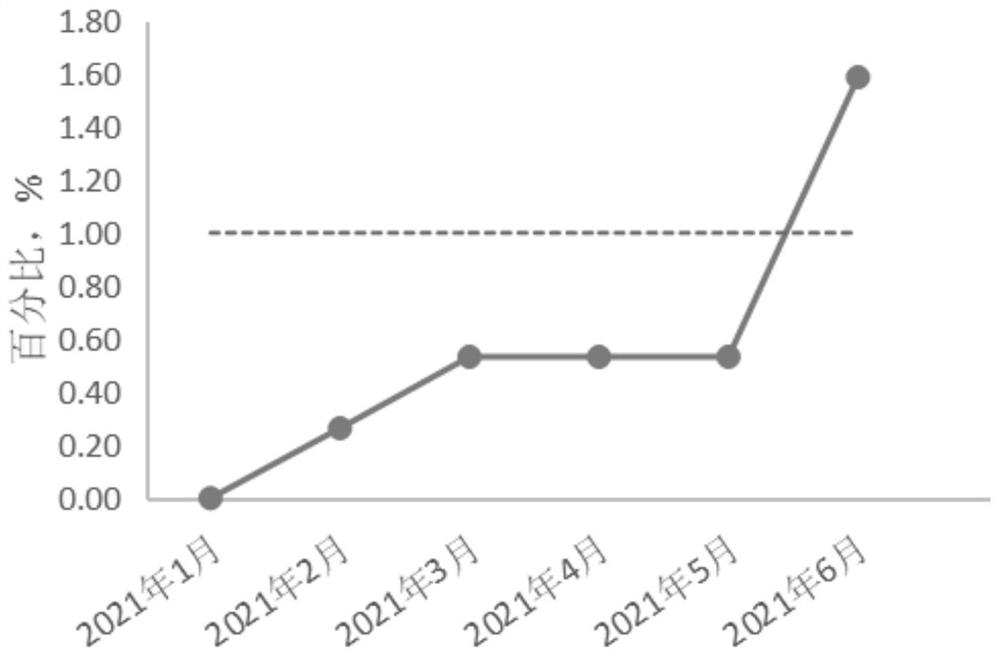

Thermal power enterprise fire coal carbon emission data quality checking method and system

PendingCN114493239AImprove data quality monitoring capabilitiesTimely correctionTechnology managementResourcesSource Data VerificationDischarge data

The invention discloses a fire coal carbon emission data quality checking method and system for a thermal power enterprise. The method comprises the following steps: S1) collecting key index data of a thermal power generating unit; s2) constructing a quality checking index based on the key index data; s3) comprehensively analyzing and evaluating each quality checking index, and performing early warning output according to the comprehensive analysis and evaluation; s4) according to the quality inspection indexes in the S3), comprehensively analyzing the judgment result and the early warning output result, formulating an inspection scheme, and inspecting the fire coal carbon emission data of the thermal power enterprise according to the inspection scheme; the invention provides a method for analyzing and judging the reliability of monitoring data such as coal-fired carbon emission key index coal-fired coal unit calorific value carbon content and comprehensive sample representativeness, so that the internal data quality monitoring capability of an enterprise is improved; through the execution of the early warning scheme, the problem links of data abnormity can be effectively traced and verified, and timely correction and improvement can be carried out, thereby reducing the adverse risk caused by the inconformity of the data quality and the data verification of related departments.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD +1

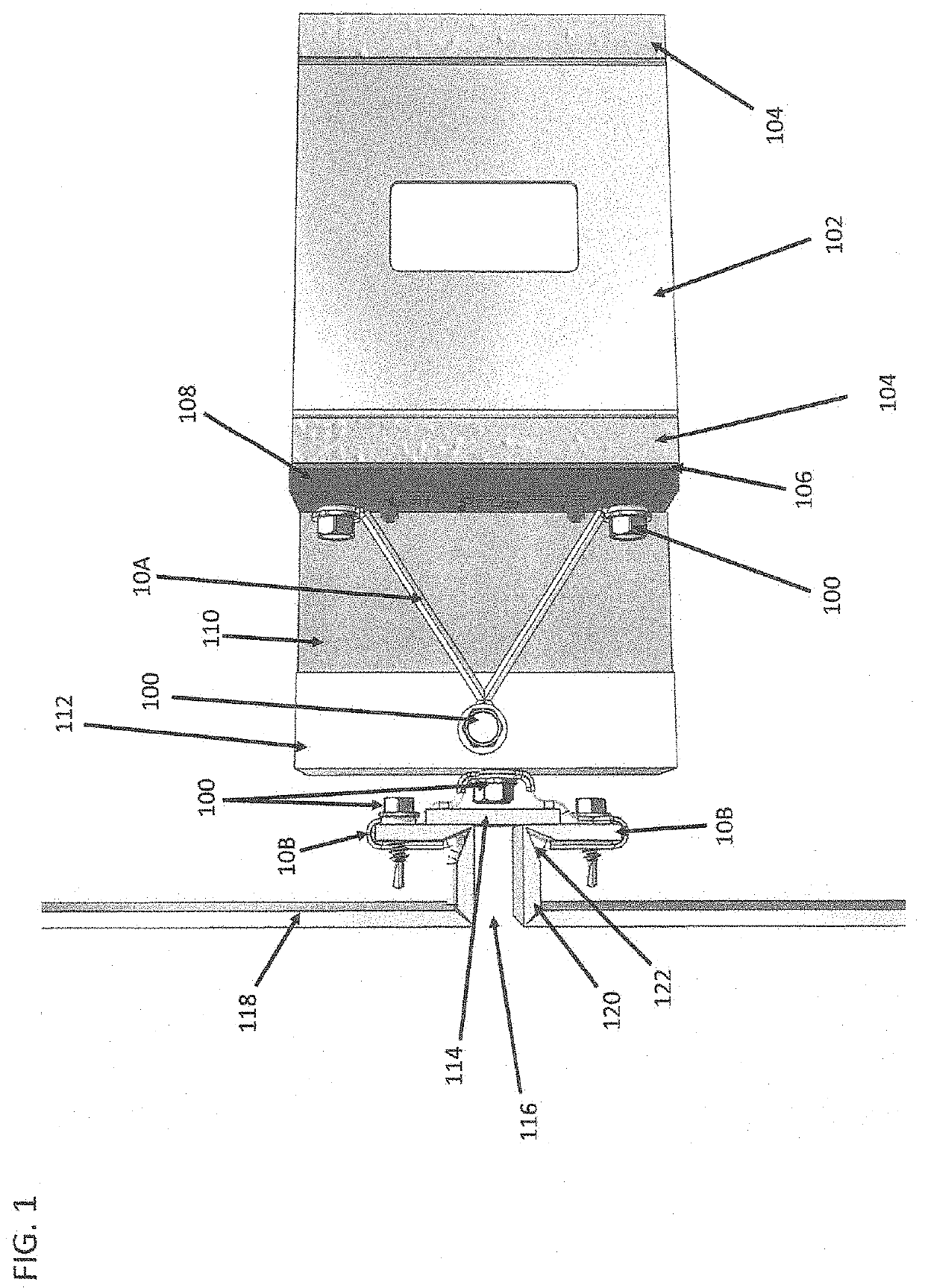

Wire Mounting Solutions

PendingUS20220251849A1Reduce carbon footprintLow costCovering/liningsHeat proofingClassical mechanicsEngineering

Wire Mounting Solutions providing low embodied carbon insulation and façade mounting systems having unmatched thermal and acoustic performance, high structural strengths, and better able to withstand seismic and hurricane activity where other mounting systems may fail due to being too rigid.

Owner:SIMONSEN DAVID JOHN

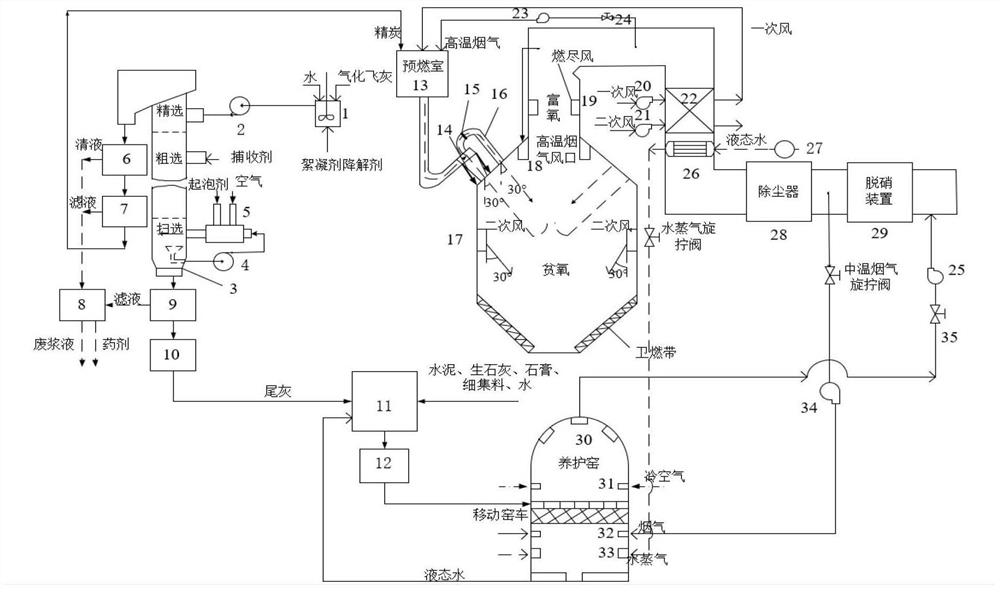

Gasification fly ash grading resource utilization system and method

ActiveCN113522929AImprove separation efficiencyHigh value-added utilizationSolid waste disposalDrying machine combinationsBrickWater vapor

The invention discloses a gasification fly ash grading resource utilization system and method. In order to solve the problems that gasified fly ash is low in volatile component content, higher in ash content, difficult to ignite directly, short in hearth retention time and the like, the invention provides a gasification fly ash grading resource utilization system and method. The system is divided into a flotation system, a pre-combustion system, a combustion system and a wall brick preparation system. According to the system, cyclic utilization of chemical reagents in a flotation system, pre-combustion of refined carbon, angle arrangement of a combustor in a hearth, angle arrangement of secondary air and surrounding air in the hearth, over fire air oxygenation treatment and heat energy utilization of smoke and water vapor are comprehensively considered, according to the system and method, high-value additional utilization of the refined carbon and tail ash is helpful in solving the problem that the gasified fly ash cannot be massively used for building materials due to too high carbon content, and is expected to solve the problems of aggravated abrasion of boiler equipment and the like caused by blending combustion of bituminous coal in a boiler by the gasified fly ash.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com