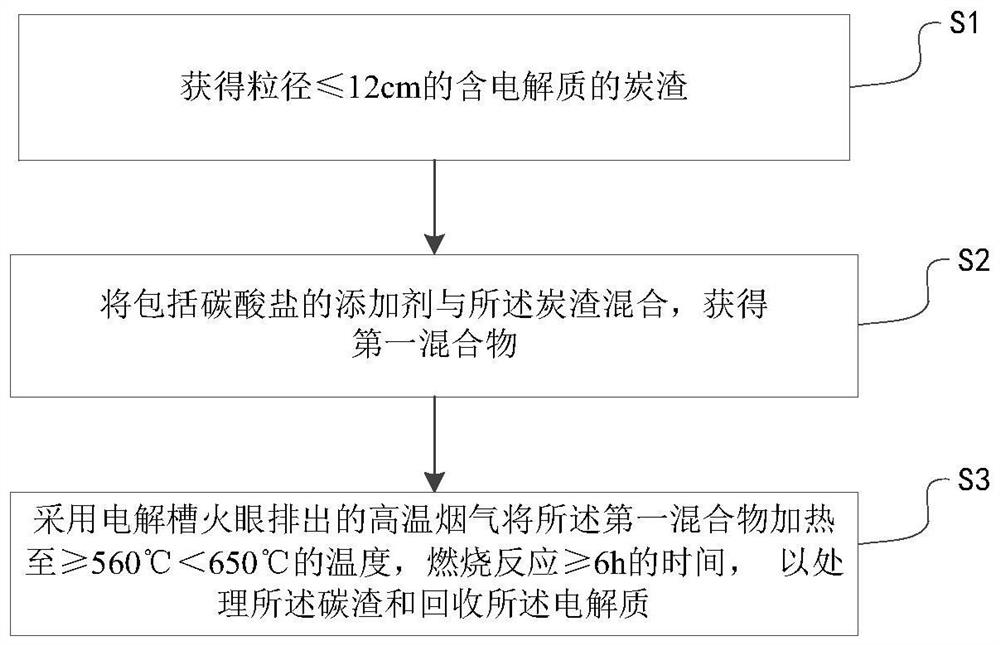

Method and device for treating carbon residues and recycling electrolyte

An electrolyte and carbon slag technology, which is applied in the field of carbon slag recovery electrolyte, can solve the problems of roasting furnace corrosion, high cost, short life, etc., and achieve the effect of low impurity content and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

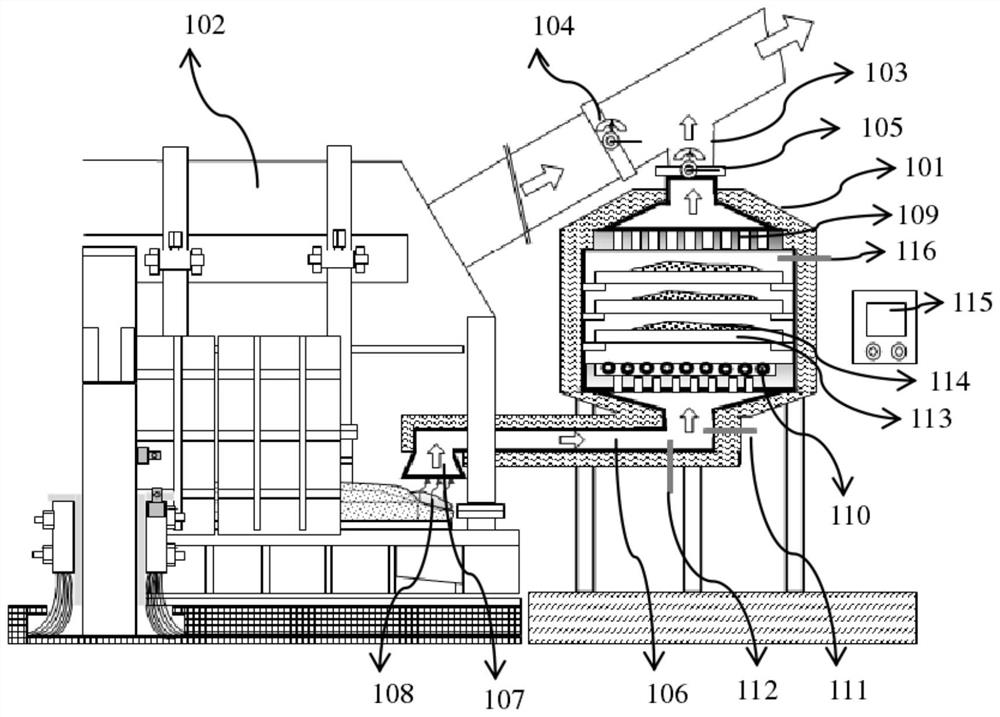

[0068] At the flue end of a 400kA electrolytic cell in an electrolytic aluminum enterprise, a combustion box is installed, such as figure 1 shown. The 400kA electrolyzer produces a total of about 30kg of carbon residue per day (about 10kg per 8 hours).

[0069] 1) The charcoal slag to be treated produced after the electrolysis of the electrolytic cell is crushed so that its particle size is less than 12 cm. Mix the charcoal slag particles and sodium carbonate with a mixer according to the mass ratio of 3:100 to form the first mixture, and pack them in three trays 113, each tray 113 is loaded with 4kg, and the charcoal slag is flattened, and the flattened thickness is less than 5cm ;

[0070] 2) Put the tray 113 into the combustion chamber of the combustion chamber 101, and close the chamber door;

[0071] 3) Open the valve 105 on the exhaust pipe 103, so that the high-temperature flue gas discharged from the fire hole at the flue end of the electrolytic cell enters the comb...

Embodiment 2

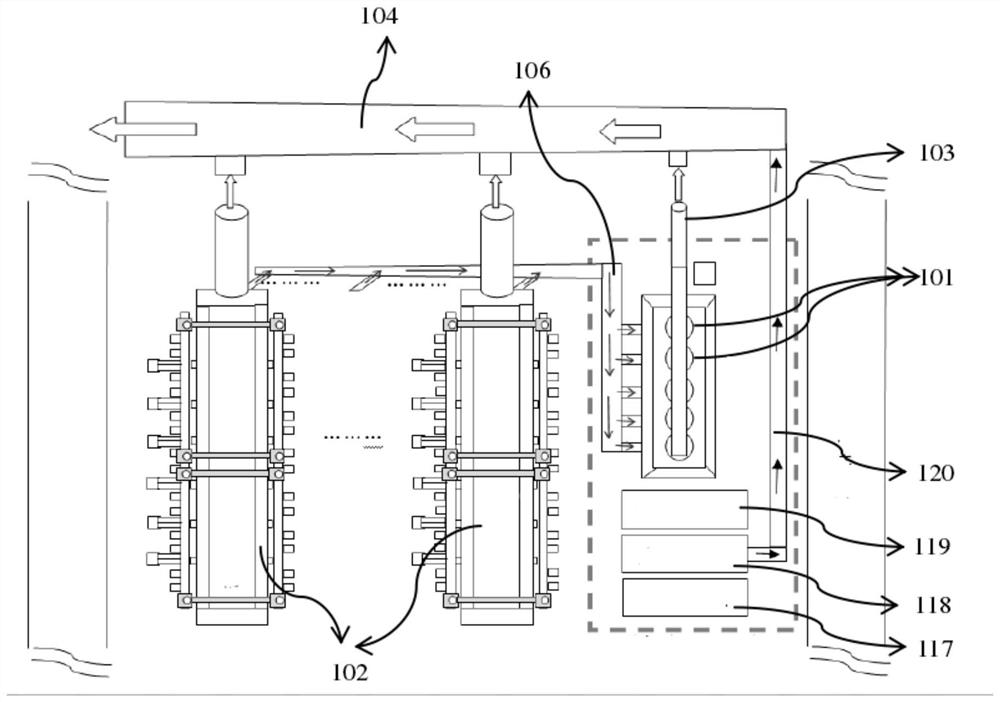

[0076] In the reserved area of a work area of a 400kA electrolytic workshop of an electrolytic aluminum enterprise, a centralized combustion box is set up, such as Figure 3-4 shown.

[0077] There are 36 sets of 400kA electrolytic cells in this work area, which produce about 360kg of carbon residue every 8 hours, and a total of about 1080kg of carbon residue is produced every day.

[0078] 1) Place the charcoal slag in the whole work area of the electrolysis workshop in the charcoal slag box 117, and the charcoal slag is crushed in the crusher 118 to become charcoal slag particles with a particle size of less than 12mm; the gas collecting pipe 120 is opened during the crushing process to discharge the smoke to In the flue gas pipe 104.

[0079] 2) Mix the crushed charcoal slag into the industrial AlF which accounts for 5% of the mass of the charcoal slag 3 and calcium carbonate accounting for 1% of the mass of charcoal slag, mixed to form the first mixture, loaded int...

Embodiment 3

[0088] Embodiment 3 takes embodiment 1 as a reference, and embodiment 3 is different from embodiment 1 in that:

[0089] The surface of the first mixture was sprayed with 30% hydrogen peroxide in the mass fraction of sodium carbonate, the mass ratio of carbon residue particles to sodium carbonate was 5:100, the heating temperature was 610°C, and the rest were the same as in Example 1.

[0090] Processing effect:

[0091] 1) Treat 3 heats per day, and process all the charcoal slag in this tank, totaling about 30kg, and recover about 21.8kg of electrolyte accumulatively. The auxiliary heating system consumes about 24kwh of alternating current accumulatively every day, and the average power consumption per kilogram of carbon residue is 0.8kwh / kg.

[0092] 2) Sampling the recovered electrolyte and analyzing the carbon content, the carbon content is about 0.191%, which is basically equivalent to the carbon content analysis result of the electrolyte in the electrolytic cell.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com