Patents

Literature

80results about How to "Improve the level of resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

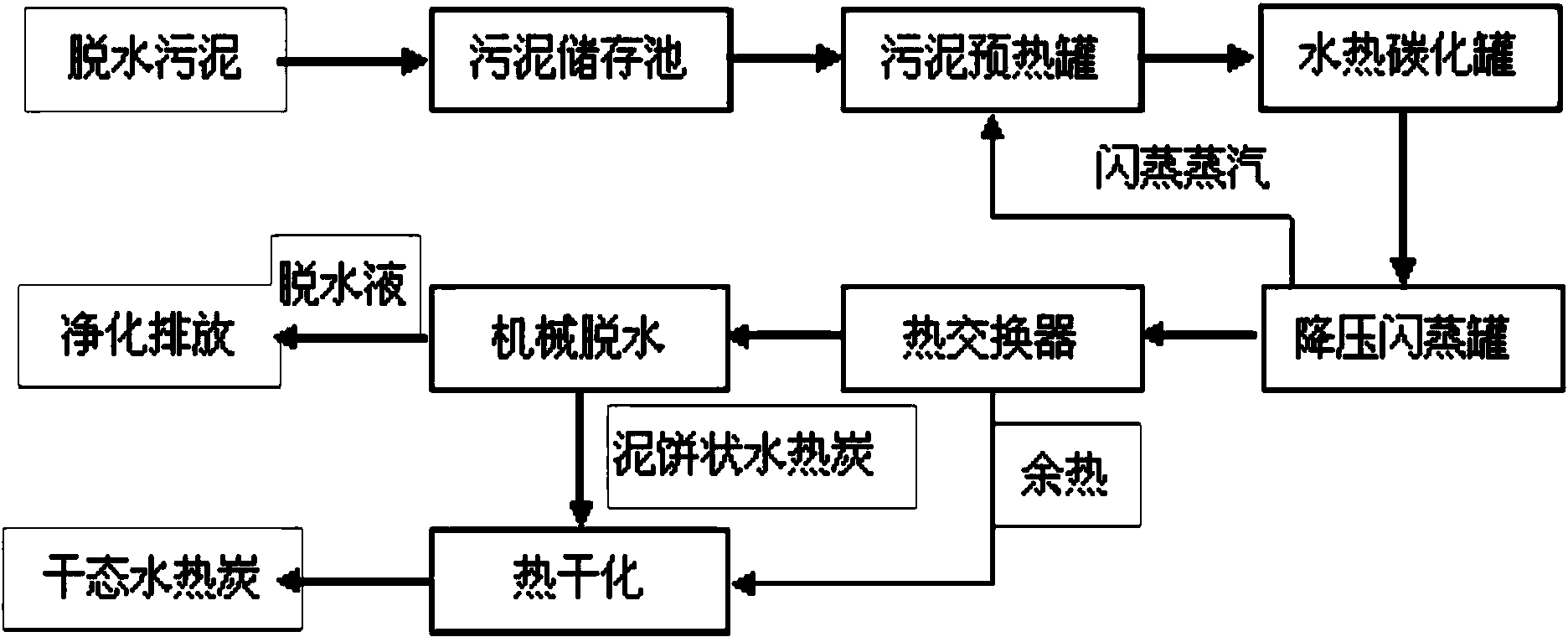

Sludge treatment method based on hydrothermal carbonization

InactiveCN103755124AEmission reductionIncrease organic carbon contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeToxic material

The invention relates to a treatment method of sludge generated by urban sewage treatment plant and industrial sludge and discloses a sludge treatment method based on hydrothermal carbonization. The sludge treatment method comprises four steps: sludge preheating treatment, hydrothermal carbonization, waste heat recovery and dehydration desiccation. By adopting the sludge treatment method, as the sludge is converted to hydrothermal carbon by adopting a hydrothermal carbonization technology, pathogenic microorganisms in the sludge are completely killed, most heavy metal pollutants in the sludge are dissolved out, and organic toxic substances in the sludge are effectively decomposed, so that the energy recovery utilization rate is high, and the sludge treatment method is clean, environment-friendly, rapid and effective and has high product additional values.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

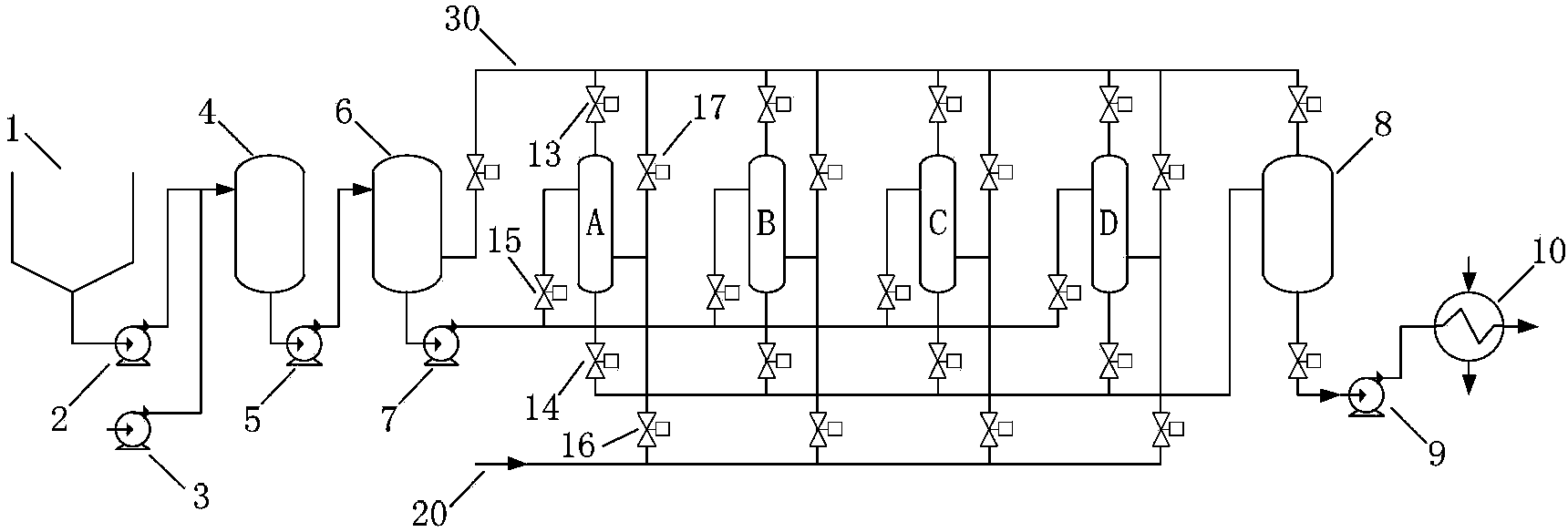

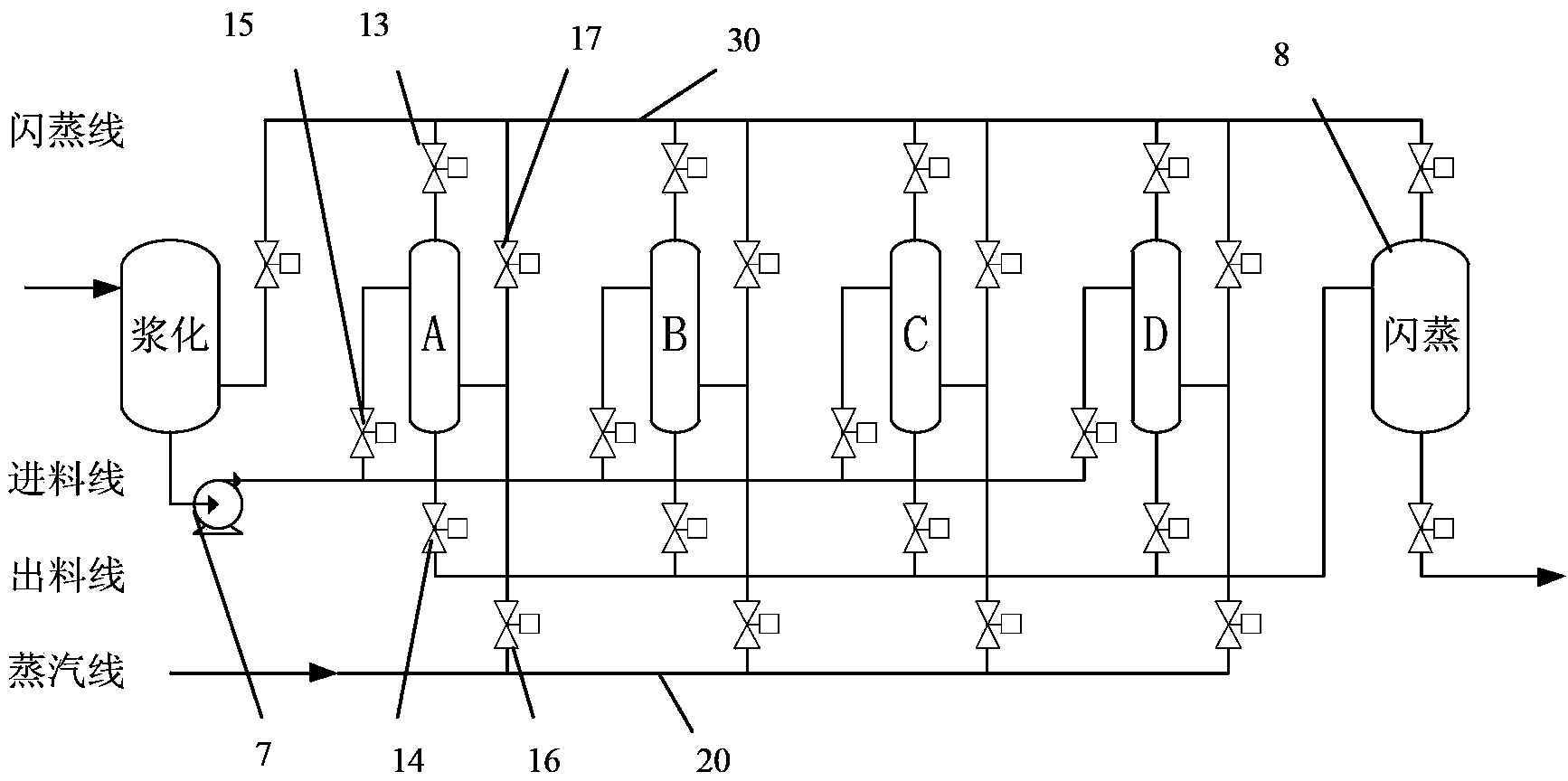

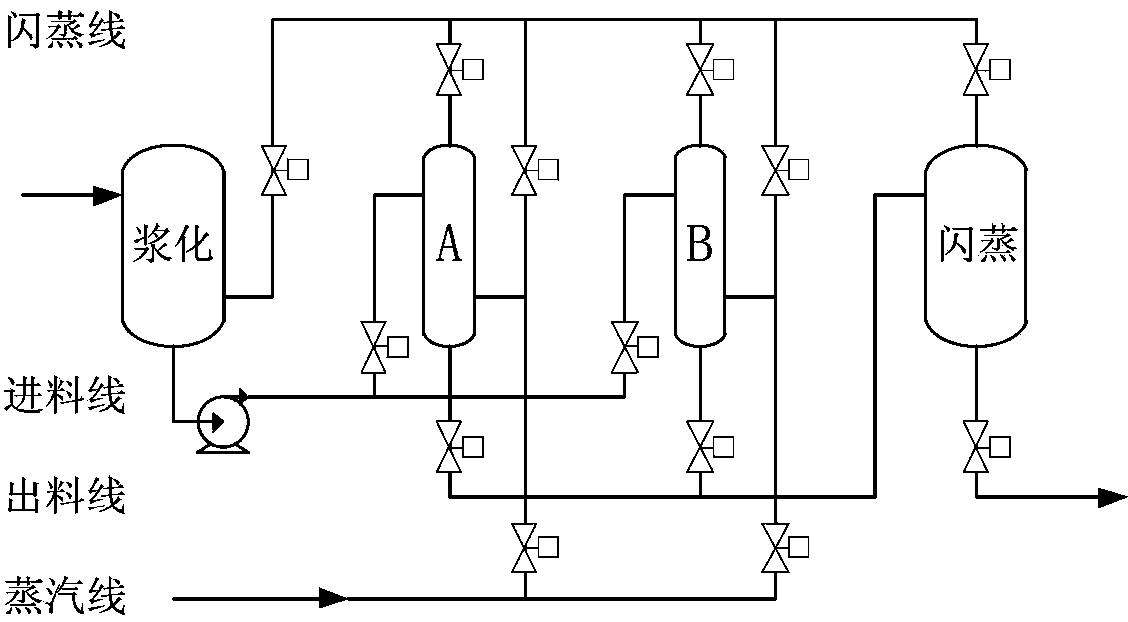

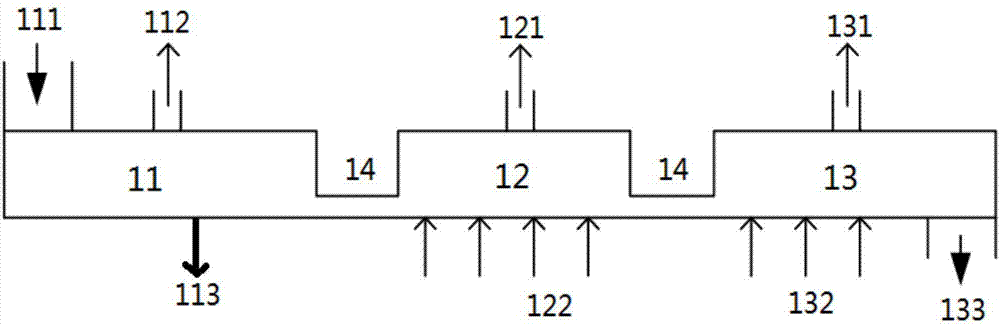

Biomass waste hydrothermal processing method and system thereof

ActiveCN103386411AReduce energy consumptionContinuous consumptionSolid waste disposalSludge treatment by pyrolysisBiomassProcess engineering

The invention provides a biomass waste hydrothermal processing method and a system thereof. The method comprises the steps that: a material is sequentially subjected to slurrying preheating treatment, high-pressure-steam hydrothermal treatment, and flash evaporation treatment. Steam adopted in the hydrothermal treatment comprises raw steam and secondary steam. According to the secondary steam, with steam pressure difference between hydrothermal reaction devices, steam pressure and temperature equalization of the two hydrothermal reaction devices are finished. Through multilevel pressure equalization between the hydrothermal reaction devices, heat exchange efficiency is improved, and raw steam consumption amount can be reduced.

Owner:青岛伟华新能源科技有限公司

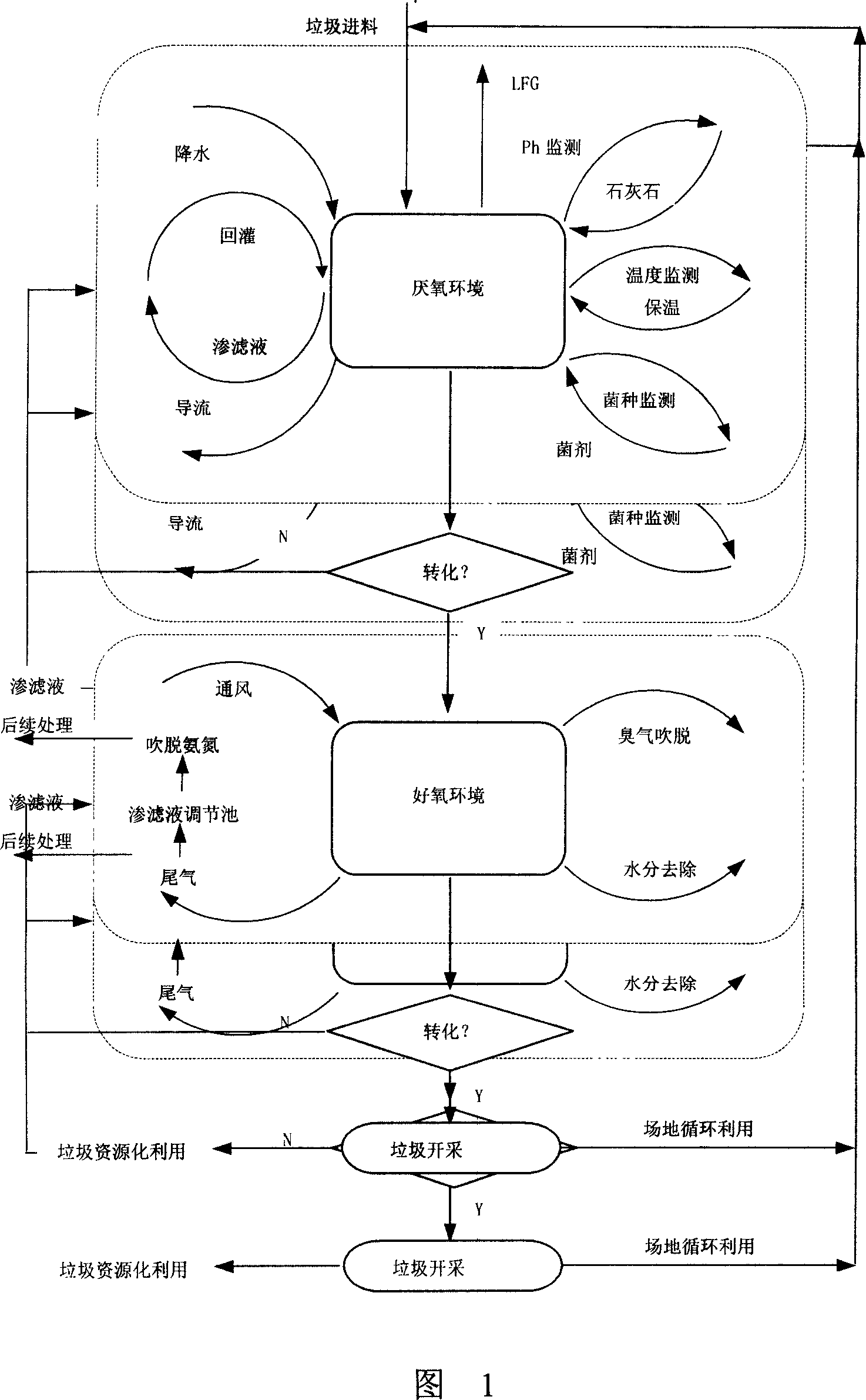

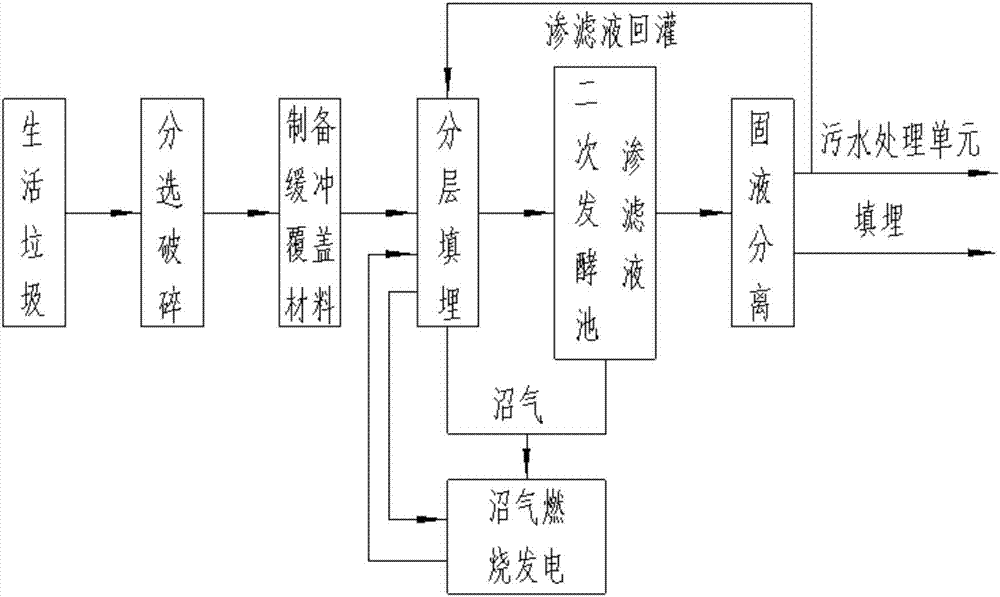

Domestic refuse anaerobic-aerobic reactor circulating operation landfill method

InactiveCN1923382AReduce processing difficultySolve the waste of land resourcesSolid waste disposalWater qualityOxygen

The invention relates to a method for embedding life waste via anaerobic-aerobic reactor. Wherein, it comprises that embedding anaerobically the life waste, the generated filter water refluxes to the top of embed layer, and recycles the embed gas; refluxing, to reach certain technique standard, stopping refluxing filter water, to ventilate the embed layer; making said embedded layer in aerobic condition, to remove the water and smell gas of waste layer, lead tail gas into filer water to remove ammonia nitrogen; stopping aerobic step; treating waste water, selecting putrefactive waste to be recycled. The invention can reduce cost and improve the quality of filter water.

Owner:HUAZHONG UNIV OF SCI & TECH

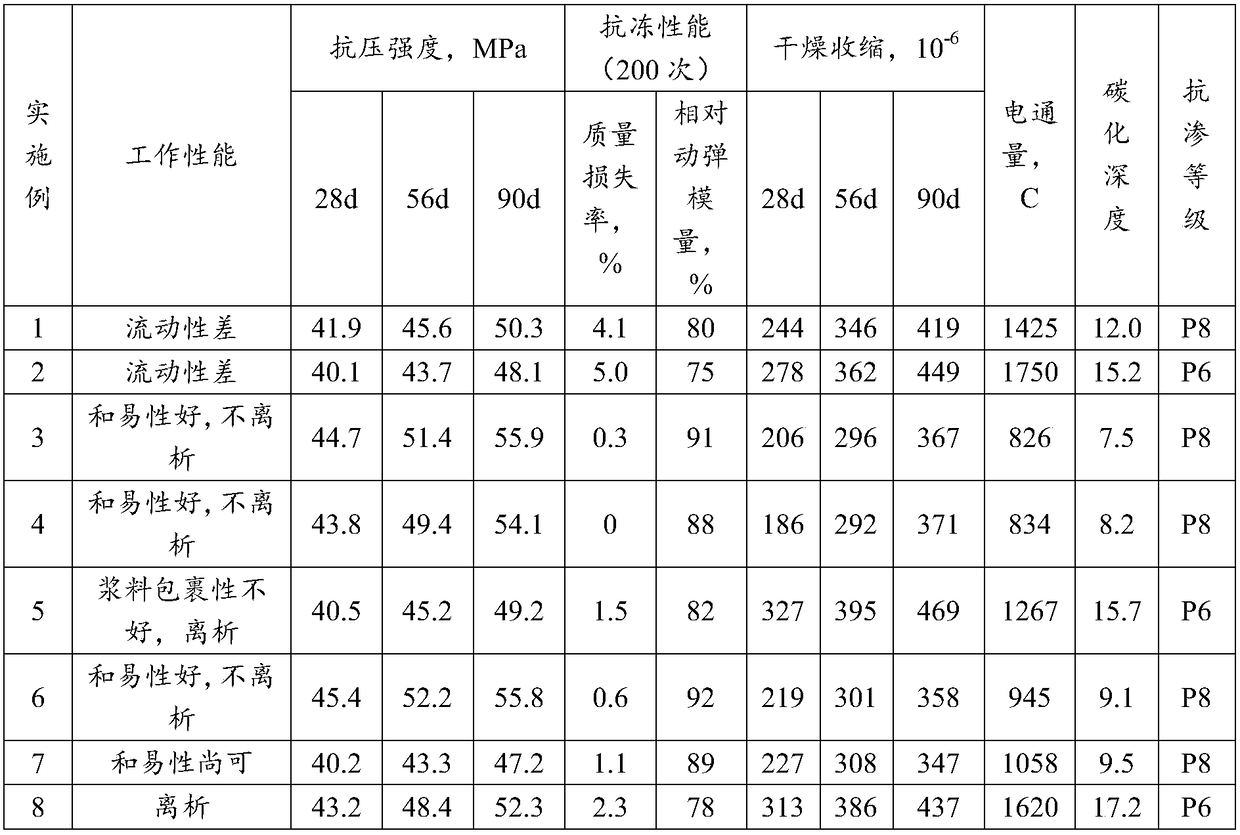

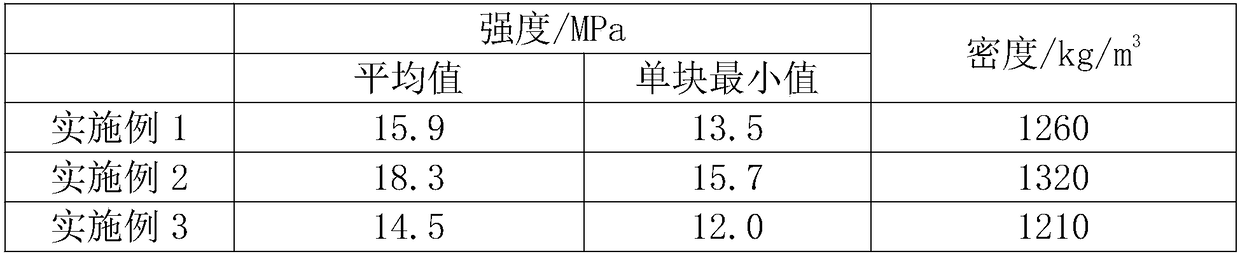

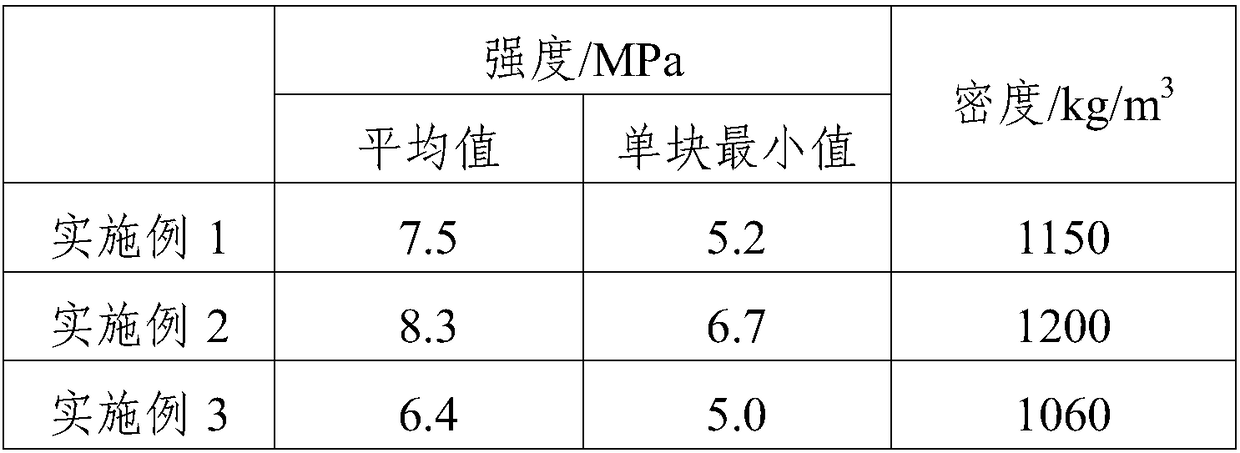

C40-level high-volume solid waste concrete and preparation method thereof

ActiveCN109437718ARaise the ratioImprove the level of resource utilizationAcid waterResource utilization

The invention discloses a C40-level high-volume solid waste concrete and a preparation method thereof. Each m<3> of concrete comprises the following components in parts by weight (kg): 213-258 parts of cement, 213-258 parts of a composite admixture, 341-367 parts of natural sand, 1048-1105 parts of strengthened recycled coarse aggregates, 170-195 parts of water, one of 0.01-5.68 parts of a polycarboxylic acid water reducing agent and 0.01-9.24 parts of a composite water reducing agent, and one or a mixture of two selected from 1-313 parts of tailings mechanism sand and 1-313 parts of recycledfine aggregates; and the concrete has a slump of 160-200 mm. The 28d strength of the above concrete is above 40 MPa or more, the durability is high, and the solid waste volume of solid waste such as construction waste is up to 70%, so that the resource utilization level of construction waste is greatly improved, the current shortage of natural sand and gravel aggregates is alleviated, and the production cost is reduced.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

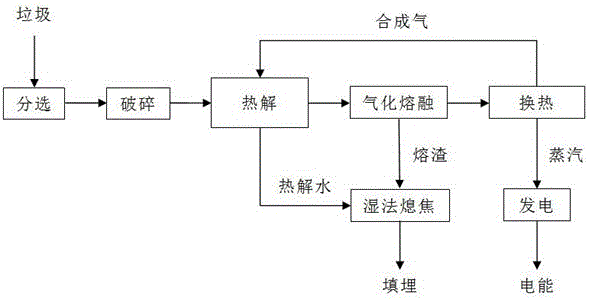

System and method for waste pyrolysis, gasification and fusion

ActiveCN106500107AHigh yieldHigh calorific valueIncinerator apparatusCombined combustion mitigationSlagQuenching

The invention provides a system and method for waste pyrolysis, gasification and fusion. The system comprises a sorting device, a crushing device, a heat storage type rotating bed used for performing drying and pyrolysis treatment on waste so as to obtain pyrolytic water, pyrolytic oil and gas mixtures and pyrolytic carbon, a gasification and fusion reaction chamber used for making pyrolytic oil and hydrocarbon gas subjected to gasification and recombination under the high-temperature gasification effect of a plasma torch so as to obtain synthesized gas comprising CO and H2 and fusing the pyrolytic carbon into glass state slag, a heat exchange device, a power generation device and a coke quenching device. The heat storage type rotating bed is adopted to perform pyrolysis on pretreated waste raw materials; the gasification and fusion reaction chamber is used for gasifying the pyrolytic oil and gas mixtures, water obtained through drying serves as water for coke quenching of the pyrolytic carbon, and the obtained synthesized gas is high in yield and heat value and is used as fuel gas of a heat storage type radiant pipe; and steam obtained by performing heat exchange treatment on the synthesized gas can be used for power generation selling, and the 'harmless, reduction and recycling' treatment of waste is achieved.

Owner:SHENWU TECH GRP CO LTD

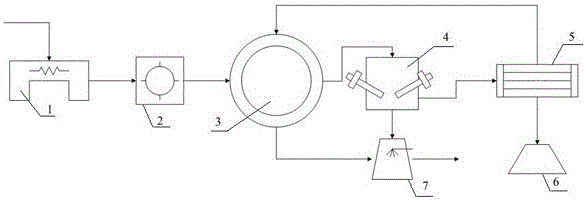

Anaerobic catalytic thermal cracking system and method for waste batteries

PendingCN107774698AEasy to operateHigh degree of automationTransportation and packagingSolid waste disposalScrew conveyorPollutant

The invention relates to anaerobic catalytic thermal cracking system and method for waste batteries. The system comprises a lifter, a flow stabilizing bin communicated to an outlet of the lifter, double pneumatic gate valves arranged at the outlet of the flow stabilizing bin, a drying tower arranged below the flow stabilizing bin, a wind blockage valve arranged at an outlet of the drying tower, atubular spiral conveyor communicated to the outlet of the drying tower, a disc feeder arranged below an outlet of the tubular spiral conveyor, a crusher communicated to an outlet of the disc feeder, avalve inserting plate arranged at an outlet of the crusher, a spiral conveyor arranged below the crusher, a charge and discharge barrel communicated to an outlet of the spiral conveyor, a double-drumrotary kiln communicated to an upper transverse hole of the charge and discharge barrel, and a combustion furnace sleeving the double-drum rotary kiln, wherein a lower transverse outlet of the chargeand discharge barrel is communicated to an outlet of the double-drum rotary kiln, and the lower end of the charge and discharge barrel is successively communicated to an unloader and a vertical tubular spiral conveyor. The system provided by the invention can achieve harmless recycling treatment of waste batteries, and is high in degree of automation. Without inert gas protection, the process isfree of secondary pollutant generation or emission.

Owner:GUANGZHOU WEIGANG ENVIRONMENT TECH CO LTD

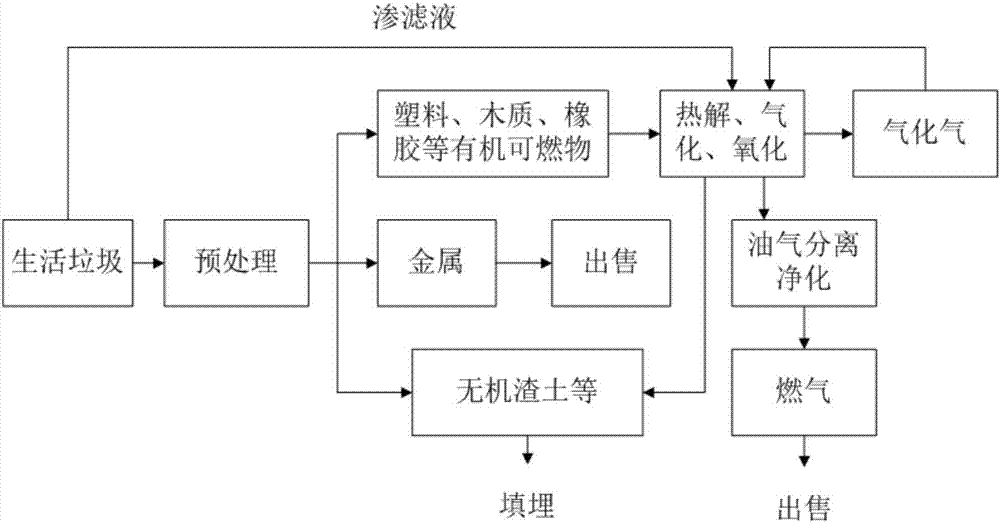

Integrated biological and gasifyign treatment process for dewatered city domestic garbage

InactiveCN1857803AImprove processing efficiencyImprove efficiencySolid waste disposalLitterEnvironmental engineering

The integrated biological and gasifying treatment process for dewatered city domestic garbage is the following steps: breaking trash bag; separating; gasifying the separated recyclables capable of being gasified in a gasifying furnace to produce fuel gas; collecting organic matters and refuse percolate and anaerobic fermenting; using the marsh gas generated during fermentation as fuel, drying the marsh gas residue and incinerating in incinerator; and burning the fuel gas in a boiler to provide energy. The present invention has high garbage treating efficiency and benefit and less secondary pollution.

Owner:南京绿展能源有限公司

Method for preparing magnetic biochar by one-step method

InactiveCN112263989AImprove the level of resource utilizationImprove economyOther chemical processesAlkali metal oxides/hydroxidesActivated carbonIron salts

The invention discloses a method for preparing magnetic biochar by a one-step method. The method comprises the following steps: S1, straw pretreatment: drying and crushing plant straws, and screeningparticles with the particle size of 60-30 meshes for later use; S2, iron salt dipping: adding an iron salt solution into the straw particles in the step S1 for dipping, adjusting the pH value to 10-11with an alkali solution, and then carrying out heat preservation dipping; S3, high-temperature pyrolysis: performing suction filtration on the impregnated particles in the step S2, drying, and transferring into an atmosphere furnace for high-temperature pyrolysis to obtain a magnetic biochar crude product; and S4, post-treatment: carrying out suction filtration, cleaning and drying on the magnetic biochar crude product obtained by pyrolysis in S3 to obtain a magnetic activated carbon finished product. According to the method for preparing the magnetic biochar through the one-step method, plant straw serves as a raw material, pyrolysis and magnetization can be achieved through one step to prepare the magnetic activated carbon, the method is simple, and large-scale production is easy to achieve.

Owner:NANJING FORESTRY UNIV

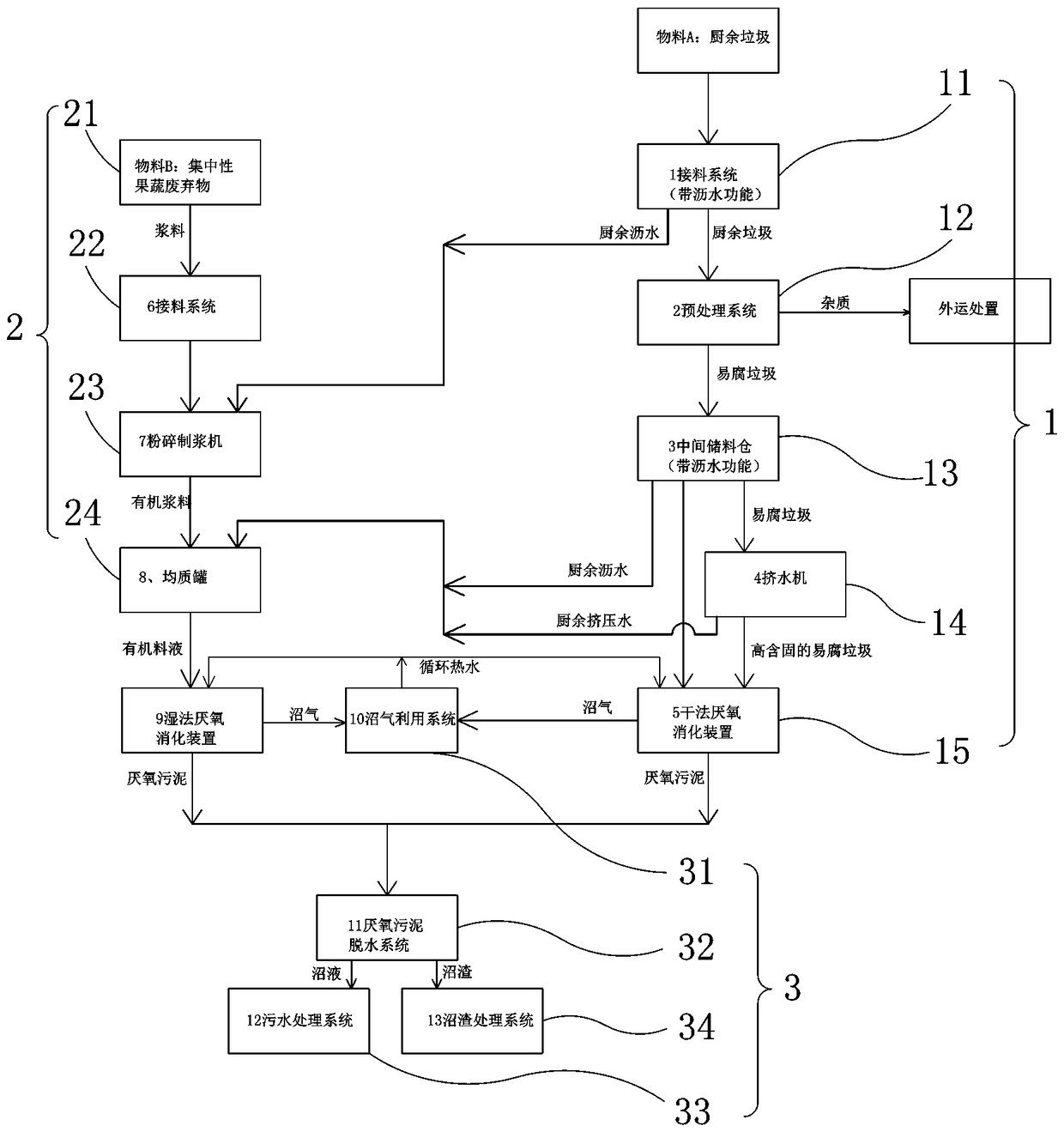

Multi-type perishable garbage synergistic anaerobic digestion treatment equipment and treatment method

PendingCN109290343AImprove the level of resource utilizationRealize resource utilizationSolid waste disposalResource utilizationHigh water content

The invention discloses multi-type perishable garbage synergistic anaerobic digestion treatment equipment and treatment method. The equipment comprises a kitchen garbage treatment system, a garden stuff garbage treatment system and an after-treatment system, wherein the kitchen garbage treatment system and the garden stuff garbage treatment system are linked with the after-treatment system separately. According to the invention, the equipment is merged into a wet process anaerobic fermentation technology production line to be treated, so that the defect that the single technology treatment cannot realize comprehensive resource utilization of organic matters and various nutrient elements in kitchen waste is effectively avoided, and the resource utilization level of kitchen waste is increased. The equipment is provided with a middle storage silo and a wringing machine with the water drainage function, so that the problem that after garbage classification, excessively high water content of high-purity perishable garbage cannot meet the index requirement of material solid content from the dry method anaerobic fermentation technology is solved.

Owner:厦门市联谊吉源环保工程有限公司

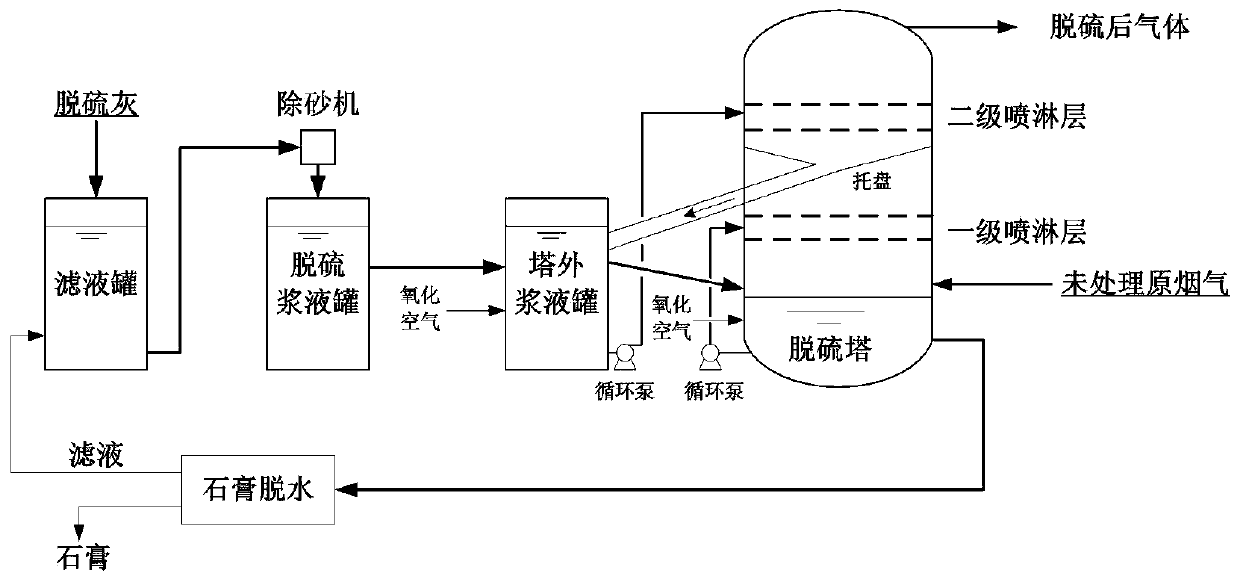

Method for reusing lime semi-dry desulfurization ash

InactiveCN109865421ALow densityReduce desulfurization costDispersed particle separationSocial benefitsResource utilization

The invention discloses a method for reusing lime semi-dry desulfurization ash, and belongs to the technical field of resource utilization of three wastes (waste gas, waste water and industrial residue). The invention solves the problems that desulfurization ash is difficult to comprehensively utilize, and piling of the desulfurization ash easily generates secondary pollution. A filtrate obtainedby dehydrating gypsum is reused, a desulfurization ash slurry filtering device is added in the process flow, the density, pH value and the like of each desulfurization ash slurry are controlled, so that the purposes that the desulfurization ash is used to completely replace a lime / limestone raw material, spray desulfurization is carried out in a secondary spray layer and a first spray layer in a desulfurization tower to remove sulfur dioxide from flue gas are achieved. The method of the invention reduces the consumption of lime / limestone resources and the generation amount of flue gas desulfurization by-products, reduces the cost of flue gas desulfurization, avoids secondary pollution caused by stockpiling and landfill, helps to improve the resource utilization level of desulfurization products, and has extremely obvious economic benefits and social benefits.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

A wear-resistant concrete mixed with nickel slag

ActiveCN104478368BImprove wear resistanceImprove bending resistanceSolid waste managementSlagRoad engineering

Owner:YANGZHOU UNIV

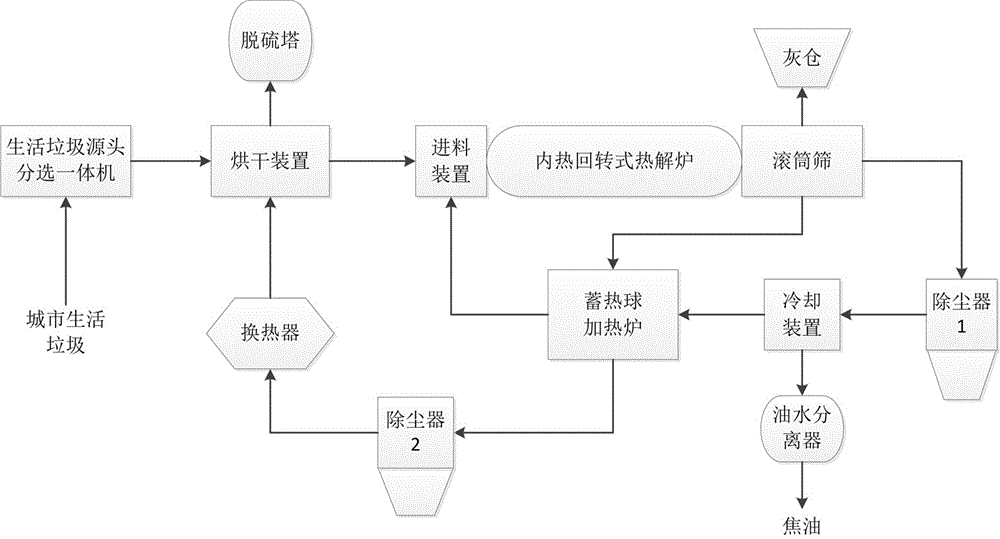

Internal thermal domestic waste pyrolysis system

InactiveCN107435928AIncrease profitLow running costBiofuelsEnergy inputFlue gasHeat transfer efficiency

An internal thermal domestic waste pyrolysis system comprises a domestic waste source sorting machine, a drying device, a feeding device, an internal heat rotary pyrolysis furnace, a drum screen, a regenerative ball heating furnace, a dust remover 1, a dust remover 2, a cooling device, an oil-water separator, a heat exchanger, a desulfurization tower and an ash bin; after automatic sorting of the domestic waste by the domestic waste source sorting integrated machine and after the combustible matter suitable for pyrolysis is dried by the flue gas, the combustible matter and high-temperature regenerative balls are put in the internal heat rotary pyrolysis furnace at certain ratio for direct heat transfer pyrolysis; the cooled regenerative balls pass through the drum screen to separate the pyrolysis solid of the domestic waste and then enter the internal heat rotary pyrolysis furnace with new domestic waste; the operation is cycled and repeated. In the invention, the heat source body and the domestic waste are directly heat-transferred, the pyrolysis heat transfer efficiency is improved, the pyrolysis residence time is reduced, and the processing capability of the equipment is enhanced.

Owner:BEIJING SANTAI ENVIRONMENTAL TECH

Method for landfill gas in-the-field and out-of-the-field combined treatment

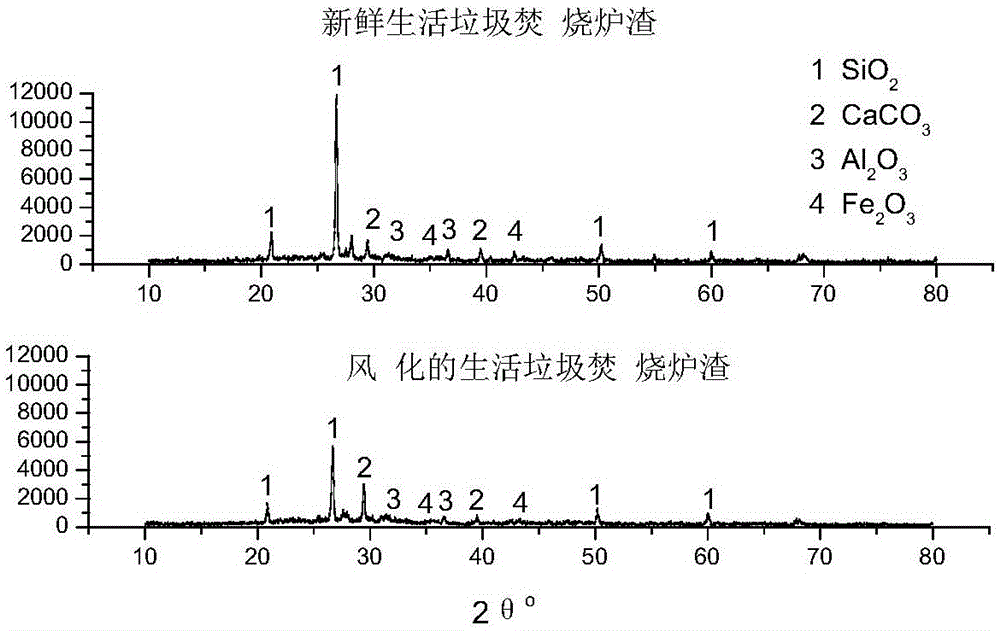

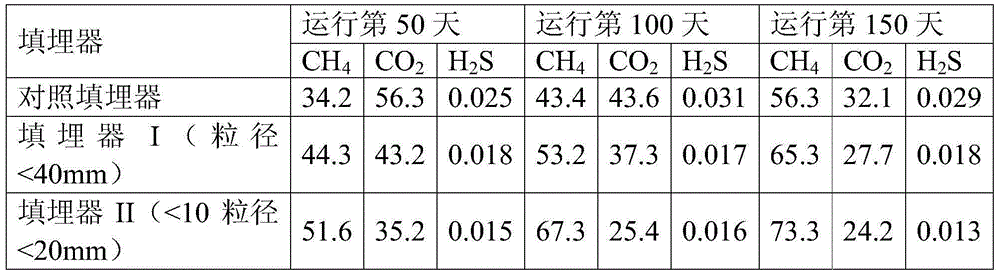

ActiveCN105062598AHigh methane contentImprove the taste of resourcesGaseous fuelsWaste based fuelSlagCarbon dioxide

The invention discloses a method for landfill gas in-the-field and out-of-the-field combined treatment. A combined treatment device comprises a landfill device and a purification packing tower. The landfill device is arranged in a landfill site, the purification packing tower is arranged outside the landfill site, the landfill device is filled with fresh household garbage incineration slag particles, so that landfill gas undergoes in-situ purification, and a packing layer formed by weathering household garbage incineration slag particles is arranged in the purification packing tower, so as to further perform adsorption purification treatment on the landfill gas having undergone in-situ purification treatment. The technical means of in-the-field and out-of-the-field combination is adopted, carbon dioxide in the gas is fixed while the landfill gas is purified, and the quality of released gas is improved.

Owner:TAIZHOU UNIV

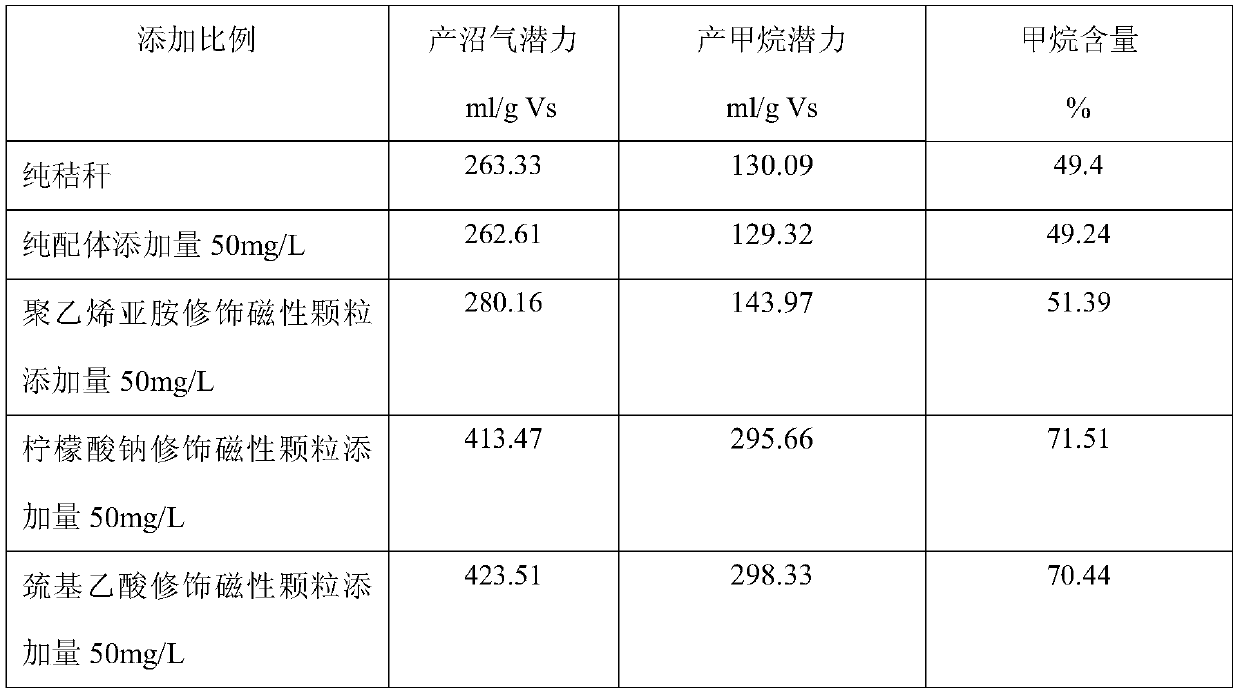

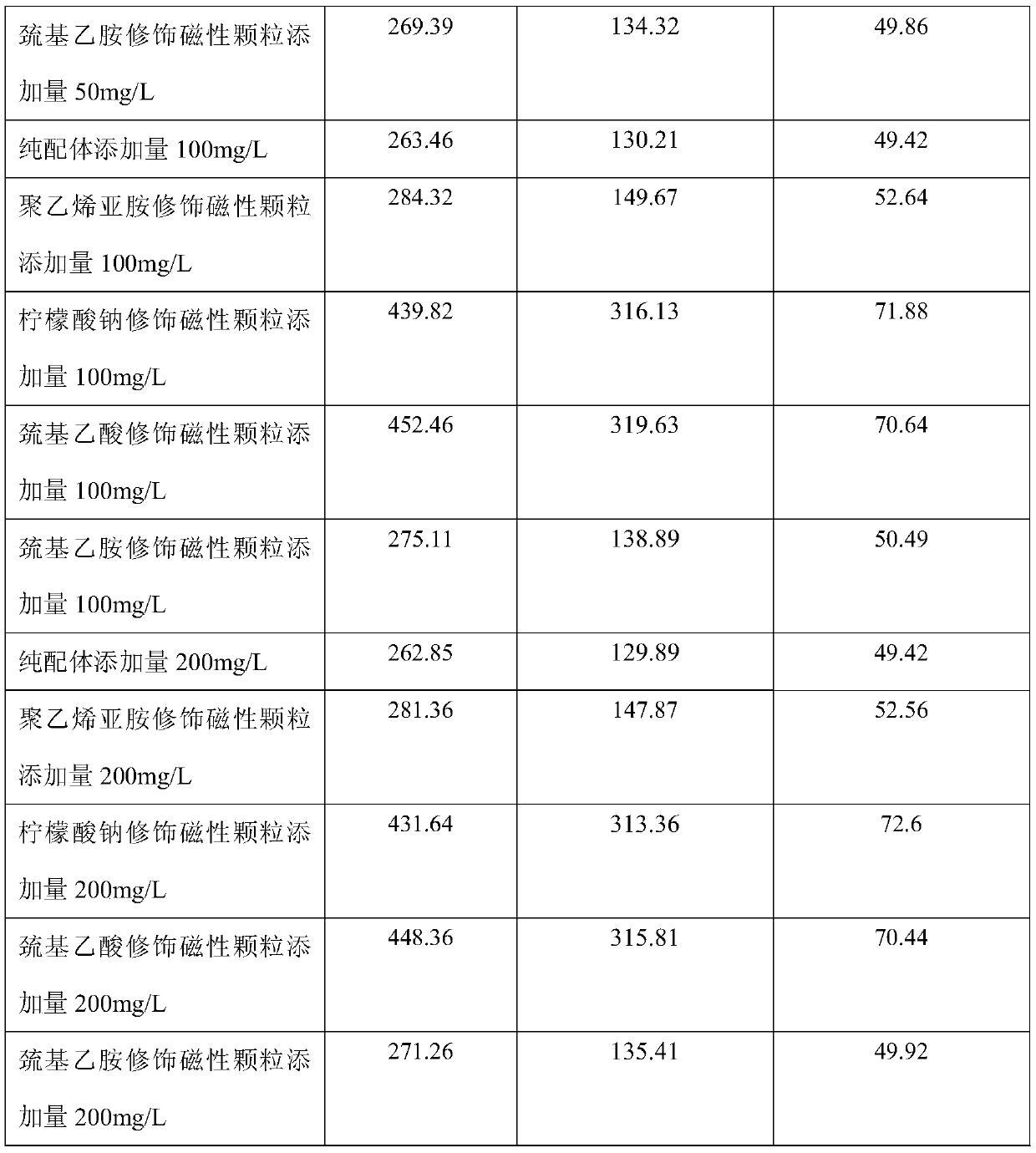

Method for producing methane by anaerobic fermentation

ActiveCN110628829ATake advantage ofAchieve purificationClimate change adaptationWaste based fuelElectronic transmissionResource utilization

The invention discloses a method for producing methane by anaerobic fermentation. Agricultural waste resources are utilized as raw materials for anaerobic fermentation to produce biogas, a small amount of magnetic nanoparticles are added to the fermentation system, and the magnetic nano particles are modified with nano-sized iron oxide particles on the surface so that the iron oxide particles havedifferent types of charges, which can promote the interaction between acidogenic bacteria and methanogenic bacteria so as to increase electronic transmission, and promote the transformation of organic acid to methane generation path so as to greatly increase the yield of methane. According to the present invention, nano-materials and agricultural waste resource utilization are combined, and a newapproach is opened for improving the level of waste resource utilization and breaking through the bottleneck of anaerobic fermentation technology.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

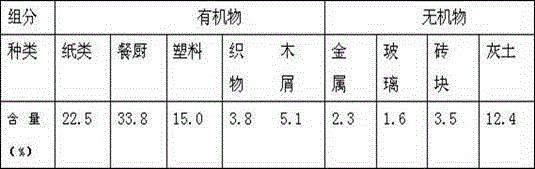

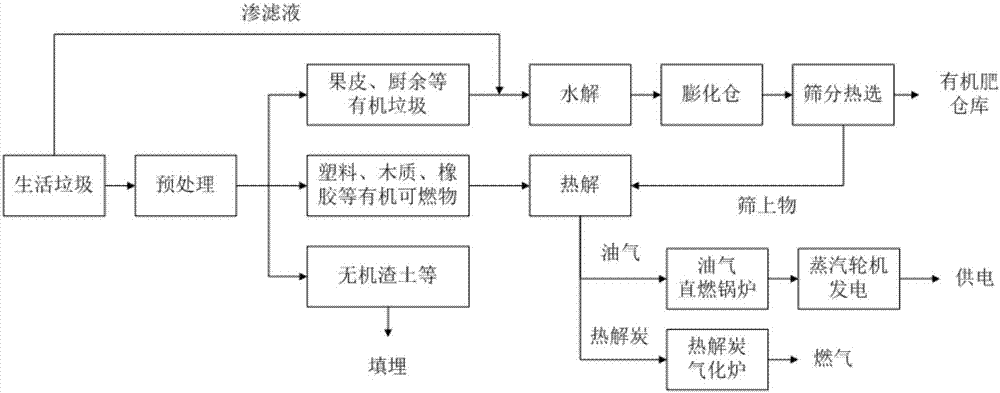

Treatment system and method for domestic waste

PendingCN106944461AGive full play to the reduction effectImprove the level of resource utilizationTransportation and packagingSolid waste disposalEnvironmental engineeringRaw material

The invention relates to a treatment system and method for domestic waste. The treatment system comprises a pretreatment device, a revolving bed pyrolyzing furnace, an organic waste hydrolyzing device and an oil gas direct-burning boiler, wherein the pretreatment device comprises a waste inlet, a combustible outlet and an organic compound outlet; the revolving bed pyrolyzing furnace comprises a pyrolyzing raw material inlet, a high-temperature oil gas outlet and a pyrolytic carbon outlet; the pyrolyzing raw material inlet is connected with the combustible outlet of the pretreatment device; the organic waste hydrolyzing device comprises an organic compound inlet and a hydrolysate outlet; the organic compound inlet is connected with the organic compound outlet of the pretreatment device; the oil gas direct-burning boiler comprises a high-temperature oil gas inlet and a superheated steam outlet; and the high-temperature oil gas inlet is connected with the superheated steam outlet of the revolving bed pyrolyzing furnace. According to the treatment system disclosed by the invention, the reducing effect of waste pyrolyzing can be sufficiently achieved, the innocuity and reducing of combustible components are realized, and degradable organic compounds can be treated by a hydrolyzing method; and various waste treatment techniques are combined, so that the purpose that the domestic waste is thoroughly and effectively treated is realized.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

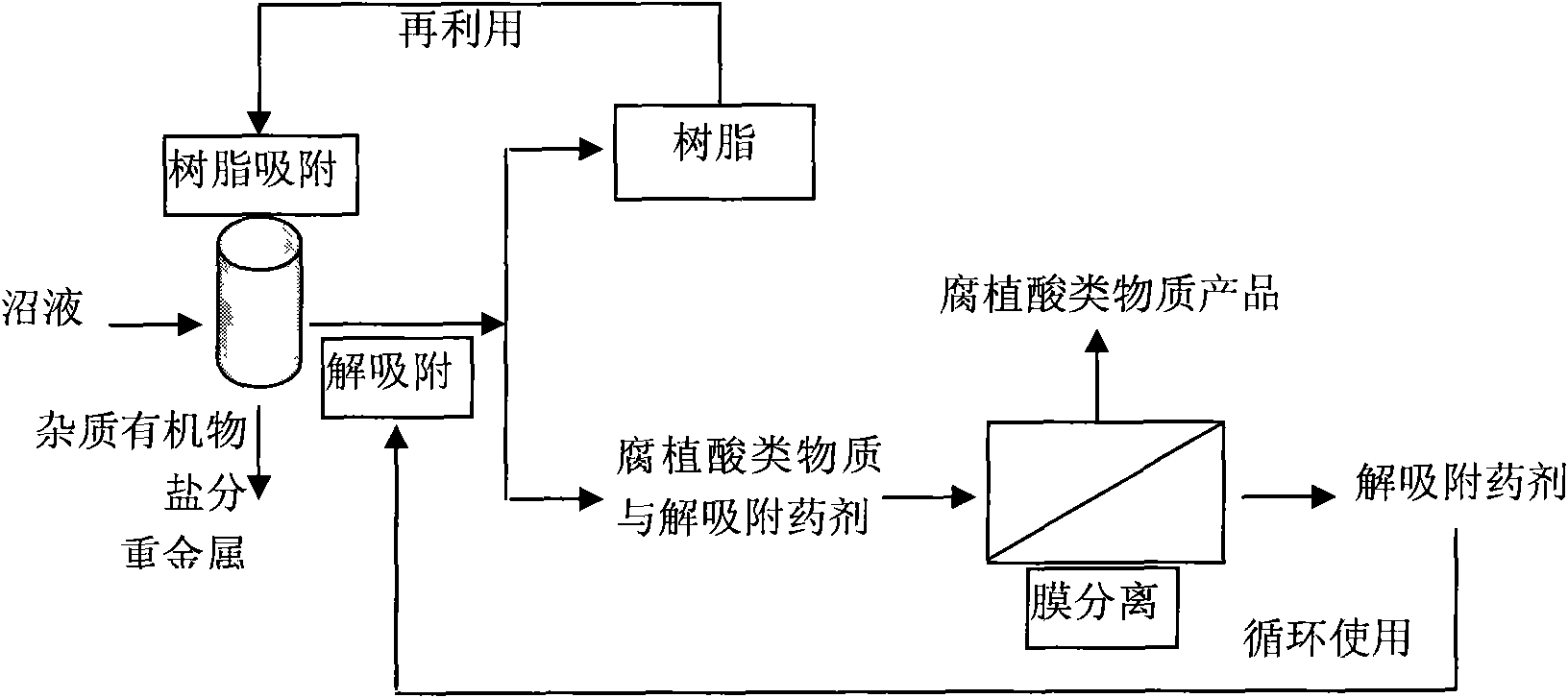

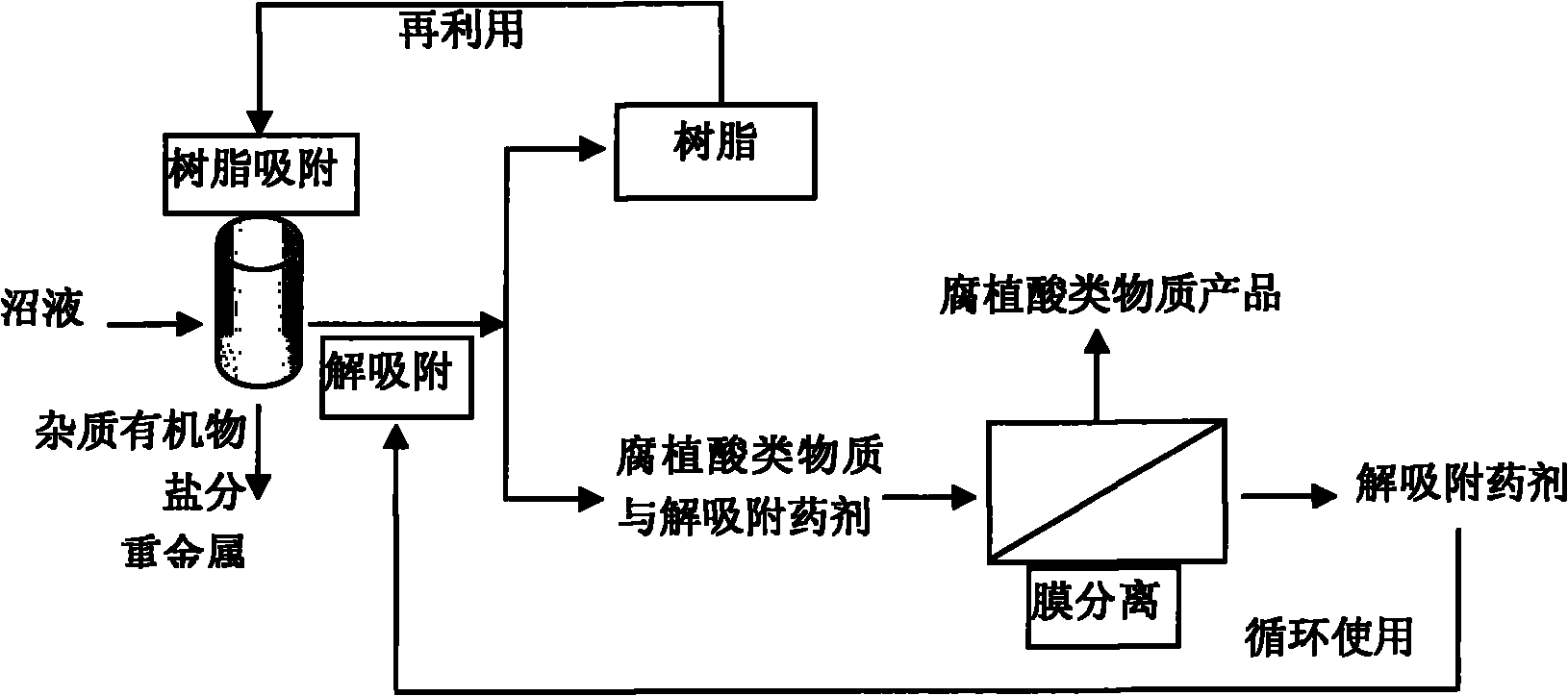

Method for extracting humic acid substances from methane fluid

The invention discloses a method for extracting humic acid substances from methane fluid and belongs to the technical field of separation and purification of humic acid substances from methane fluid. In the method, by combining ion exchange resin and an ultrafiltration membrane, the humic acid substances are extracted from the methane fluid; through adsorption of resin, the humic acid substances are effectively separated from other impurities, and the purity of the humic acid substances in the products is improved; and the desorbed resin can be recovered to the initial state and recycled. Mixed solution of the humic acid substances and a desorption medicine, which is desorbed from the resin is separated through the ultrafiltration membrane, so that the purity and concentration of the humic acid substances can be further improved, the recycling level of the humic acid substances is improved, and the desorption medicine can be separated and recycled so as to reduce operating cost. The method solves the treatment problem that organic matters in the methane fluid are difficult to degrade, the humic acid substances are recycled, and the purity, concentration and recovery rate of the humic acid substances are obviously improved.

Owner:TSINGHUA UNIV

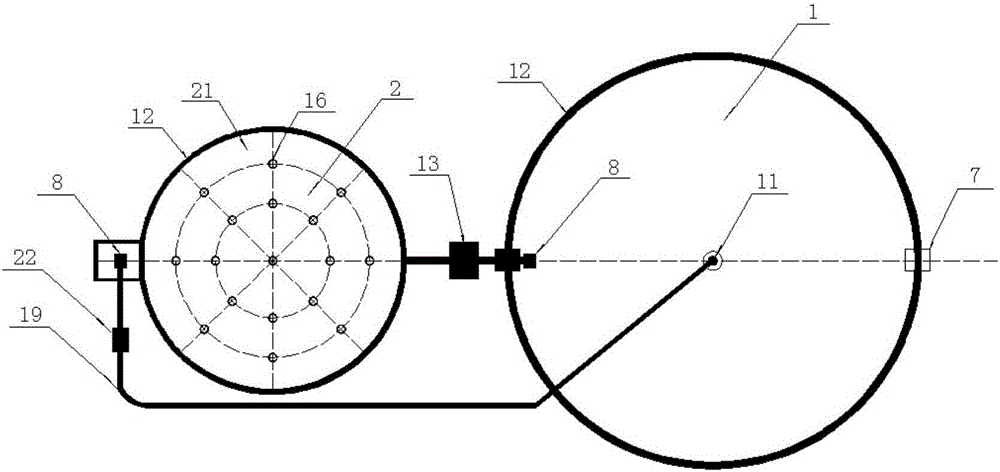

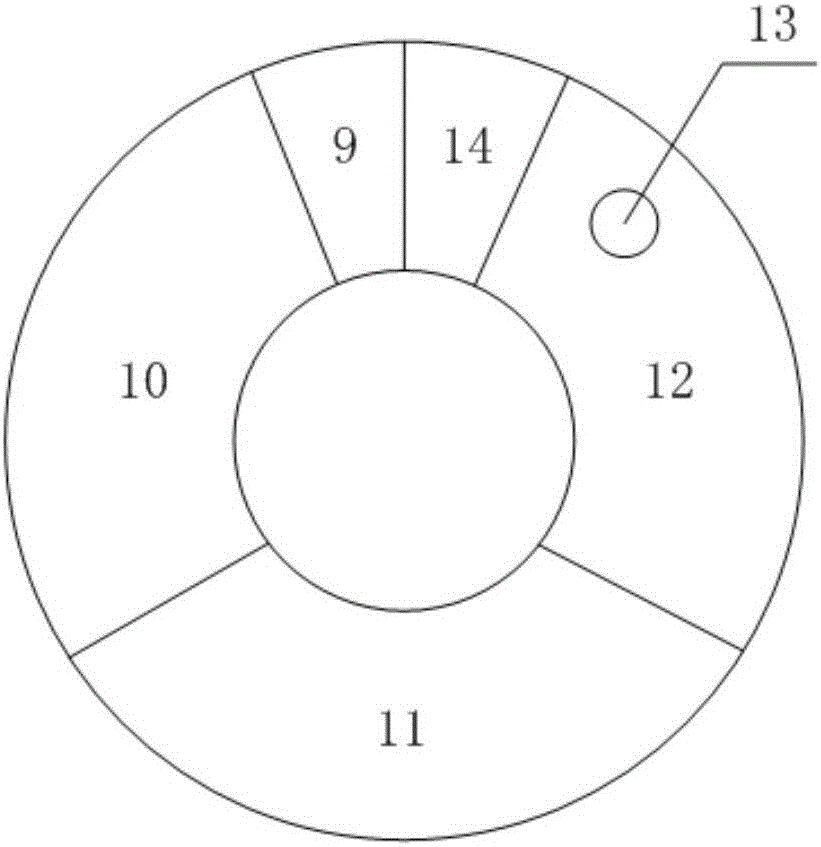

Device for preparing biogas through plant straw degradation and anaerobic fermentation and application method

InactiveCN106148171AEfficient use ofRealize resource utilizationBiological substance pretreatmentsGas production bioreactorsBiotechnologySlag

The invention discloses a device for preparing biogas through plant straw degradation and anaerobic fermentation and an application method. According to the device, an aim of efficiently preparing biogas through anaerobic fermentation of plant straw is achieved by adopting the plant straw (4) as main raw material and mixing with human and animal excreta (5) and a degradation strain. The device comprises a degradation tank (1) and a fermentation tank (2), wherein the human and animal excreta (5) and the plant straw (4) are stacked in layers in the degradation tank (1), and meanwhile, the degradation bacteria are mixed, and the degraded mixture is conveyed into the fermentation tank (2) through a slag discharge pump (13) for anaerobic fermentation to prepare biogas. The biogas slurry in the fermentation tank (2) is pumped and circulated to a ventilation liquid spray port (11) in a top cover plate (10) of the degradation tank (1) and sprayed in; and the humidity of the plant straw (4) and the human and animal excreta (5) is adjusted to increase the degradation speed. Compared with conventional methods, the plant straw (4) does not need to be ground, the cost is low, the biogas yield is high, and the application range is wide.

Owner:NORTHEAST NORMAL UNIVERSITY

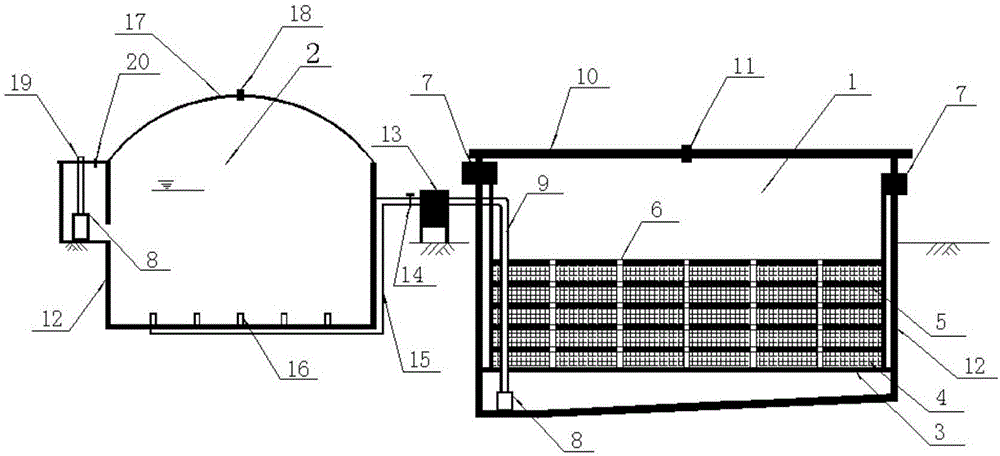

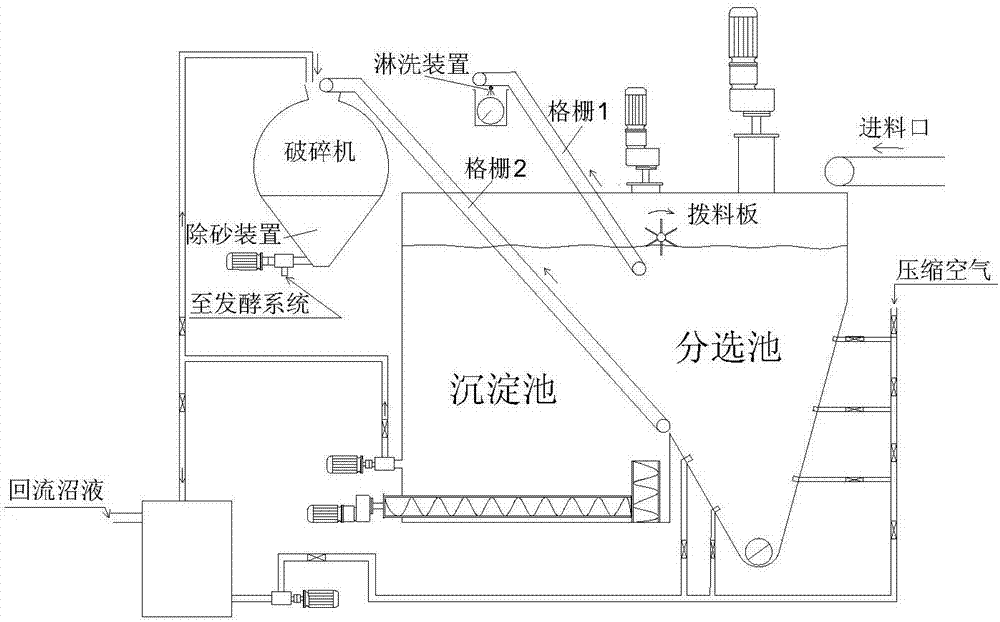

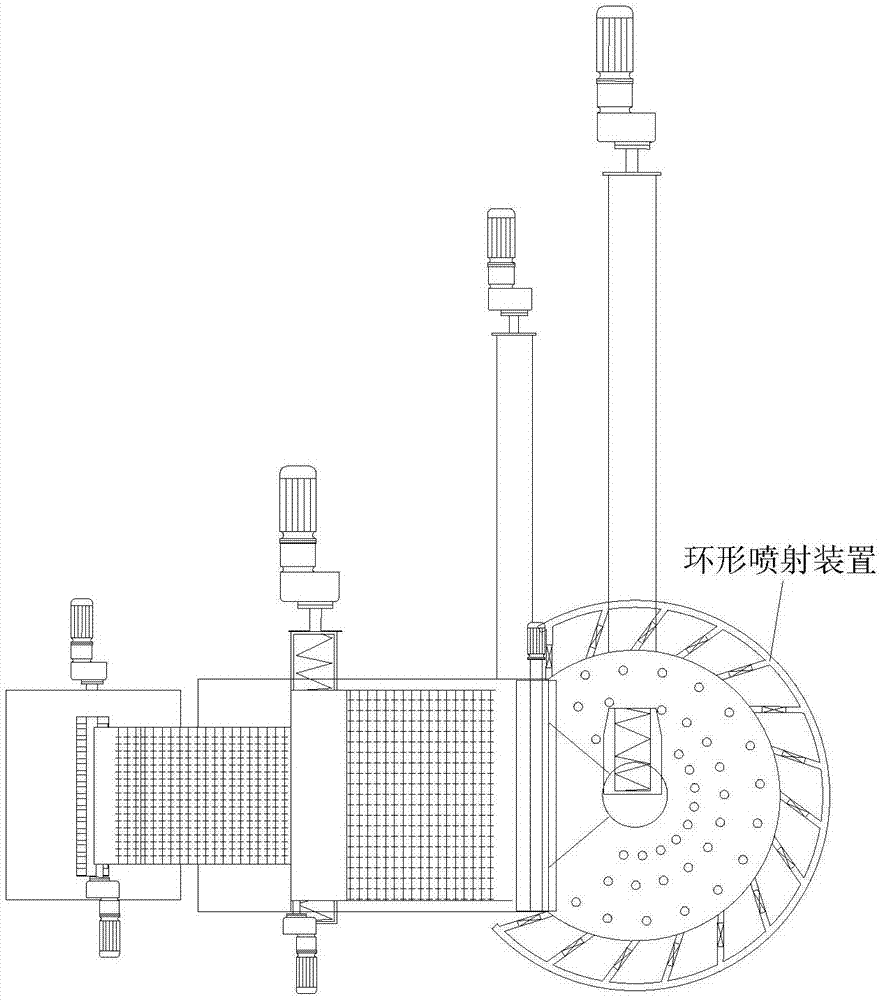

Household waste hydro-separation and pulping technology and treatment system

InactiveCN107511389AImprove the level of resource utilizationFully recycleSolid waste disposalEngineeringSlurry

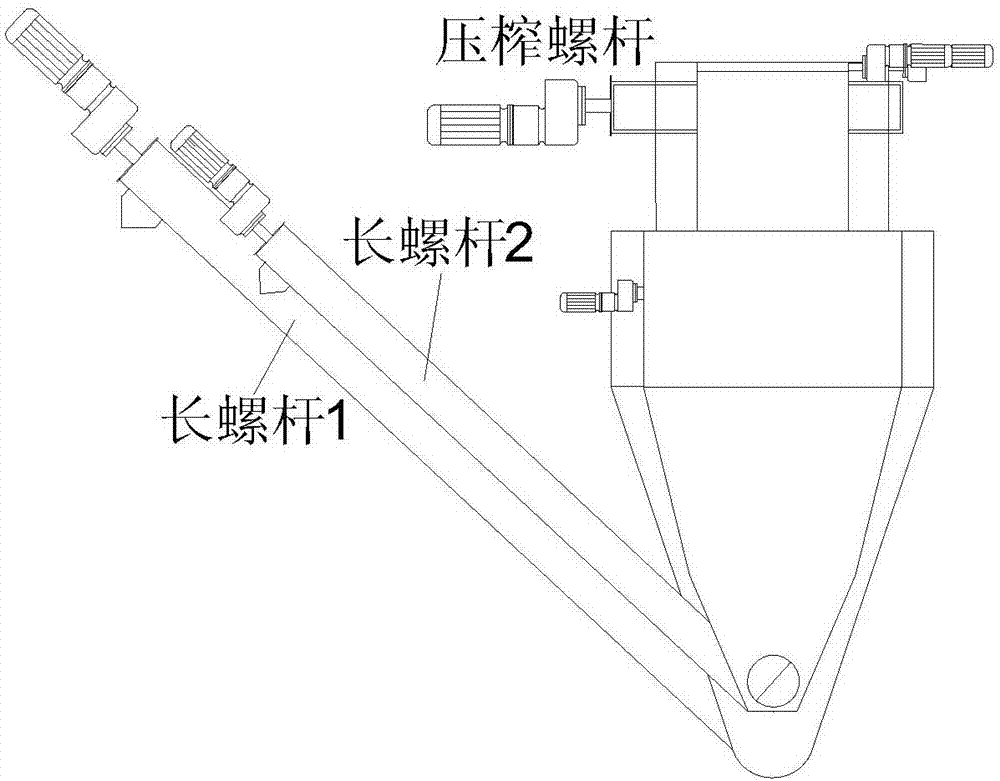

The invention provides a household waste hydro-separation and pulping technology and a treatment system. The treatment system comprises a hydro-separation system, a pulping system and a fermentation system. The hydro-separation system comprises a separation tank, a water spraying device, a first separation grid, a switching plate and a discharging squeezing threaded rod, wherein the water spraying device is arranged in the separation tank, the first separation grid is used for conveying light materials, the switching plate is arranged at the bottom of the first separation grid, and the discharging squeezing threaded rod is arranged at the top of the first separation grid and used for conveying inorganic matter. The hydro-separation system further comprises a sedimentation basin, a discharging long threaded rod, a second separation grid and a water drainage exit, wherein the discharging long threaded rod is arranged at the bottom of the sedimentation basin, the second separation grid is used for conveying organic matter, and the water drainage exit is formed in the bottom of the sedimentation basin. The pulping system comprises a hammer type pulping machine for pulping and a rotational flow sand removing device for removing sand. An eluting device arranged on the upper portion of the first separation grid is further included. According to the design, the organic matter and the inorganic matter in urban household waste can be separated effectively, the separated-out organic matter is subjected to smashing and sand removing, grid connection is conducted on fermented biogas, and biogas slurry is recycled, so that the waste resource recovery level is improved greatly.

Owner:深圳市海吉星环保有限责任公司

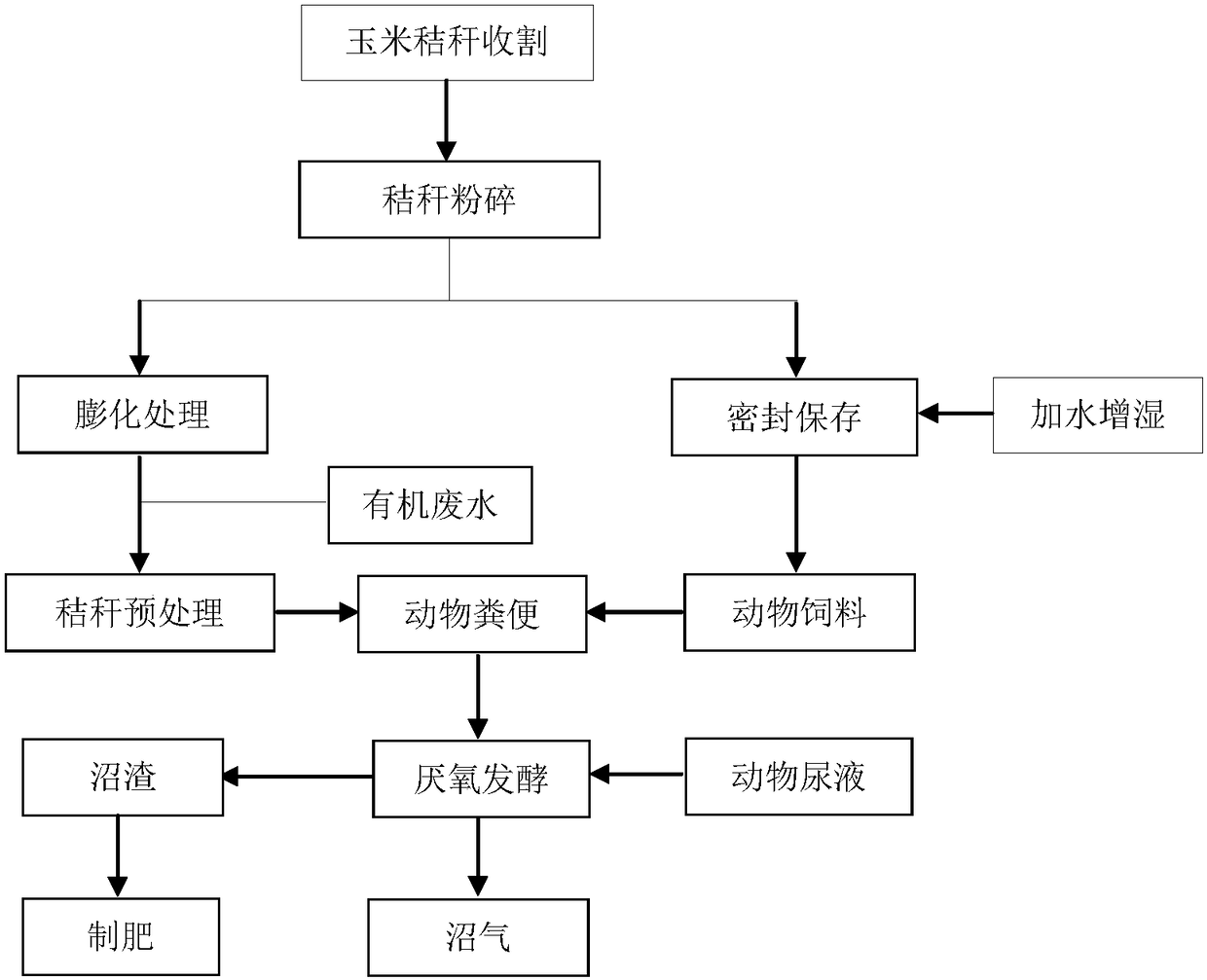

Method for improving straw fermentation for preparing biogas

PendingCN108570483AIncrease profitRealize resource utilizationClimate change adaptationAnimal feeding stuffAnimal fecesWastewater

The invention discloses a method for improving straw fermentation for preparing biogas. The method is characterized by comprising smashing harvested fresh straw, then carrying out puffing treatment ona part of the straw, adding water to another part of the straw, humidifying the other part of the straw and then hermetically storing the other part of the straw; adding the straw subjected to puffing treatment into organic wastewater, pretreating the straw for 3-5 days, hermetically storing the straw for 15 days and then utilizing the straw for animal feed; mixing pretreated puffed straw and animal feces with each other to obtain mixtures, adding animal urine into the mixtures, carrying out anaerobic fermentation, utilizing biogas residues for fertilizer preparation, purifying the biogas andthen utilizing the biogas as fuel. The method has the advantages that the biogas yield and the biogas production rate of the biogas prepared from the straw can be increased by the aid of the method,the straw can be completely recycled, the organic wastewater is consumed, and accordingly the problem of environmental pollution due to the straw can be fundamentally solved; the method is free of added substances harmful for environments and is little in environmental influence; the method is simple, is high in operability and has a high practical value, and waste can be truly recycled by the aidof the method.

Owner:NORTHEAST NORMAL UNIVERSITY

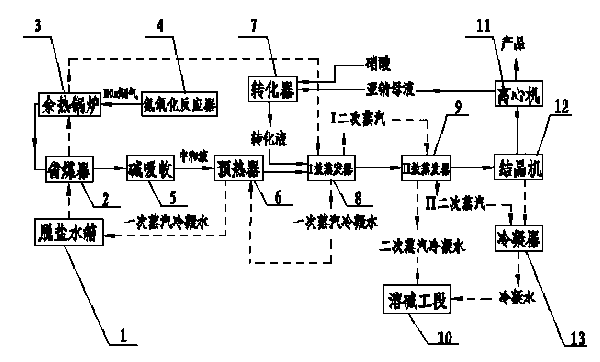

Steam self-supply system for producing sodium nitrate/sodium nitrite

ActiveCN103848443AConducive to emission reductionReduce the temperatureEnergy inputAlkali metal nitrate preparationEngineeringSodium nitrite

The invention discloses a steam self-supply system for producing sodium nitrate / sodium nitrite, which is suitable for preparing sodium nitrate / sodium nitrite. A desalination water tank is connected with a waste heat boiler through a coal economizer, and the waste heat boiler is connected with an ammoxidation reactor; the coal economizer is communicated with a crystallizer through an alkaline absorber, a preheater, an I-effect evaporator and an II-effect evaporator; the preheater is connected with the desalination water tank; a converter is respectively connected with the I-effect evaporator and a centrifugal machine; the II-effect evaporator is respectively connected with an alkaline dissolving workshop section and the crystallizer; the alkaline dissolving workshop section is connected with the centrifugal machine through a condenser and the crystallizer. The steam self-supply system is remarkable in energy saving benefit, convenient for process regulation and pollutant discharge reduction, high in degree of automation, remarkable in steam saving effect and high in recycling ratio.

Owner:襄阳泽东化工集团股份有限公司

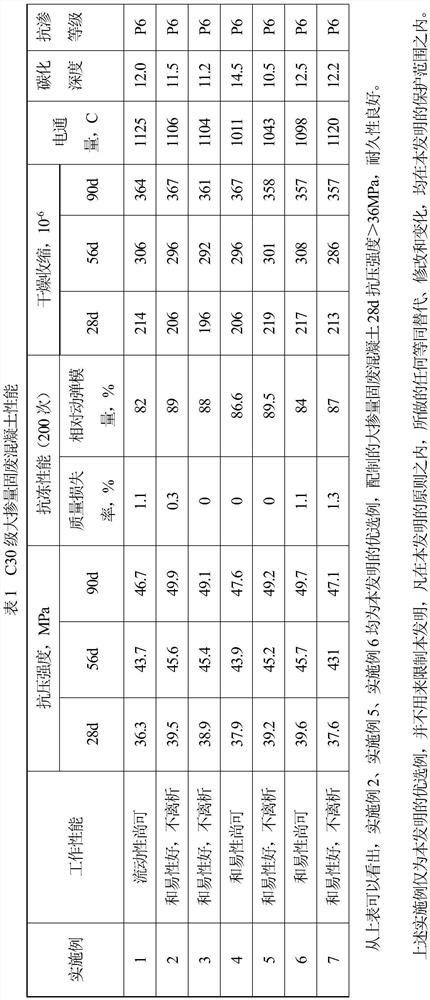

High-volume solid waste concrete and preparation method thereof

InactiveCN112341086ARaise the ratioImprove the level of resource utilizationAggregate (composite)Superplasticizer

The invention discloses high-volume solid waste concrete and a preparation method thereof. The concrete comprises the following components in parts by weight: 173-187 parts of cement, 172-187 parts ofa composite admixture, 0-362 parts of machine-made sand of tailings, 400-424 parts of natural sand, 0-313 parts of recycled fine aggregate, 1063-1080 parts of reinforced recycled coarse aggregate, 0-3.63 parts of a polycarboxylate superplasticizer and 159-243 parts of water. The 28-d strength of the high-volume solid waste concrete reaches 36 MPa or above, the durability of the concrete is good,and the proportion of recycled aggregate in the recycled concrete is increased; and solid waste such as construction waste is utilized on a large scale, the resource utilization level of the construction waste is improved, and the current situation that natural sandstone aggregate is extremely short at present is relieved.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

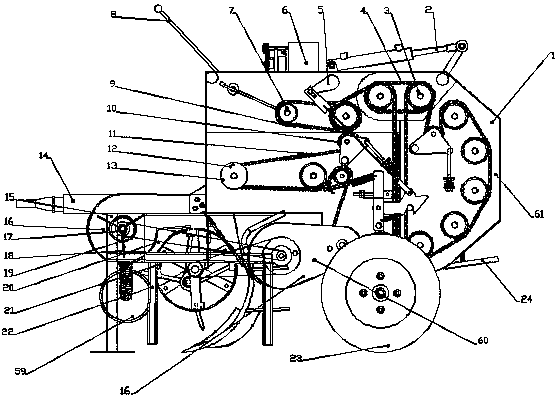

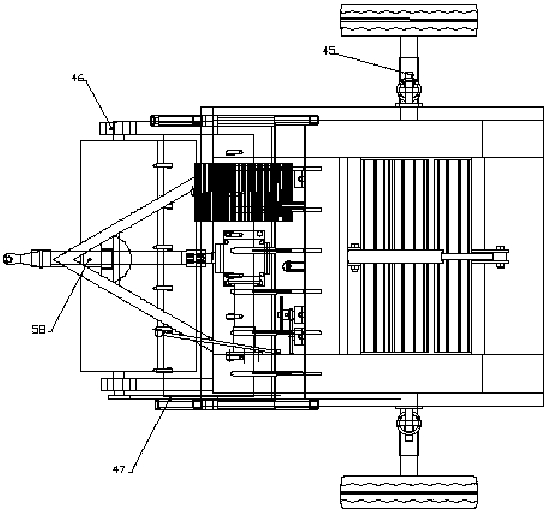

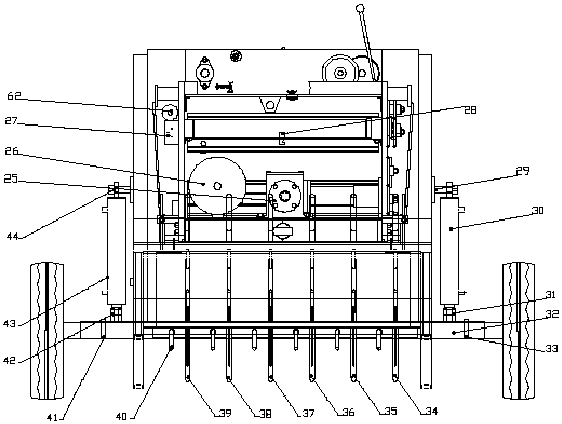

Method for manufacturing waste mulching film picking and bundling machine

InactiveCN107896525AImprove recycling efficiencyExtended service lifeGatherer machinesGear driveAgricultural engineering

The invention relates to a method for manufacturing a waste plastic mulching film picking and bundling machine. The machine comprises a rack, an eccentric retractable film picker, a fan, a soil shaking winding mechanism, a land-arc imitated film-removing tooth mechanism, a winding mechanism, a bundling mechanism, a tire assembly mechanism, a hydraulic oil cylinder mechanism and a rolling disc cutter mechanism. The eccentric retractable film picker is arranged at the front lower portion of the rack, the front portion of the eccentric retractable film picker is provided with the fan, and the soil shaking winding mechanism is arranged at the rear portion of the eccentric retractable film picker; the output end of a gear drives the eccentric retractable film picker, the fan and the rolling disc cutter mechanism to rotate through chains with different teeth separately, when uncovered mulching film is lifted to a certain height along a film removing tooth, retractable teeth of the eccentricretractable film picker lift the mulching film, the retractable teeth rotate along with an eccentric drum and gradually get shorter, after the lifted mulching film is taken to the highest point of thefilm picker, all the retractable teeth retract back, the mulching film stays on the retractable film picker, and the fan blows the mulching film to the rotating soil shaking winding mechanism.

Owner:EASTERN GANSU UNIVERSITY

Preparation process for producing baking-free brick from household garbage incineration furnace slag

InactiveCN108439874ARealize comprehensive utilizationImprove the level of resource utilizationSocial benefitsBrick

The invention discloses a preparation process for producing a baking-free brick from household garbage incineration furnace slag. The preparation process comprises the following steps: mixing the pretreated household garbage incineration furnace slag, mining and mineral separation waste residue and cement according to a ratio, and adopting a high-pressure molding process to prepare the high-strength baking-free brick product after uniformly stirring. The household garbage incineration furnace slag is pretreated, the high-pressure molding process is adopted, the utilization of the household garbage incineration furnace slag in the baking-free brick is realized, a new way is explored for comprehensively using the household garbage incineration furnace slag, the household garbage incinerationfurnace slag treatment pressure in the urbanization process is effectively relieved, and the preparation process has remarkable environment and social benefits.

Owner:上海秦望环保材料有限公司

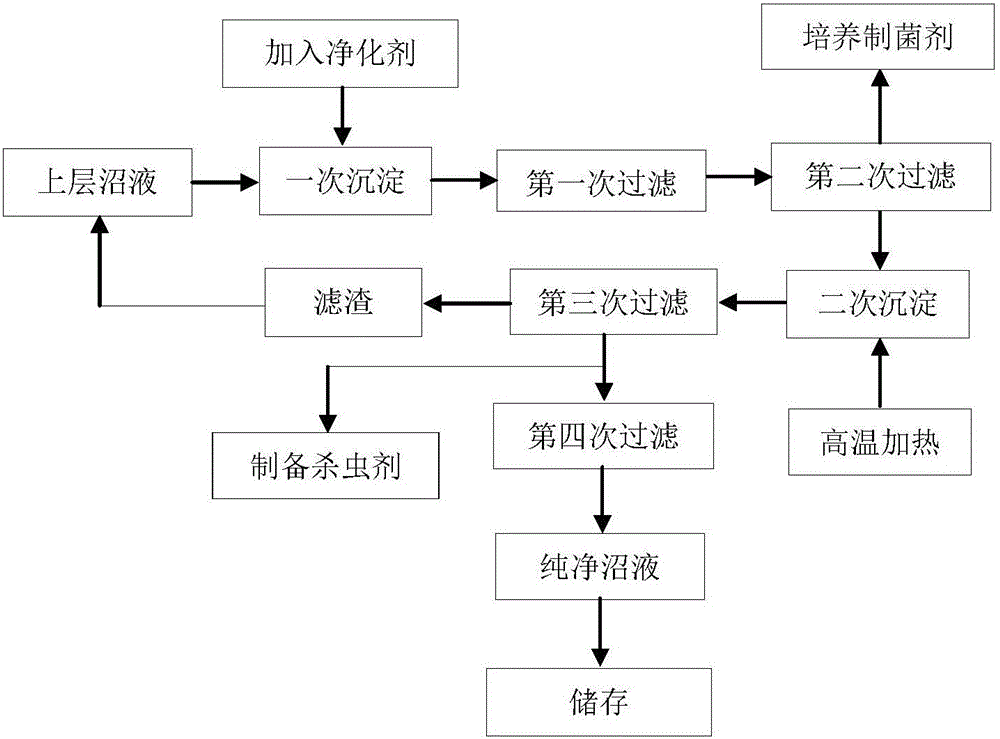

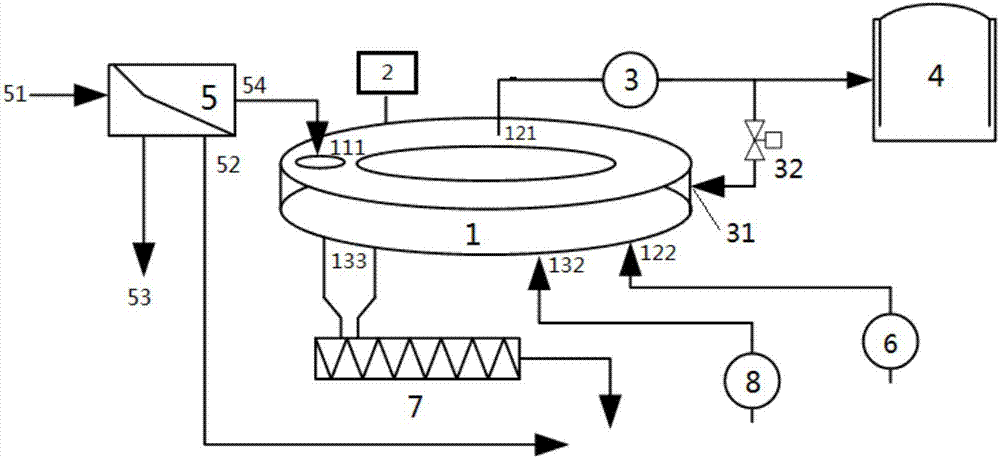

Method of efficiently purifying and comprehensively utilizing biogas slurry

InactiveCN106007140AWide range of usesImprove the level of resource utilizationTreatment involving filtrationMultistage water/sewage treatmentResource utilizationSlurry

The invention relates to a method of efficiently purifying and comprehensively utilizing biogas slurry. The method of efficiently purifying and comprehensively utilizing the biogas slurry is characterized by comprising the following steps: adding a purifying agent for a primary sedimentation after pumping excessive biogas slurry at an upper layer of a biogas digester; performing primary filtering after the sedimentation to filter out coarse impurities in the biogas slurry; performing secondary filtering to filter out fine impurities in the biogas slurry; performing a secondary sedimentation after heating the secondarily filtered biogas slurry at a high temperature and filtering the biogas slurry; performing tertiary filtering after the sedimentation to filter out sediments and impurities in the biogas slurry; performing quartus filtering after the tertiary filtering to filter out the fine impurities in the biogas slurry; and storing the treated biogas slurry as manure for roots and leaves of plants or as a plant pest inhibitor. The method of efficiently purifying and comprehensively utilizing the biogas slurry according to the invention has the advantages of high purification degree, wide application of purified biogas slurry and improved resource utilization level of wastes; the purifying agent used in the invention can be recycled after being heated and crystallized, so that cost is lowered; and the method according to the invention has the advantages of no waste discharge, environmental protection, simplicity, large treatment capacity, wide application range and low cost.

Owner:NORTHEAST NORMAL UNIVERSITY

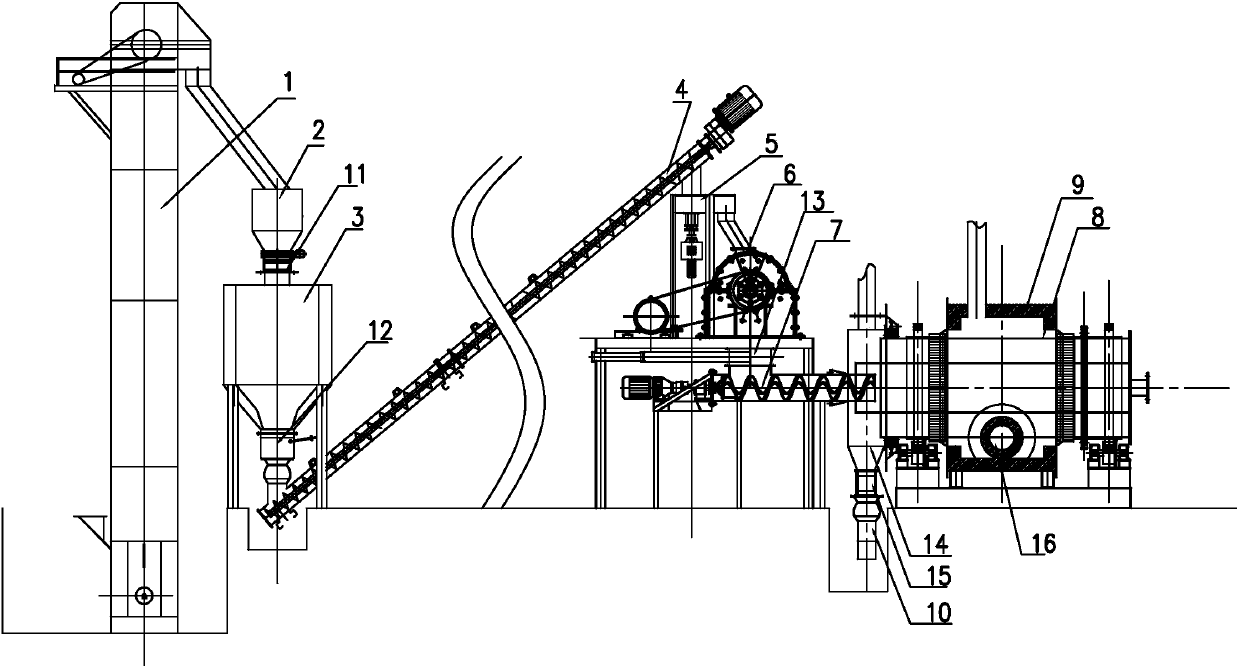

Revolving-bed pyrolysis furnace and method for treating garbage

PendingCN107876542AResource optimizationImprove harmless effectTransportation and packagingSolid waste disposalThermodynamicsCombustor

The invention relates to a revolving-bed pyrolysis furnace and a method for treating garbage. The revolving-bed pyrolysis furnace is provided with a drying pyrolysis region, a gasifying region and a combustion region, wherein a transition region with low top pressure is arranged between every two regions; an inner furnace wall and an outer furnace wall are provided with a plurality of radiant tubecombustors, and each radiant tube combustor is provided with a fuel hole and a smoke gas hole; a pyrolysis material inlet and a pyrolysis oil-gas outlet are formed in the top of the drying pyrolysisregion, and a pyrolytic carbon outlet is formed in the bottom of the drying pyrolysis region; a gasified gas outlet is formed in the top of the gasifying region, and an air gasifying agent and a watervapor inlet are formed in the bottom of the gasifying region; the gasified gas outlet is connected with the fuel holes; a smoke gas outlet is formed in the top of the combustion region, and an air inlet and an ash outlet are formed in the bottom of the combustion region; the smoke gas holes of the radiant tube combustors communicate with the smoke gas outlet; and the smoke gas outlet is connectedwith the air gasifying agent inlet. The revolving-bed pyrolysis furnace realizes that one furnace body completes drying, pyrolysis, gasifying and oxidizing of garbage, shortens process flow, reducesequipment investment, and increases a heat utilization rate.

Owner:BEIJING SHENYUAN ENVIRONMENTAL PROTECTION CO LTD

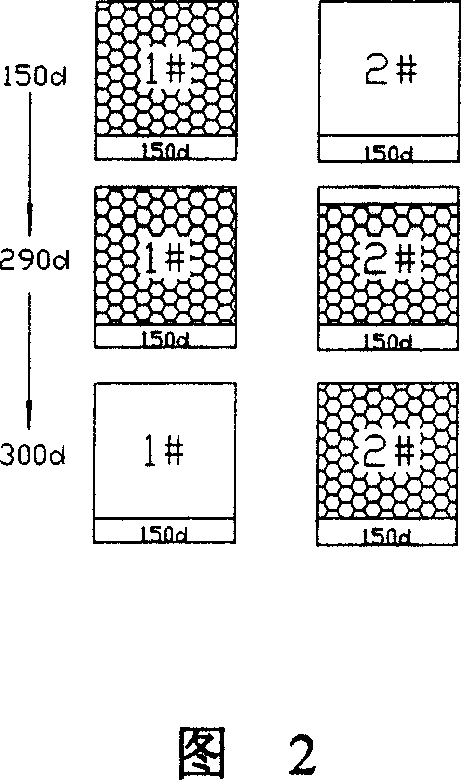

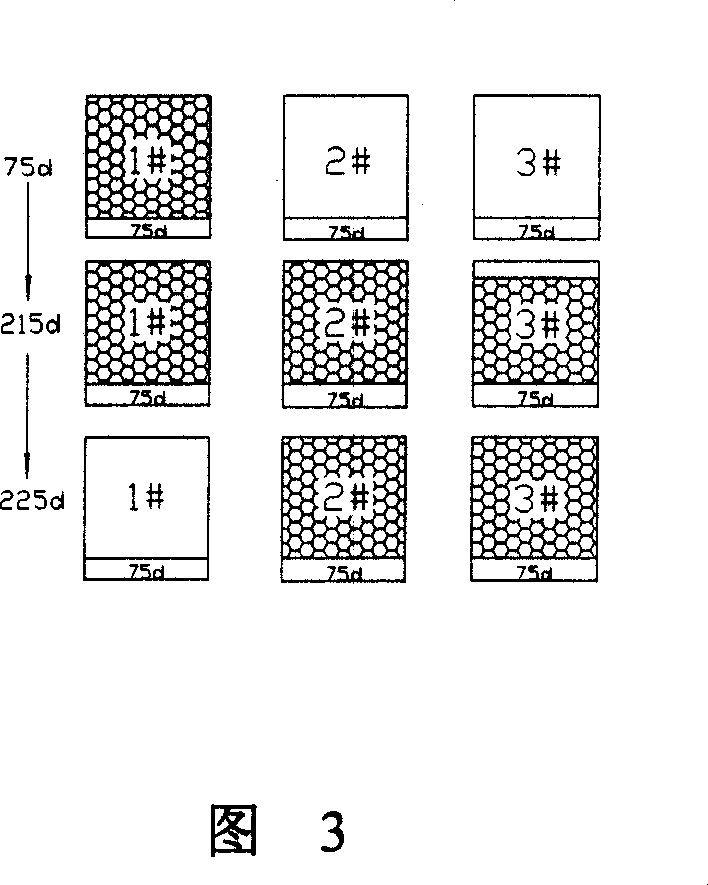

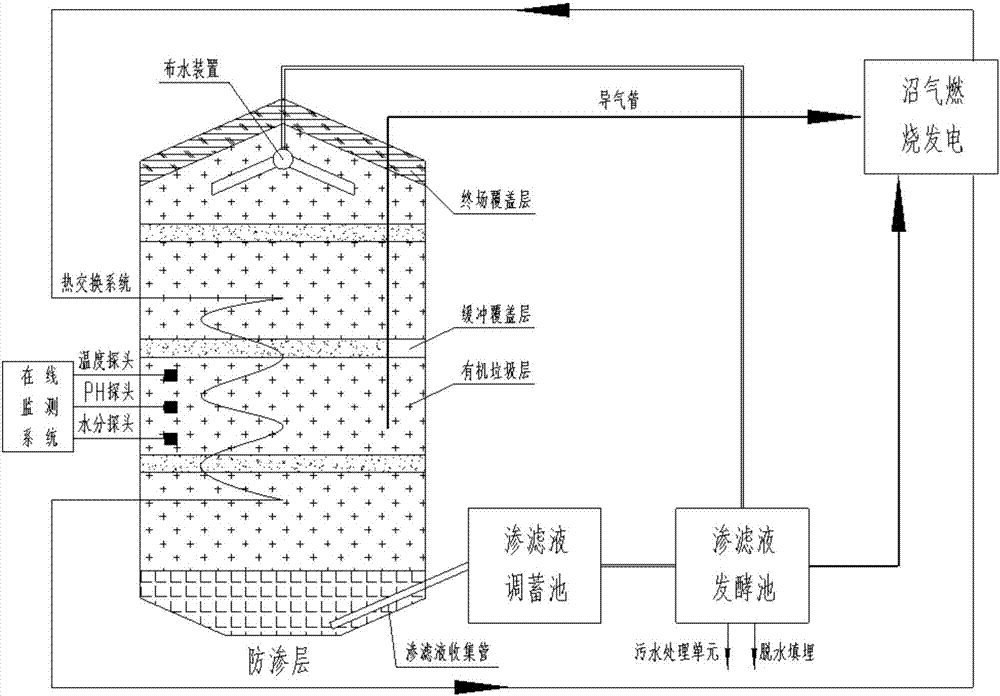

Landfill disposal method for rapidly stabilizing organic household waste and increasing methane yield

InactiveCN106947785AMake full use of the effective volumeStable degradationEnergy inputWaste based fuelMetabolic powerMethane yield

The invention discloses a landfill disposal method for rapidly stabilizing organic household waste and increasing methane yield. Household wastes are comprehensively sorted, the effective volume of a landfill unit of a bioreactor is sufficiently utilized, and cost is reduced; a buffer covering material, a heat exchange pipeline system and a leachate recharge system are laid to regulate pH, temperature and moisture content of waste digestion reaction in a landfill area, enhancing the growing and metabolic capability of microorganisms, consequently, waste degradation is accelerated, and the period of stabilizing wastes is shortened; and an IC (internal circulation) reactor is adopted to ferment initial leachate for the second time and recover methane. By utilizing leachate recharge after fermentation, the treatment load of the landfill area cannot be increased, and problems, such as easy excessive acidification in the operation process of a high-load anaerobic system, are improved; and moreover, the method abides by the objective law of anaerobic digestion of organic matter, effectively promotes the stability of organic household waste degradation, greatly increases the methane production rate and methane yield of the landfill unit, and increases the reclamation level of the landfill unit of the bioreactor.

Owner:CHONGQING UNIV

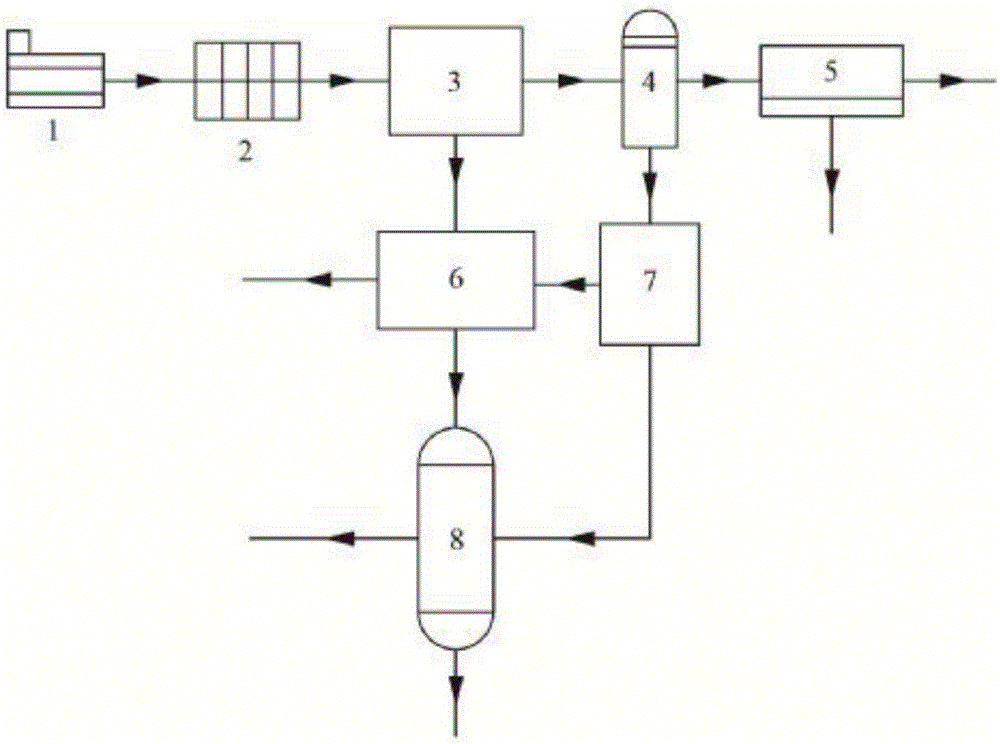

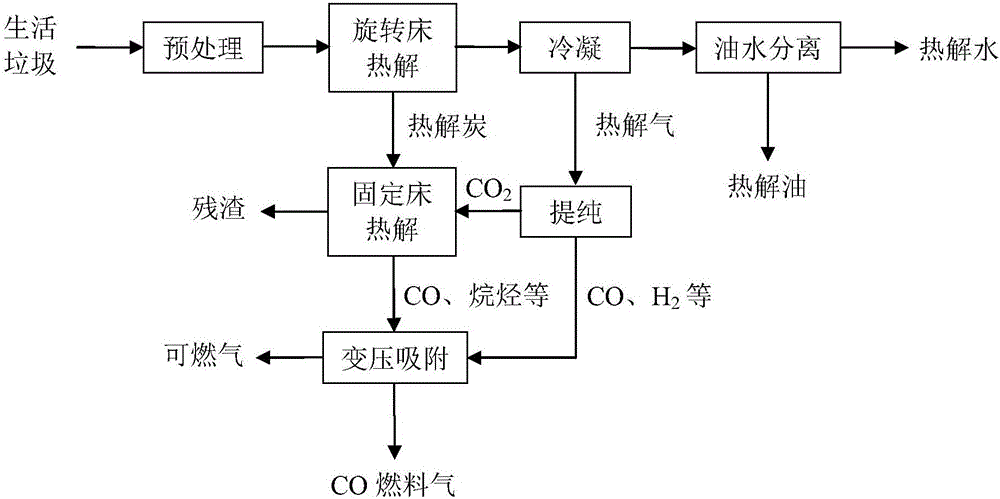

Method and system for purifying CO fuel gas through continuous pyrolysis of carbon-containing organic matter

PendingCN105861073AEase of industrial applicationNo secondary pollutionSpecific water treatment objectivesSludge treatment by pyrolysisAlkaneFixed bed

The invention provides a method and system for purifying a CO fuel gas through continuous pyrolysis of a carbon-containing organic matter. The system comprises a separation device, a breaking device, a rotary-bed pyrolyzing furnace, a fixed-bed pyrolyzing furnace, a condensing device, an oil-water separation device, a purifying device and a variable-pressure adsorption device. The method comprises the following steps: pretreating the carbon-containing organic matter and conveying to the rotary-bed pyrolyzing furnace for pyrolysis; treating the pyrolysis gas-liquid mixture obtained by the pyrolysis by the condensing device, the oil-water separation device and the gas purifying device to obtain a high-purity CO2 gas and combustible gases such as CH4, CO and H2; conveying the pyrolytic carbon obtained by the pyrolysis together with CO2 obtained by purifying the pyrolysis gas into a pyrolysis reactor of the fixed-bed pyrolyzing furnace for pyrolysis; and conveying the generated CO, alkane gases and the like together with the gases such as CO and H2 obtained by the pyrolysis of the rotary-bed pyrolyzing furnace and purification into the variable-pressure adsorption device to prepare the CO fuel gas. In the invention, large treatment quantity and low oil yield can be realized, the resources are saved, and industrial application is promoted.

Owner:SHENWU TECH GRP CO LTD

Method for preparing sintered insulating bricks from undisturbed wet sludge

InactiveCN109437843ARealize comprehensive utilizationNo secondary drying treatmentCeramic materials productionClaywaresTunnel kilnSocial benefits

The invention discloses a method for preparing sintered insulating bricks from undisturbed wet sludge. The method comprises the following steps: the undisturbed wet sludge with water content of 30%-50% from a sewage plant, foundation pit soil and a dry powder regulating material are mixed in a ratio, evenly stirred, and subjected to low-temperature aging, extrusion forming is performed for blank preparation, a blank is dried in a drying chamber, and the dried blank is sintered in a tunnel kiln. The moisture content of the mixture of the sludge and the foundation pit soil is adjusted by the drypowder regulating material, so that utilization of the undisturbed wet sludge in sintered bricks is realized, a new road is explored for sludge resource utilization, pressure of sludge treatment anddisposal in urban development is effectively relieved, and remarkable environmental and social benefits are achieved.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

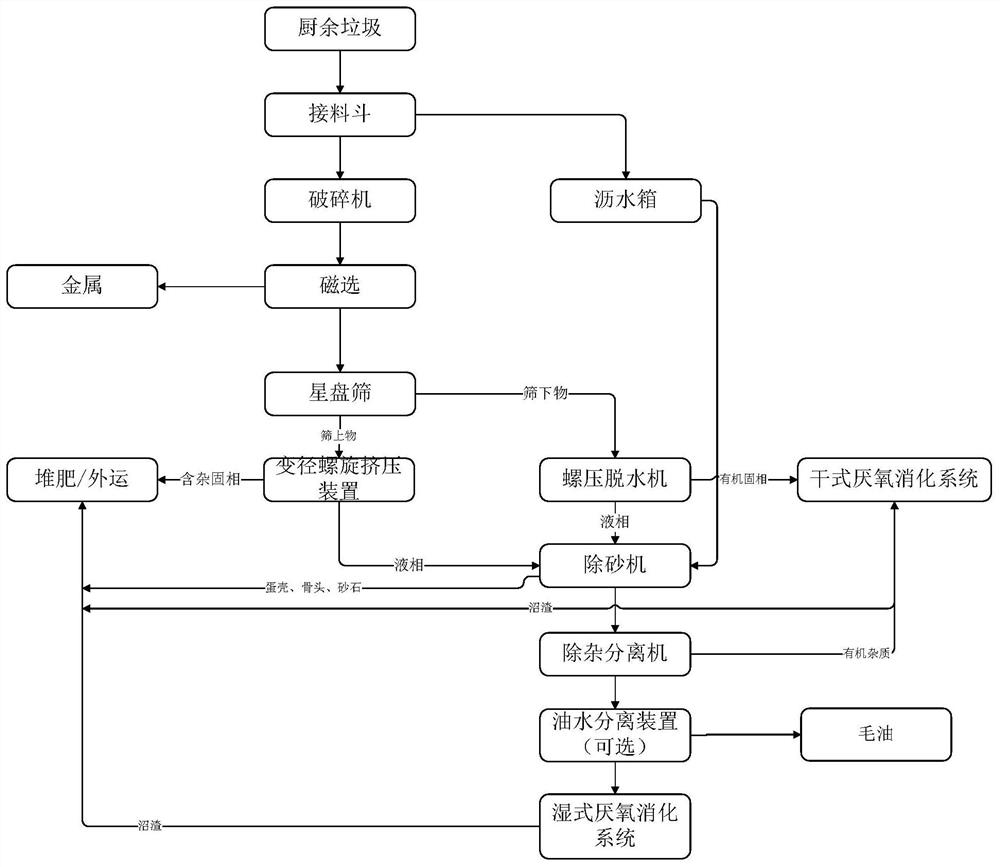

Kitchen waste collaborative wet and dry anaerobic digestion treatment system and method

PendingCN113399434AReduce equipment wear and tearImprove the utilization rate of organic matterSolid waste disposalMagnetic separatorPre treatment

The invention relates to a kitchen waste collaborative wet and dry anaerobic digestion treatment system and method. The kitchen waste collaborative wet and dry anaerobic digestion treatment system comprises a kitchen waste receiving hopper, a coarse crusher, a magnetic separator, a star disc sieve, a reducing screw extrusion device, a screw press dehydrator, a sand remover, an impurity removal separator, an oil-water separation device, a wet anaerobic fermentation tank and a dry anaerobic fermentation tank, wherein the oil-water separation device is selected according to the actual oil content of materials. According to the kitchen waste collaborative wet and dry anaerobic digestion treatment system and method, a pulping section of a traditional pretreatment link can be omitted, the problems of equipment abrasion caused by the pulping link, difficult sand and stone separation caused by high solid content of slurry, small flux of pulping equipment and the like are greatly reduced, the collaborative advantages of wet anaerobic treatment for fine waste and dry anaerobic treatment for coarse waste are fully exerted, and an oil removal pretreatment section can be selectively added in combination with the oil content of the materials; and the kitchen waste collaborative wet and dry anaerobic digestion treatment system and method have a series of advantages of high separation efficiency, low equipment abrasion, high organic matter utilization rate, no need of additional water in the process, low sewage yield, land saving and the like.

Owner:TONGJI UNIV

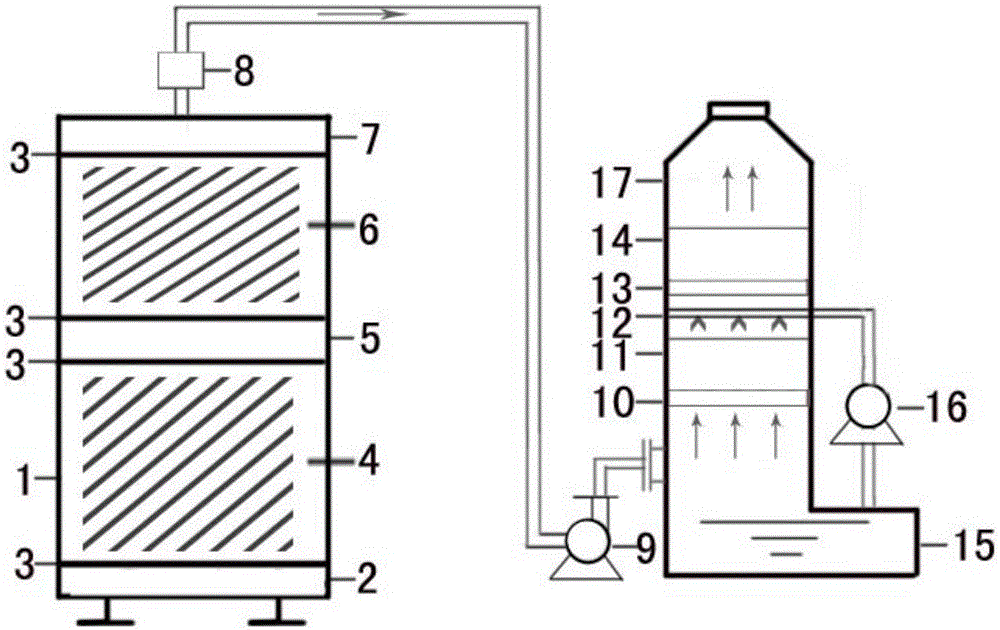

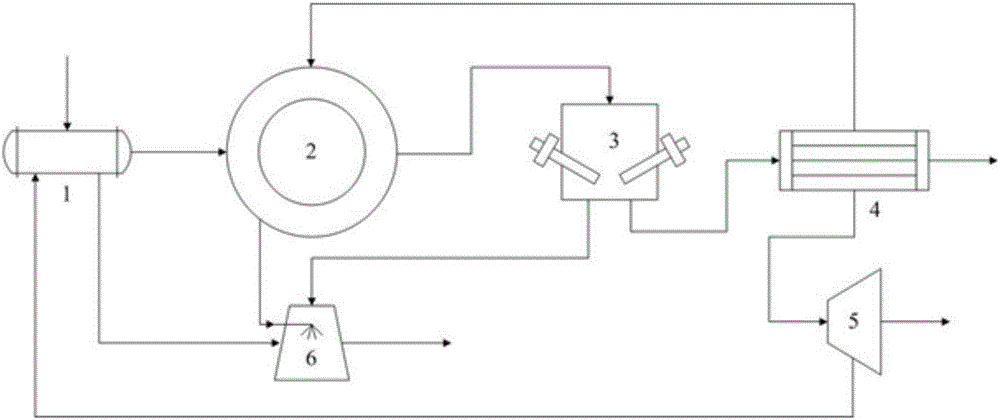

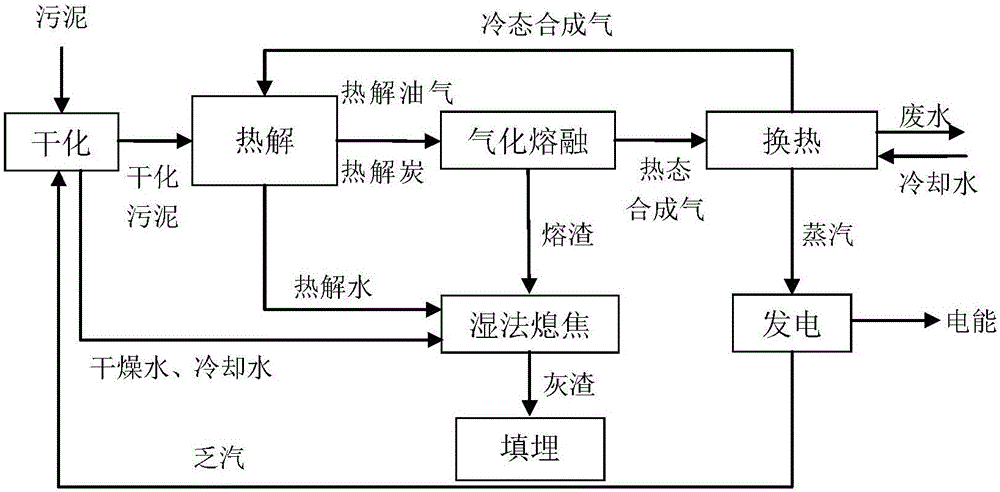

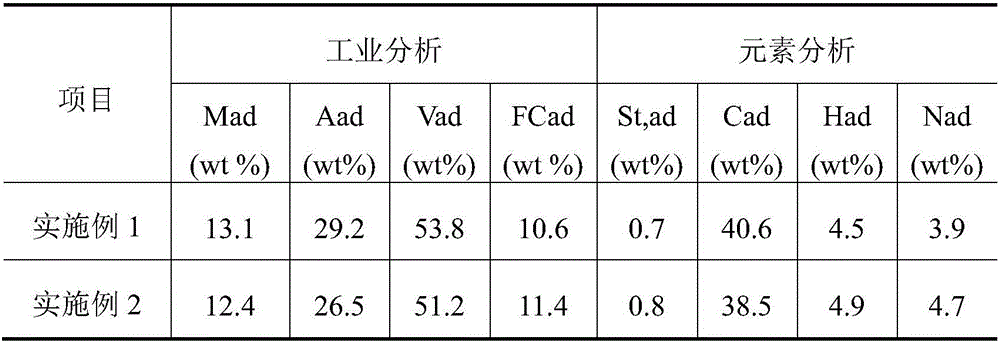

System and method for generating power by means of sludge

PendingCN106477837AHigh yieldHigh calorific valueSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSyngasSlag

The invention discloses a system and a method for generating power by means of sludge. The system comprises a drying device, a heat accumulating type revolving bed, a gasification and melting reaction chamber, a heat exchange device and a power generation device, wherein a sludge inlet, a dried sludge outlet, a drying water outlet, a steam inlet and a cooling water outlet are formed in the drying device; a raw material inlet, a pyrolytic water outlet, a pyrolytic oil gas outlet and a pyrolytic carbon outlet are formed in the heat accumulating type revolving bed, and the raw material inlet is connected with the dried sludge outlet; a pyrolytic oil gas inlet, a pyrolytic carbon inlet, a thermal-state synthesis gas outlet and a slag outlet are formed in the gasification and melting reaction chamber, the pyrolytic oil gas inlet is connected with the pyrolytic oil gas outlet, and the pyrolytic carbon inlet is connected with the pyrolytic carbon outlet; a thermal-state synthesis gas inlet, a cool-state synthesis gas outlet, a waste water outlet, a cooling water inlet and a steam outlet are formed in the heat exchange device, and the thermal-state synthesis gas inlet is connected with the thermal-state synthesis gas outlet; a steam inlet, a steam exhaust outlet and an electric quantity outlet end are formed in the power generation device, and the steam inlet is connected with the steam outlet. With the adoption of the system and the method, harmlessness, reduction and recycling of sludge are realized.

Owner:SHENWU TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com