Method for landfill gas in-the-field and out-of-the-field combined treatment

A joint treatment and landfill gas technology, applied in the direction of gas fuel, petroleum industry, waste fuel, etc., can solve the problems of landfill gas resource utilization, one-time investment and high operation and maintenance, global greenhouse effect, etc., to save clay Resources and economic costs, the effect of improving the taste of resources and improving the level of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

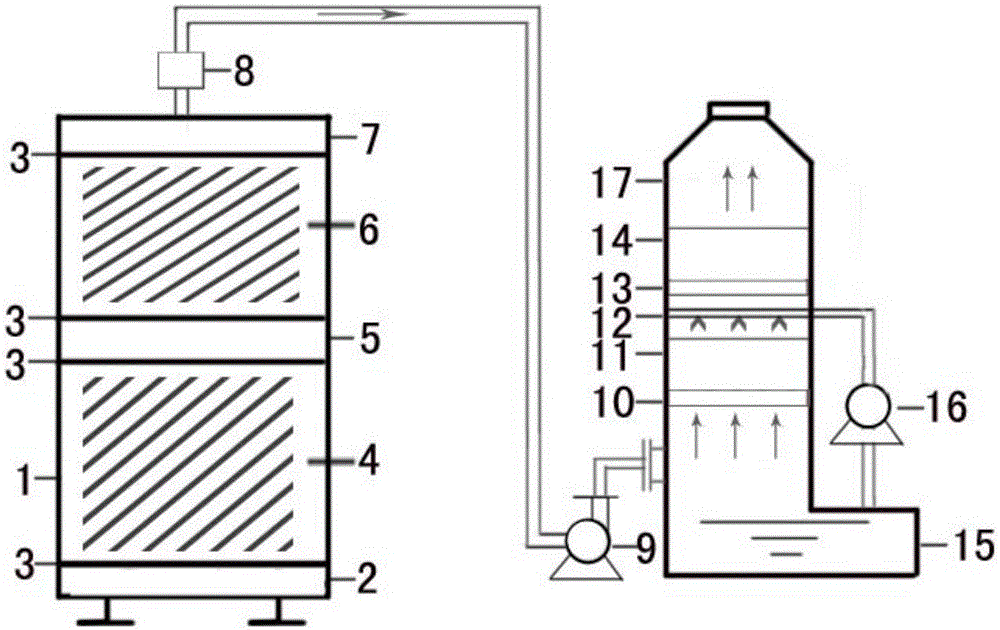

[0046] Such as figure 1 Shown, in order to realize the landfill gas field of the present invention method-off-site combined treatment device, comprise garbage landfill device and purification packing tower, garbage landfill device is arranged in the landfill site, and purification packing tower is located in garbage filling Buried outside.

[0047] The landfill device includes a shell 1, and the gravel layer 2, the first domestic waste landfill layer 4, the carbon-fixing intermediate layer 5, the second domestic waste landfill layer 6 and the carbon-fixing cover are sequentially arranged in the shell 1 from bottom to top. Layer 7, two adjacent layers are separated by geotextile layer 3, and an air outlet is provided on the top of the shell.

[0048] The ratio of the thickness of the carbon-fixing intermediate layer 5 to the total thickness of the two domestic waste landfill layers is 1:3-3.5; the thickness of the carbon-fixing covering layer 7 is 20-30 cm. Both the carbon-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com