Domestic refuse anaerobic-aerobic reactor circulating operation landfill method

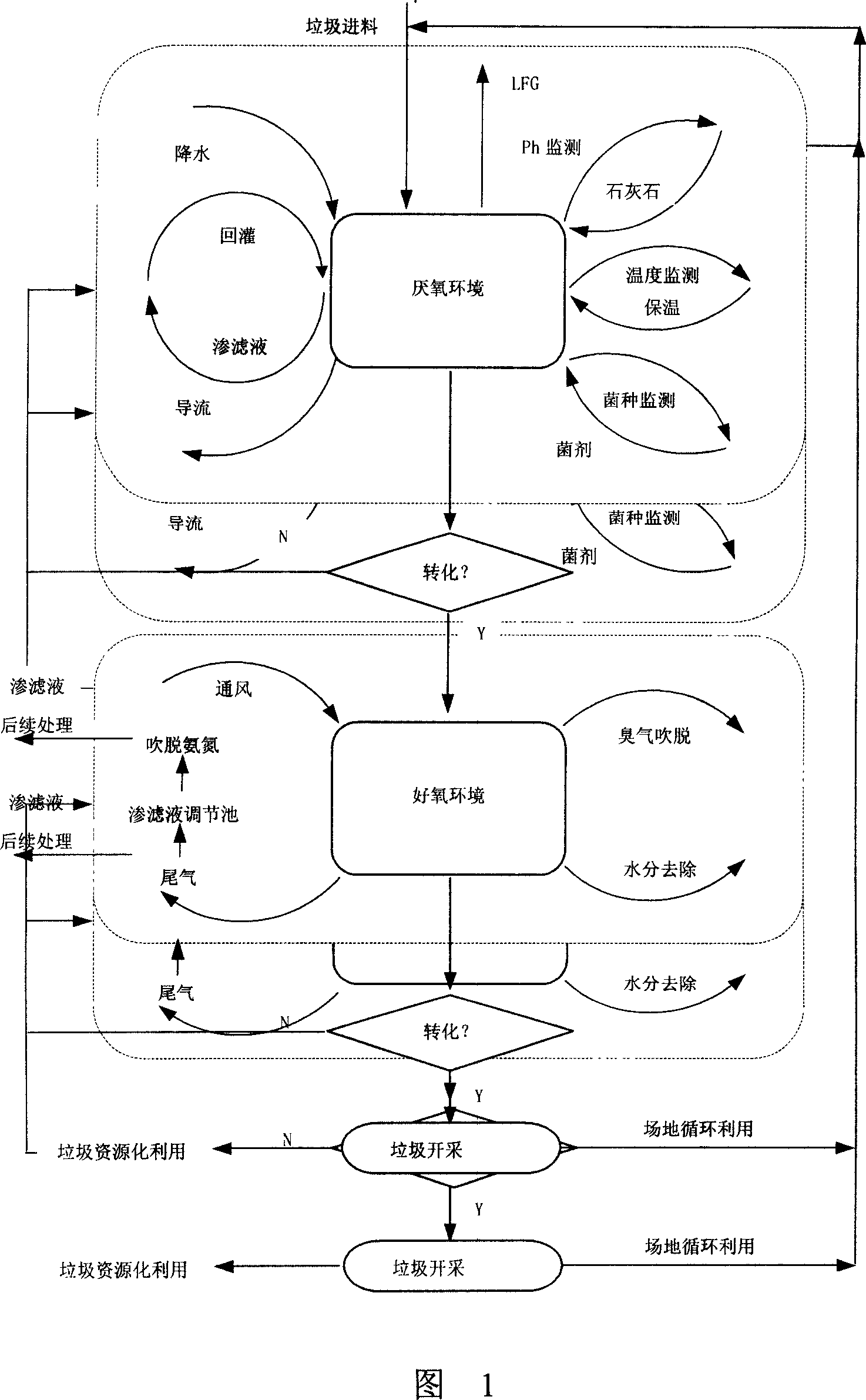

An aerobic reactor and anaerobic reactor technology, applied in the direction of solid waste removal, etc., can solve the problem of not taking the overall consideration of landfill gas production, the recycling of garbage stable landfill sites, and the lack of in-depth research on anaerobic-aerobic conversion. Process parameters and other issues to achieve the effect of reducing landfill operating costs, improving resource utilization, and saving disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

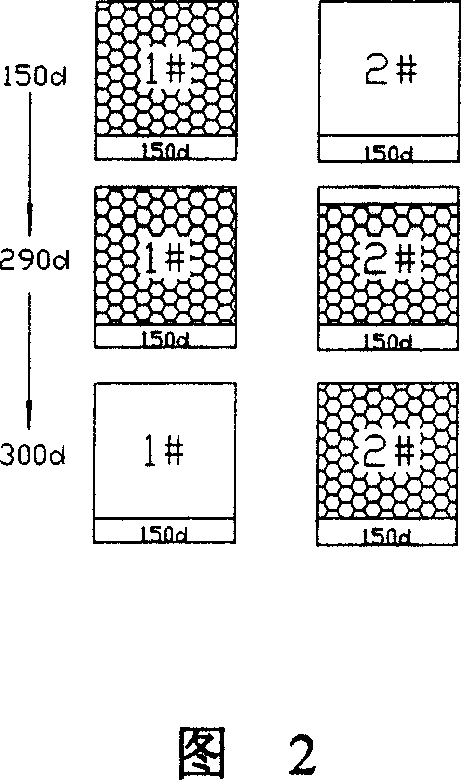

[0042] Process conditions: (1) The daily processing demand of the landfill unit is 100t; (2) The moisture content of the landfill waste is 50-60%, the volatile organic solid content is 35-45% (dry weight), and the compacted density is 1t / m 3 (According to a municipal garbage composition survey); (3) The average monthly precipitation is 150mm, and the maximum monthly precipitation is 234mm (according to the meteorological data of a certain city for many years); (4) The height of the landfill unit (bioreactor) is 3m.

[0043] Build 2 unit storage capacity of 100m×50m×3m (15000m 3 ) landfill unit to meet the anaerobic-aerobic cycle landfill operation. In the anaerobic landfill stage, leachate recharge is used, and each landfill unit is recharged once a day, each time 2000m 3 ; During the aerobic landfill phase, forced ventilation is carried out for 8 hours a day.

[0044] The filling time of each unit is 150d; the completion time of the anaerobic phase is 110d; the completion...

example 2

[0046] Processing condition is identical with example 1.

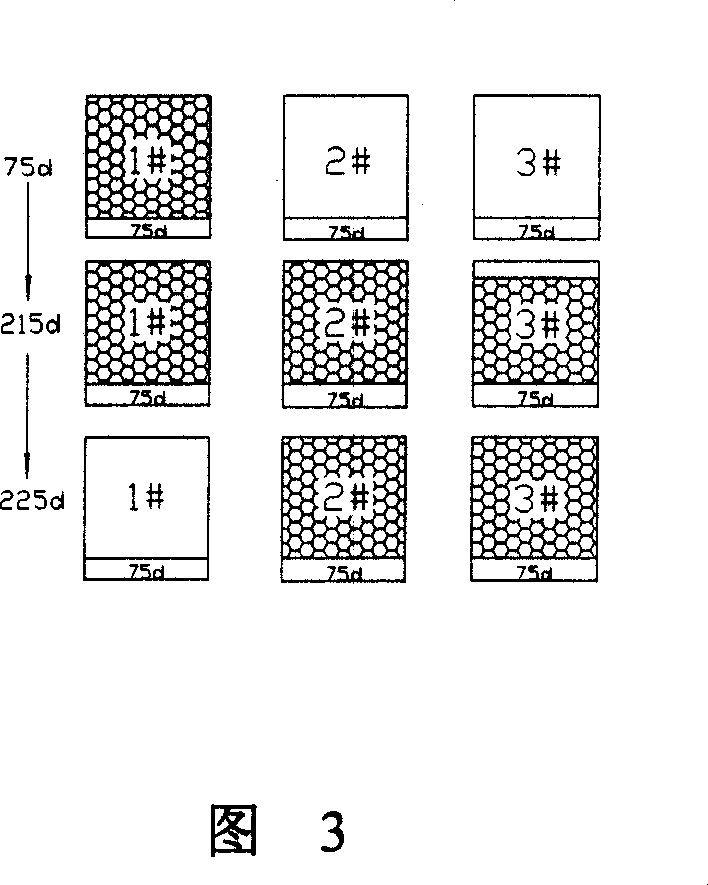

[0047] Build 3 unit storage capacity of 50m×50m×3m (7500m 3 ) landfill unit to meet the anaerobic-aerobic cycle landfill operation. In the anaerobic landfill stage, leachate recharge is used, and each landfill unit is recharged once a day, each time 850m 3 ; During the aerobic landfill phase, forced ventilation is carried out for 12 hours a day.

[0048] The filling time of each unit is 75d; the completion time of the anaerobic phase is 120d; the completion time of the aerobic phase is 20d; the garbage excavation time is 10d; the unit process cycle is 225d.

[0049] The job diagram of Example 2 is shown in Figure 3:

[0050] The small storage capacity of the landfill unit is beneficial to reduce the landfill cycle, increase the circulation speed of the landfill site, and save land resources at the same time. As in Example 2, the landfill area is 7500m 3 , saving 25% of land resources compared with Scheme 1. Howev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com