Kitchen waste collaborative wet and dry anaerobic digestion treatment system and method

A kitchen waste, dry anaerobic technology, applied in the removal of solid waste and other directions, can solve the problem of high oil content, achieve the effects of low equipment wear, reduced tap water consumption, and high organic matter utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

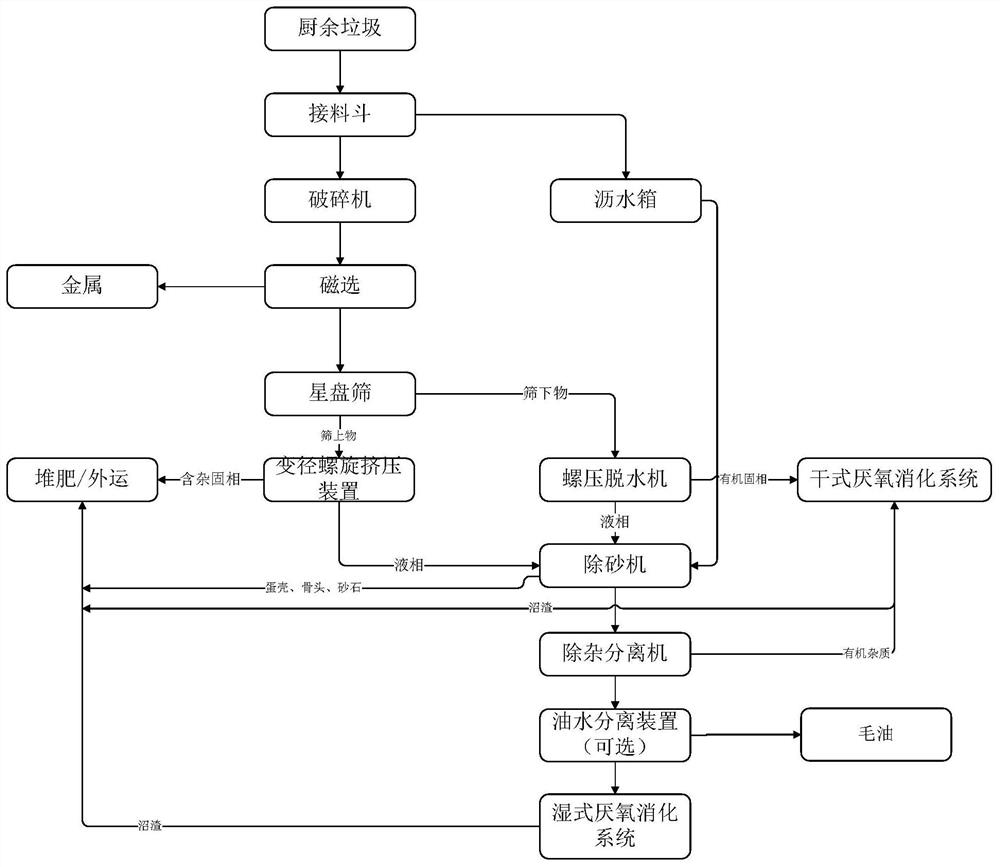

[0040] refer to figure 1 , this embodiment provides a method for synergistic wet and dry anaerobic digestion of kitchen waste, including the following steps:

[0041] The kitchen waste receiving hopper receives the kitchen waste and separates the free water in the kitchen waste. The free water is drained into the drain tank and sent to the desander through the conveying pump. The solid phase is sent to the coarse Crusher,

[0042] The coarse crusher performs coarse crushing on the solid phase materials, and the coarsely crushed materials are sent to the astro-disc screen through the shaftless screw conveyor after the metal is removed by the magnetic separation of the magnetic separator.

[0043] The star plate sieve screens and separates the materials, the oversize material is sent to the variable-diameter screw extrusion device, and the undersize material of the star plate sieve enters the screw press dehydrator.

[0044] The variable-diameter screw extrusion device extrude...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Screen aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com