Method of efficiently purifying and comprehensively utilizing biogas slurry

A biogas slurry and high-efficiency technology, applied in the field of waste resource utilization, can solve the problems of high storage and long-distance transportation costs, low farmers' enthusiasm for utilization, and low nutrient element concentration, so as to improve the level of resource utilization and reduce the cost of use. , the effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

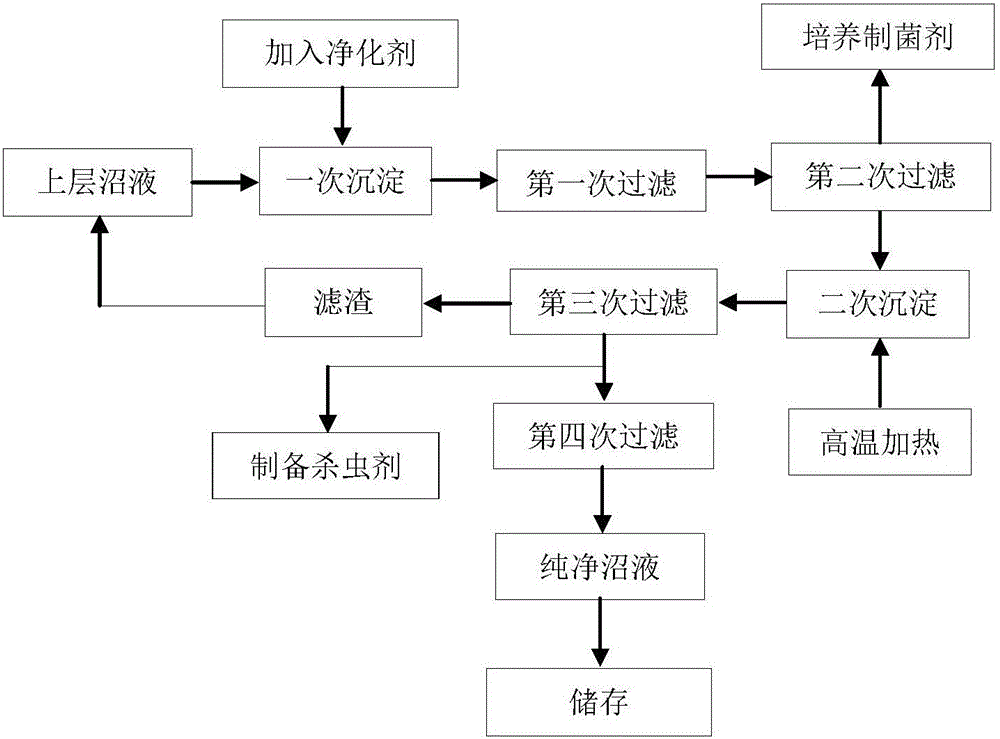

[0017] The excess biogas slurry from the biogas digester is used as raw material to carry out multi-stage filtration and purification by physical and chemical methods. The specific process is as follows: ①The first step is to extract the excess biogas slurry from the upper layer of the biogas tank and then add a purifying agent to conduct a precipitation; ②The second step is to filter for the first time after the precipitation to filter out the coarse impurities in the biogas slurry; The third step is to perform the second filtration to filter out the fine impurities in the biogas slurry; ④ The fourth step is to heat the filtered biogas slurry at high temperature for the second precipitation; ⑤ The fifth step is to perform the third filtration after precipitation Filter out the precipitated impurities in the biogas slurry; ⑥The sixth step is to perform the fourth filtration to filter out the fine impurities in the biogas slurry; ⑦The seventh step is to store the treated biogas ...

example 2

[0026] The excess biogas slurry from the biogas digester is used as raw material to carry out multi-stage filtration and purification by physical and chemical methods. The specific process is as follows: ①Extract excess biogas slurry from the upper layer of the biogas digester and then add a purifying agent to conduct a precipitation; ②After the precipitation, perform the first filtration to filter out the coarse impurities in the biogas slurry; ③Perform the second filtration to filter out the biogas ④ Heating the filtered biogas slurry at high temperature for the second precipitation; ⑤ After the precipitation, perform the third filtration to filter out the precipitated impurities in the biogas slurry; ⑥ Perform the fourth filtration to filter out the biogas slurry ⑦Store the treated biogas slurry and use it as plant root and foliage fertilizer or plant pest inhibitor.

[0027] When the excess biogas slurry in the upper layer of the biogas digester is pumped into the treatmen...

example 3

[0034] The excess biogas slurry from the biogas digester is used as raw material, and multi-stage filtration and purification are carried out by using a combination of physical and chemical methods. The specific process includes adding a purifying agent to the biogas slurry pumped from the biogas digester, and then undergoing two precipitations, four filtrations, one high-temperature heating, and the purified biogas slurry is cooled and then stored.

[0035] When the excess biogas slurry in the upper layer of the biogas digester is pumped into the treatment system, a filter is installed at the entrance of the biogas slurry of the pumping equipment, and the filter mesh has a pore size of 1.5mm.

[0036] The purification agent added to the biogas slurry is soda ash. The amount of biogas slurry to be treated for the first time is 200 grams per cubic meter. After mixing with the biogas slurry evenly, it will settle for more than 16 hours; after a treatment cycle, add new biogas slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com