Method for reusing lime semi-dry desulfurization ash

A semi-dry desulfurization and desulfurization ash technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of secondary pollution, replacement of desulfurization ash, and difficulty in utilization, so as to reduce consumption and avoid secondary pollution. The effect of reducing secondary pollution and improving the level of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

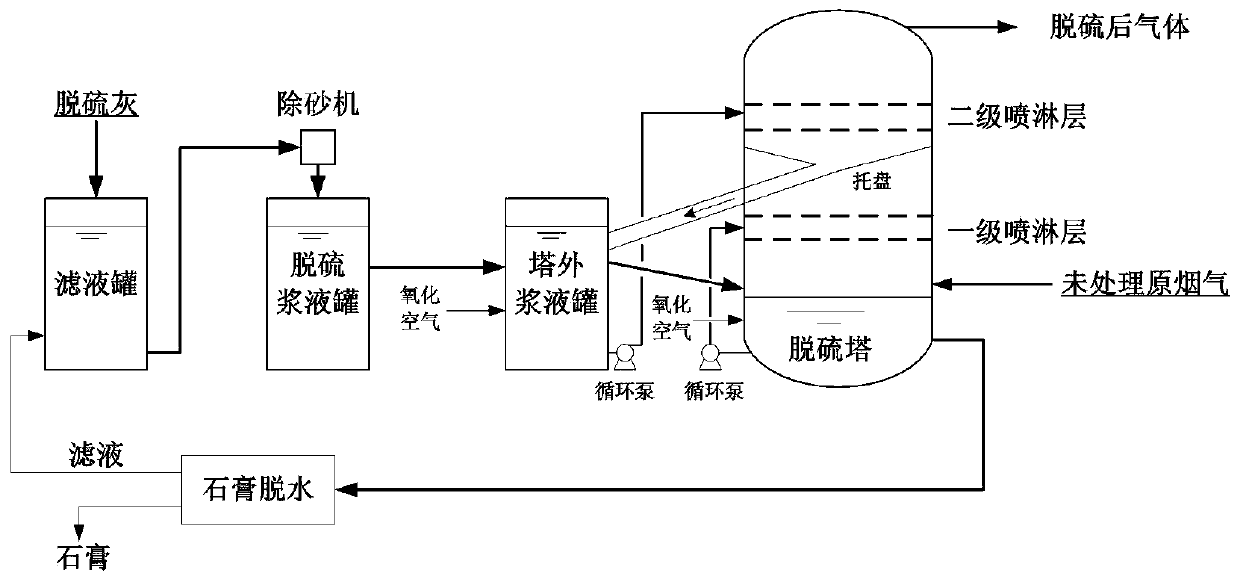

[0030] Add the semi-dry desulfurization ash to the filtrate tank and prepare the filtrate to a density of 1.25×10 3 kg / m 3 The pH value of the slurry is 12.3. The slurry is transported to the desander with a pump to filter out particles larger than 45 μm and then enters the desulfurization slurry tank. Mix the circulating slurry in the spray layer, and then use the slurry pump to send the mixed slurry in the slurry tank outside the tower to the secondary spray layer of the desulfurization tower to circulate the flue gas and absorb the sulfur dioxide in the flue gas. The slurry after absorbing the sulfur dioxide is collected by the tray After returning to the slurry tank outside the tower, when the pH value of the slurry in the slurry tank outside the tower is reduced to about 6.0, discharge 1 / 4 (accounting for the proportion of the total slurry volume in the tank) slurry to the bottom of the desulfurization tower, and use the circulating slurry pump to desulfurize The slurry ...

Embodiment 2

[0035] Add the semi-dry desulfurization ash to the filtrate tank and prepare the filtrate to a density of 1.28×10 3 kg / m 3 The pH value of the slurry is 12.5. The slurry is pumped to the desander to filter out particles larger than 45 μm and then enters the desulfurization slurry tank. The frequency conversion pump is used to transport the desulfurization raw slurry to the slurry tank outside the tower. Mix the circulating slurry in the spray layer, and then use the slurry pump to send the slurry in the slurry tank outside the tower to the secondary spray layer of the desulfurization tower to circulate the flue gas and absorb the sulfur dioxide in the flue gas. The slurry after absorbing the sulfur dioxide is collected by the tray and returned The slurry tank outside the tower, when the pH value of the slurry in the slurry tank outside the tower drops to 6.1, discharge 1 / 3 of the slurry to the bottom of the desulfurization tower; use the circulating slurry pump to send the slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com