Sludge treatment method based on hydrothermal carbonization

A hydrothermal carbonization and sludge treatment technology, which is applied in the directions of dehydration/drying/concentrated sludge treatment, sludge treatment through temperature control, and pyrolysis treatment of sludge, etc., to achieve simple equipment, strong adjustable application scale, and ease The effect of the greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

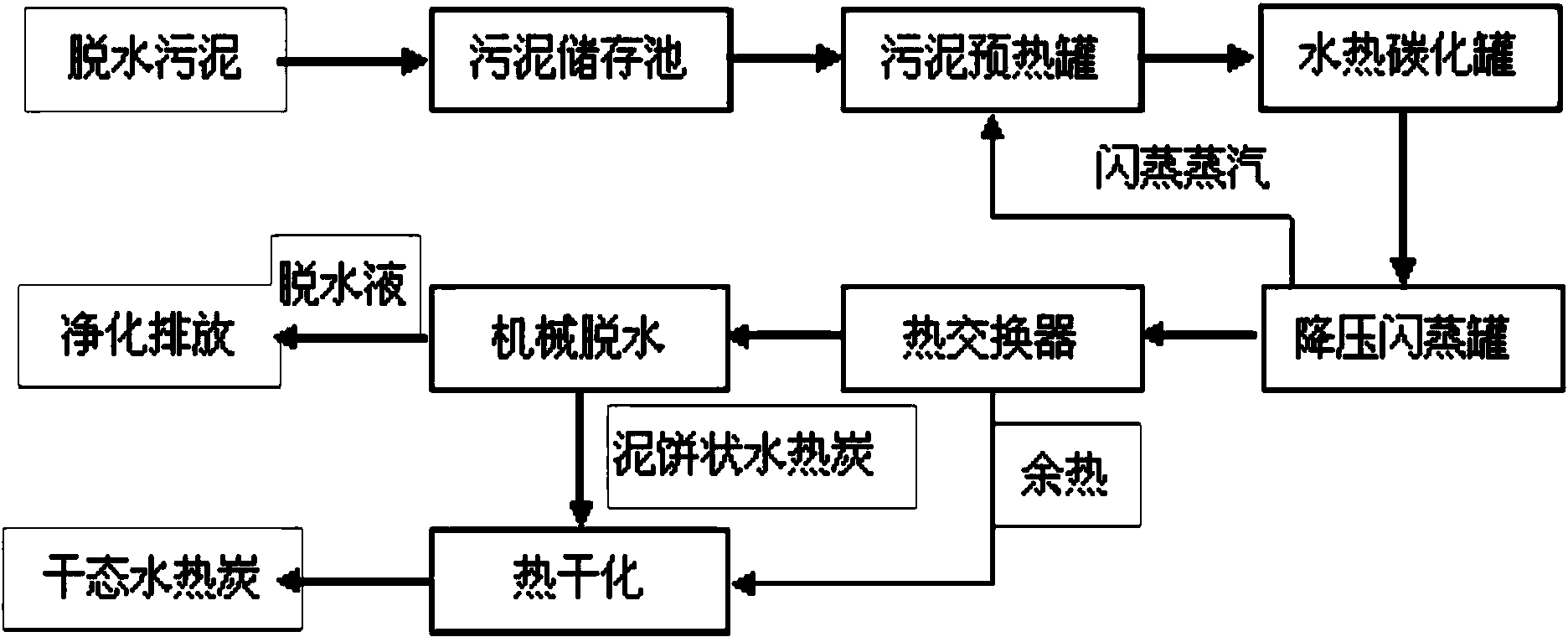

[0028] Sludge treatment methods based on hydrothermal carbonization, such as figure 1 shown, including the following steps:

[0029] (1) Sludge preheating treatment: input the dewatered sludge in the sludge storage bin into the preheating tank for preheating treatment, the preheating temperature is 50°C, the preheating treatment time is 3h, and the moisture content of the sludge is adjusted 75%;

[0030] (2) Hydrothermal carbonization: Inject the preheated sludge into the hydrothermal carbonization tank, add citric acid, adjust the pH value of the material in the hydrothermal carbonization tank to 5.0, and control the reaction temperature in the hydrothermal carbonization tank to 180°C. Hydrothermal carbonization reaction 6h;

[0031] (3) Recovery and utilization of waste heat: transport the material after hydrothermal carbonization treatment to the flash tank, reduce it to normal pressure and then transport it to the heat exchanger;

[0032] (4) Dehydration and drying: the...

Embodiment 2

[0035] Sludge treatment methods based on hydrothermal carbonization, such as figure 1 shown, including the following steps:

[0036] (1) Sludge preheating treatment: input the dewatered sludge in the sludge storage bin into the preheating tank for preheating treatment, the preheating temperature is 60°C, the preheating treatment time is 2.5h, and the moisture content of the sludge is adjusted 80%;

[0037] (2) Hydrothermal carbonization: Inject the preheated sludge into the hydrothermal carbonization tank, add acetic acid, adjust the pH value of the material in the hydrothermal carbonization tank to 6.2, control the reaction temperature in the hydrothermal carbonization tank to 200 °C, water Thermal carbonization reaction 5h;

[0038] (3) Recovery and utilization of waste heat: transport the material after hydrothermal carbonization treatment to the flash tank, reduce it to normal pressure and then transport it to the heat exchanger;

[0039] (4) Dehydration and drying: the...

Embodiment 3

[0042] Sludge treatment methods based on hydrothermal carbonization, such as figure 1 shown, including the following steps:

[0043] (1) Sludge preheating treatment: input the dewatered sludge in the sludge storage bin into the preheating tank for preheating treatment, the preheating temperature is 70°C, the preheating treatment time is 2h, and the moisture content of the sludge is adjusted 80%;

[0044] (2) Hydrothermal carbonization: Inject the preheated sludge into the hydrothermal carbonization tank, add citric acid and acetic acid, adjust the pH value of the material in the hydrothermal carbonization tank to 5.6, and control the reaction temperature in the hydrothermal carbonization tank to 260 ℃, hydrothermal carbonization reaction for 3h;

[0045] (3) Recovery and utilization of waste heat: transport the material after hydrothermal carbonization treatment to the flash tank, reduce it to normal pressure and then transport it to the heat exchanger;

[0046] (4) Dehydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com