Method for improving straw fermentation for preparing biogas

A technology for straw and biogas, which is applied in the field of improving straw fermentation to prepare biogas, can solve the problems of low utilization rate of resources, difficulty in popularization and application, and high operation cost, and achieves the effects of low cost, strong operability, and solving difficulty in treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Example 1: Corn Stalks

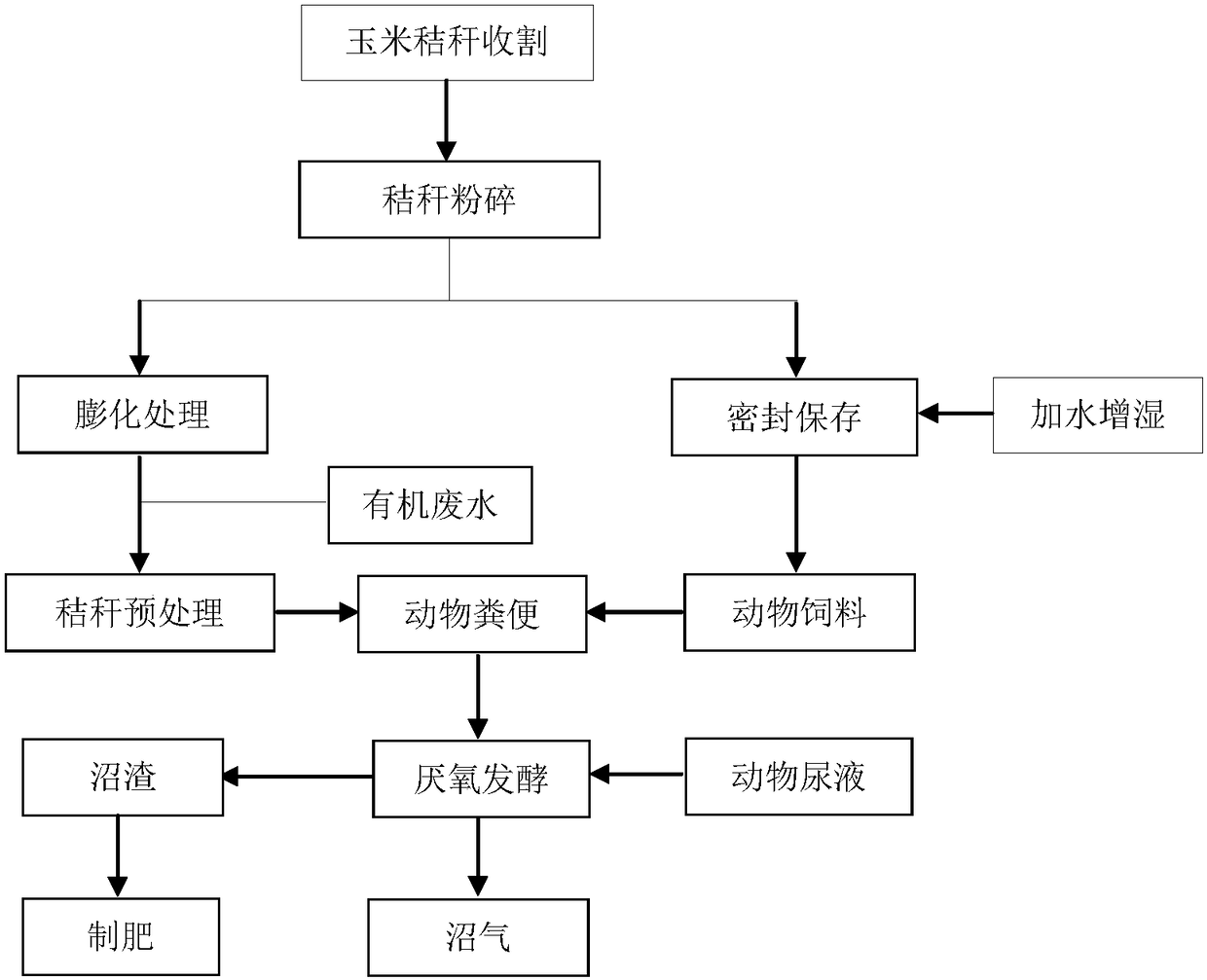

[0019] Such as figure 1 As shown, part of the harvested fresh corn stalks was crushed and puffed, and the other part was added with water and humidified and then sealed and stored; the puffed straw was pretreated by adding organic wastewater for 3 days, and the sealed and stored straw was used for animal feed after 15 days; The pretreated puffed straw is mixed with animal manure, and at the same time, animal urine is added for anaerobic fermentation. The biogas residue produced is used for fertilizer making, and the biogas is purified and used as fuel.

[0020] The moisture content of the straw used for puffing treatment shall not exceed 45% before pulverization, and the moisture content of the straw shall be saturated by adding organic waste water after pulverization; the moisture content of the straw used for preparing animal feed shall not be less than 55% before pulverization, and water shall be added for humidification during sealed storage...

example 2

[0028] Such as figure 1 As shown, the puffed rice straw was added to organic wastewater for pretreatment for 5 days, and the sealed stored straw was used for animal feed after 15 days.

[0029] The moisture content of the straw used for puffing treatment shall not exceed 45% before pulverization, and the moisture content of the straw shall be saturated by adding organic waste water after pulverization; the moisture content of the straw used for preparing animal feed shall not be less than 55% before pulverization, and water shall be added for humidification during sealed storage The water content is more than 80%; the length of crushed straw used for puffing is less than 50 mm, and the crushed length of straw used for preparing animal feed does not exceed 80 mm.

[0030] After the puffing treatment, the volume increases by 1.5 times; 4.5% plant ash is added to the straw pretreatment and mixed evenly; the mixing ratio of the pretreated straw and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com