Method and system for purifying CO fuel gas through continuous pyrolysis of carbon-containing organic matter

A technology for organic matter and fuel gas, applied in the field of solid waste recycling, can solve the problems of low calorific value of pyrolysis gas, greenhouse effect, low sales price, etc., and achieve good economic benefits, low operating costs, and waste heat recovery and utilization rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Using municipal solid waste from a certain city as raw material, the moisture content of the waste is 55%, and the contents of each component are as follows:

[0066] Table 1 Percentage of each component of domestic waste (wet basis)

[0067]

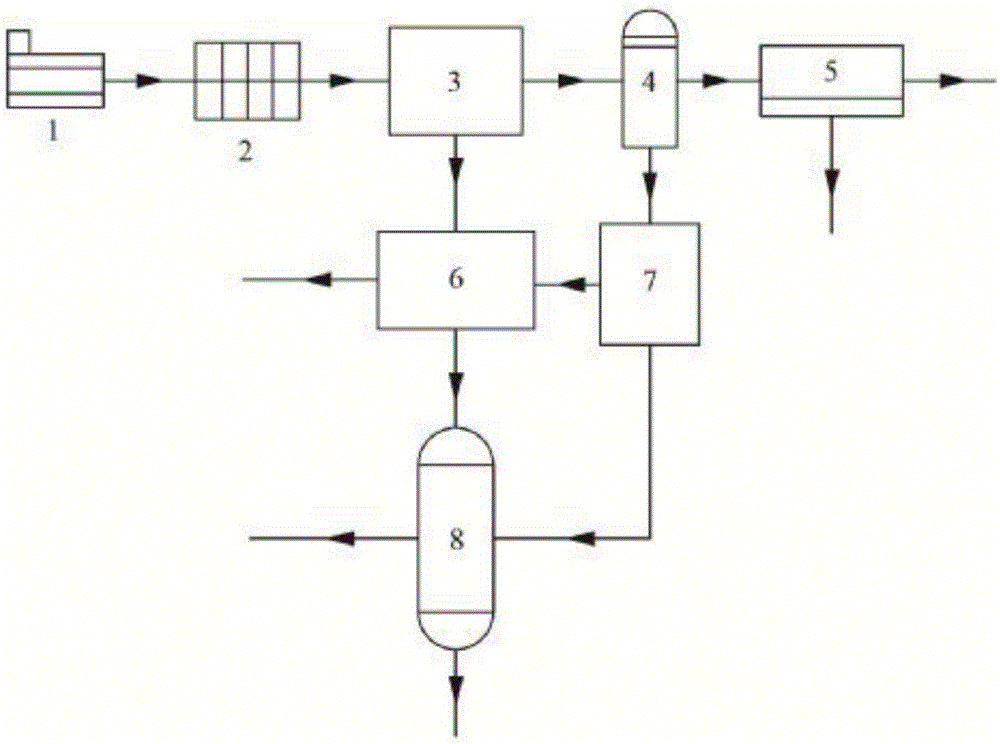

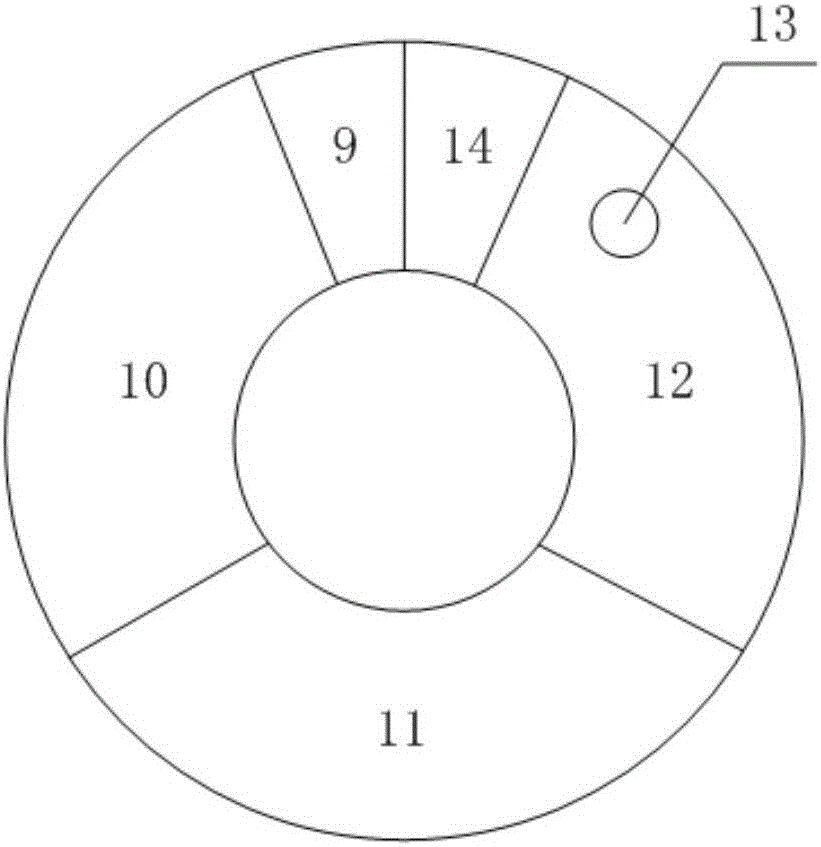

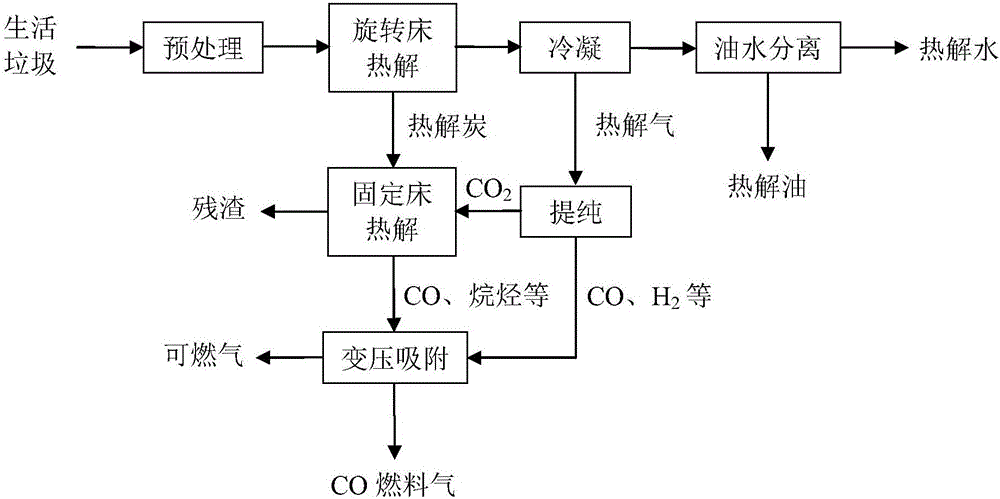

[0068] The domestic waste with a moisture content of 55% is sent to the pretreatment system such as sorting and crushing. After 3 days of heap filtration in the storage pit, the moisture content of the waste is reduced to 25%, and then transported to the rotary bed pyrolysis furnace. Garbage in the rotary bed pyrolysis furnace passes through the drying zone, pyrolysis zone, and catalytic reaction zone in sequence. The drying zone mainly evaporates the remaining water in the garbage; after the pyrolysis oil and other products generated in the pyrolysis zone enter the catalytic reaction zone, the secondary Cracking produces a large amount of CO, CO 2 、H 2 Wait for pyrolysis. The pyrolysis gas-liquid mixture obtained by pyroly...

Embodiment 2

[0070] Adopt the stalk of certain city, moisture content is 38%, its industrial analysis and elemental analysis are as follows:

[0071] Table 2 Elemental analysis and industrial analysis of raw materials

[0072]

[0073] The meanings of the abbreviations in Table 1 are as follows:

[0074] Mad—moisture content of air-dried raw materials;

[0075] Aad - the ash content of the air-dried raw material;

[0076] Vad - the volatile content of the air-dried raw material;

[0077] FCad - fixed carbon content of air-dried feedstock;

[0078] Cad - the carbon content of the air-dried raw material;

[0079] Had - the hydrogen content of the air-dried raw material;

[0080] Nad - the nitrogen content of the air-dried raw material;

[0081] St,ad - the total sulfur content of the air-dried raw material.

[0082] The straw with a moisture content of 38% is crushed and heaped and filtered for 2 days, the moisture content of the straw is reduced to 20%, and then transported to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com