System and method for generating power by means of sludge

A sludge and inlet technology, applied in the field of power generation systems using sludge, can solve the problems of difficult industrial application, high maintenance frequency, and high operating costs, and achieve easy industrialization and scale, high resource utilization level, and increase economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

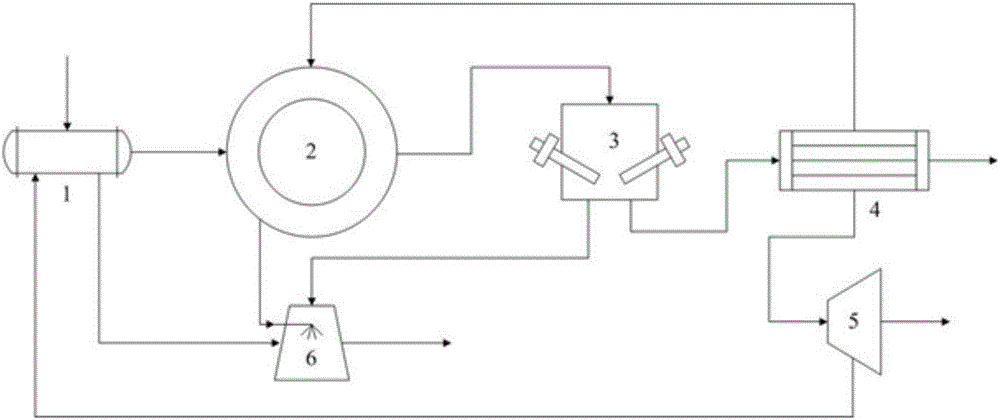

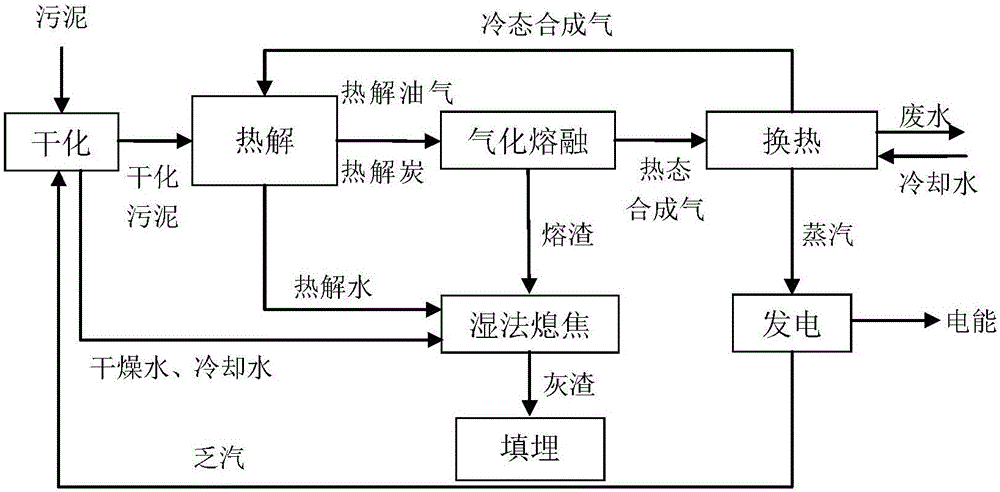

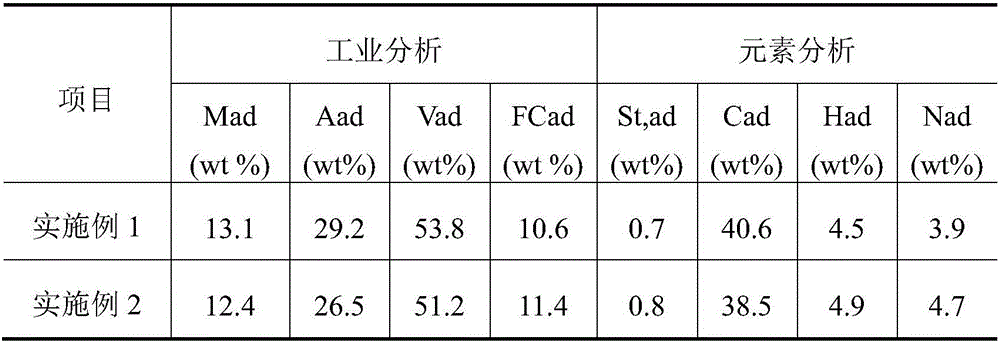

[0068] This embodiment adopts figure 1 The system shown and figure 2 The process route shown uses sludge for power generation. The sludge used is the sludge from a certain urban sewage treatment plant. Its industrial analysis and elemental analysis are shown in Table 1. The specific treatment process is as follows:

[0069] The sludge with a moisture content of 88% is sent to the drying device 1 to produce 48% dry water, and the sludge with a moisture content of 40% is sent to the regenerative rotary bed 2, and the regenerative radiant tube in the drying area The temperature of the pyrolysis zone is 400°C and the temperature of the regenerative radiant tube is 600°C. The sludge undergoes drying and pyrolysis successively in the regenerative rotary bed 2, and the finally obtained pyrolysis water flows out from the pyrolysis water outlet, and enters the coke quenching device 6 together with the drying water and cooling water produced by drying , the pyrolysis oil gas is disc...

Embodiment 2

[0072] This embodiment adopts figure 1 The system shown and figure 2 The process route shown uses sludge for power generation. The sludge used is the sludge from a certain urban sewage treatment plant. Its industrial analysis and elemental analysis are shown in Table 1. The specific treatment process is as follows:

[0073] The sludge with a moisture content of 85% is sent to the drying device 1 to produce 45% dry water, and the sludge with a moisture content of 40% is sent to the regenerative rotary bed 2, and the regenerative radiant tube in the drying area The temperature of the pyrolysis zone is 500°C and the temperature of the regenerative radiant tube is 900°C. The sludge undergoes drying and pyrolysis successively in the regenerative rotary bed 2, and the finally obtained pyrolysis water flows out from the pyrolysis water outlet, and enters the coke quenching device 6 together with the drying water and cooling water produced by drying , the pyrolysis oil gas is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com