Method for producing methane by anaerobic fermentation

An anaerobic fermentation and methane technology, applied in fermentation, climate change adaptation, organic fertilizer, etc., can solve the problem of low gas production rate of raw materials, achieve the effect of increasing methane production, promoting transformation, and improving the level of waste recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 Preparation of modified nano-iron oxide particles

[0023] (1) Preparation of magnetic nanoparticles with polyethyleneimine as a surface ligand molecule

[0024] FeCl 3 and FeCl 2 Dissolve in a certain amount of distilled water at a molar ratio of 2:1 and heat to 60°C. Under the protection of argon, concentrated ammonia water was slowly added to make the pH of the solution 9 and kept for 2 h. After the reaction, the sample was washed three times with deionized water and ethanol to obtain bare-core magnetic nanoparticles.

[0025] Take a certain amount of nano-Fe 3 o 4 Dissolve the magnetic particles in 100ml of distilled water, and ultrasonically treat them for 15-30 minutes to completely disperse them. Then slowly add 50-70 mg of surface ligand molecule polyethyleneimine into the solution. After stirring for 24-48 hours, the ligand-modified Fe 3 o 4 The nanoparticles are separated from the solution, washed repeatedly with distilled water and metha...

Embodiment 2

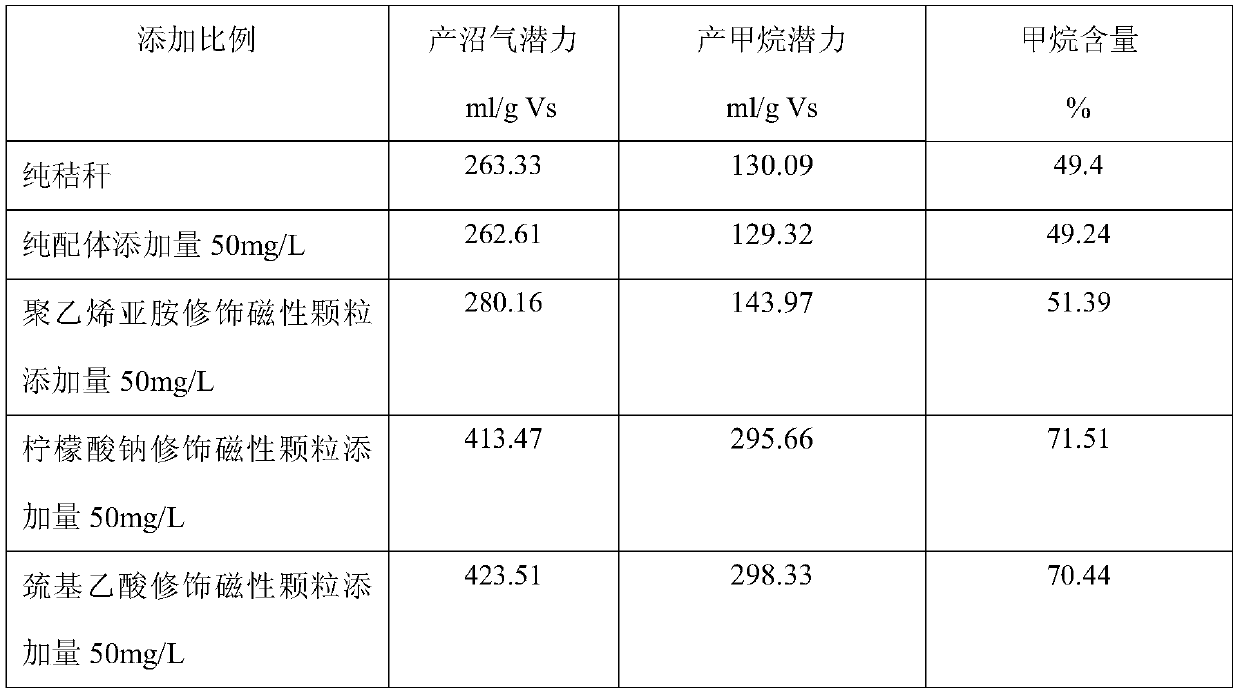

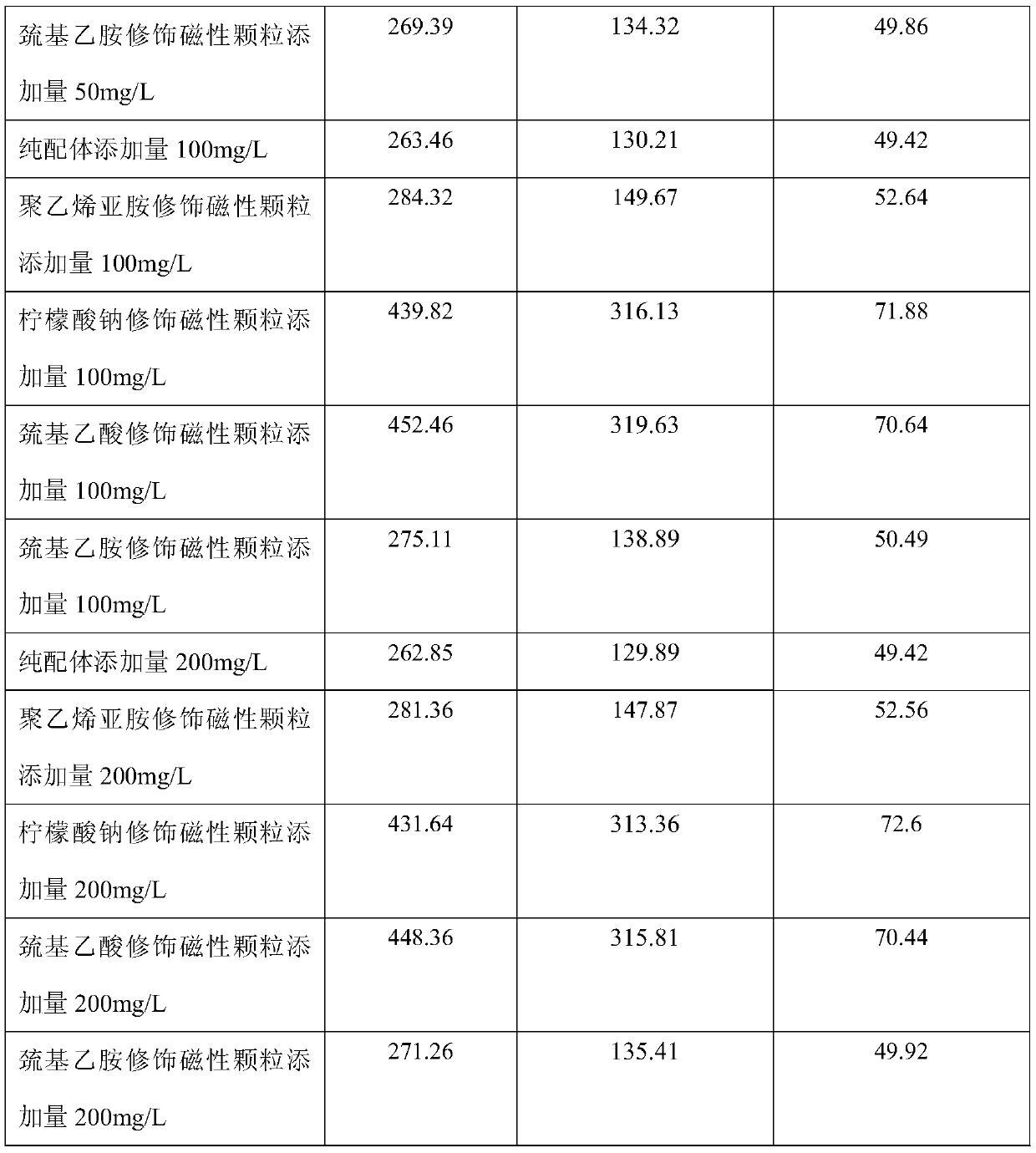

[0035] Embodiment 2 anaerobic fermentation produces methane

[0036] (1) Chopping the straw raw material into small sections of 1-5 cm for later use;

[0037] (2) get the mixture of anaerobic sludge and animal excrement as the inoculum for subsequent use;

[0038] (3) In the anaerobic digester, add 10-200 mg / L of straw raw material dry matter and inoculum, adjust the C / N ratio to 25:1-30:1, and add four kinds of magnetic nanoparticles prepared in Example 1, respectively. Granules 50-200 mg / L, and finally replenished with water until all materials in the entire anaerobic digester are 80% (v / v) of the effective volume of the reaction vessel, and the initial pH is adjusted to 7.0-7.6; among them, the dry matter of straw raw materials accounts for the above-mentioned 6-20% (g / 100mL) of the 80% effective volume, and the inoculum accounts for 20-60% (g / 100mL) of the above-mentioned 80% effective volume.

[0039] (4) Close the anaerobic digester, control the reaction temperature at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com