Method for preparing composite photocatalyst containing metal simple substance particles from carbon-containing solid waste

A solid waste and simple metal technology, applied in the field of resource utilization of solid waste, can solve problems such as unrecyclable reuse, improper ash disposal, toxic pollution, etc., and achieve the effects of easy operation and implementation, uniform heating, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of composite photocatalysts containing Au elemental nanoparticles based on municipal domestic sludge

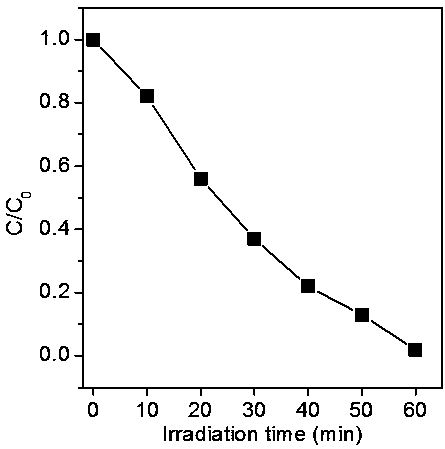

[0027] The carbon-containing sludge was obtained from the urban sewage treatment plant, and the carbon content of the wet sludge was determined to be 2%. Take 5 g of wet sludge and 0.5 g of AuCl 3 ·HCl·4H 2 O was added to a beaker filled with distilled water at a solid-to-liquid ratio of 1:10, and the pH of the distilled water was adjusted to 1 in advance. The mixed solution was heated and stirred in a water bath at 90°C for 6 h, and then centrifuged to obtain a solid precipitate; after washing with ethanol-water mixed solution three times, the precipitate was dried and ground into powder, and the ground powder particles were put into a crucible, Under the protection of argon, it was calcined at 500° C. for 100 min in a tube furnace to obtain a composite photocatalyst containing Au elemental particles based on sludge activated carbon. The BET of the obta...

Embodiment 2

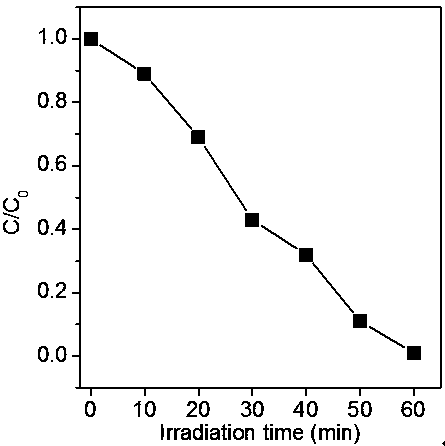

[0029] Preparation of Ag-containing nanoparticle composite photocatalyst based on wood chips

[0030] Saw chips were obtained from the wood processing plant, and the carbon content of the saw chips was determined to be 98%. Take 2 g wood chips and 0.2 g AgNO 3 According to the solid-to-liquid ratio of 1:20, it was added into a beaker filled with distilled water, and the pH value of the distilled water was adjusted to 2 in advance. The mixed solution was heated and stirred in a water bath at 90°C for 1 h, and then centrifuged to obtain a solid precipitate; washed with an ethanol-water mixed solution for three times, the precipitate was dried, and the dried precipitate was put into a crucible, under the protection of argon. Calcined at 1000 °C for 10 min in a tube furnace to obtain a composite photocatalyst based on wood chips containing Ag elemental particles. The BET of the obtained sawdust-Ag elemental particle composite photocatalyst reaches 1800 m 2 / g, and the degradati...

Embodiment 3

[0032] Preparation of Composite Photocatalysts Containing Cr Elemental Nanoparticles Based on Waste Resin

[0033] The waste resin is obtained from the resin production plant, and the carbon content of the waste resin is determined to be 60%. Take 3 g waste resin and 15 g Cr(NO 3 ) 3 9H 2 O was added into a beaker filled with distilled water at a solid-to-liquid ratio of 1:30, and the pH of the distilled water was adjusted to 3 in advance. The mixed solution was stirred at room temperature 20°C for 24 h, and then centrifuged to obtain a solid precipitate; washed with ethanol-water mixed solution for three times, the precipitate was dried, and the dried precipitate was put into a crucible, and used under the protection of argon The tube furnace was calcined at 200°C for 1440min to obtain a composite photocatalyst based on waste resin containing Cr elemental particles. The BET of the obtained waste resin-Cr simple particle composite photocatalyst reaches 2000 m 2 / g, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com