Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Repair wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

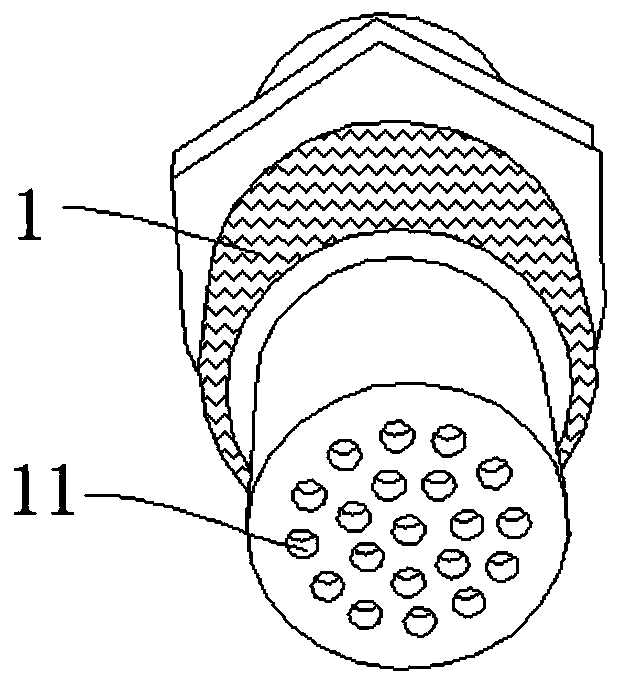

Nano metal self-restoring lubricating oil for mechanical sealing element and preparation method thereof

The invention discloses nano-metal self-repairing lubricating oil for mechanical seal elements and the process for preparation, which comprises the following components, the weight percentage content which occupies the total amount of self-repairing lubricating oil is that nano-metal powder which is 0.07-0.15%, nano-metal powder body dispersing agent which is 0.2-1% and disperse medium 98.9-99.7%. The process for preparation of the invention comprises the following steps: adding nano-metal powder body dispersing agent which is needed by proposition into disperse medium to evenly stir, further adding nano-metal powder according to the above proposition, properly stirring till nano-metal powder has no obvious settlement, placing with a container into a KH-700 type ultra-audio wave oscillator to oscillate 20-30 minutes, wherein source of power is 500-600w, and getting product. The nano-metal self-repairing lubricating has low production cost, which is beneficial for popularizing, and can lead the gap between friction pairs to be optimized, and the nano-metal self-repairing lubricating oil can not be dropped off after a self-repairing layer is formed, operation with low friction factor of equipment is kept, and the nano-metal self-repairing lubricating oil is energy-saving and environmental-friendly, which can effectively prolong maintenance down periodic time, and lowers maintenance cost.

Owner:MIYOU GROUP

Nano lubricating oil additive

InactiveCN101148628AReduce fuel consumptionReduce fuel consumption by 5-15%, reduce noiseAdditivesOil additiveOxidation stability

The present invention discloses one kind of nanometer lubricating oil additive, which consists of liposoluble nanometer copper or copper alloy and liposoluble nanometer silica. The nanometer lubricating oil additive of the present invention can realize the self repair of the worn part, and possesses the functions of saving oil, resisting abrasion, reducing noise, decreasing carbon deposit, raising power performance, etc. It has high dispersivity in lubricating oil, high oxidation stability and long term stability, and is favorable to solving different friction and wear problems in different work conditions.

Owner:BEIJING SIBNANO TECH

Environment-friendly composite multisoap base self-repairing bearing grease and preparation method thereof

ActiveCN102604724AImprove performanceOvercoming the lack of extreme pressure wear resistanceLubricant compositionMaximum levelWear resistant

The invention relates to environment-friendly composite multisoap base self-repairing bearing grease and a preparation method of the bearing grease. The bearing grease is prepared from composite base liquid, a composite calcium soap thickening agent, an oxidation and corrosion resistant additive, a tungsten disulfide extreme pressure additive, a metal deactivator, a polarization graphite wear resistant additive, a self-repairing additive and a structure improving agent. According to the bearing grease provided by the invention, an additive containing non-heavy metal elements is used to replace the originally used additive containing heavy metal elements. Because base liquid, a thickening agent and an additive are all optimized, the bearing grease provided by the invention is more excellent in combination property and highlighted in abrasion resistance, maintains an excellent level in extreme pressure property, can fully meet the requirements of the bit bearing extreme pressure, the high temperature, a deep well with high temperature, the high-impact load and the abrasion resistance, meanwhile, can effectively supplement the defect that silver coating is not sufficiently brushed onthe bearing axial diameter plane, and acts a function of repairing an abrasion resistant layer on a metal seal and a rubber seal of a bit bearing, so that the service life of the bearing is prolongedat a maximum level.

Owner:KINGDREAM PLC CO +2

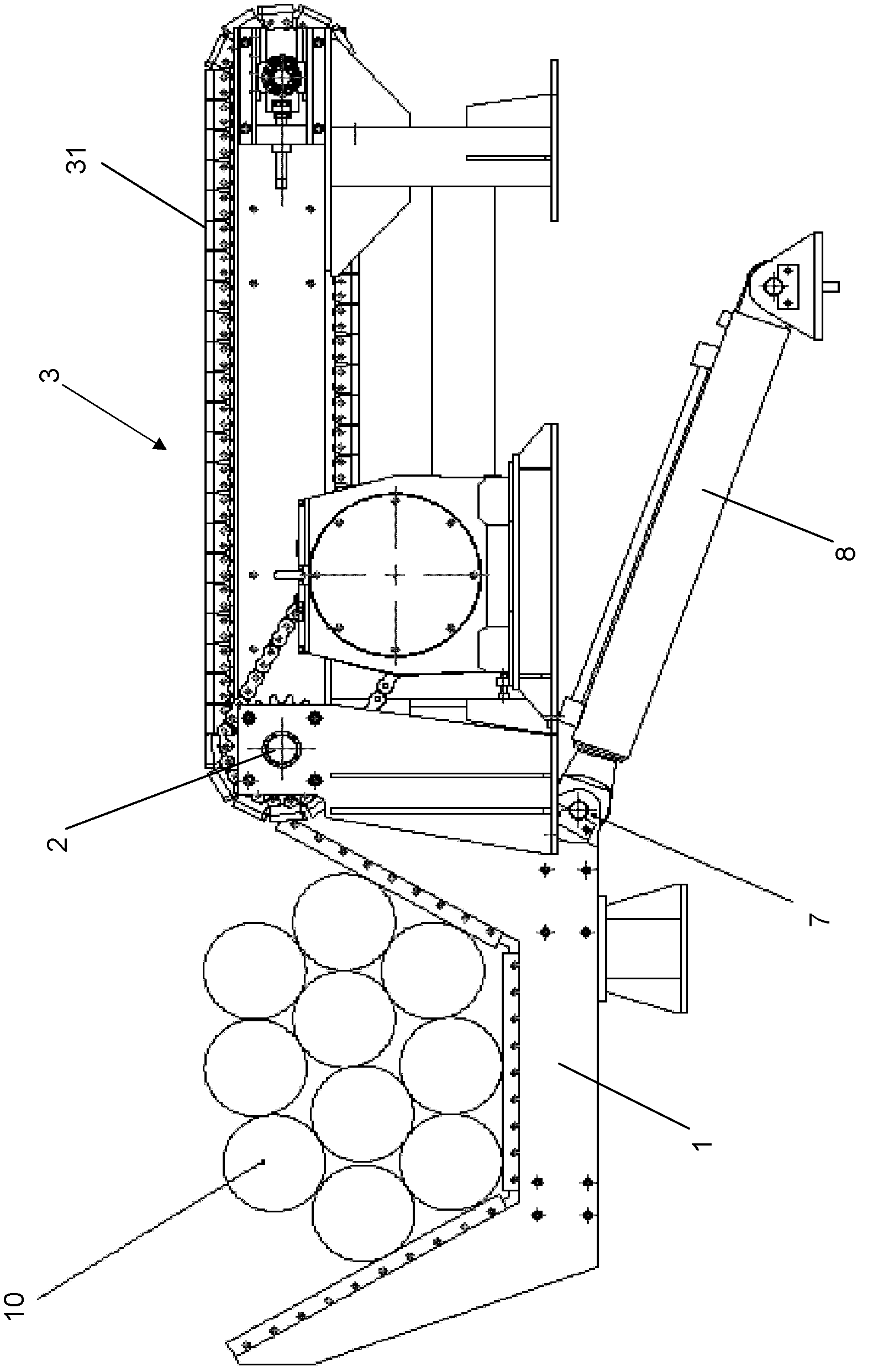

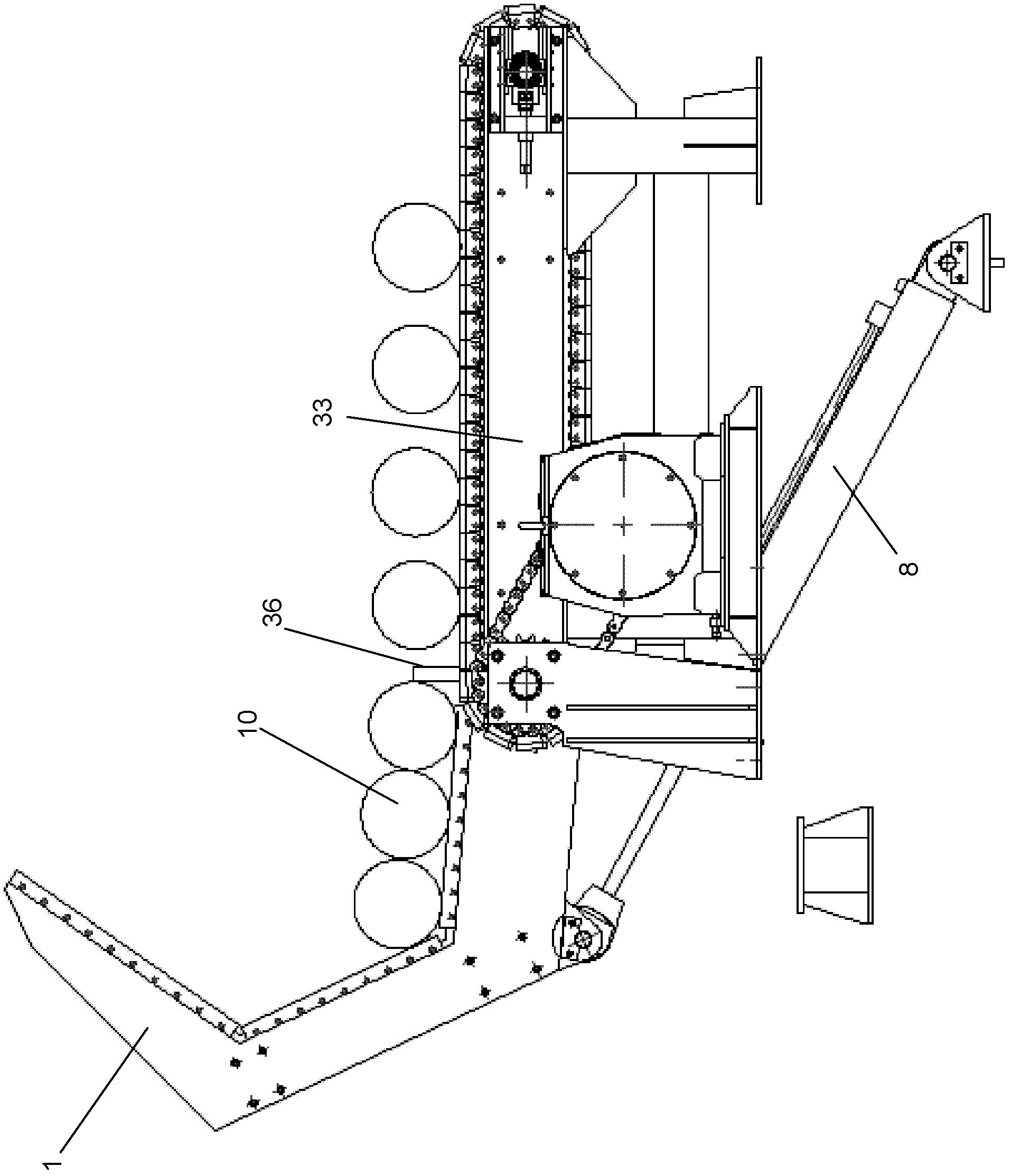

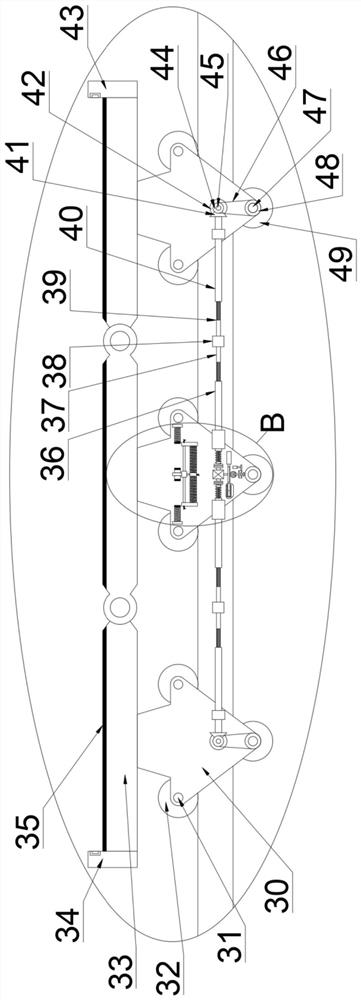

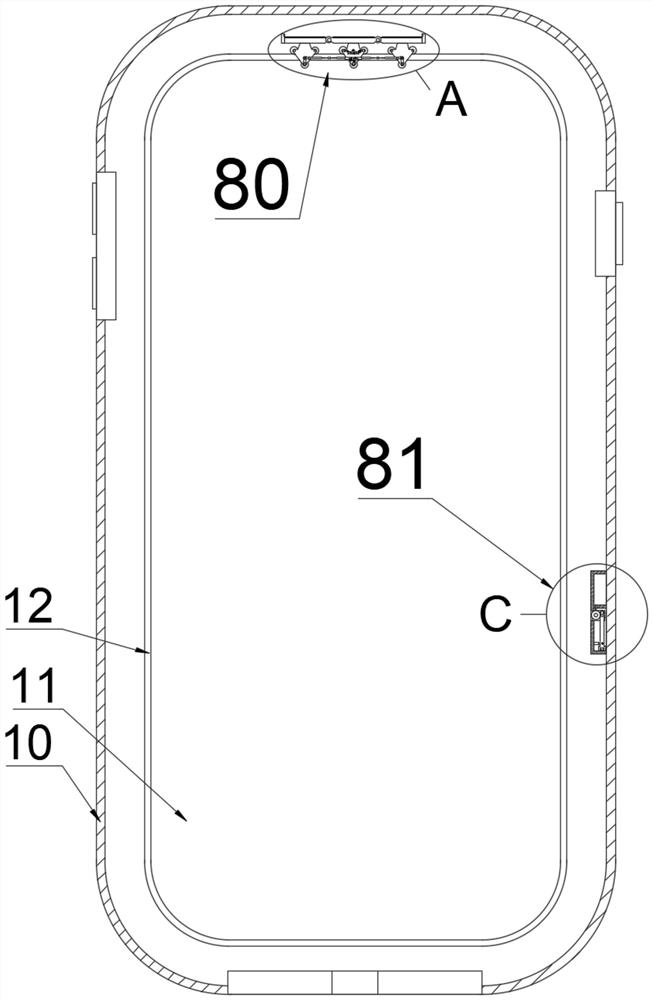

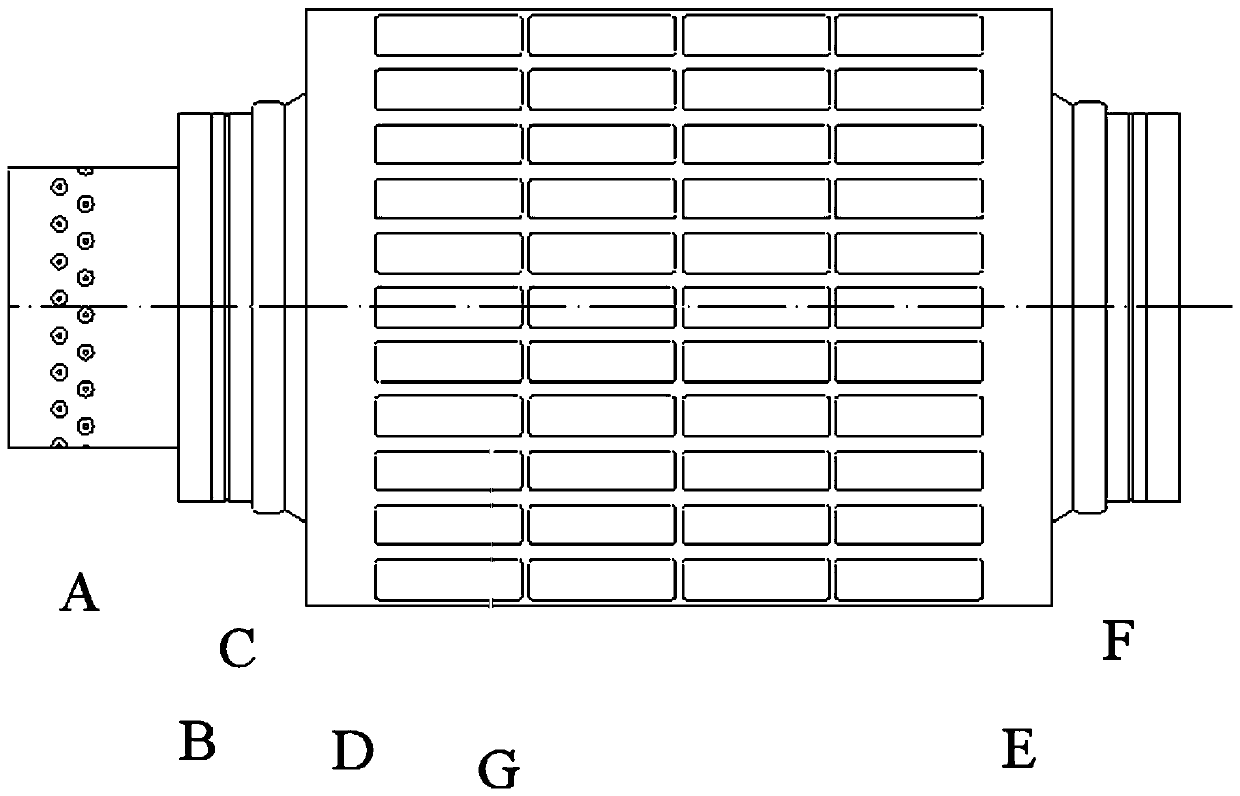

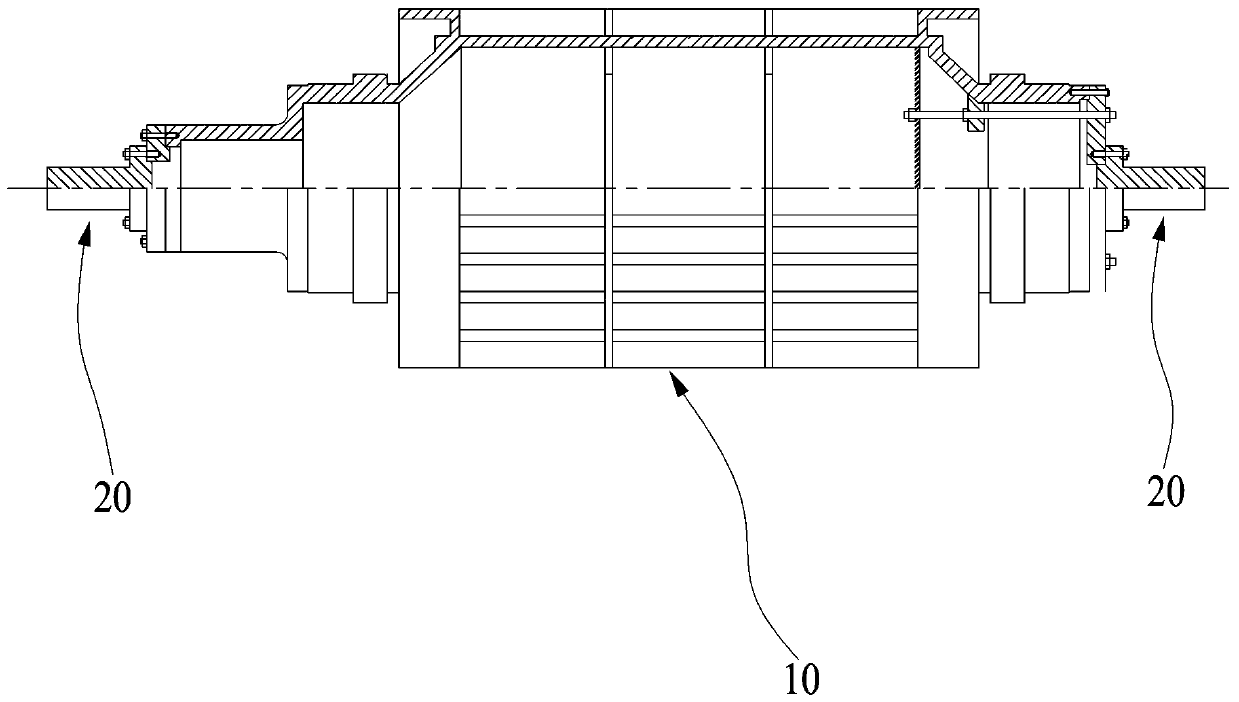

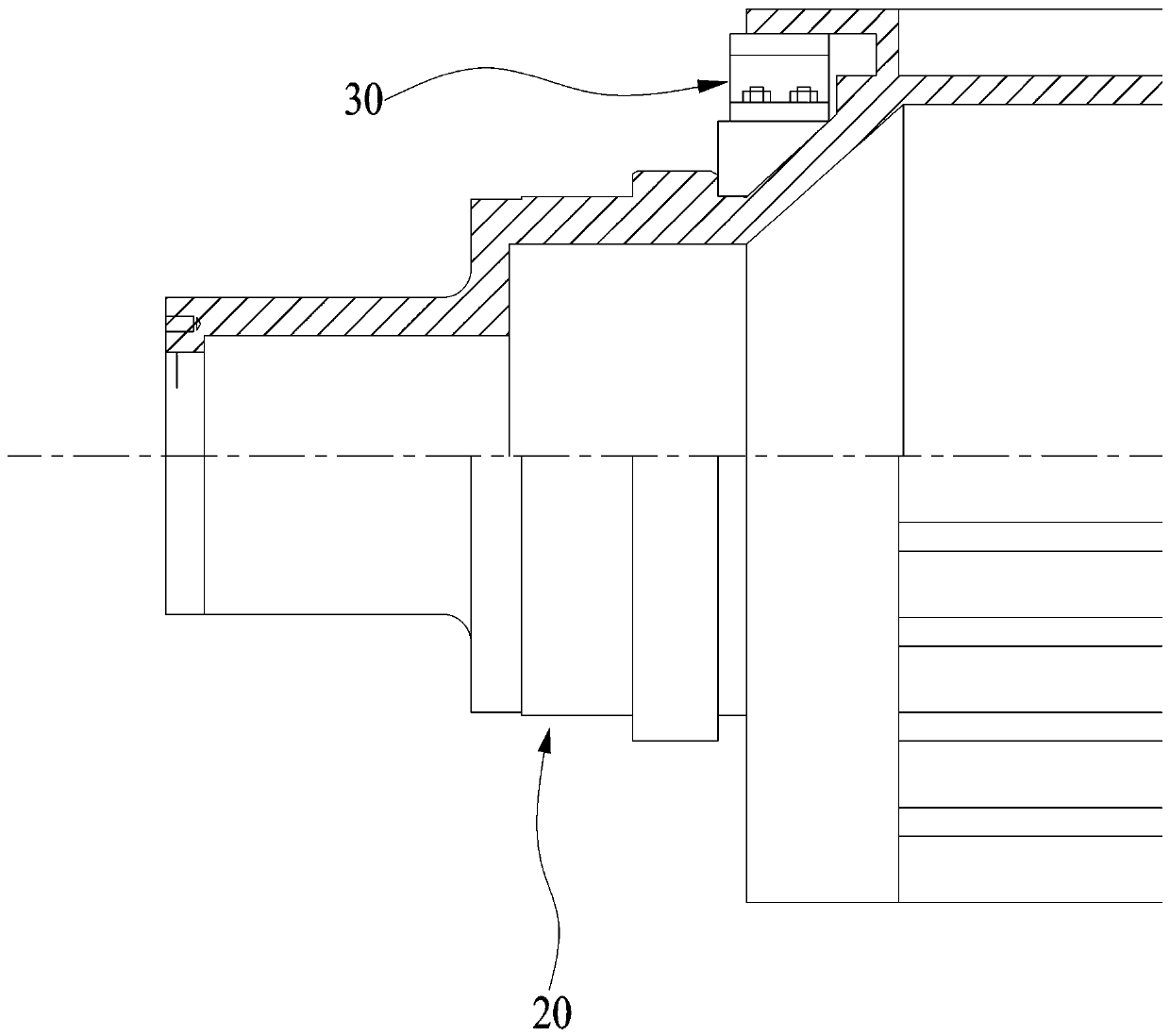

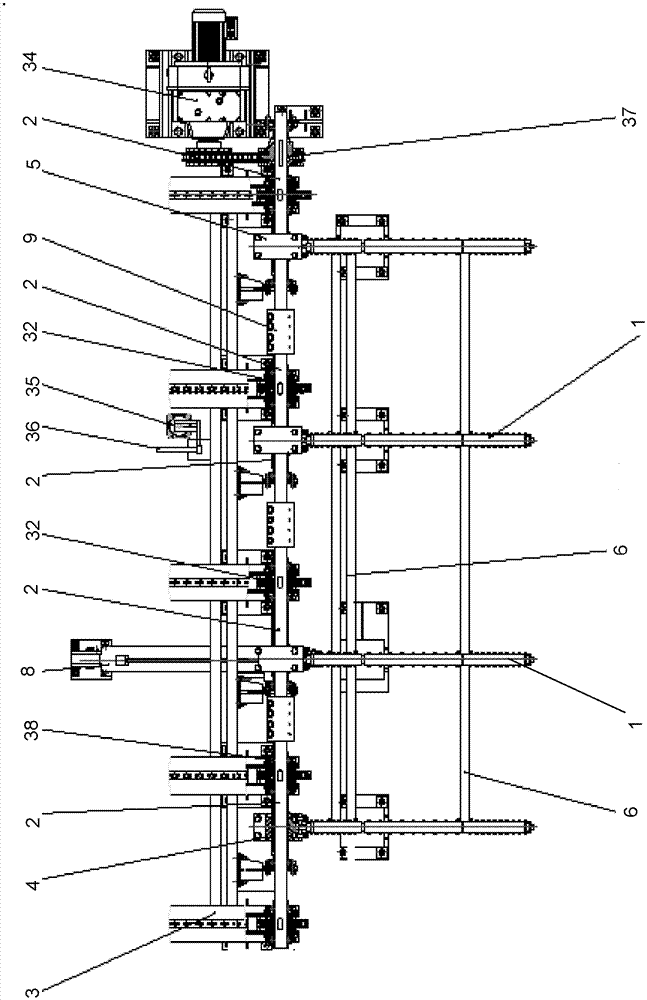

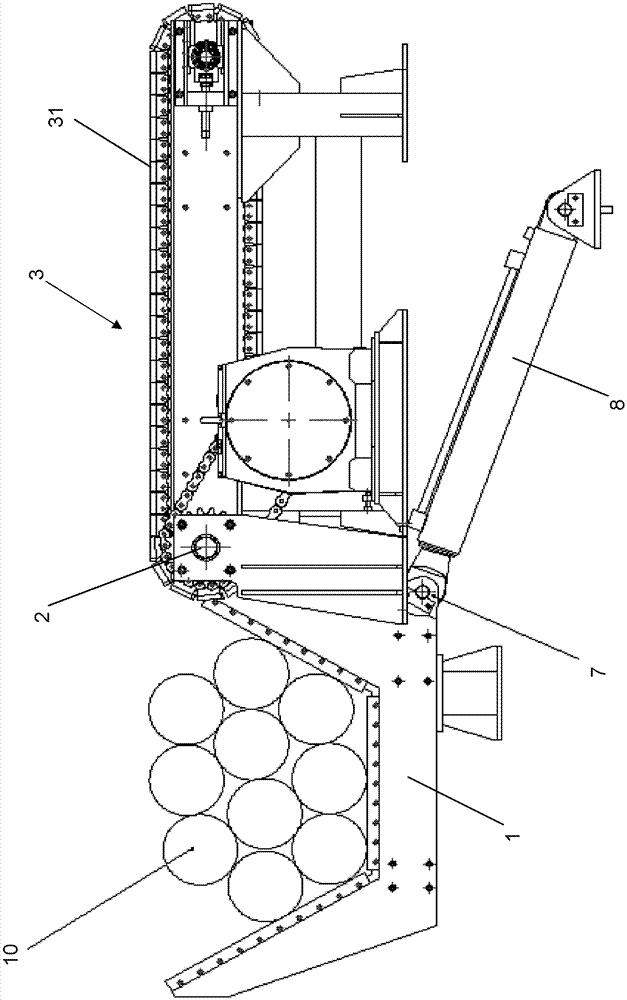

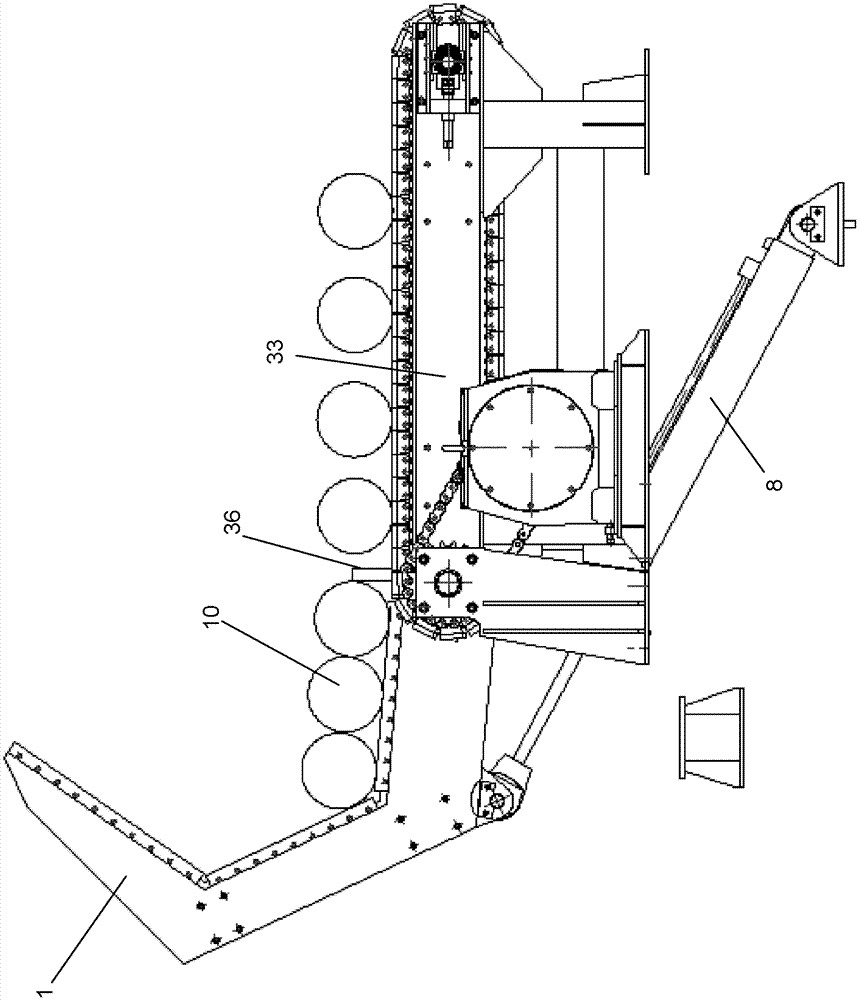

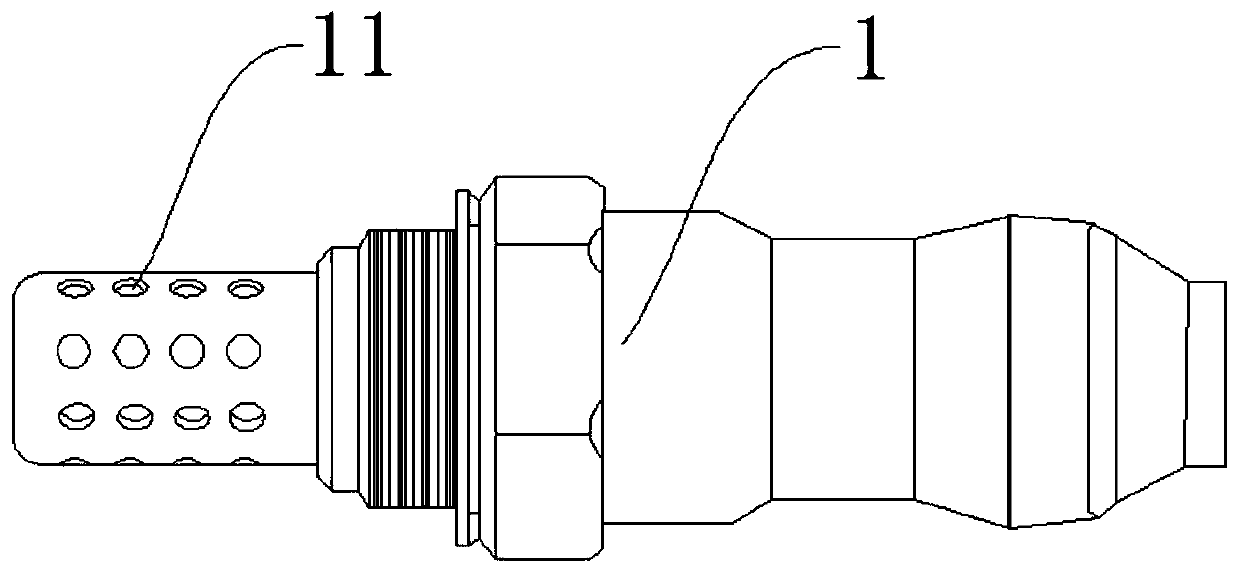

Workpiece feeding and distributing device

ActiveCN103101735ASuccessful realization of material loadingSuccessful realization of material distributionConveyor partsMechanical conveyorsEngineeringSprocket

The invention discloses a workpiece feeding and distributing device. The workpiece feeding and distributing device comprises a plurality of U-shaped feeding tanks, a rotating shaft and a chained material-distributing table, wherein the plurality of U-shaped feeding tanks are arranged in parallel and one end of each U-shaped feeding tank is connected with the rotating shaft, one bottom of each U-shaped feeding tank is connected with an oil cylinder through a trunnion, and the oil cylinders drive the U-shaped feeding tanks to conduct feeding operation. The chained material-distributing table comprises a drive sprocket which is provided with a conveying chain, a table frame and a gear motor, wherein the drive sprocket is arranged on the rotating shaft, the rotating shaft is connected on the table frame through a bearing, the gear motor is connected with the rotating shaft through a chain, a material-blocking mechanism which is driven by a cylinder to rise and fall is fixedly arranged on the table frame, the drive sprocket is driven by the gear motor, and thus an upper chain of the workpiece is enabled to conduct material distributing operation. The device is suitable for workpieces with a large scope of standards, feeding and material-distributing operations of bar materials, pipe materials and square billets can be achieved smoothly, and meanwhile, manual material-setting is of no need, and security accidents are avoided.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

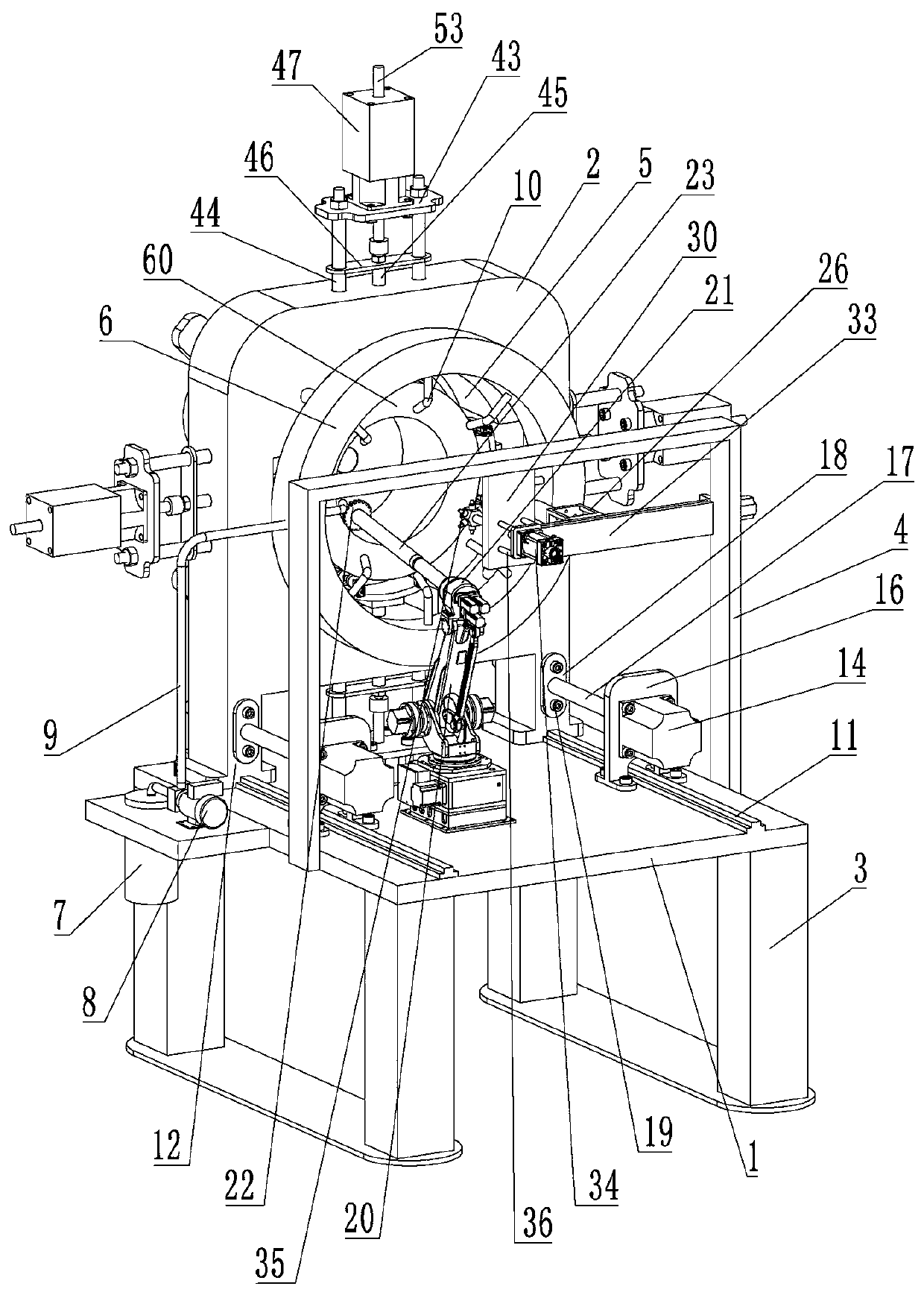

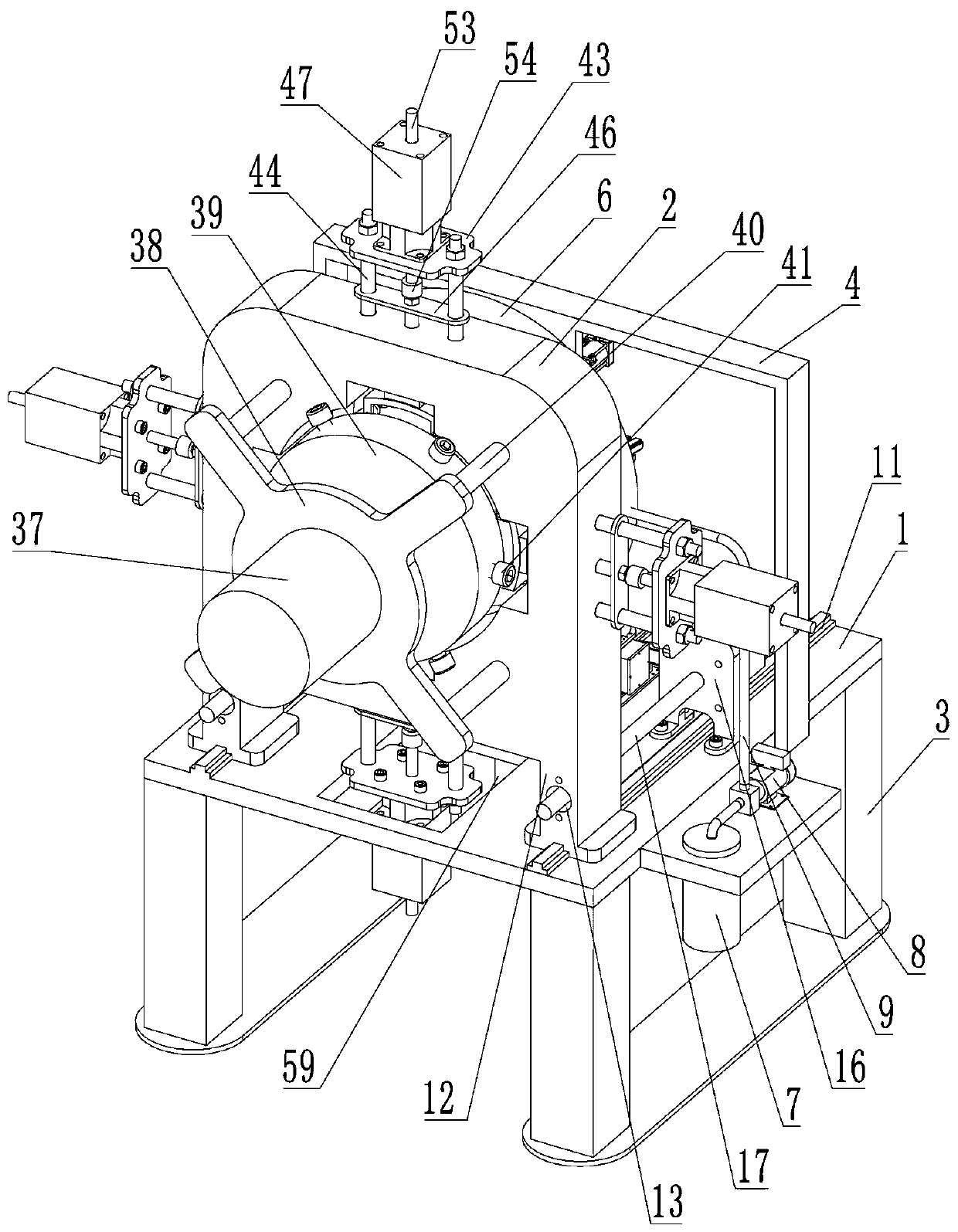

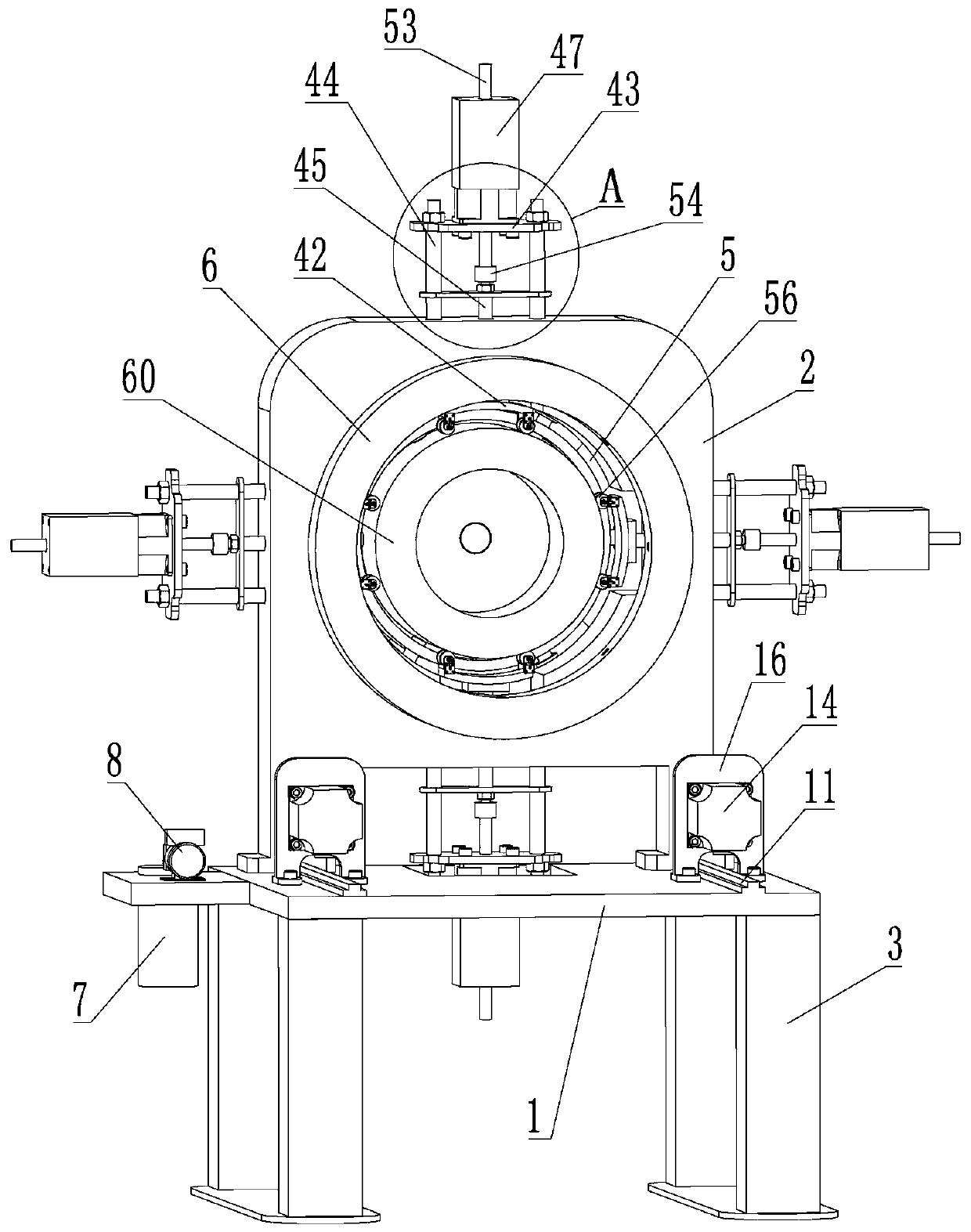

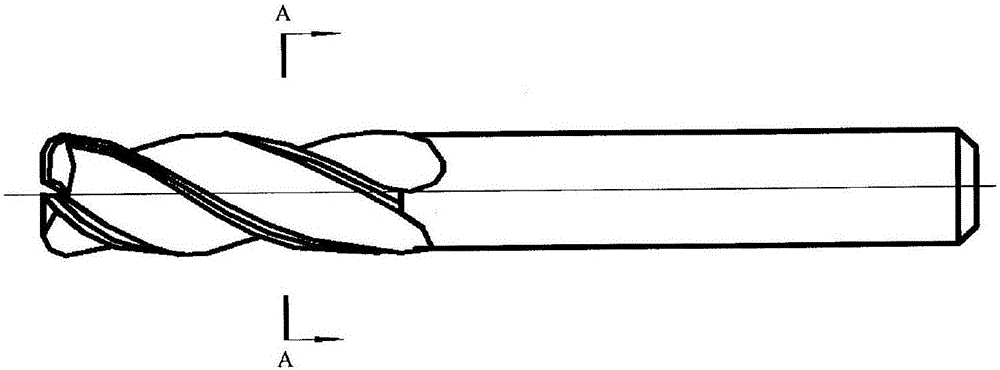

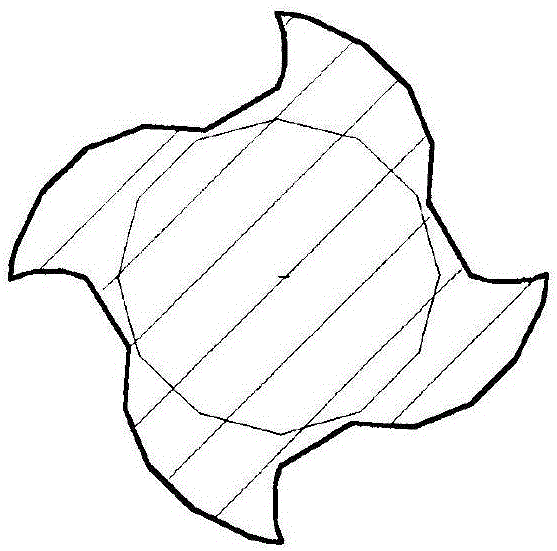

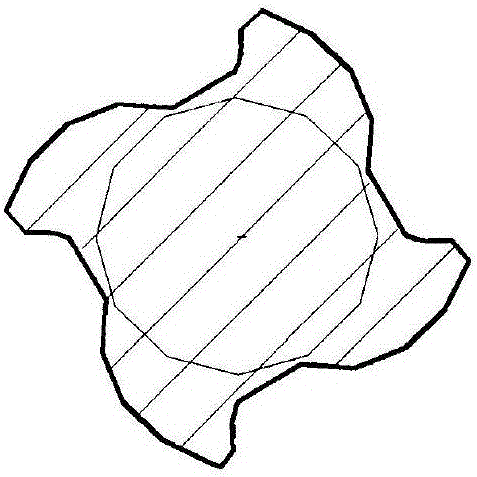

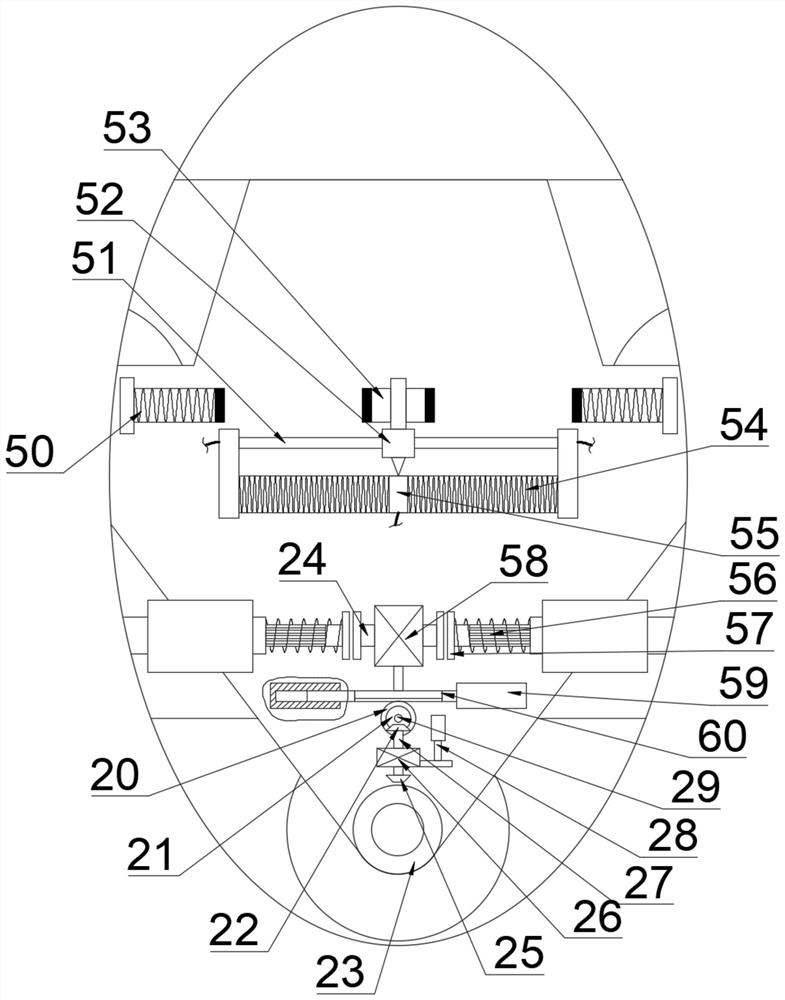

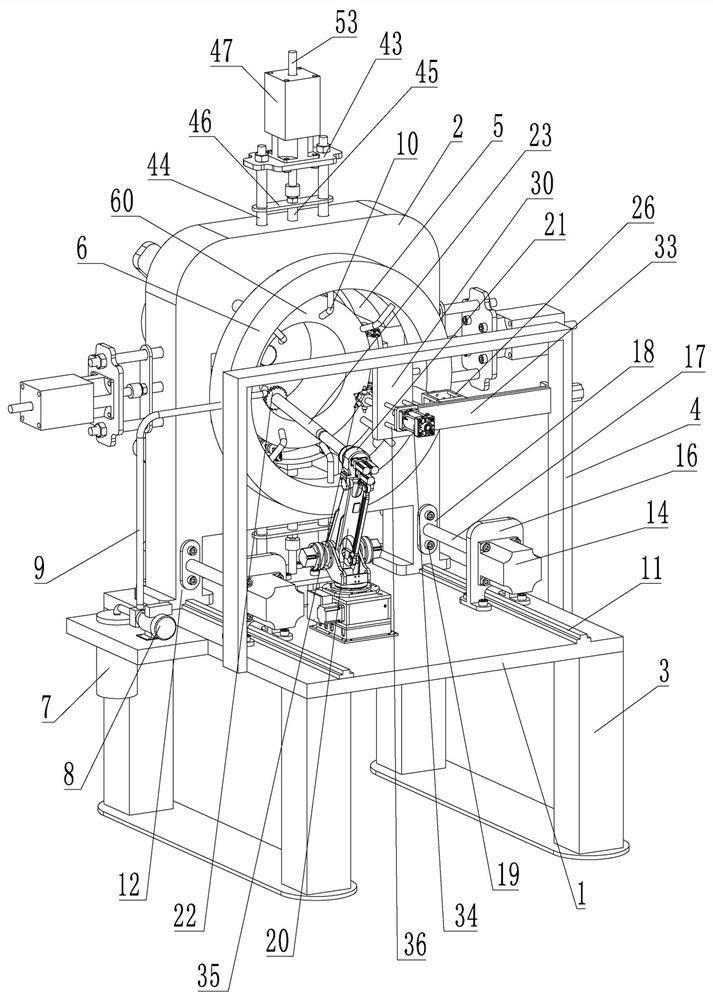

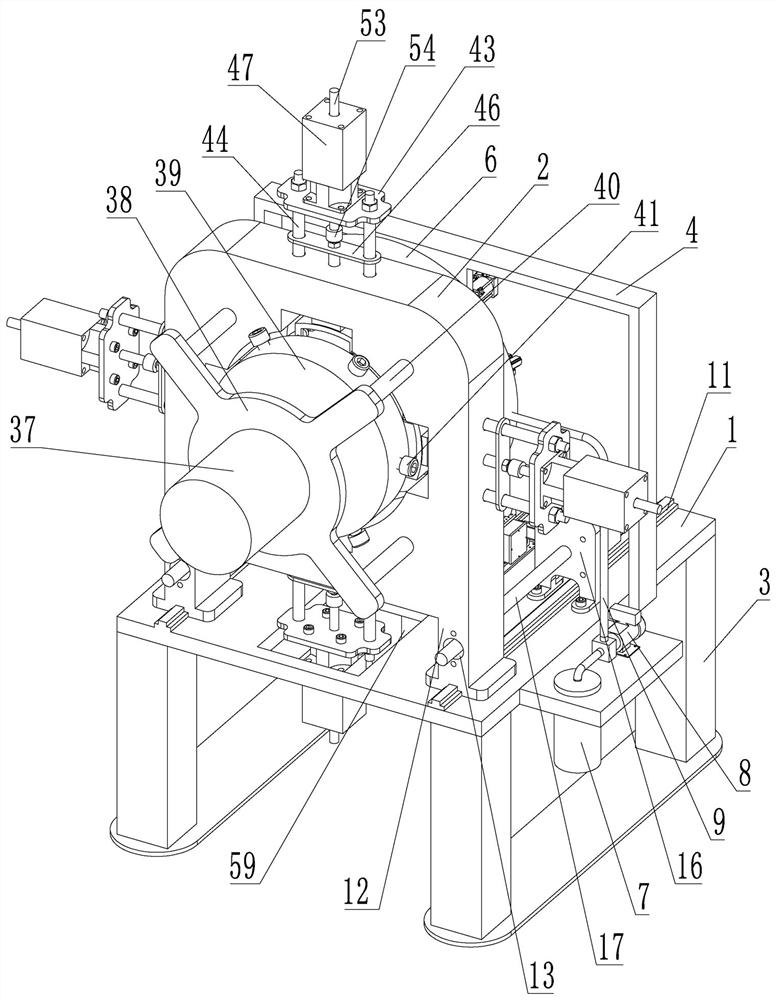

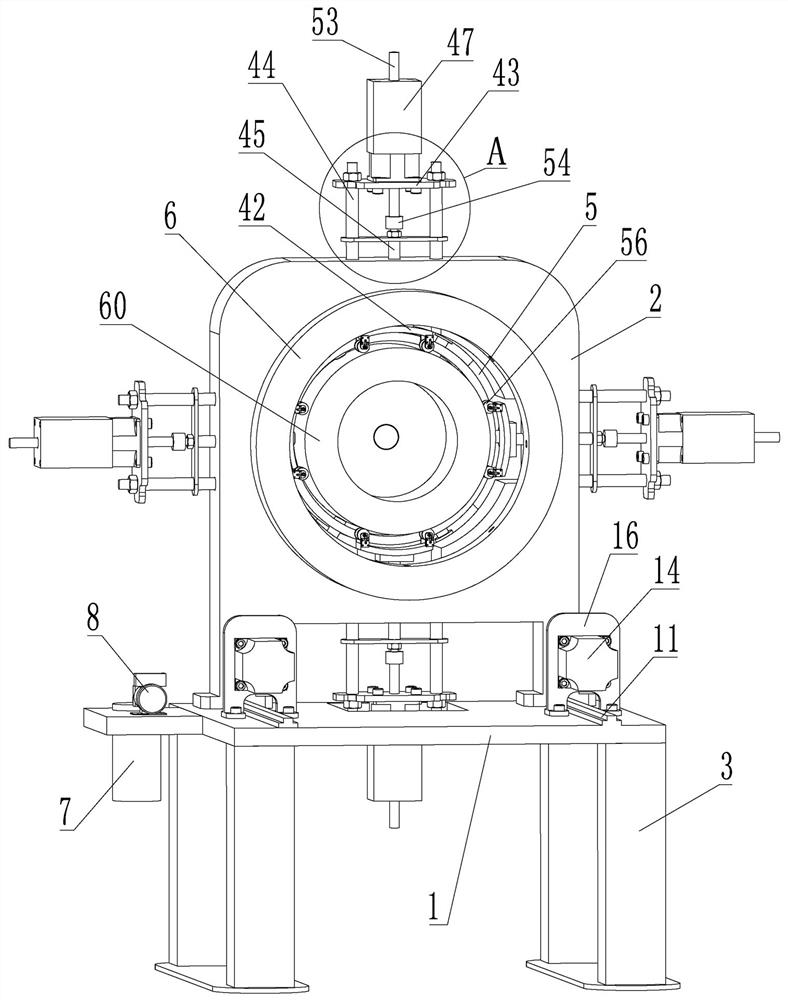

Multifunctional cutting tooth machining device and work method thereof

InactiveCN111331201AImprove machining accuracyRepair wearMeasurement/indication equipmentsFeeding apparatusLaser rangingEngineering

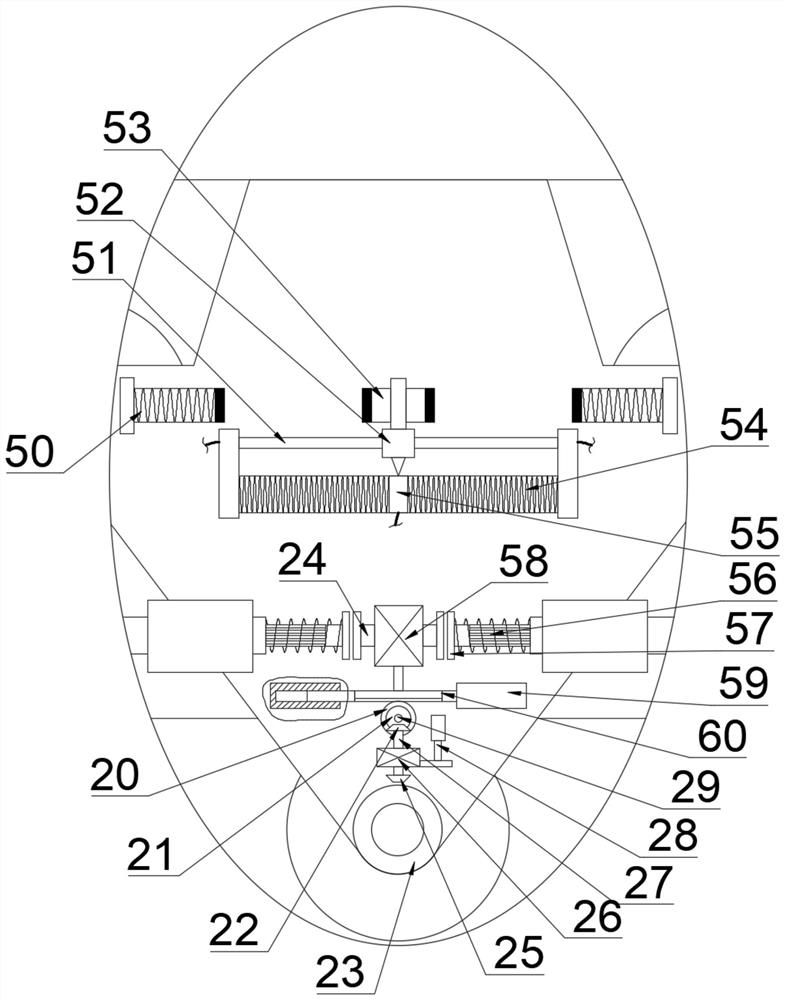

The invention discloses a multifunctional cutting tooth machining device which comprises a supporting tabletop, a vertical worktable, a cutting tooth mechanism, an insertion tooth mechanism, a laser ranging detection mechanism and a workpiece clamping and rotating mechanism. The cutting tooth mechanism is fixedly installed at the front side portion of the upper surface of the supporting tabletop.The front side portion of the supporting tabletop is fixedly connected with a U-shaped fixing frame. The insertion tooth mechanism and the laser ranging detection mechanism are installed on the U-shaped fixing frame. The workpiece clamping and rotating mechanism is fixedly installed on the rear side of the vertical worktable. Wheel-carrying clamp mechanisms are installed on the upper side, the lower side, the left side and the right side of the vertical worktable correspondingly. A cooking ring box is fixedly connected with the front side of the vertical worktable, and a cooling liquid storagebox and a cooling pump are installed at the side portion of the supporting tabletop. A cooling liquid pipe is connected between the cooling liquid storage box and the cooling ring box, and the cooling pump is arranged on the cooling liquid pipe. Multiple cooling liquid nozzles are arranged on the cooling ring box in the circumferential array manner. The multifunctional cutting tooth machining device is compact in structure and diversified in function, cutting tooth and insertion tooth integration is achieved, and the machining precision is high.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

Self-repairing multi-soap based composite bearing lubricating grease and preparation method thereof

ActiveCN100412179CReduced antioxidant capacityGuaranteed validityDrill bitsAdditivesStructural ModifierPetroleum

The related composite poly-soap self-repair bearing lubricating grease comprises the basic liquid, composite calcium sulfonate, composite Ca-Li-base thickener, non-oxidizing anti-corrosion additive, metal deactivator, tungsten disulfide extreme pressure additive, wear-well additive, self-repair additive, and structural modifier; has well anti-oxidation ability and bearing capacity, can repair wore part on condition of extreme pressure and high temperature to supply the silver-plating lacking on bearing radial surface effectively, prolongs bearing service time on maximum limit, and has special application in oil drilling exploration.

Owner:SINOPEC OILFIELD EQUIP CORP +1

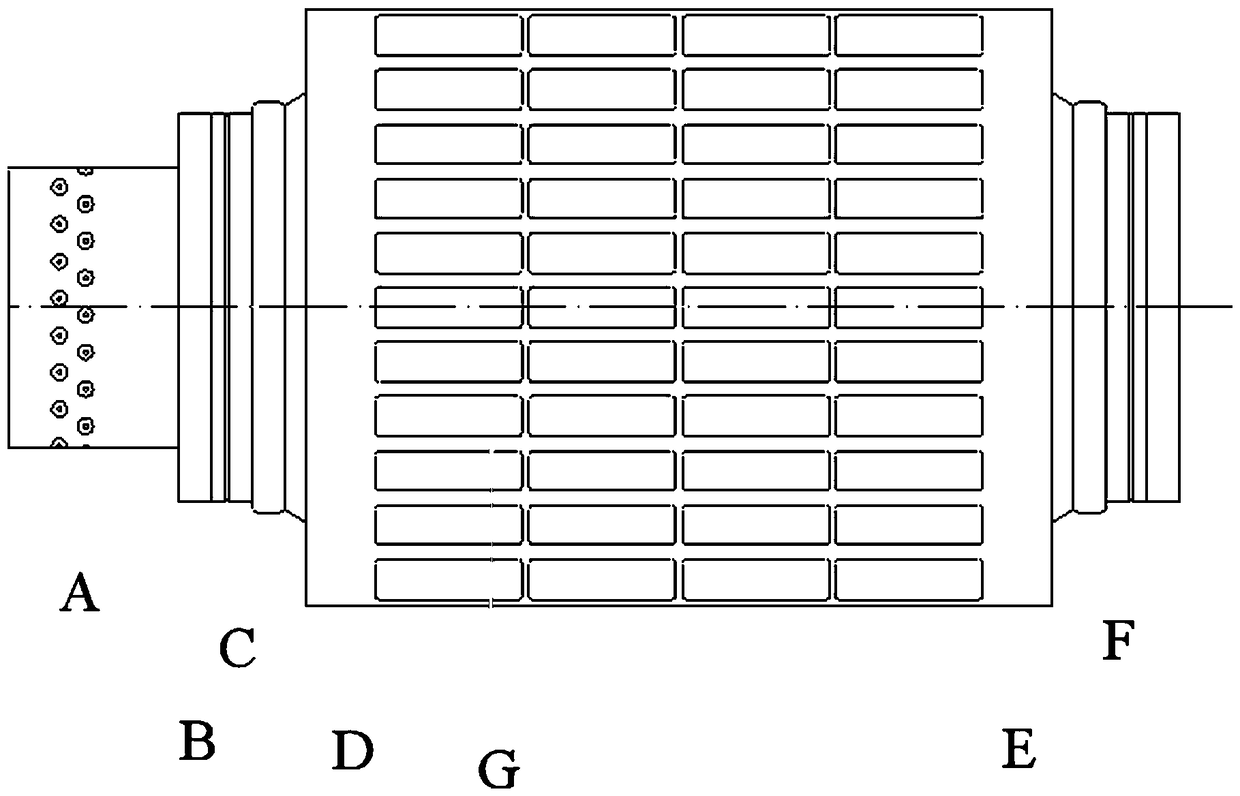

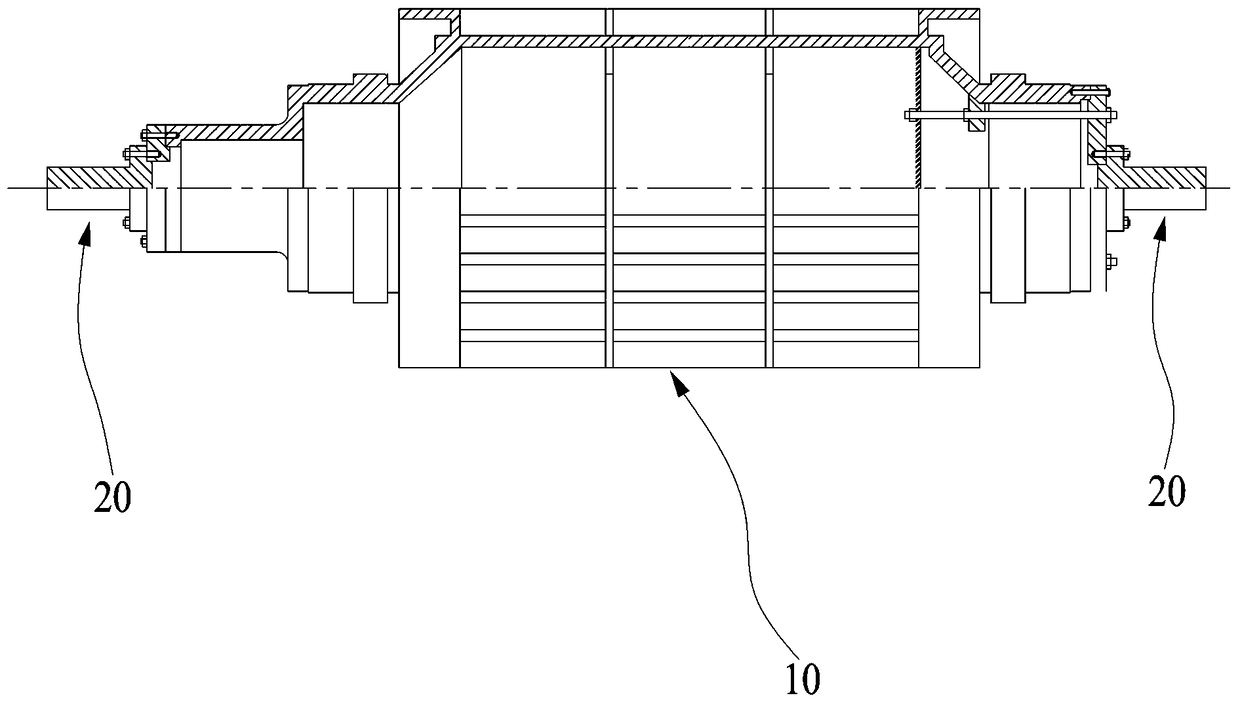

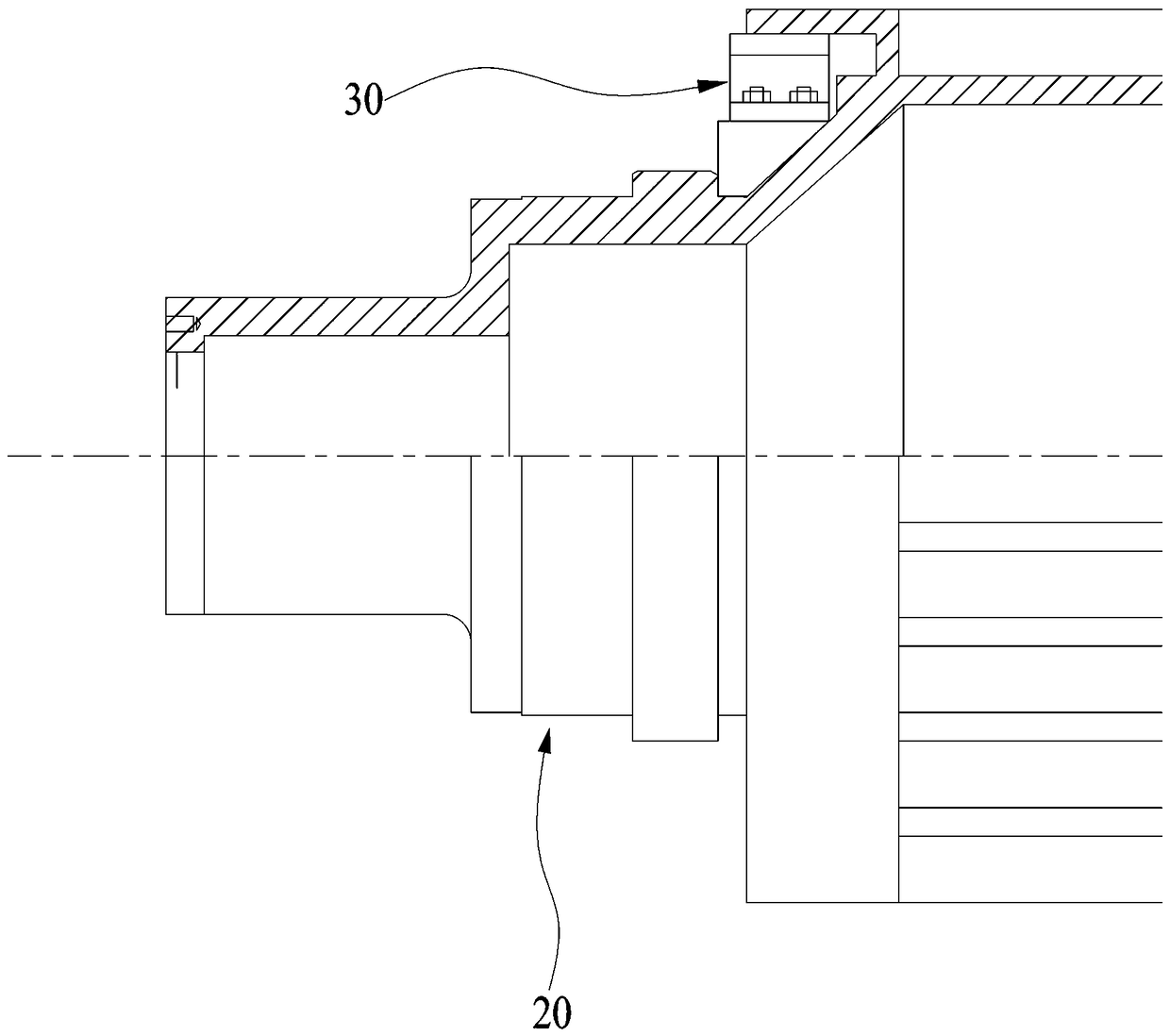

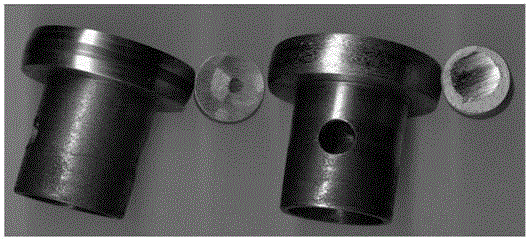

Method for repairing packing barrel of drum type vacuum filter

The invention discloses a method for repairing a packing barrel of a drum type vacuum filter. The method for repairing the packing barrel of the drum type vacuum filter comprises the following steps of 1, conducting rough turning on a shaft neck at the driving end of the packing barrel, an oil seal shaft neck, packing seal shaft necks, a filter groove outer circle and bearing shaft neck damaged parts; 2, milling and cleaning R-angle connecting weld seams of the filter tank partition plates by using a forming milling cutter or manually grinding and cleaning the R-angle connecting weld seams ofthe filter tank partition plate by using a hard alloy rotary file electric grinding and angle grinding machine; 3, carrying out build-up welding to R-angles of the filter tank; 4, repairing and polishing R-angle weld seams of the filter tank to complete the repairing of R-angle weld seams of the filter tank of the packing barrel; 5, conducting laser cladding complex machining on the packing barrel, wherein the cladding is carried out in the shaft neck at the driving end, the oil seal shaft neck, the packing seal shaft necks at the driving end, the packing seal shaft necks at the non-driving end and the filter groove outer circle sequentially; 6, conducting rough turning to laser cladding parts; and 7, carrying out fine grinding on the rough turning parts. According to the method for repairing the packing barrel of the drum type vacuum filter, a surface of a wear packing barrel can be repaired, so that the wear packing barrel can be reused and the use cost is reduced.

Owner:岳阳大陆激光技术有限公司

Method for enhancing strength of cutting edge of tool through additive manufacturing technology

InactiveCN105728731AExtended service lifeIncrease productivityAdditive manufacturing apparatusIncreasing energy efficiencyNumerical controlManufacturing technology

The invention discloses a method for enhancing the strength of a cutting edge of a tool through an additive manufacturing technology. The method comprises the steps that 1, the work cutting edge of the tool is evenly removed by 0.8 mm to 1.5 mm, a basic platform is formed, and the surface of the basic platform is perpendicular to the cutting direction of the tool; 2, a digital model is established according to the dimension and shape of the tool, the dimension of the removed part and the dimension of the platform reserved on the tool after the cutting edge of the tool is removed; 3, programming is carried out according to the digital model and programming language of machining equipment; 4, the tool is clamped on a workbench of the machining equipment, the machining equipment is adjusted, a coaxial powder conveying work head of the machining equipment exactly faces the additive forming position of the tool, forming is called to start additive manufacturing work, and formed height is 0.5 mm larger than the height of the removed part; and 5, after forming is finished, the tool is mounted on a numerical control tool sharpener, and grinding is carried out again according to original grinding forming. According to the method, the service life of the tool can be prolonged, production efficiency can be improved, cost can be reduced, and good application prospects are achieved.

Owner:SHENYANG AIRCRAFT CORP

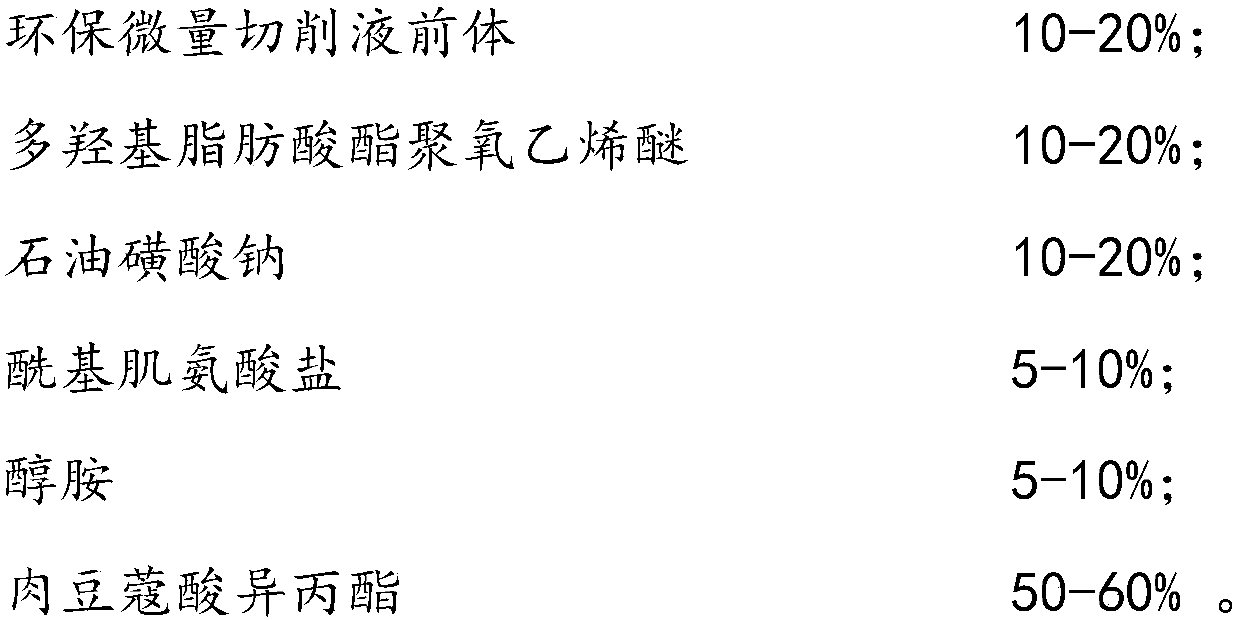

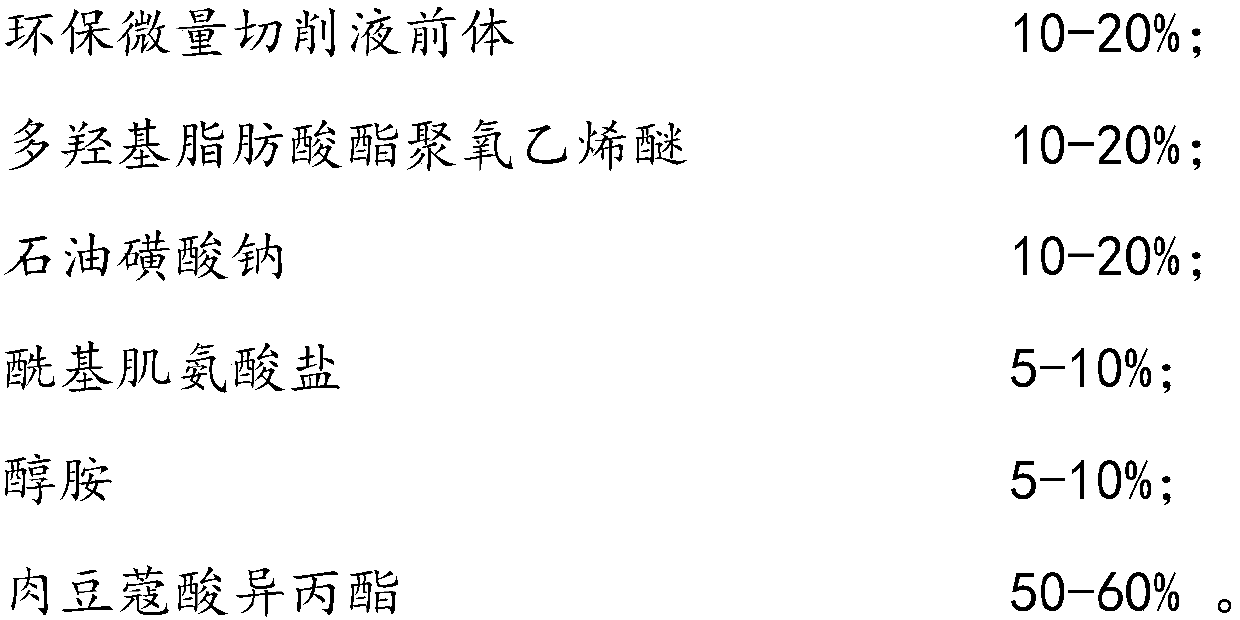

Environment-friendly microscale cutting fluid and preparation method thereof

InactiveCN107699313AGood extreme pressure and anti-wear propertiesRepair wearAdditivesSulfonateSODIUM COCOYL SARCOSINATE

The invention provides environment-friendly microscale cutting fluid. The environment-friendly microscale cutting fluid is characterized in that components are mixed and blended at 40-60DEG C to be completely transparent, and the components include, by weight, 10%-20% of an environment-friendly microscale cutting fluid precursor, 10%-20% of polyhydroxy fatty acid ester polyoxyethylene ether, 10%-20% of petroleum sodium sulfonate, 5%-10% of sodium cocoyl sarcosinate, 5%-10% of alkylol amine and 50%-60% of isopropyl myristate. The environment-friendly microscale cutting fluid is used cooperatively with a microscale lubricating device, usage can be reduced to less than original 5%; good lubrication and cooling effects are achieved, and energy conservation and emission reduction and environment protect effects are remarkable.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

Nano lubricating oil additive

The invention discloses a nano lubricating oil additive. The lubricating oil additive mainly consists of oil-soluble nano-copper or oil-soluble nano-copper alloy and oil-soluble nano-silicon dioxide. Using the lubricating oil additive of the present invention can realize the self-repair of the worn part, and has the functions of fuel saving, anti-wear, noise reduction, carbon deposition reduction, power improvement and the like. The lubricating oil additive of the present invention can be well dispersed in various lubricating oil base oils, has good oxidation stability, can exist stably for a long time, and is suitable for solving the friction, wear and maintenance of various mechanical equipment under various working conditions question.

Owner:BEIJING SIBNANO TECH

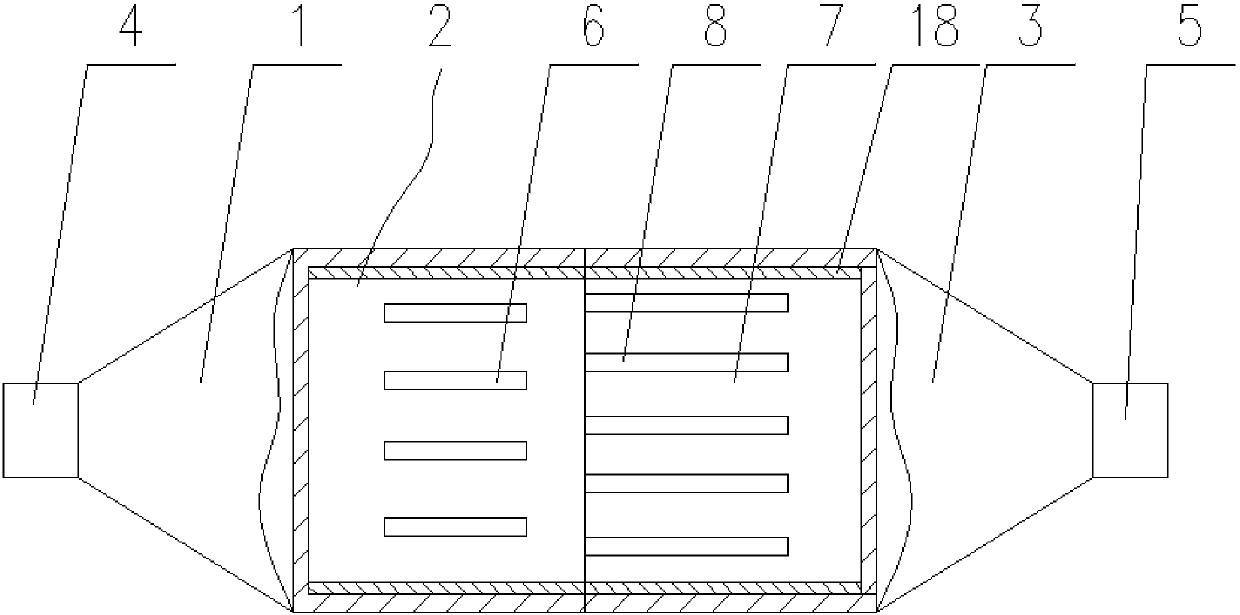

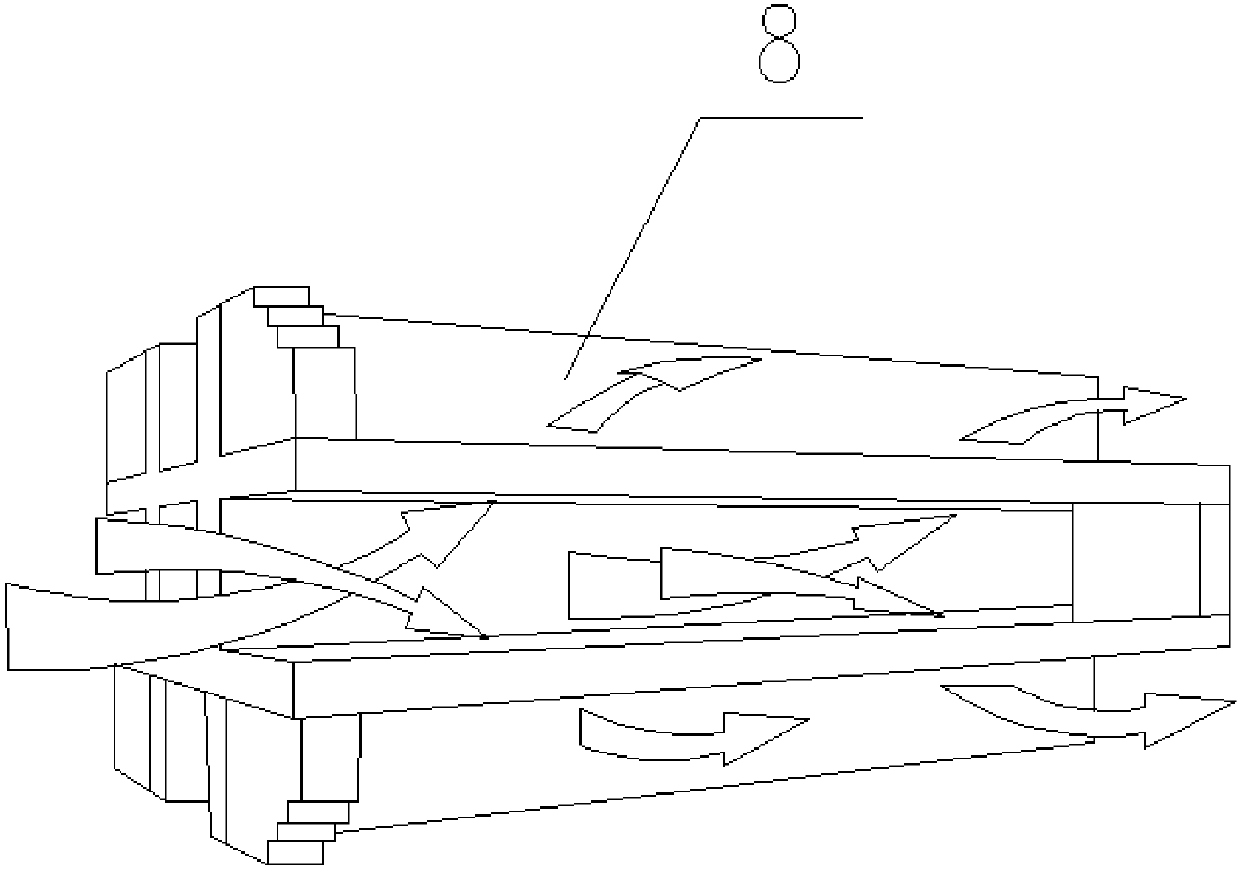

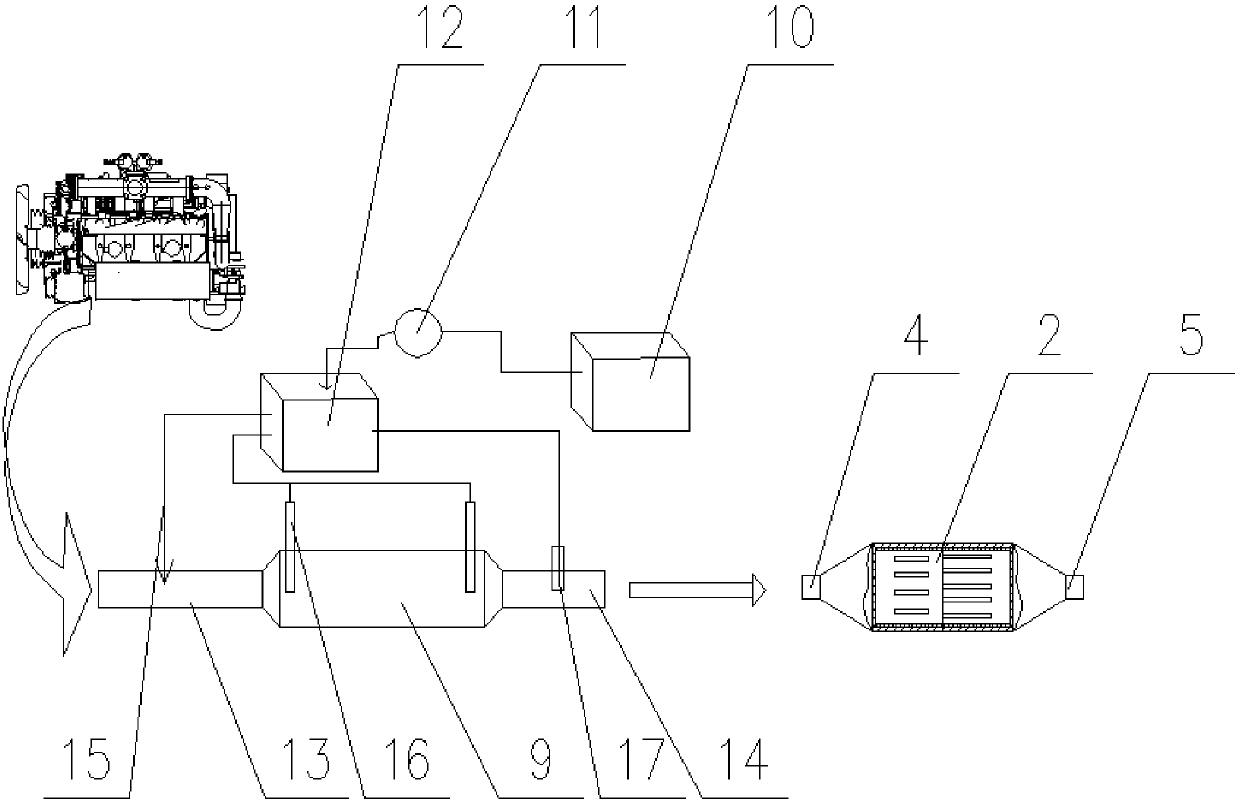

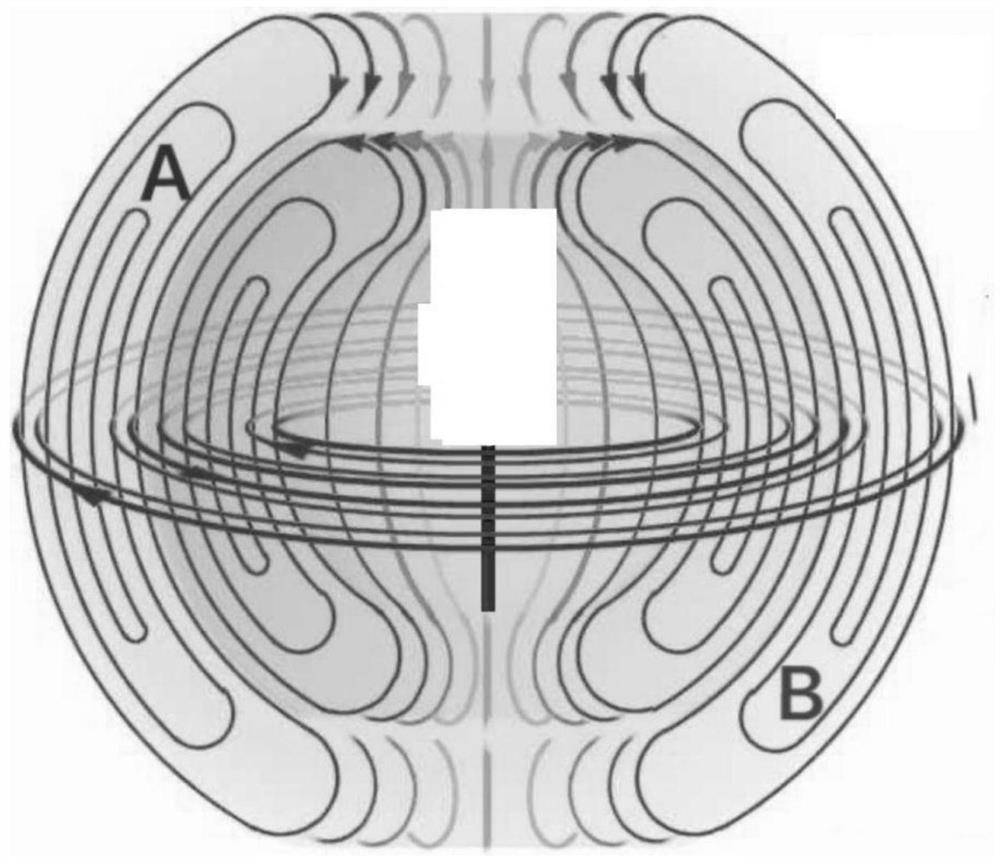

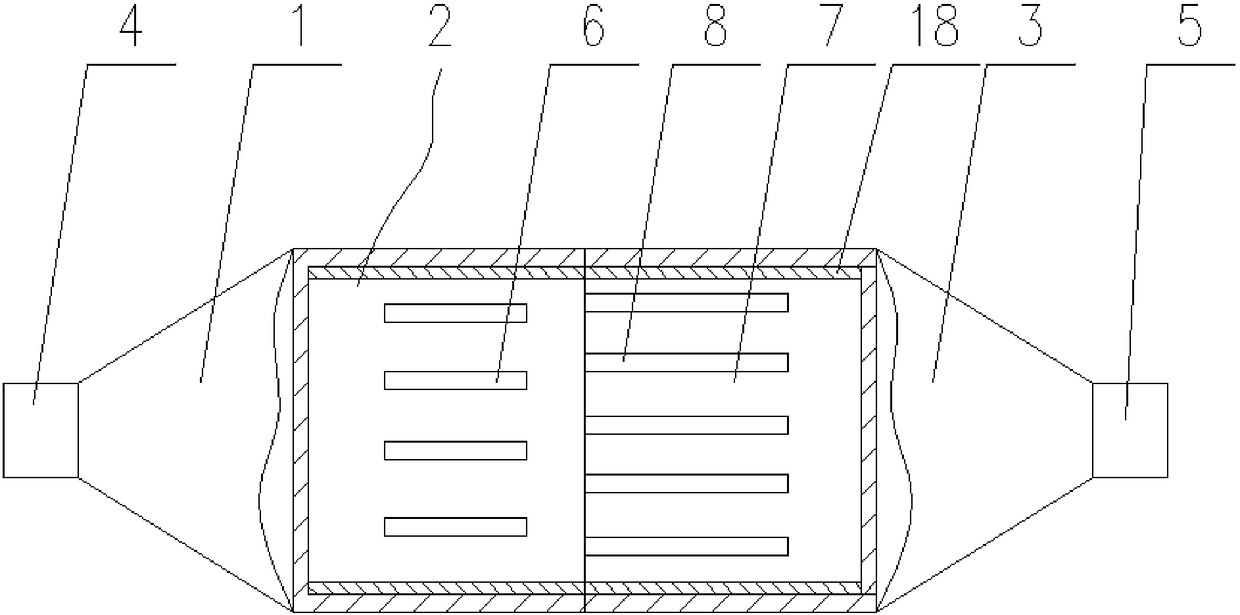

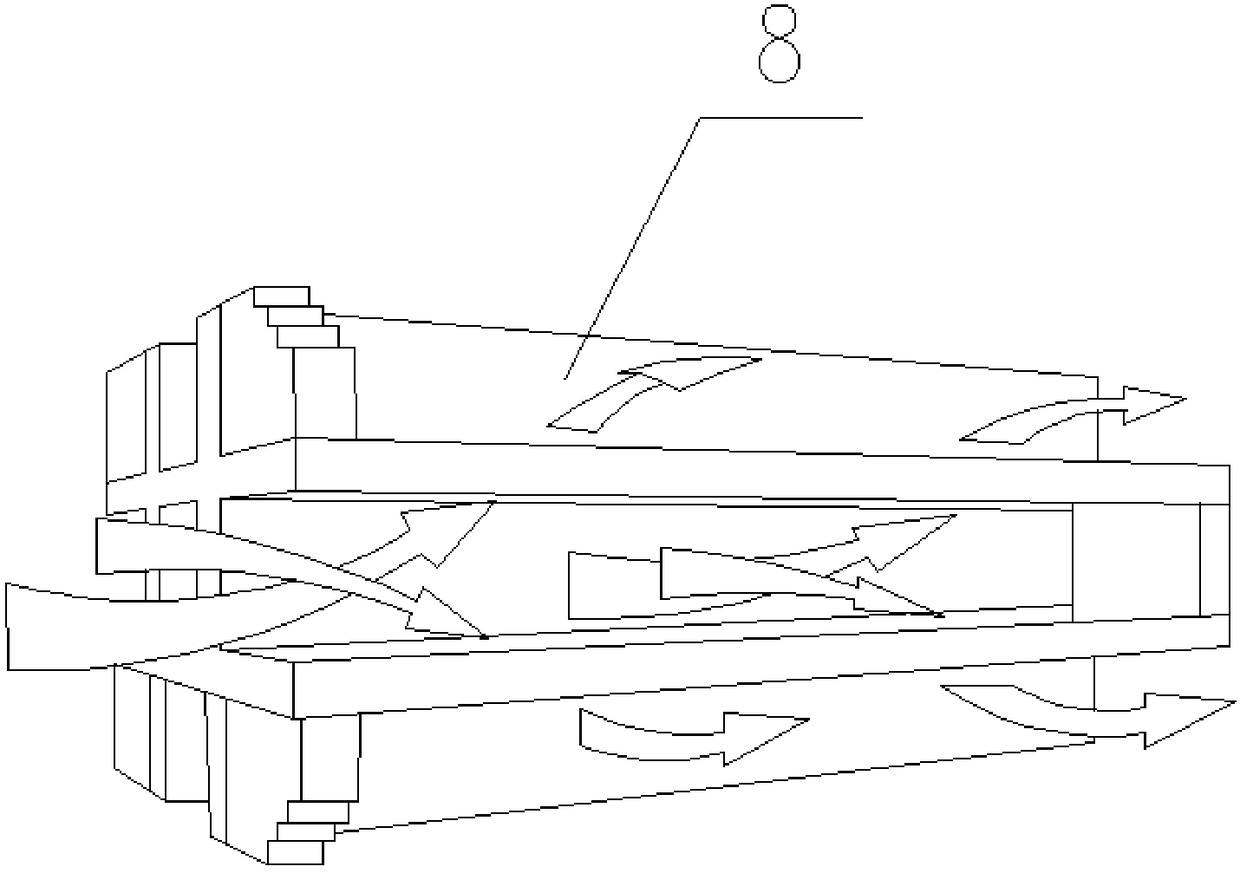

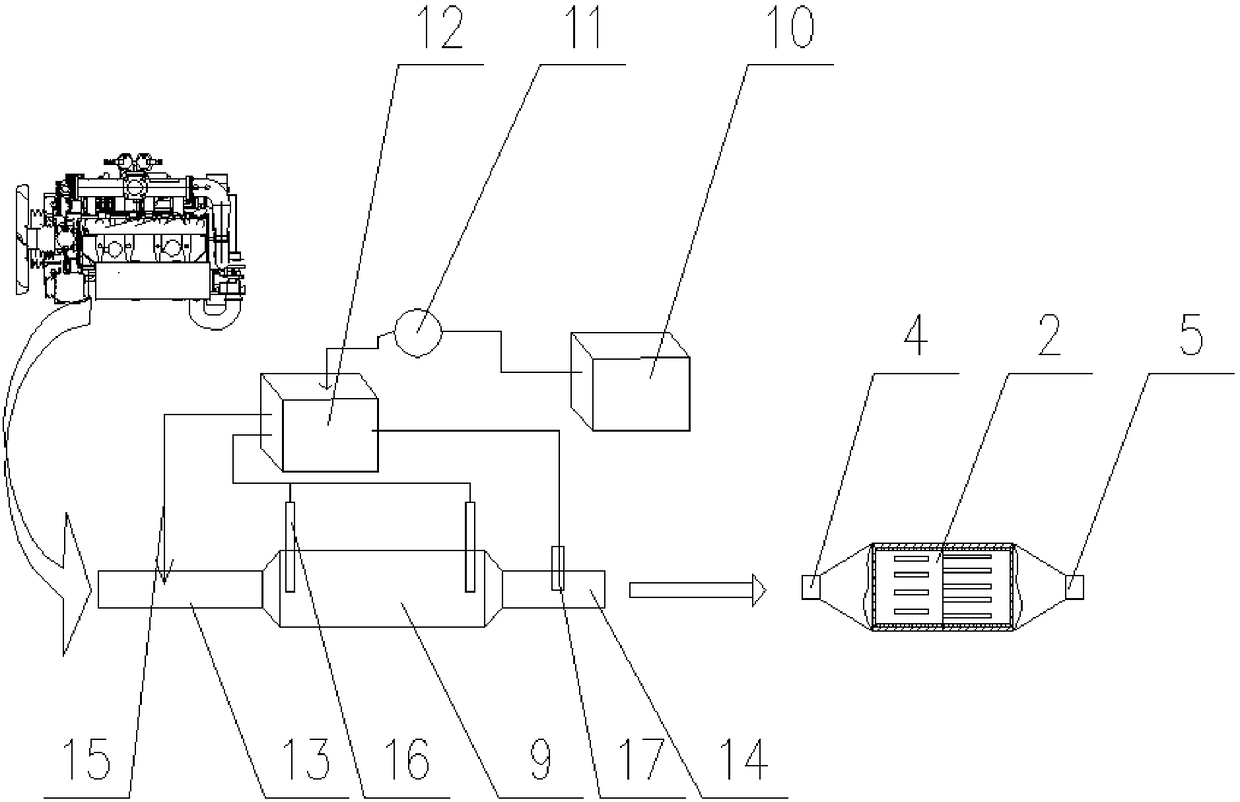

Engine pretreatment, self-repairing material and tail gas governing integrated process method

ActiveCN107829822AFast self-healingRepair wearInternal combustion piston enginesSilencing apparatusParticulatesAfter treatment

The invention discloses an engine pretreatment, self-repairing material and tail gas governing integrated process method and belongs to the technical field of engine tail gas governing. The inventionaims at solving the problems that an existing engine tail gas governing effect is not thorough, and the emission pollutants of an engine harm the living environment. The engine pretreatment, self-repairing material and tail gas governing integrated process method includes the following steps that firstly, mixed powder with the function of cleaning an engine friction pair surface metamorphic layer,rotted points and oil stains is prepared; secondly, a metal abrasion self-repairing material composition is prepared; thirdly, engine pretreatment is performed; fourthly, engine self-repairing treatment is performed; and fifthly, a tail gas after-treatment device is additionally arranged. According to the engine pretreatment, self-repairing material and tail gas governing integrated process method, by means of integration and advantage complementation of the three technologies of engine pretreatment and self-repairing and additional arranging of the tail gas treatment device, the technical defects that a current domestic engine is purely provided with a tail gas treatment device, the engine performance is lowered, the oil consumption rises, and a particulate trap can be easily blocked areovercome, and an effective path is provided for scientific prevention and treatment of tail gas of high-emission motor vehicles in future.

Owner:黑龙江西亚金属表面工程技术研究院(有限合伙) +2

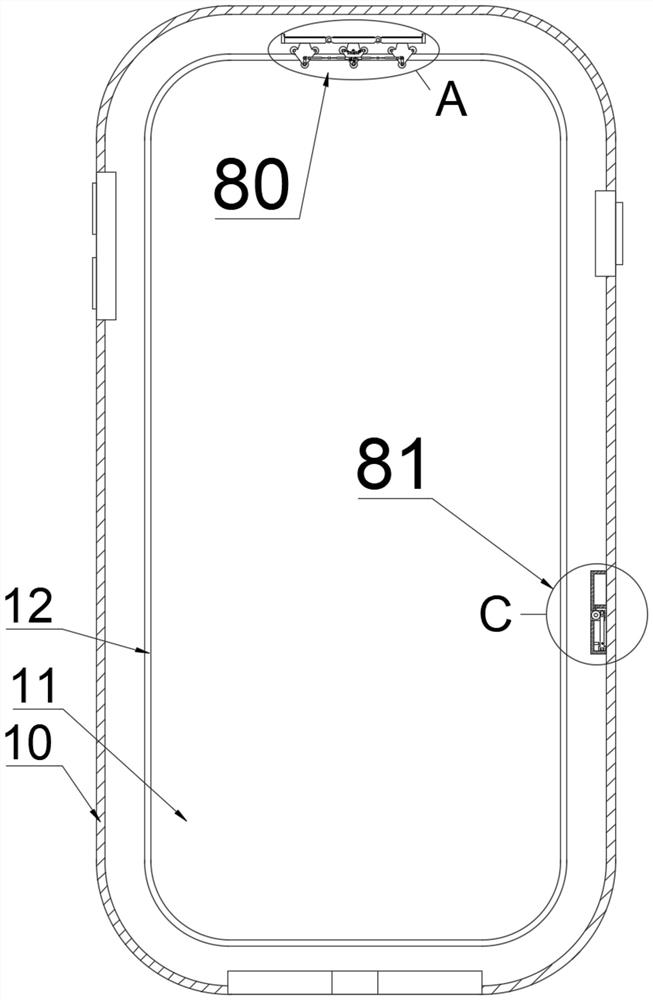

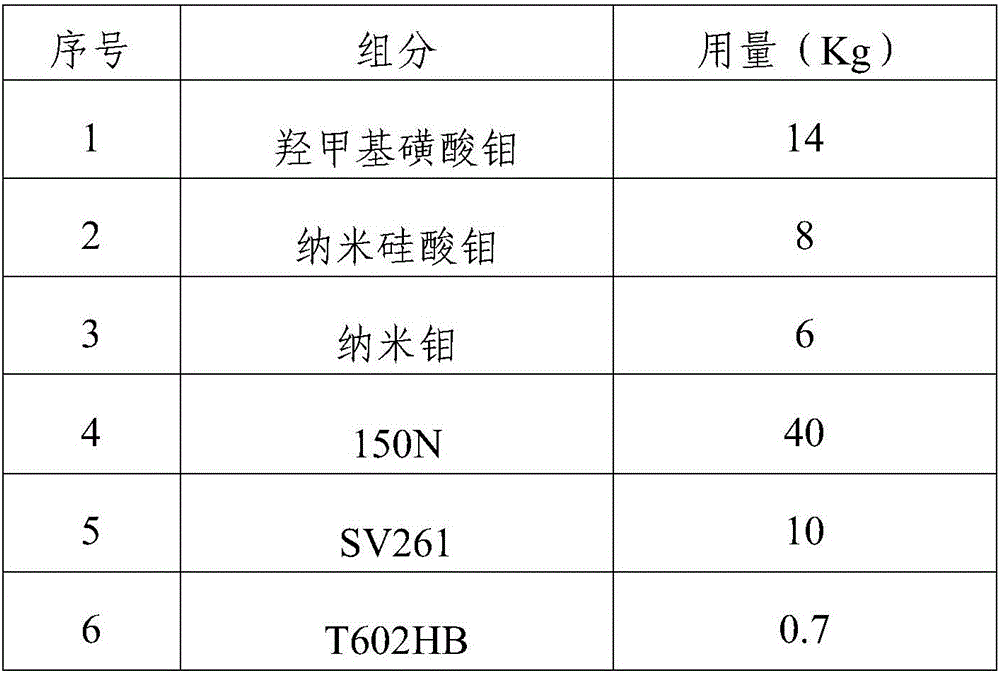

A 5g millimeter wave antenna terminal equipment

ActiveCN112531324BExtend your lifeRepair wearAntenna supports/mountingsIndividually energised antenna arraysTerminal equipmentMillimetre wave

The invention discloses a 5G millimeter-wave antenna terminal device, which includes a mobile phone casing, the mobile phone casing is provided with a mobile phone inner cavity, and the mobile phone inner cavity contains a mobile phone casing located at the rear end of the mobile phone inner cavity. There is a slide rail, and the front side of the slide rail located at the upper end of the mobile phone cavity is provided with three identical bearing plates on the left, middle, and right in turn. The present invention can automatically adjust the 5G frequency of the mobile phone according to the size of the received 5G millimeter wave. The position of the millimeter wave antenna, so that the antenna is always located at the position with the largest signal, can effectively avoid the occlusion of foreign objects, or the phenomenon of 5G signal weakening or even disappearing caused by the occlusion of the hand when holding the mobile phone, and at the same time repair the phenomenon caused by the continuous movement of the antenna The wear and tear of the surface protection layer can effectively prolong the life of the antenna, greatly enhance the experience of 5G mobile phone users, and lay the foundation for the promotion of 5G mobile phones.

Owner:鸿基无线通信(深圳)有限公司

Nano diamond-containing additive of lubricating oil for engine

InactiveCN106479598AImprove suspension stabilityIncrease frictionAdditivesLubricationLiquid suspension

The invention discloses a preparation method of a nano diamond-containing additive of lubricating oil for an engine. The method comprises the following steps of first, using a nano diamond as organic ligand through adding ethylenediaminetetraacetic acid (EDTA), and obtaining nano diamond particles which are high in purity and moreover have favorable liquid suspension properties through the treatment on impurities on the surfaces of non-diamond particles and the nano diamond particles; afterwards, screening out the nano diamond particles of which the particle sizes are 20 to 170 nanometers through a centrifuge; finally, dispersing the additive into No. 10 white oil through an ultrasonic wave, wherein the proportion of the nano diamond is 7 to 10 percent, and the proportion of a basic white oil component is 90 to 93 percent. The nano diamond applied to a product can form a free disperse system in oil, and has high liquid suspension stability; Zeta electric potential is from -40 to -85 millivolts. Through the achievement of the preparation method, the purity and the suspension stability of the nano diamond particles are improved; the high-efficiency service performance of the lubricating oil is guaranteed. The lubricating oil can be applied to the lubrication on all metallic friction surfaces. The preparation method has the functions of improving friction efficiency, repairing the wear of friction surfaces and prolonging the service life of the lubricating oil.

Owner:TIANJIN DIMAI AIKE TECH CO LTD

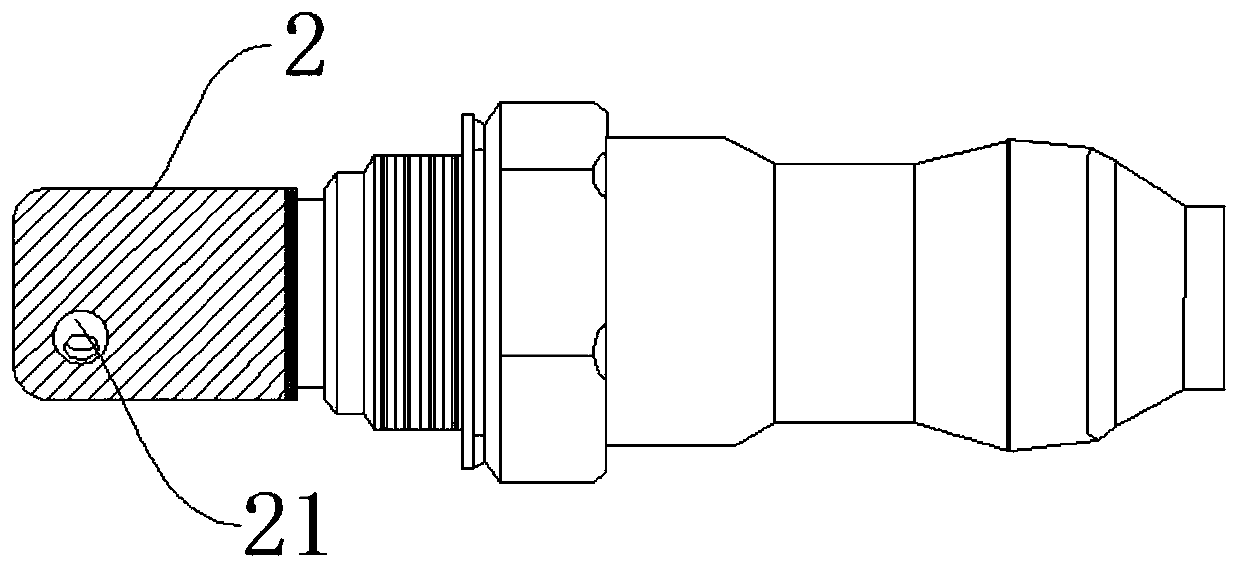

Energy saver and equipment

InactiveCN113482809ARepair wearPromote combustionCombustion-air/fuel-air treatmentMachines/enginesInfraredEngineering

The invention relates to an energy saver and equipment. The energy saver comprises a shell used for being fixed with an engine of the equipment to be subjected to energy saving, and various metals are arranged in the shell. From the perspective of science, all objects higher than absolute zero can release electromagnetic waves, the electromagnetic waves are one of energy, the higher the temperature is, the shorter the wavelength of the released electromagnetic waves is, the stronger the action is, and when the engine is started, the temperature rises; and the electromagnetic waves and energy waves are generated at the same time, the various metals arranged in the shell are heated to release high-energy infrared rays, the electromagnetic waves absorb scrap iron and other impurities in a cylinder body of the engine of equipment to be subjected to energy saving, energy waves activate engine oil of the engine all the time, oil film covering is formed, cylinder score abrasion is repaired, air tightness is enhanced, power is improved, fuel oil combustion is promoted through the infrared rays, oil sludge hardening is prevented, oil consumption is reduced, and the high-energy-saving effect is achieved.

Owner:无限者(北京)国际科技股份有限公司

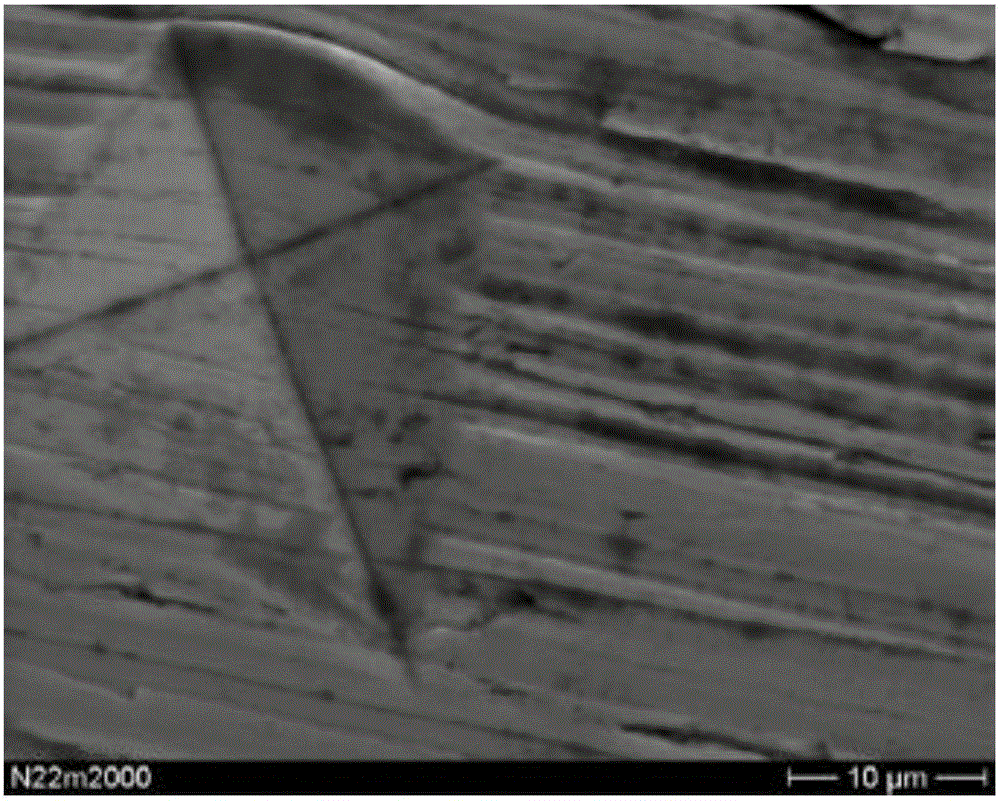

Preparation method and application of micron copper powder lubricating oil additive with low apparent density

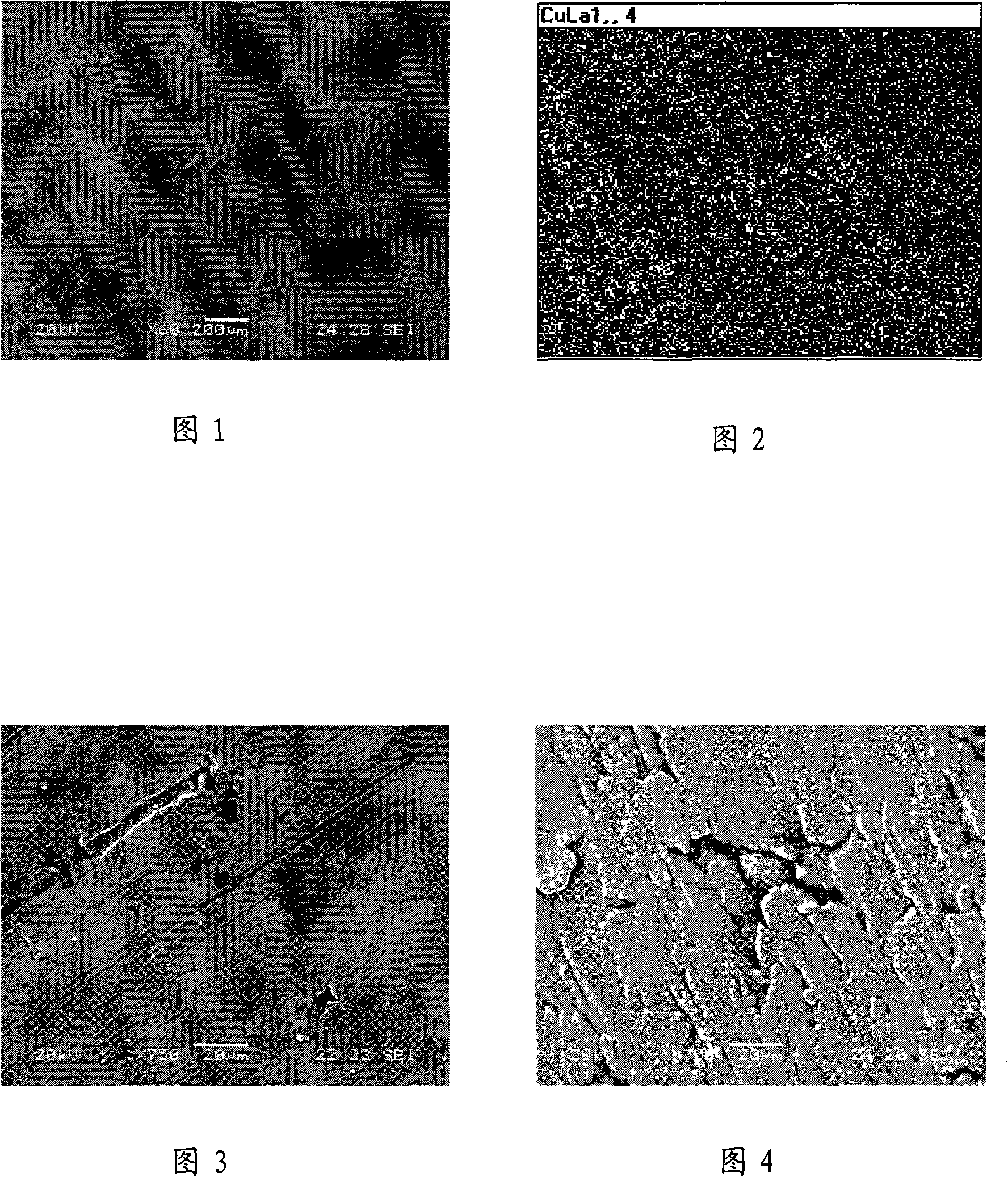

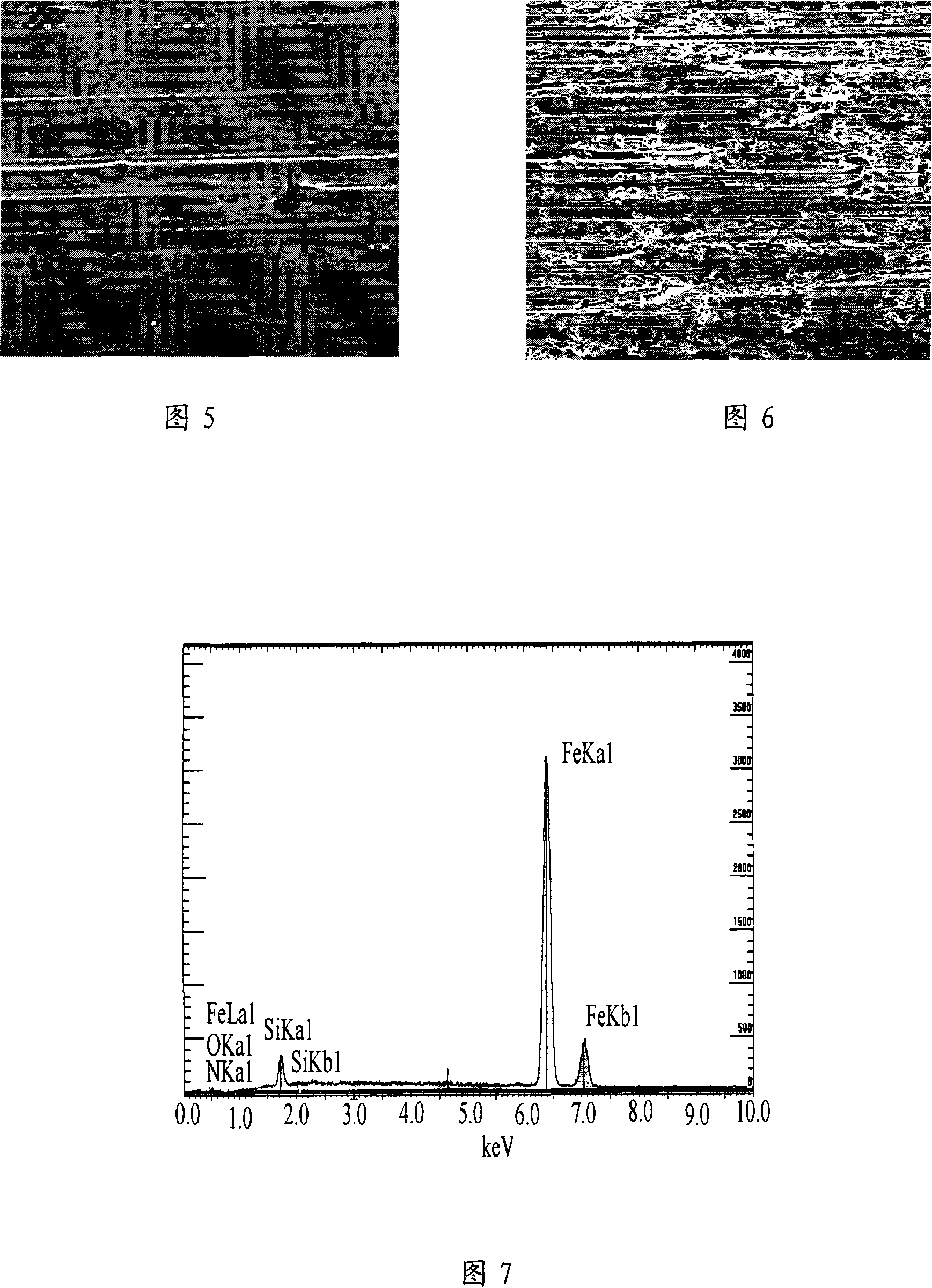

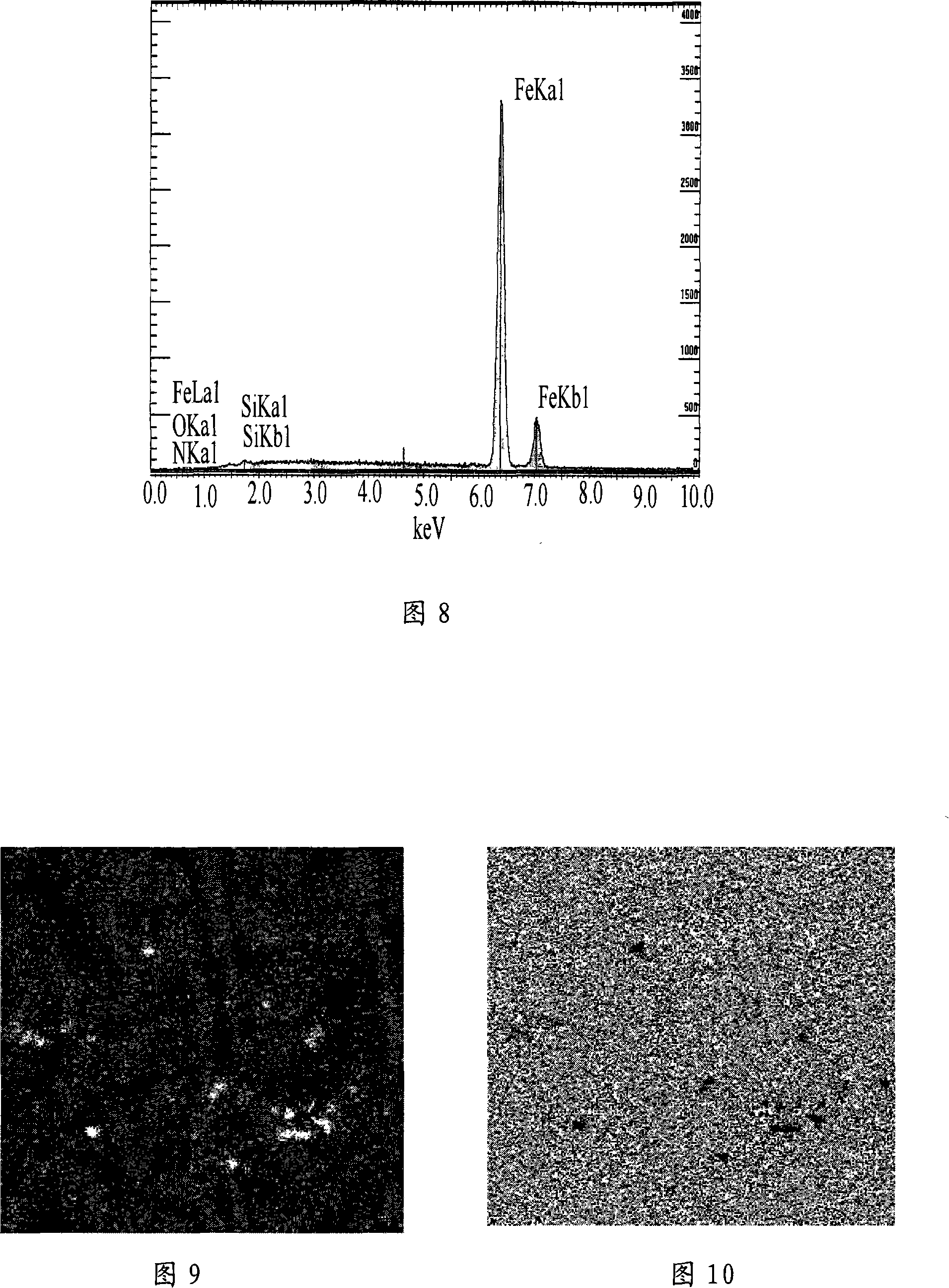

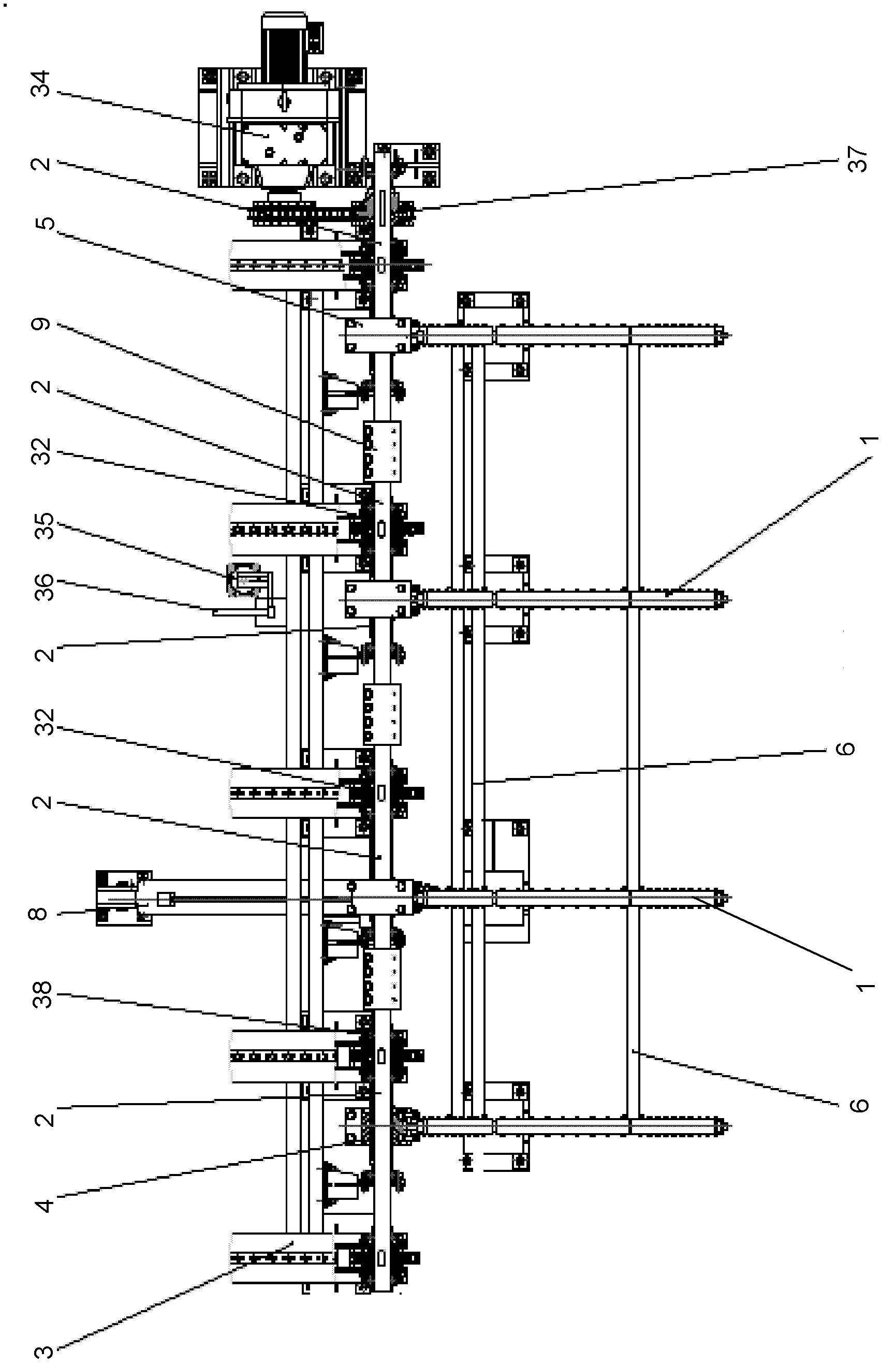

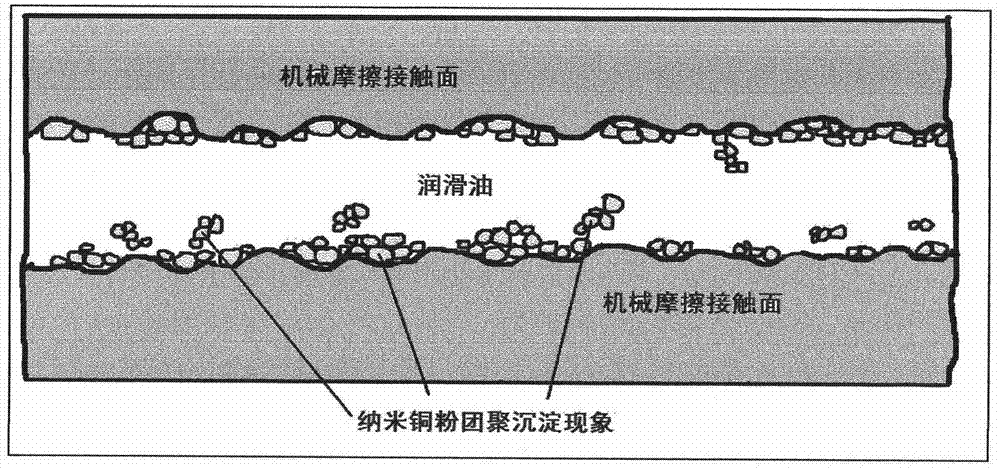

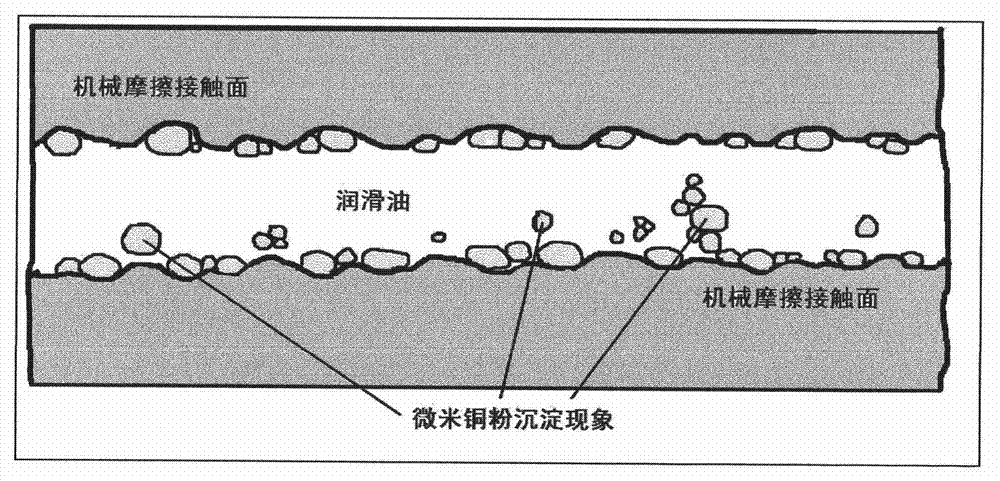

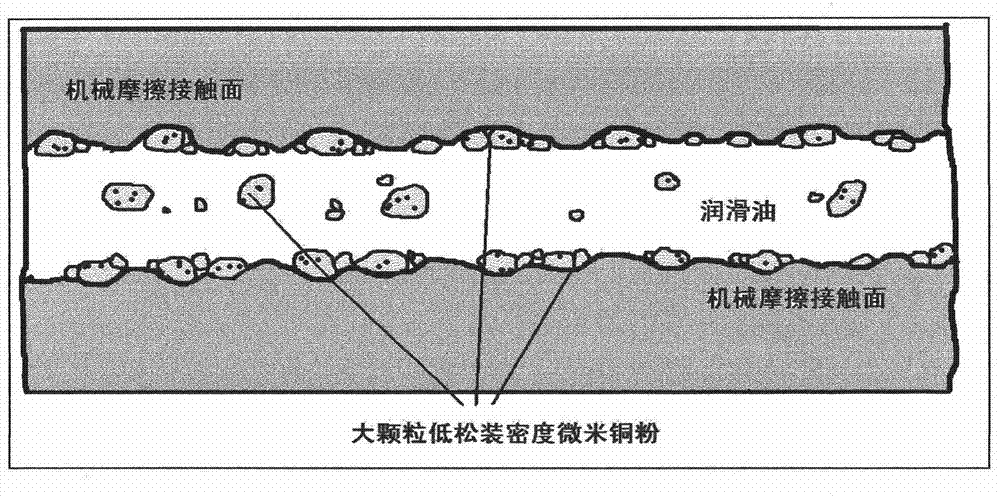

The invention provides a preparation method of an energy saving and emission reduction type lubricating oil additive in the technical field of industry and manufacturing industry, which overcomes the precipitation and agglomeration phenomenon of copper powder in the previous similar technology and avoids the application difficulty and potential mechanical damage caused by the agglomeration of the copper powder. The preparation method comprises the following steps: stirring micron copper powder with low apparent density (0.8-1.00 g / cm<3> and the particle size is 0.1-100 microns) with base oil for 20 minutes according to a proportion of 1:2 by using a planetary stirrer, deoiling by using a centrifugal deoiling machine, taking out the micron copper powder, and roasting for later use; adding the base oil into the copper powder according to a proportion of 1:10, and stirring for 20 minutes by using the planetary stirrer to prepare the micron copper powder lubricating oil additive; adding lubricating oil into the micron copper powder lubricating oil additive according to a proportion of 1:20, and stirring for 20 minutes using the planetary stirrer to prepare a finished product of micron copper powder lubricating oil; adding lubricating grease into the micron copper powder according to a proportion of 1:80, and stirring for 30 minutes by using the planetary stirrer to prepare a finished product of micron copper powder lubricating grease. The specific gravity of the used copper powder is close to that of the oil, and thus the copper powder precipitation phenomenon is well solved.

Owner:苏惠卿

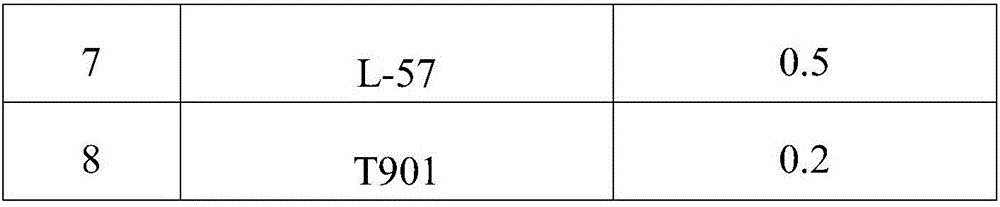

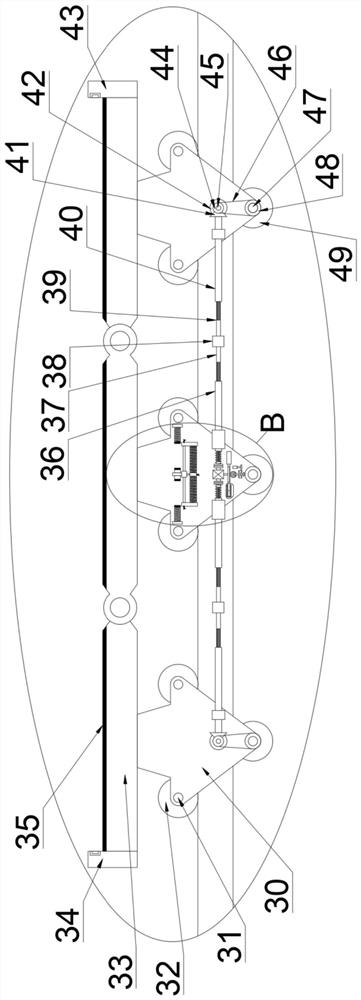

Engine anti-wear repairing agent and preparation method thereof

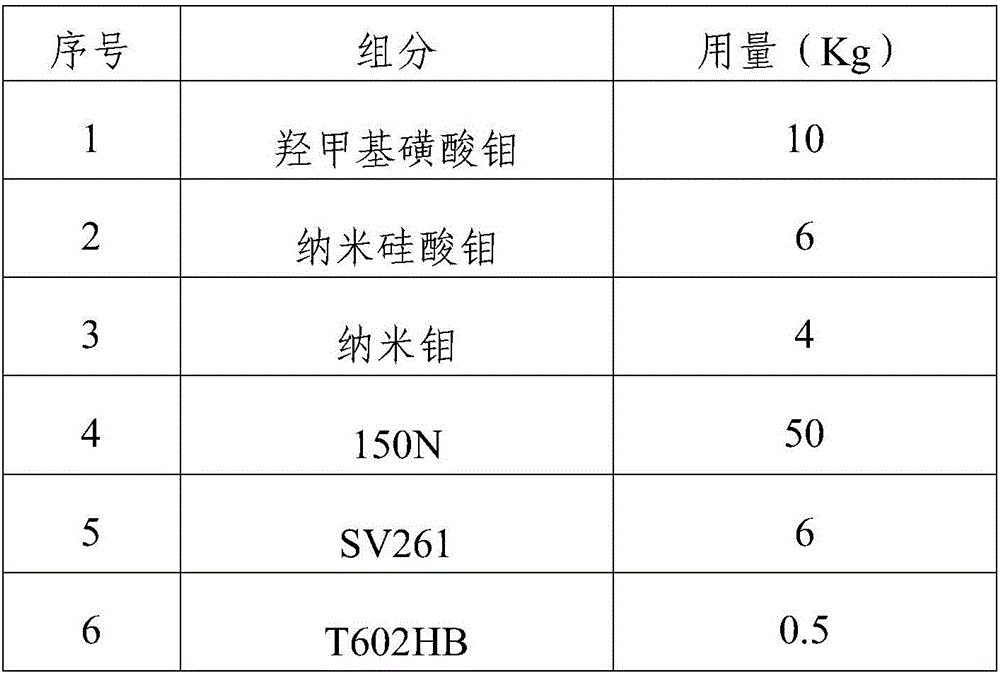

The invention discloses an engine anti-wear repairing agent and a preparation method thereof. The engine anti-wear repairing agent comprises 17 to 40% by mass of an anti-wear repairing factor. The anti-wear repairing agent comprises, by weight, 7 to 15 parts of molybdenum hydroxymethylsulfonate, 6 to 8 parts of nanometer molybdenum silicate and 2 to 6 parts of nanometer molybdenum. Used additives comprise 5 to 12 parts of a viscosity index improver, 0.5 to 2 parts of a pour point depressant, 0.2 to 1 part of a high temperature antioxidant and 0.1 to 1 part of an antifoaming agent. The engine anti-wear repairing agent adopts the repairing component, the repairing component can be effectively fixed to the friction surface of a machine part during the operation of the engine, repair the original damage and form a permanent high strength protective film. The film has wear resistance and reduction effects and realizes easy and smooth operation of the machine so that the engine endures and remains fresh. The engine anti-wear repairing agent reduces energy consumption and tail gas emission and protects the air environment.

Owner:中润超油(北京)新材料有限公司

Casting welding process

InactiveCN109986182AReduce welding man-hoursSave welding materialWelding accessoriesField conditionsCurrent range

The invention discloses a casting welding process that comprises the following welding process steps: (1), cleaning a to-be-welded part: eliminating defect factors such as greasy dirt and rust; (2), preparing a welding rod: drying the welding rod for 40 minutes at the temperature of 360-380 DEG C by using an E50157 alkaline welding rod with the diameter of 3.2 mm, and putting the welding rod intoa heat preservation barrel for heat preservation for later use after the welding rod is dried; and (3), welding: selecting a direct-current electric welding machine, adopting a direct-current positiveconnection method, that is, the welding rod is connected with a cathode and a weldment is connected with an anode, wherein the current range is kept about 95-105 A. According to the invention, the casting is welded by adopting a casting cold welding process, so that the problems that the working environment of a casting hot welding process is poor and the heating temperature is difficult to meetthe requirements of the hot welding process under many field conditions are solved, the welding time is shortened, and the welding material is saved.

Owner:常鑫

Composite coating for repairing surface of silver coin or souvenir medal and preparation method of composite coating

PendingCN113789485AUniform structureConsistent thicknessVacuum evaporation coatingSputtering coatingCoinChromium

The invention relates to a silver-based amorphous alloy and nanocrystalline pure silver composite coating for repairing the surface of a silver souvenir coin or medal and a preparation method of the composite coating. The composite coating comprises a silver-based amorphous alloy coating serving as a substrate and a nanocrystalline pure silver coating on the surface; and the silver-based amorphous alloy coating comprises a silver component and an active metal component, and representative active elements suitable for the silver-based amorphous alloy coating comprise chromium, nickel, silicon and the like. The preparation method comprises the following steps: cleaning the silver coin and a magnetron sputtering target material, preparing the composite coating through magnetron sputtering deposition in a vacuum state, and post-processing the target material and the silver coin. By means of the silver-based amorphous alloy and nanocrystalline pure silver composite coating and the preparation method thereof, damaged silver coins with scratches, abrasion and color spots and the height difference smaller than 2 micrometers from the original surface can be repaired, the surface of the repaired silver coins is covered with the composite coating uniform in component and compact in structure, good binding force exists between the silver coins and the composite coating, and the appearance color is the same as that of pure silver. The problems that tiny scratches, abrasion and other flaws are generated on the surfaces of the silver coins in the production, storage and circulation processes, black spots, white spots, yellowing and other flaws are formed on the surfaces of the silver coins due to the influence of sulfur, chlorine, oxygen and other corrosion elements in the environment, and therefore the appearance and luster of the silver coins are seriously influenced are solved.

Owner:SHENYANG MINT CO LTD

5G millimeter wave antenna terminal device

ActiveCN112531324AExtend your lifeRepair wearAntenna supports/mountingsIndividually energised antenna arraysTerminal equipmentMillimetre wave

The invention discloses 5G millimeter wave antenna terminal device which comprises a mobile phone shell, a mobile phone inner cavity is formed in the mobile phone shell, and a sliding rail is arrangedon the mobile phone shell located at the rear end of the mobile phone inner cavity and located in the mobile phone inner cavity. Three identical bearing plates including the left bearing plate, the middle bearing plate and the right bearing plate are sequentially arranged on the front side of the sliding rail located at the upper end of the inner cavity of the mobile phone. According to the mobile phone 5G millimeter wave antenna, the position of the mobile phone 5G millimeter wave antenna can be automatically adjusted according to the size of received 5G millimeter waves, so that the antennais always located at the position with the maximum signal, foreign object shielding can be effectively avoided. The 5G signal weakening or even disappearing phenomenon caused by shielding of the handwhen the mobile phone is held by hand is avoided, meanwhile, abrasion of the surface protection layer caused by continuous movement of the antenna is repaired, the service life of the antenna can beeffectively prolonged, the use experience of a 5G mobile phone user is greatly enhanced, and a foundation is laid for popularization of the 5G mobile phone.

Owner:鸿基无线通信(深圳)有限公司

A Repairing Method for Filling Cylinder of Rotary Drum Vacuum Filter

Owner:岳阳大陆激光技术有限公司

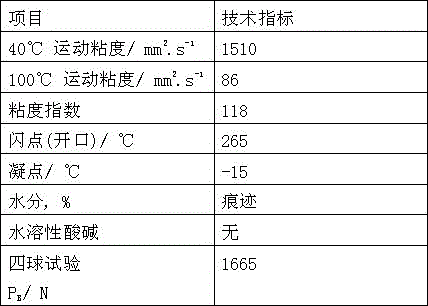

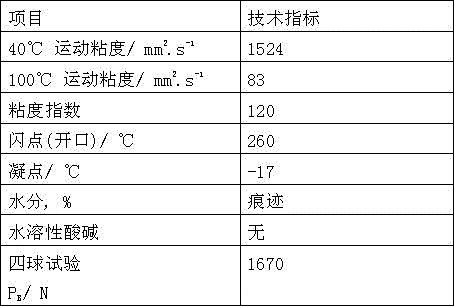

A kind of anti-friction synergist of rotary kiln supporting wheel bearing pad lubricating oil and preparation method thereof

The invention discloses a friction-reducing synergist and a preparation method thereof for the lubricating oil of the supporting wheel bearing bush of a rotary kiln. The mass ratio of each component is as follows: 40-60 parts of polybutene synthetic oil, 20-40 parts of nano molybdenum disulfide 8-17 parts of plastic mixture, 8-12 parts of nano-alumina, 4-6 parts of nano-titanium oxide, 4-6 parts of nano-copper, 2-3 parts of nano-nickel, 6-8 parts of composite antioxidant mixture, poly 3-8 parts of isobutylene and ethylene propylene rubber mixture, wherein the plastic mixture is a mixture of nano polytetrafluoroethylene, polyphenylene sulfide powder and polyimide powder. The beneficial effects of the present invention are: excellent resistance to extreme pressure and wear, low temperature fluidity, high temperature resistance, water shower resistance, anti-oxidation performance and anti-rust and anti-corrosion properties, which can fully repair bearing pad wear, reduce bearing pad heating, and hold pad. , even tile overturning and other phenomena, reduce wear and tear, prolong the service life of the supporting wheel bearing bush, and achieve the purpose of saving energy and reducing consumption; it is easy to operate during use.

Owner:山东中坤石油科技股份有限公司

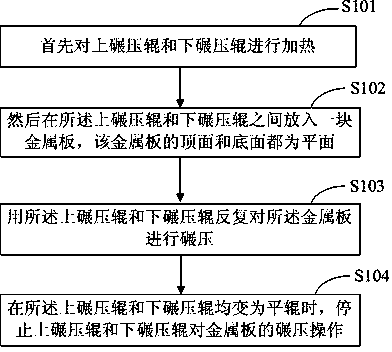

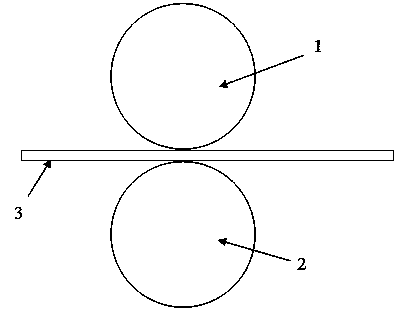

Method for automatically repairing extreme differences of rolling rollers of battery pole plate

The invention discloses a method for automatically repairing extreme differences of rolling rollers of a battery pole plate. The method comprises the following steps of: 1, heating an upper rolling roller and a lower rolling roller at first; 2, placing a metal plate between the upper rolling roller and the lower rolling roller, wherein the top surface and the bottom surface of the metal plate are flat surfaces; 3, repeatedly grinding the metal plate by using the upper rolling roller and the lower rolling roller; and 4, stopping grinding the metal plate when both the upper rolling roller and the lower rolling roller become flat rollers. According to the method for automatically repairing the extreme differences of the rolling rollers of the battery pole plate, abrasions and slight distortions appearing on the surfaces of the rolling rollers of the battery pole plate can be conveniently and quickly repaired, so that gaps between the upper rolling roller and the lower rolling roller are effectively reduced, the battery pole plate placed between the upper rolling roller and the lower rolling roller can be normally rolled by the upper rolling roller and the lower rolling roller, and then the production quality of a produced battery pole plate is ensured.

Owner:TIANJIN LISHEN BATTERY +1

Workpiece feeding and distributing device

ActiveCN103101735BGuaranteed accuracyRepair wearConveyor partsMechanical conveyorsRotational axisSprocket

The invention discloses a workpiece feeding and distributing device. The workpiece feeding and distributing device comprises a plurality of U-shaped feeding tanks, a rotating shaft and a chained material-distributing table, wherein the plurality of U-shaped feeding tanks are arranged in parallel and one end of each U-shaped feeding tank is connected with the rotating shaft, one bottom of each U-shaped feeding tank is connected with an oil cylinder through a trunnion, and the oil cylinders drive the U-shaped feeding tanks to conduct feeding operation. The chained material-distributing table comprises a drive sprocket which is provided with a conveying chain, a table frame and a gear motor, wherein the drive sprocket is arranged on the rotating shaft, the rotating shaft is connected on the table frame through a bearing, the gear motor is connected with the rotating shaft through a chain, a material-blocking mechanism which is driven by a cylinder to rise and fall is fixedly arranged on the table frame, the drive sprocket is driven by the gear motor, and thus an upper chain of the workpiece is enabled to conduct material distributing operation. The device is suitable for workpieces with a large scope of standards, feeding and material-distributing operations of bar materials, pipe materials and square billets can be achieved smoothly, and meanwhile, manual material-setting is of no need, and security accidents are avoided.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

A method of improving engine compression efficiency and saving fuel

InactiveCN109630232BImprove the finishIncreased microhardnessElectrical controlInternal combustion piston enginesOxygen sensorExhaust gas emissions

The invention discloses a method combining an oxygen sensor improved structure and a surface ceramic recombination metal wear self-repair technology for improving engine compression efficiency and saving fuel oil. An aeration area of an oxygen sensor is reduced to 3-30% of an original aeration area by the oxygen sensor improved structure, the oxygen content in the exhaust gas detected by the oxygen sensor is lower than the actual content, and thus a deception signal is sent to an ECU, being in a rich oil state is received by an oil injection control module by mistake, and thus the oil injection quantity is reduced. The surface ceramic recombination metal wear self-repair technology enhances the cylinder pressure by 20-45%, the compression efficiency is improved, and an ideal oil-gas mixture ratio ignition mode of a traditional gasoline engine is enabled to qualitative change to a high compression ratio and rare oil-gas mixture ratio ignition pressure explosion type combustion mode. According to the method, an ignition combustion engine does not need to change hardware manufactured by an original vehicle factory and electronic control software, a rare oil-gas mixture ratio and highcylinder pressure ignition pressure explosion combustion mode is achieved, the fuel oil is saved, the power is improved, the exhaust emission is reduced, and the vehicle environmental protection standard is improved.

Owner:纪晓光

Integrated process method of engine pretreatment, self-healing materials and exhaust gas treatment

ActiveCN107829822BFast self-healingRepair wearInternal combustion piston enginesSilencing apparatusParticulatesAfter treatment

Owner:黑龙江西亚金属表面工程技术研究院(有限合伙) +2

Nano metal self-restoring lubricating oil for mechanical sealing element and preparation method thereof

The invention discloses nano-metal self-repairing lubricating oil for mechanical seal elements and the process for preparation, which comprises the following components, the weight percentage content which occupies the total amount of self-repairing lubricating oil is that nano-metal powder which is 0.07-0.15%, nano-metal powder body dispersing agent which is 0.2-1% and disperse medium 98.9-99.7%. The process for preparation of the invention comprises the following steps: adding nano-metal powder body dispersing agent which is needed by proposition into disperse medium to evenly stir, furtheradding nano-metal powder according to the above proposition, properly stirring till nano-metal powder has no obvious settlement, placing with a container into a KH-700 type ultra-audio wave oscillator to oscillate 20-30 minutes, wherein source of power is 500-600w, and getting product. The nano-metal self-repairing lubricating has low production cost, which is beneficial for popularizing, and canlead the gap between friction pairs to be optimized, and the nano-metal self-repairing lubricating oil can not be dropped off after a self-repairing layer is formed, operation with low friction factor of equipment is kept, and the nano-metal self-repairing lubricating oil is energy-saving and environmental-friendly, which can effectively prolong maintenance down periodic time, and lowers maintenance cost.

Owner:MIYOU GROUP

Environment-friendly composite multisoap base self-repairing bearing grease and preparation method thereof

ActiveCN102604724BImprove performanceOvercoming the lack of extreme pressure wear resistanceLubricant compositionMaximum levelWear resistant

The invention relates to environment-friendly composite multisoap base self-repairing bearing grease and a preparation method of the bearing grease. The bearing grease is prepared from composite base liquid, a composite calcium soap thickening agent, an oxidation and corrosion resistant additive, a tungsten disulfide extreme pressure additive, a metal deactivator, a polarization graphite wear resistant additive, a self-repairing additive and a structure improving agent. According to the bearing grease provided by the invention, an additive containing non-heavy metal elements is used to replace the originally used additive containing heavy metal elements. Because base liquid, a thickening agent and an additive are all optimized, the bearing grease provided by the invention is more excellent in combination property and highlighted in abrasion resistance, maintains an excellent level in extreme pressure property, can fully meet the requirements of the bit bearing extreme pressure, the high temperature, a deep well with high temperature, the high-impact load and the abrasion resistance, meanwhile, can effectively supplement the defect that silver coating is not sufficiently brushed on the bearing axial diameter plane, and acts a function of repairing an abrasion resistant layer on a metal seal and a rubber seal of a bit bearing, so that the service life of the bearing is prolonged at a maximum level.

Owner:KINGDREAM PLC CO +2

Multifunctional cutting gear processing device and its working method

InactiveCN111331201BImprove machining accuracyRepair wearMeasurement/indication equipmentsFeeding apparatusLaser rangingCooling fluid

Owner:INNER MONGOLIA UNIV FOR THE NATITIES

Automobile lubricating oil additive of semi-solid high-strength film, synthesis method of automobile lubricating oil additive and lubricating oil

PendingCN112920875AImprove Oxidation StabilityImprove cold start performanceAdditivesMeth-Oil additive

The invention relates to the technical field of lubricating oil additives, in particular to a semisolid high-strength film vehicle lubricating oil additive, a synthesis method thereof and lubricating oil. Molybdenum oxide is used as a basis to react with o-aminobenzene sulfonic acid and alkylated diphenylamine, then potassium permanganate is added, a method of adjusting the pH value is adopted to obtain an organic molybdenum amine mixture beneficial to a good reaction in the next step, then the organic molybdenum amine mixture reacts with calcium titanate, methyl methacrylate and didodecyl methyl tertiary amine, and a two-step pressure method is adopted, so the molybdenum-titanium alloy lubricating oil additive with good lubricity and excellent wear resistance is prepared, is dissolved in various lubricating oil in a liquid ionic form, is a friction modifier, an anti-wear agent and an antioxidant of the lubricating oil for an internal combustion engine, has a remarkable oil-saving effect, and can remarkably improve the film-forming capacity and the bearing capacity of the lubricating oil. A chemical adsorption film with antifriction and antiwear effects is formed on the friction surface; and the engine is further protected under harsh working conditions such as high speed, high temperature and high pressure.

Owner:池素玲

Graphene engine oil, preparation method and equipment thereof

PendingCN114774187AExtended service lifeReduce wearRotary stirring mixersMixing methodsReciprocating motionGraphite

The invention discloses graphene engine oil as well as a preparation method and equipment thereof. The graphene engine oil is mainly prepared from the following raw materials in percentage by mass: 0.03 to 0.09 percent of nano graphene, 0.015 to 0.03 percent of dispersing agent and the balance of base oil. The high-purity graphene is adopted, can be uniformly dispersed in an oily system for a long time under the action of the dispersing agent, and is not easy to precipitate; the graphene used in the invention does not chemically react with the metal surface of the engine, the inner wall of the engine is protected completely through physical adsorption film formation, and wear between internal friction pairs is reduced; the used graphene can be used for filling and repairing cylinder wall abrasion in a high-temperature and high-pressure environment when an engine works; meanwhile, carburization is formed on the inner wall surface of the engine after long-time use, the surface strength is improved, and the service life of the engine is prolonged; the used graphene can be uniformly coated in the engine along with the reciprocating motion of the piston, so that the effect of a micro bearing is achieved, sliding friction is changed into rolling friction, and the friction resistance is reduced.

Owner:德汇新材料科技南通有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com