A method of improving engine compression efficiency and saving fuel

A compression efficiency and fuel-saving technology, applied in engine components, combustion engines, engine control, etc., can solve the problems of difficult operation of control procedures and inability to popularize and use, and achieve the effect of reducing heat, reducing NOx emission content, and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

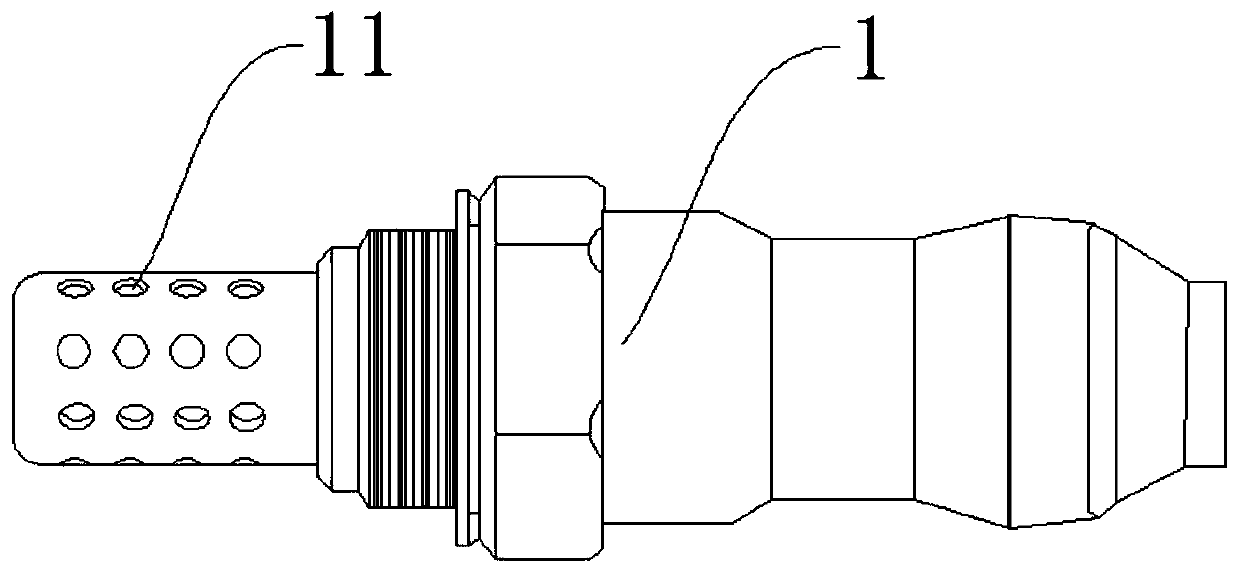

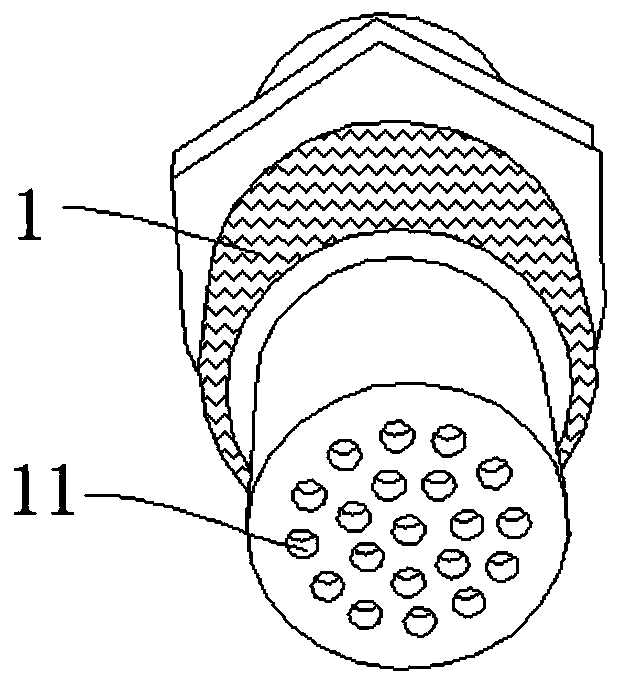

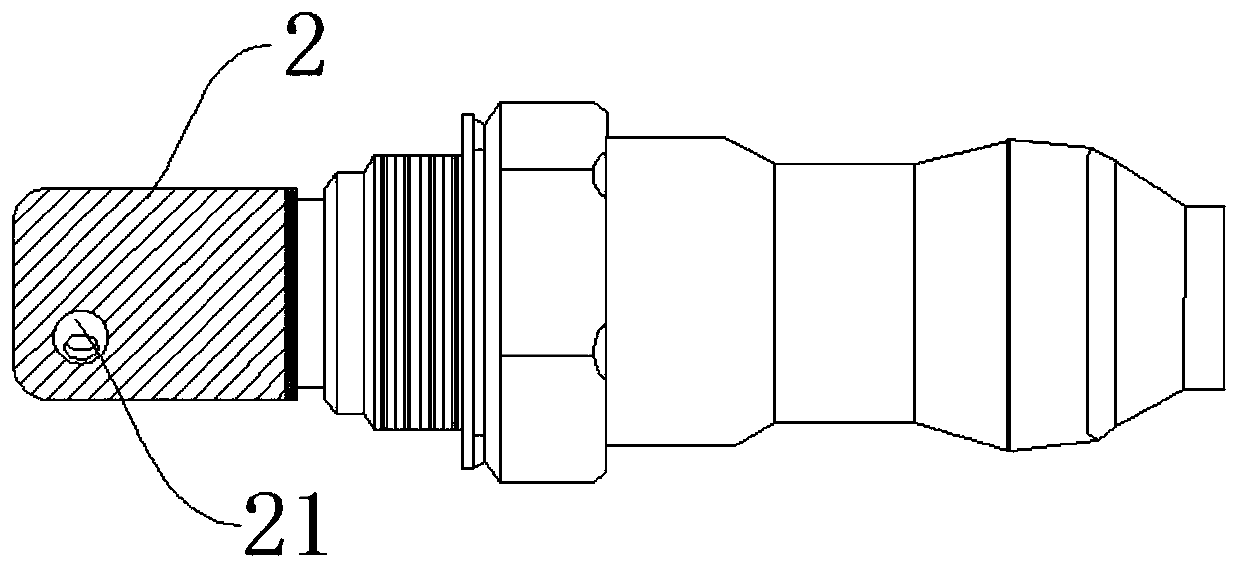

[0041] figure 1 and figure 2 Two structures of oxygen sensors commonly used in automobile engines are shown, which generally consist of a protective housing 1 and sensor elements arranged in the protective housing 1 . in, figure 1 In the oxygen sensor shown, the air intake holes 11 are arranged in multiple rows at intervals on the front side wall of the protective housing 1 . figure 2 In the oxygen sensor shown, the air inlets 11 are arranged at intervals on the front end surface of the protective housing 1 . The air intake holes 11 are all in communication with the inside of the protective housing 1, so that exhaust gas enters through the air intake holes 11, and the sensor element detects the oxygen content in the exhaust gas to control the fuel injection quantity.

[0042] This embodiment provides an improved structure of the oxygen sensor, which is figure 1 and figure 2 The improvement of the oxygen sensor shown is to reduce the effective ventilation area of the ...

Embodiment 2

[0061] This embodiment provides a method for improving the compression efficiency of the engine and saving fuel, which is realized through the improved structure of the oxygen sensor described in Embodiment 1 combined with the self-repairing technology of surface ceramic recombination metal wear, specifically, the method includes the following steps :

[0062] (1) Add a metal surface self-repair agent to the new engine lubricating oil or the engine lubricating oil that has been used for no more than 5,000 kilometers to repair the wear of the engine cylinder and repair the wear and ceramics of the metal surface of the parts. When in use, the amount of the metal surface self-repairing agent is based on the mass of the repairing factor in the metal surface self-repairing agent, and 0.2 to 6 g of the repairing factor is added to every liter of lubricating oil.

[0063] (2) After adding the metal surface self-repair agent, let the car run for more than 8,000 kilometers for dynamic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com