Preparation method and application of micron copper powder lubricating oil additive with low apparent density

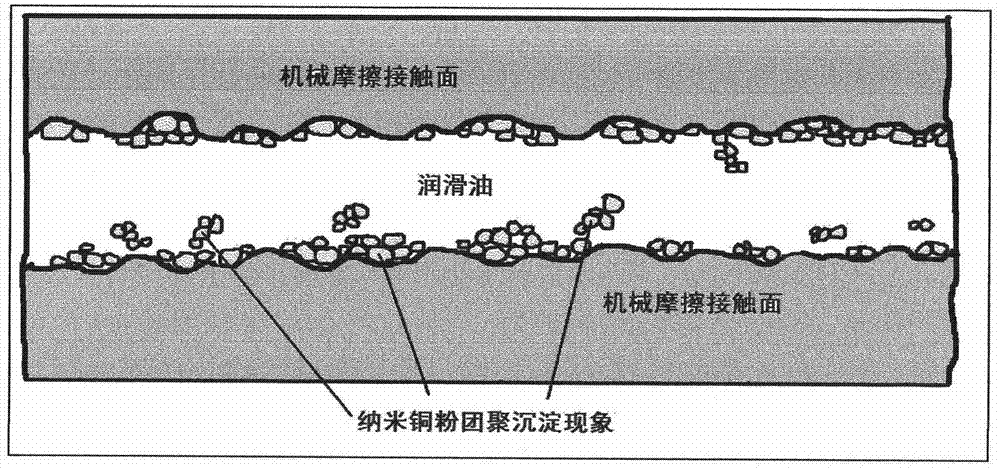

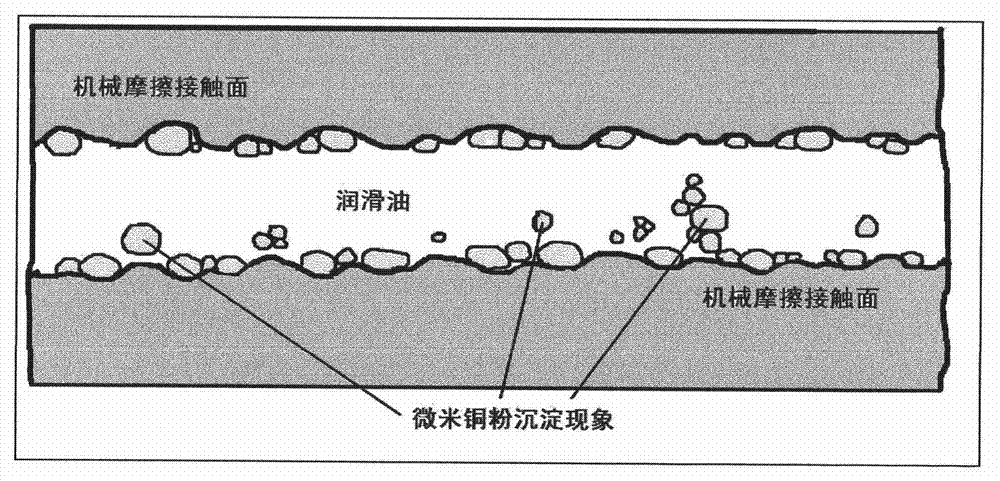

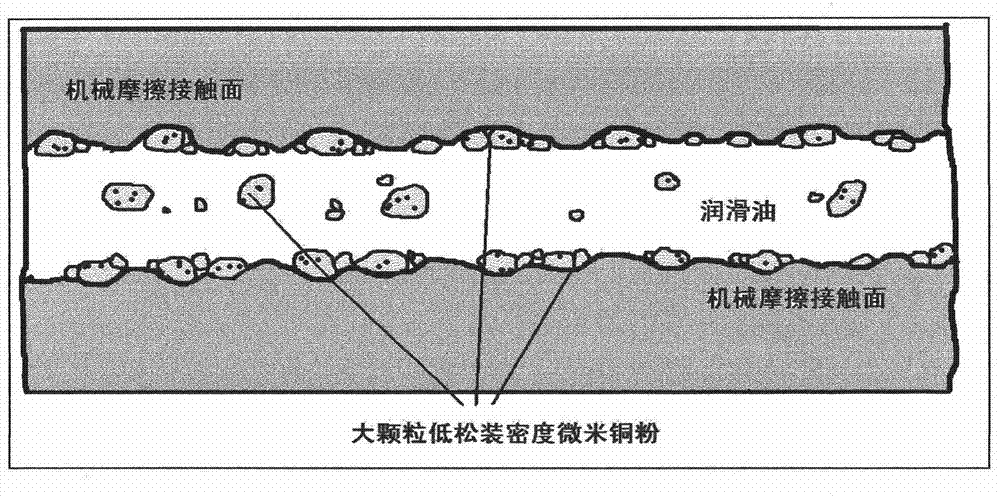

A lubricating oil additive and low-loose packing technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of unresolved separation and precipitation of copper and oil, affect product trust, and unresolved requirements, etc., to achieve resistance to cold start damage, The effect of saving fuel and repairing mechanical scratches and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Add 2000g of low bulk density micron copper powder (particle size 0.1-2.0 micron, bulk density 0.8-1.0g / cm3), add base oil 4000ml (type II, saturated hydrocarbon content greater than 90%, viscosity index greater than 80 -120, the sulfur content is less than 0.03%).

[0043] (2) The implementation temperature is 20°C±10°C, stir with a planetary mixer, set the rotation speed at 2000 rpm, set the stirring time for 20 minutes, and take it out.

[0044] (3) Deoil the copper powder with oil using a centrifugal deoiler, set the speed at 2500 rpm, set the time for 20 minutes, and take out the copper powder.

[0045] (4) Bake the deoiled copper powder with a high-temperature dryer at 500° C. for 60 minutes, and set aside.

[0046] (5) Add 400ml of prepared oily low bulk density micron copper powder to 4000ml of base oil (Type III, with saturated hydrocarbon content greater than 90%, viscosity index greater than 120, and sulfur content less than 0.03%).

[0047] (6) Stir wi...

Embodiment 2

[0050] (1) Add 300ml of prepared micron copper powder lubricating oil additive to 6000ml of lubricating oil (Shell Heineken yellow barrel HX5, viscosity 10W-40, grade SN gasoline engine) at a volume ratio of 1:20.

[0051] (2) Use a planetary mixer, set the speed at 2000 rpm, and stir for 20 minutes to make a finished product with low bulk density micron copper powder lubricating oil, take 4000ml and put it in a barrel for direct filling of 4 liters of engine use.

Embodiment 3

[0053] (1) Add 500g of low bulk density micron copper powder (particle size 0.1-30 microns, bulk density 0.8-1.0g / cm3), add base oil 1000ml (type II, saturated hydrocarbon content greater than 90%, viscosity index greater than 80 -120, the sulfur content is less than 0.03%).

[0054] (2) The implementation temperature is 20°C±10°C, stir with a planetary mixer, set the rotation speed at 2000 rpm, set the stirring time for 20 minutes, and take it out.

[0055] (3) Deoil the copper powder with oil using a centrifugal deoiler, set the speed at 2500 rpm, set the time for 20 minutes, and take out the copper powder.

[0056] (4) Bake the deoiled copper powder with a high-temperature dryer at 500° C. for 60 minutes, and set aside.

[0057] (5) 100g micron copper powder of prepared oily low bulk density micron copper powder (particle size 0.1-30 micron, bulk density 0.8-1.0g / cm3), add grease 8000g in the ratio of 1:80 ( Great Wall lithium complex grease).

[0058] (6) With a planeta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com