Engine anti-wear repairing agent and preparation method thereof

A repair agent and engine technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve problems such as enlarged cylinder fit clearance, poor cylinder sealing performance, increased fuel consumption, etc., to reduce fuel consumption, reduce Energy consumption, the effect of repairing internal wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

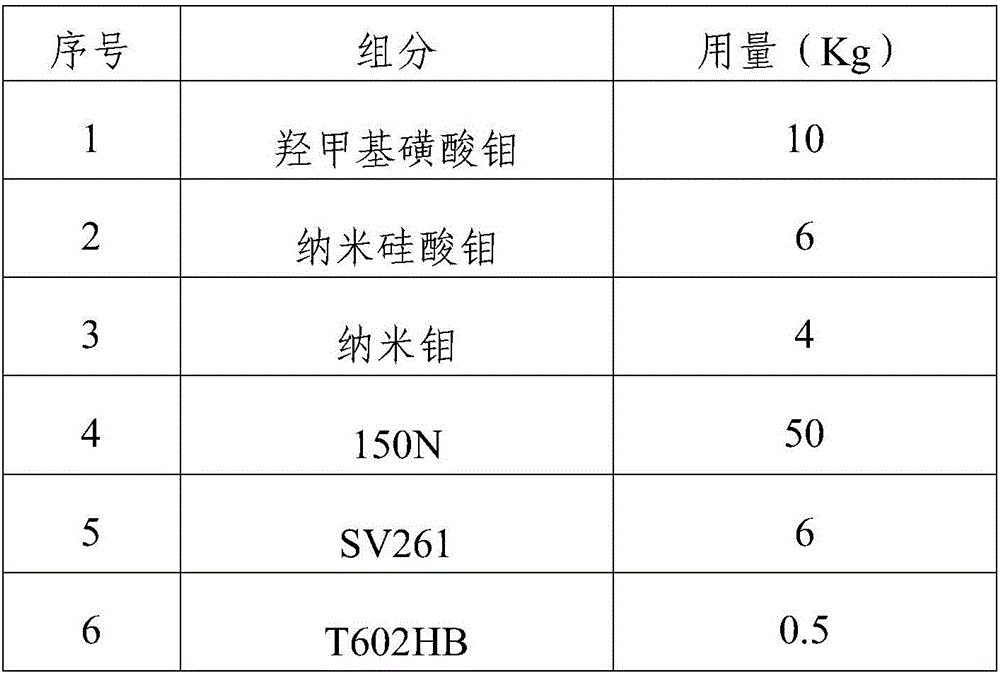

[0036] This embodiment provides an engine anti-wear repair agent, which is composed of raw materials in parts by weight shown in Table 1:

[0037] Table 1:

[0038]

[0039]

[0040] This embodiment also provides a preferred preparation method of the above-mentioned engine anti-wear repair agent, which is as follows: first add base oil, heat the base oil to 60°C, add various anti-wear repair factors and additives in a state of stirring, Stir until well mixed, that is.

Embodiment 2

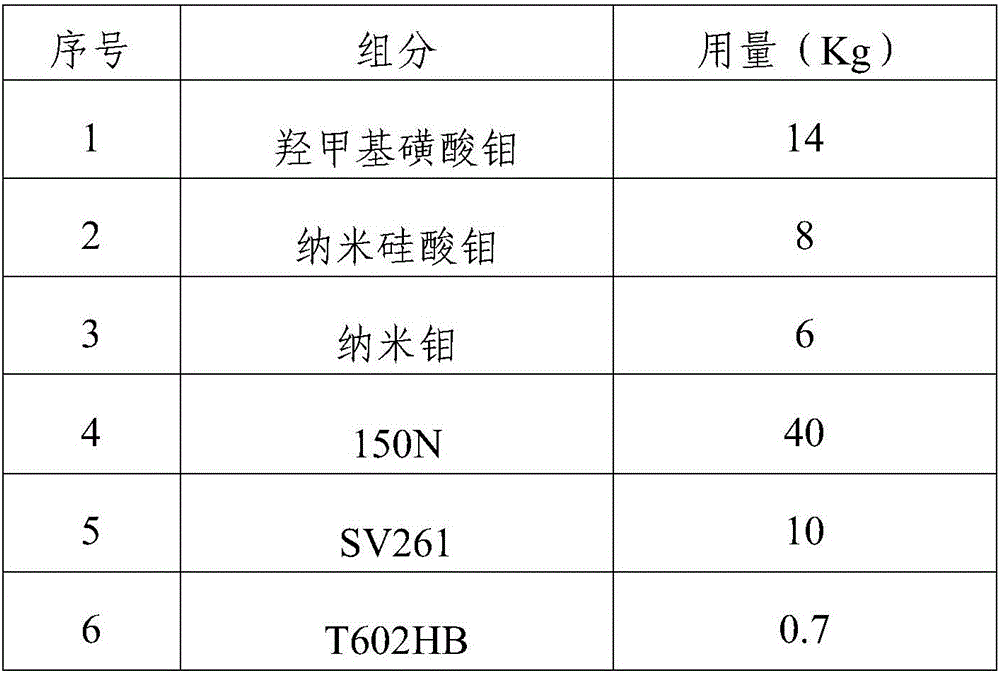

[0042] This embodiment provides an engine anti-wear repair agent, which is composed of raw materials in parts by weight shown in Table 2:

[0043] Table 2:

[0044] serial number components Dosage(Kg) 1 Molybdenum hydroxymethanesulfonate 12 2 Nano molybdenum silicate 8 3 Nanomolybdenum 4 4 150N 45 5 SV261 7 6 T602HB 0.8 7 L-57 0.2 8 T901 0.5

[0045] The preparation process is the same as in Example 1.

Embodiment 3

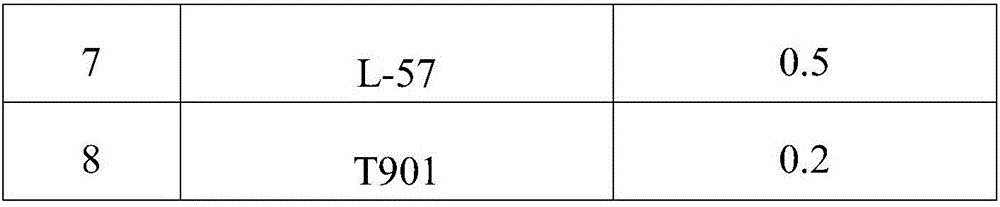

[0047] This embodiment provides a kind of engine anti-wear repair agent, and this engine anti-wear repair agent is made up of the raw material of weight part shown in table 3:

[0048] table 3:

[0049] serial number components Dosage(Kg) 1 Molybdenum hydroxymethanesulfonate 12 2 Nano molybdenum silicate 8 3 Nanomolybdenum 6 4 150N 42 5 SV261 8 6 T602HB 0.5 7 L-57 0.3 8 T901 0.2

[0050] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com