Graphene engine oil, preparation method and equipment thereof

A kind of olefin oil, nano graphene technology, applied in mixing methods, chemical instruments and methods, mixers and other directions, can solve the problems of easy agglomeration and precipitation of graphene, the anti-wear and anti-friction effect does not reach the ideal state, etc. The effect of improving fuel economy and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A graphene engine oil is mainly composed of the following raw materials by mass percentage: 0.03%-0.09% of nano-graphene, 0.015%-0.03% of dispersant, and the balance of base oil.

[0025] In this embodiment, the nano-graphene sheet diameter D50 is 2.5 μm or less.

[0026] In this embodiment, the dispersant is a powder dispersant with lipophilic groups.

Embodiment 2

[0028] A preparation method of graphene oil, comprising the following steps:

[0029] S1. First, inject the base oil into the stirring equipment, then add the dispersant to the base oil, and stir at medium speed for 30 minutes;

[0030] S2. Next, the nano-graphene is added to the base oil at a constant speed, stirred at a high speed with a multi-stage high-speed disperser for 2 hours, allowed to stand for 30 minutes, and then continued to be stirred for 2 hours, and the finished product is obtained after the system is stabilized.

Embodiment 3

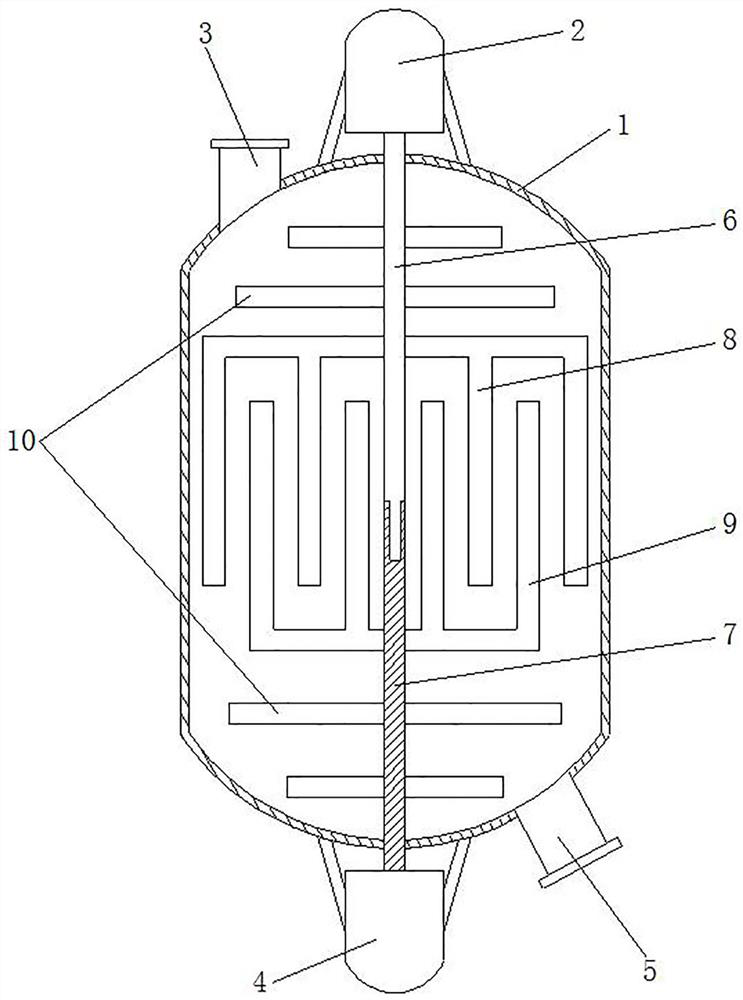

[0032] A graphene oil stirring device, the stirring device comprises a stirring tank 1, an upper motor 2 and a feeding port 3 are arranged on the top of the stirring tank 1, a lower motor 4 and a discharging port 5 are arranged on the bottom of the stirring tank 1, and the upper motor 2 is connected by transmission The upper stirring rod 6 and the lower motor 4 are connected to the lower stirring rod 7 by transmission. The lower end of the upper stirring rod 6 is embedded in the top of the lower stirring rod 7, and the two are in clearance fit. A lower stirring blade 9 is arranged on the outside of 7, and both the upper stirring blade 8 and the lower stirring blade 9 are of bifurcated structure, and the two are dislocated. Specifically, the base oil is first injected into the stirring tank 1, then the dispersant is added to the base oil, the upper motor 2 and the lower motor 4 are turned on, and the two respectively drive the upper stirring rod 6 and the lower stirring rod 7 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com