Nano diamond-containing additive of lubricating oil for engine

A lubricating oil additive and nano-diamond technology, which is applied in the direction of additives, petroleum industry, lubricating compositions, etc., can solve problems such as product process instability, and achieve the effects of ensuring high-efficiency performance, improving friction efficiency, and improving suspension stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the manufacturing method of the present invention will be specifically described below in conjunction with the accompanying drawings.

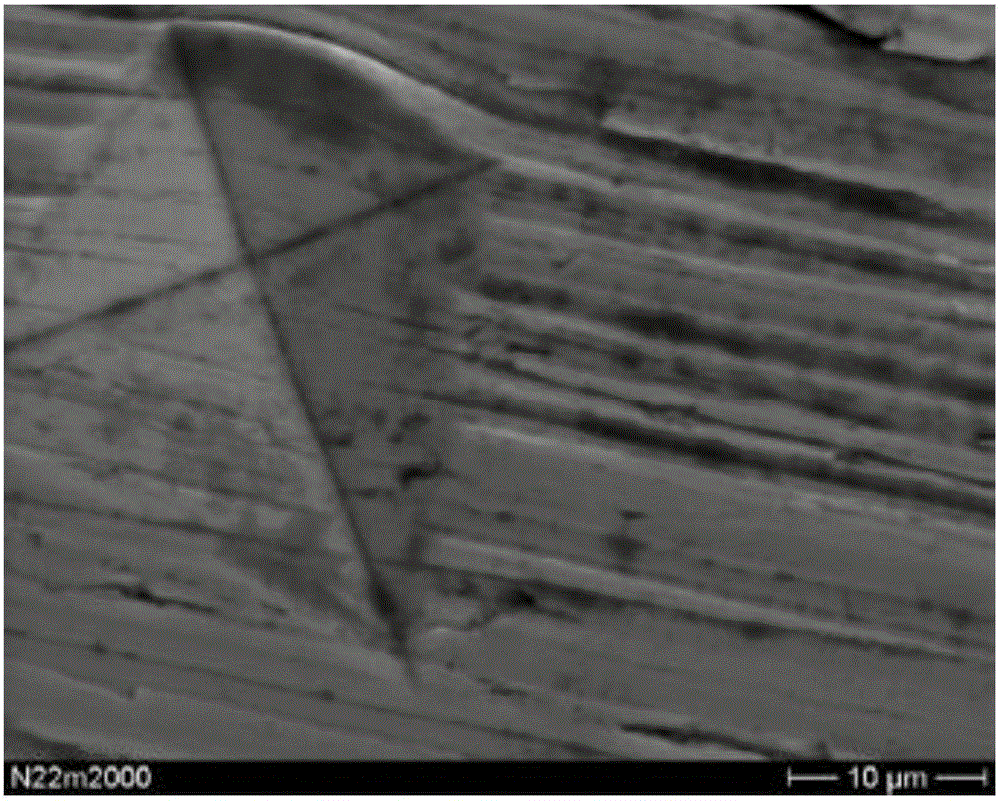

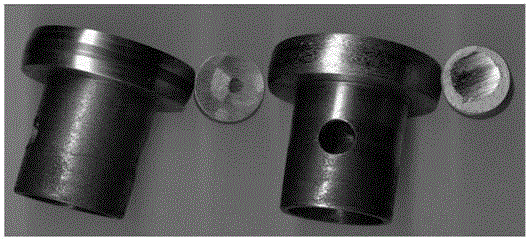

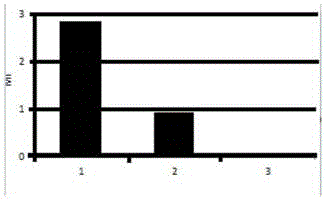

[0032] Case 1. Friction couple workbench test specification friction disc No. 45 steel, linear velocity 0.6 m / s, (Table 1). 1-Commercial lubricating oil И20А; 2-Oil additive + commercial lubricating oil И20А. The average diameter of nano-diamond particles is 150 nanometers. Experimental results Figure 1-6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com