Engine pretreatment, self-repairing material and tail gas governing integrated process method

A self-healing material and process technology, applied in the field of exhaust gas treatment and engine exhaust gas treatment, can solve the problems of inability to completely remove harmful components of exhaust gas, reduce engine power, and inability to remove exhaust gas, etc., to shorten repair time, improve power, and reduce friction. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

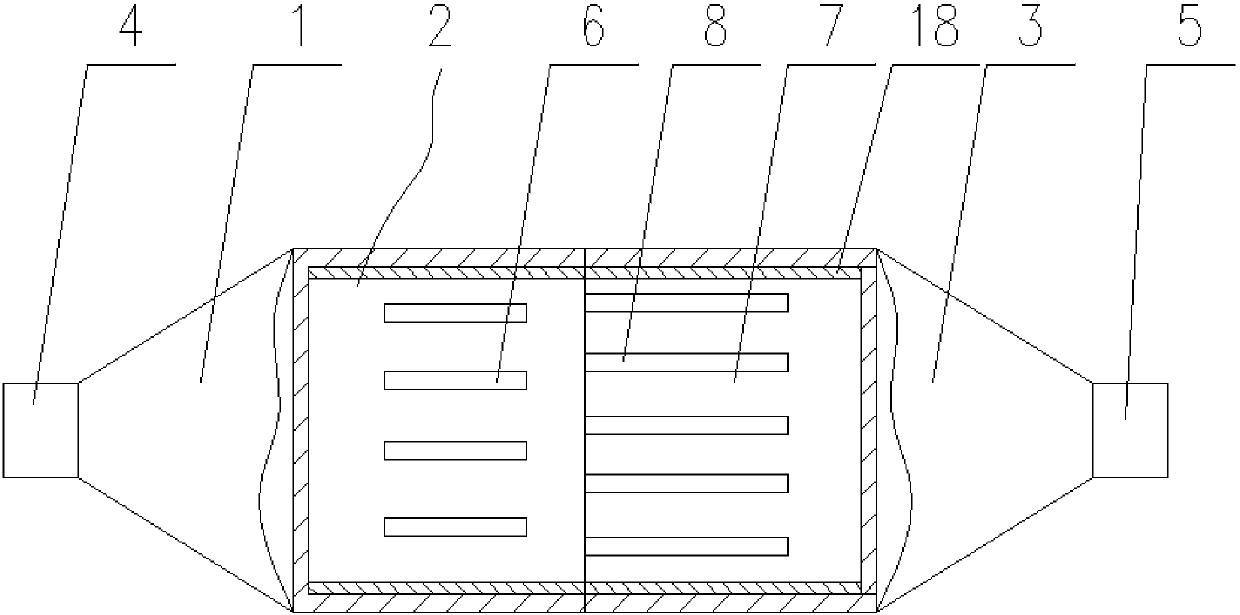

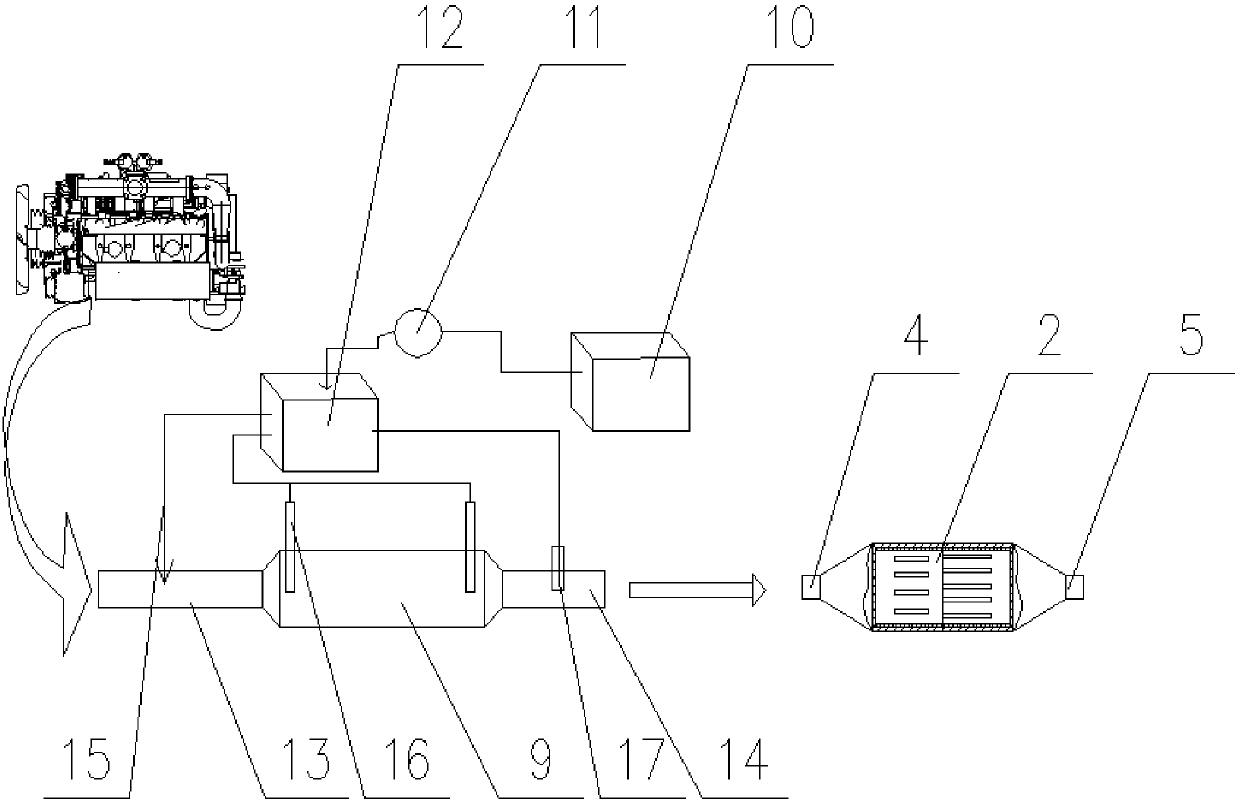

[0036] Specific Embodiments 1. The integrated process method of engine pretreatment, self-repairing materials and exhaust gas treatment includes the following steps:

[0037] Step 1, preparing a mixed powder with the function of cleaning the degenerated layer, corruption points and oil stains on the surface of the engine friction pair;

[0038] Mixed powder with the function of cleaning the metamorphic layer, corruption points and oil stains on the surface of the engine friction pair: 45-55 parts of rare earth, 4-6 parts of iron powder, 4-6 parts of aluminum powder, 4-6 parts of zinc powder , 4-6 parts of silicon powder, 6-7 parts of magnesium powder, 4-6 parts of sodium powder, 4-6 parts of calcium powder and 3-4 parts of lithium stearate are placed in a high-speed homogenizer for 30-40 minutes;

[0039] Step 2, preparing a metal wear self-repairing material composition;

[0040] The self-repairing material composition for metal wear consists of 4-11 parts of nickel chloride...

specific Embodiment approach 2

[0078] Specific Embodiment 2. Rare earth, iron powder, aluminum powder, zinc powder, silicon powder, magnesium powder, sodium powder and calcium in step 1 of the engine pretreatment, self-repairing material and exhaust gas treatment integrated process method of this embodiment The particle size of the powders were all less than 2 microns. The mixed powder of this embodiment can determine the thickness of the degenerated layer and rot point to be cleaned according to the gap between the metal friction pairs.

specific Embodiment approach 3

[0079] Specific embodiment three. The metal wear self-repairing material composition in step two described in the integrated process method of engine pretreatment, self-repairing material and exhaust gas treatment in this embodiment consists of 4 to 11 parts by weight of nickel chloride powder, 4-11 parts of aluminum powder, 19-31 parts of nickel powder, 14-21 parts of ferric oxide powder, 4-11 parts of silicon dioxide powder, 2-5 parts of powder suspending agent, 0.5-1 part of surface modifier Put 12 to 49 parts of mineral lubricating oil in a high-speed homogenizer and homogenize for 30 to 40 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com