Ultraviolet self-healing polyamide material, and preparation method and self-healing method thereof

A technology of combining polyamide and ultraviolet light, which is applied in the field of ultraviolet light self-healing polyamide materials and its preparation, can solve the problems of limiting the development of metal ligand self-healing materials and the lack of research on self-healing systems. Achieve high healing efficiency, low healing temperature and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of ultraviolet light self-healing polyamide material, the steps are as follows:

[0034] (1) Preparation of ligand polyamide: take 2g of azopyridinecarboxylic acid in a 100ml round bottom flask, add 30ml of thionyl chloride therein, and reflux overnight to obtain a deep red transparent solution. After the solvent is evaporated to dryness, use two Methyl chloride was dissolved and filtered, repeated three times, and evaporated to dryness to obtain azobispyridyl chloride.

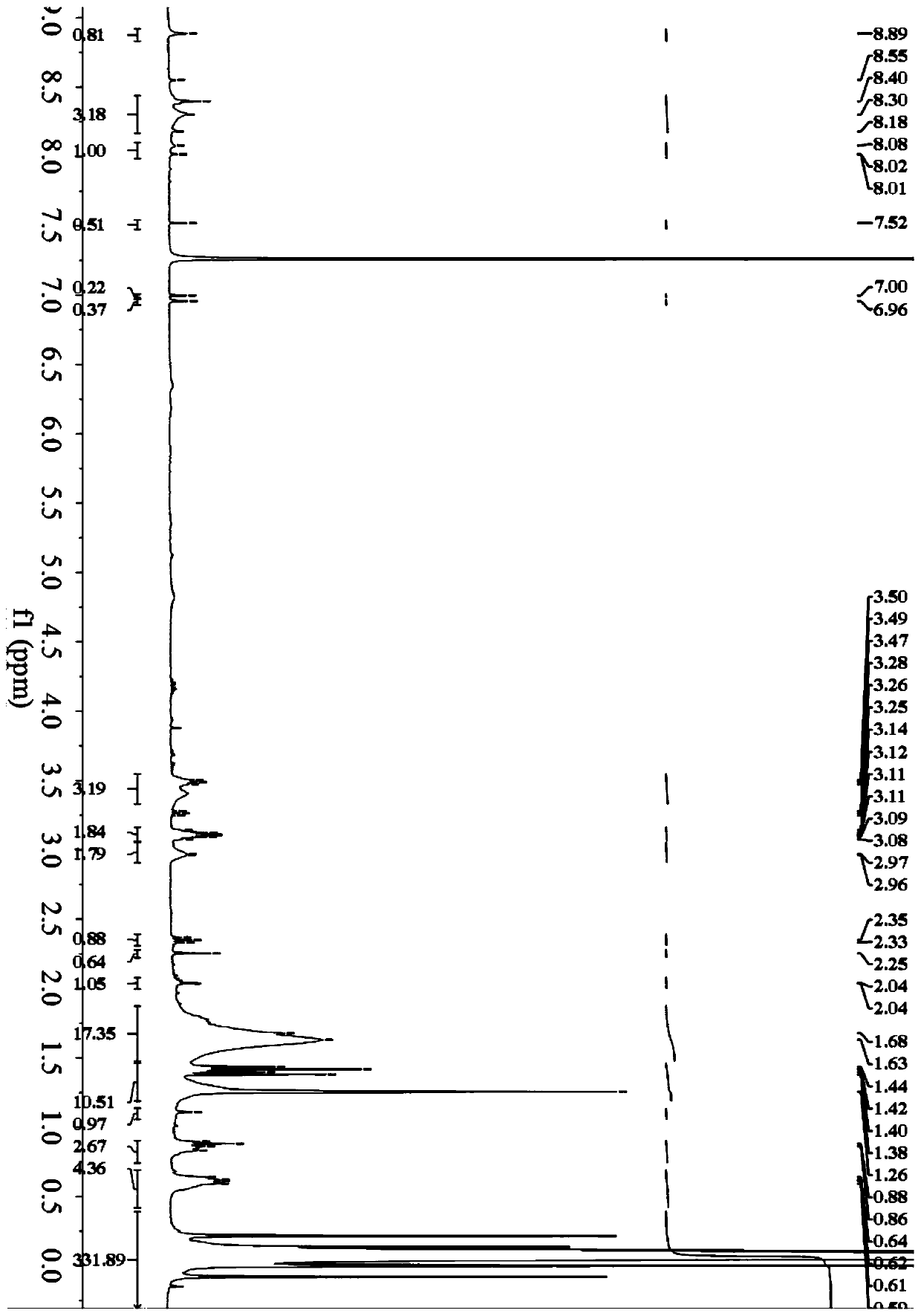

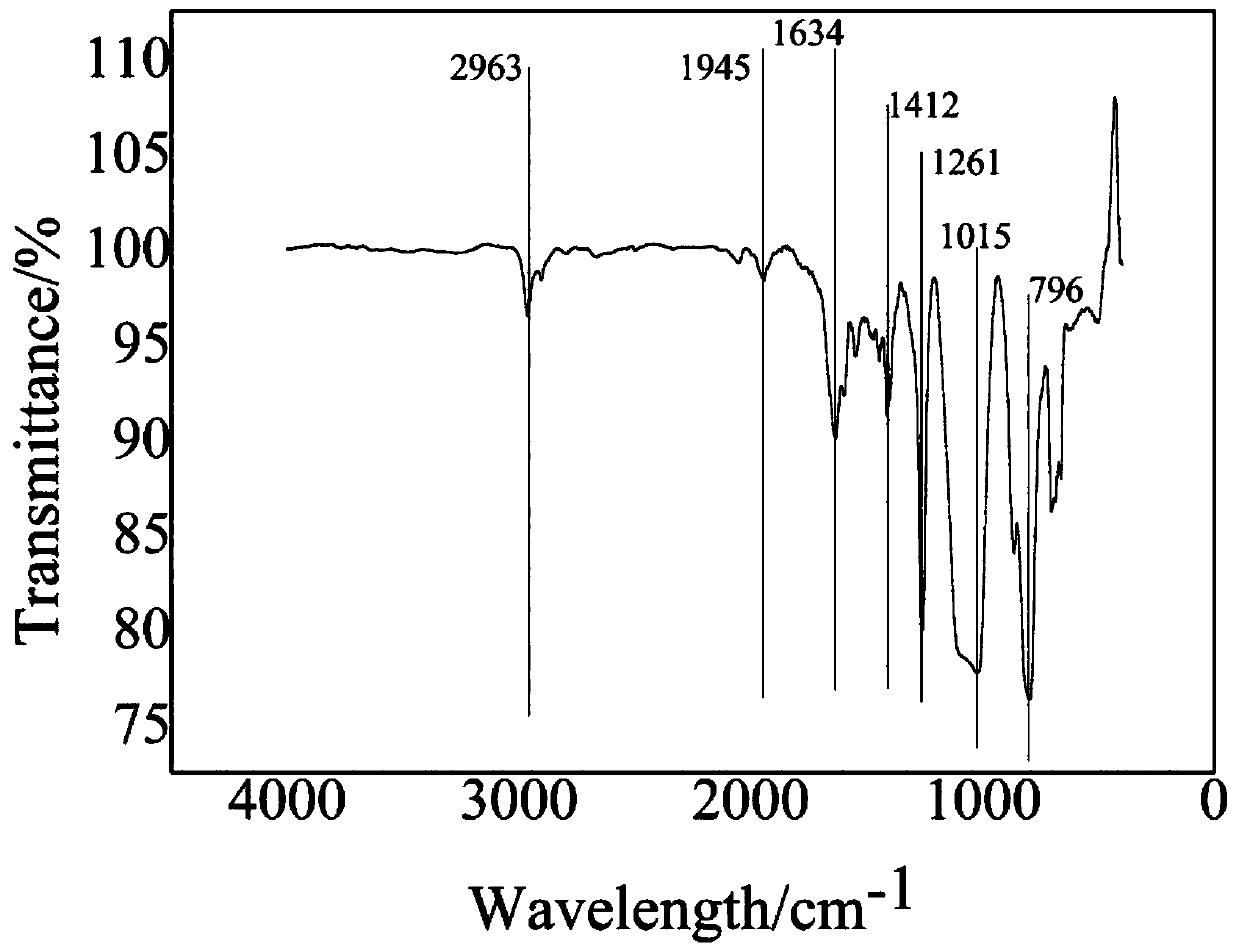

[0035] Add 16ml of polysiloxane diamine (Mn=5000g / mol), 25ml of dichloromethane, and 3.0ml of triethylamine into a 100ml round-bottomed flask, place it in a water bath at 0°C and stir for 2 hours to make it fully mixed, Under the protection of an inert gas at this temperature, 1 g of azopyridine chloride in dichloromethane was added dropwise to the round bottom flask. After the addition was complete, the reaction was continued at this temperature for 2 h, and then placed at room te...

Embodiment 2

[0043] A kind of preparation method of ultraviolet light self-healing polyamide material, step (1) is the same as embodiment 1, in step (2), in the step (2), zinc trifluoromethanesulfonate consumption 36mg, the azobispyridine unit and zinc ion in the polyamide The molar ratio is 2:1 for coordination, and other operations are the same as step (2) of Example 1.

[0044] Figure 6 It is the ultraviolet absorption spectrum of polyamide and polyamide after coordination with zinc ions. When there is no coordination with metal ions, the absorption peak of polyamide at 329nm is the trans absorption peak of the azopyridine structure, and the absorption peak at 470nm is the cis absorption peak of the azopyridine structure. After adding metal ions to coordinate with azopyridine, a new absorption peak appeared at 439nm, which proved that metal ions and azopyridine were successfully coordinated.

[0045] Figure 7 It is a self-healing material under UV light after 2:1 coordination of po...

Embodiment 3

[0047] A kind of preparation method of ultraviolet light self-healing polyamide material, step (1) is the same as embodiment 1, and step (2) is: take 1g above-mentioned polyamide and dissolve in 10ml dichloromethane, dissolve 16mg ferric trichloride in methanol (the molar ratio of the azobispyridine unit in the polyamide to the iron ion is 2:1 for coordination), the methanol solution of ferric chloride is added dropwise to the dichloromethane solution of the polyamide, and stirred at room temperature for 24h , evaporate the solvent to about 3ml, pour it into a polytetrafluoroethylene mold, place it at room temperature for 24 hours, and then dry it at 70°C for 12 hours to prepare a 15*6*1mm sample.

[0048] Figure 8 It is a UV self-healing material after 2:1 coordination of polyamide and iron ions, and the tensile curve before and after healing. The results showed that the self-healing efficiency of the material is close to 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com