Self-repairing waterborne epoxy/asphalt compound waterproof coating and preparation method thereof

A technology of water-based epoxy and waterproof coatings, applied in the field of coatings, can solve the problems of various raw materials and additives, inapplicability to the field of coatings, and cumbersome preparation processes, etc., and achieve good waterproof and anti-seepage effects, excellent self-healing performance, and repair effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

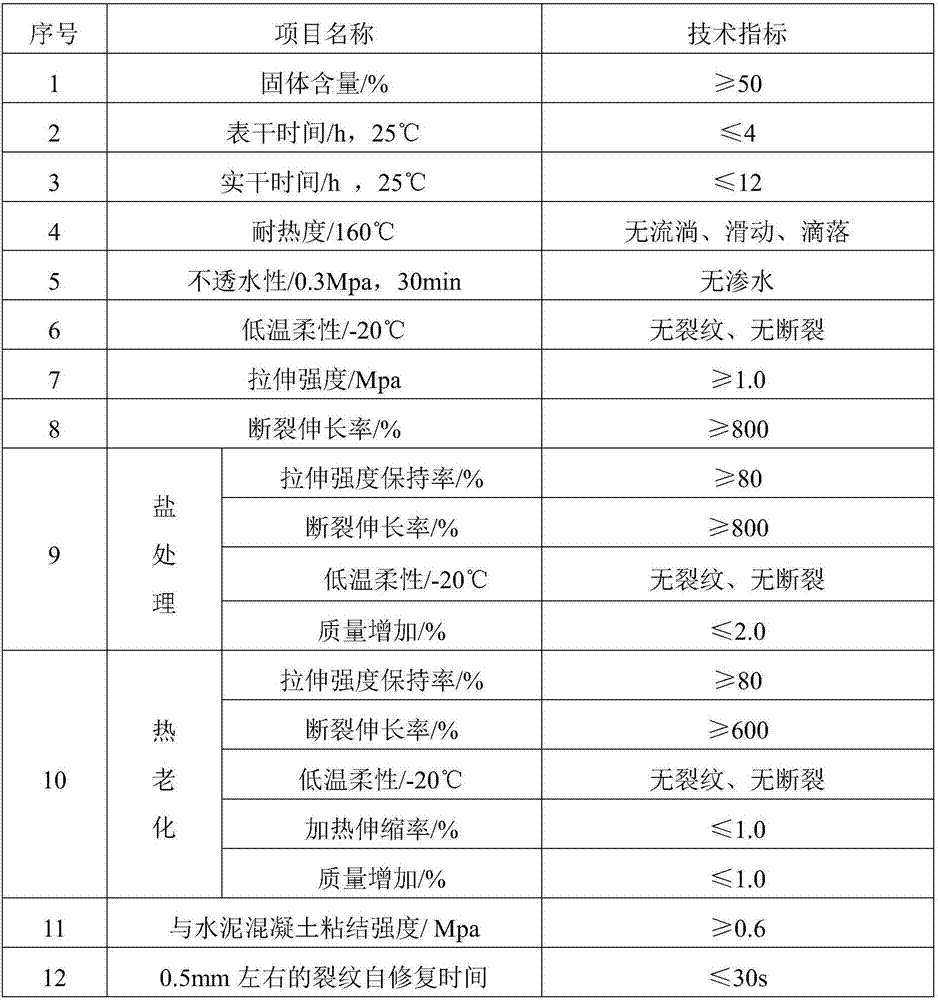

Image

Examples

Embodiment 1

[0039] A kind of self-repairing water-based epoxy / bituminous composite waterproof coating described in this embodiment comprises the following raw materials in parts by mass:

[0040] 31 parts of anionic nitrile latex, 35 parts of anionic emulsified petroleum asphalt, 7 parts of water-based epoxy emulsion, 7 parts of water-based epoxy curing agent, 1.5 parts of talcum powder, 0.5 parts of defoamer, 18 parts of microcapsule dispersion;

[0041] Wherein said microcapsule dispersion liquid is made up of the raw material of following mass fraction:

[0042] 36 parts of polyoxypropylene polyol N220, 64 parts of MDI-50, superabsorbent, molten paraffin;

[0043] The preparation method of described microcapsule dispersion liquid, completes according to the following steps:

[0044] The first step, the preparation of polyurethane prepolymer: Weigh 36 parts of polyoxypropylene polyol N220 in the above mass fraction and place them in the reactor, dehydrate at 120°C and -0.09Mpa for 2 ho...

Embodiment 2

[0059] A kind of self-repairing water-based epoxy / bituminous composite waterproof coating described in this embodiment comprises the following raw materials in parts by mass:

[0060] 19 parts of anionic nitrile latex, 38 parts of anionic emulsified petroleum asphalt, 9 parts of water-based epoxy emulsion, 9 parts of water-based epoxy curing agent, 3.5 parts of talcum powder, 0.5 parts of defoamer, 21 parts of microcapsule dispersion;

[0061] Wherein said microcapsule dispersion liquid is made up of the raw material of following mass fraction:

[0062] 36 parts of polyoxypropylene polyol N220, 64 parts of MDI-50, superabsorbent, molten paraffin;

[0063] The preparation method of described microcapsule dispersion liquid, completes according to the following steps:

[0064] The first step, the preparation of polyurethane prepolymer: Weigh 36 parts of polyoxypropylene polyol N220 in the above mass fraction and place them in the reactor, dehydrate at 120°C and -0.09Mpa for 2 ho...

Embodiment 3

[0079] A kind of self-repairing water-based epoxy / bituminous composite waterproof coating described in this embodiment comprises the following raw materials in parts by mass:

[0080] 30 parts of anionic nitrile latex, 35.5 parts of anionic emulsified petroleum asphalt, 7 parts of water-based epoxy emulsion, 7 parts of water-based epoxy curing agent, 1.5 parts of talcum powder, 0.5 parts of defoamer, 18.5 parts of microcapsule dispersion;

[0081] Wherein said microcapsule dispersion liquid is made up of the raw material of following mass fraction:

[0082] 36 parts of polyoxypropylene polyol N220, 64 parts of MDI-50, superabsorbent, molten paraffin;

[0083] The preparation method of described microcapsule dispersion liquid, completes according to the following steps:

[0084] The first step, the preparation of polyurethane prepolymer: Weigh 36 parts of polyoxypropylene polyol N220 in the above mass fraction and place them in the reactor, dehydrate at 120°C and -0.09Mpa for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com