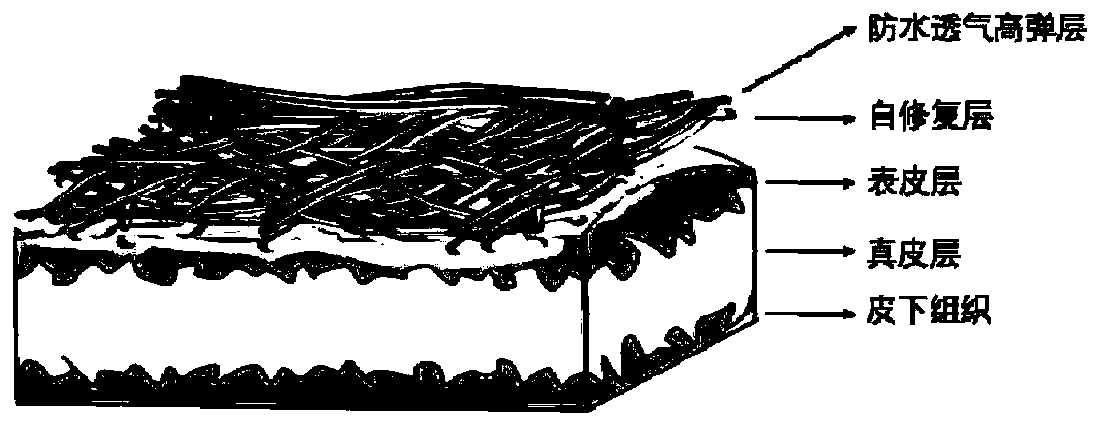

Waterproof, breathable, high-elastic and self-repairing double-layer nanofiber membrane for skin dressing and preparation method of nanofiber membrane

A nanofiber membrane, waterproof and breathable technology, used in medical science, non-woven fabrics, absorbent pads, etc., can solve problems such as difficulty in meeting different healing needs, and achieve the effect of improving healing performance, good comfort, and superior resilience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing a waterproof, breathable, highly elastic, self-repairing double-layer nanofiber membrane for skin dressing, the steps are as follows:

[0051] (1) Prepare water-based polyurethane solution with absolute ethanol, add alcohol-soluble hydrophobic agent (polymethylhydrogensiloxane emulsion), environment-friendly crosslinking agent (epoxysilane crosslinking agent) and functional drug (diclofenac sodium), Stir evenly to prepare precursor spinning solution Ⅰ; the mass fraction of water-based polyurethane in precursor spinning solution Ⅰ is 5%, and the addition amount of alcohol-soluble hydrophobic agent and environment-friendly crosslinking agent is 10wt% and 2wt of water-based polyurethane respectively %;

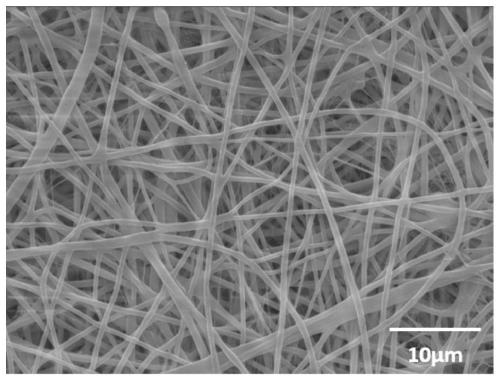

[0052] (2) Put the precursor spinning solution I prepared in step (1) into a syringe, spin with an electrospinning device, and receive it through the receiving substrate (glossy paper) to prepare a hydrophobic fiber membrane with a thickness of 0.1 μ...

Embodiment 2

[0060] A method for preparing a waterproof, breathable, highly elastic, self-repairing double-layer nanofiber membrane for skin dressing, the steps are as follows:

[0061] (1) Prepare water-based acrylic resin solution with isopropanol, add alcohol-soluble hydrophobic agent (polymethylhydrogensiloxane emulsion), environment-friendly cross-linking agent (organosilane cross-linking agent) and functional drug (warfarin) , and stir evenly to prepare the precursor spinning solution Ⅰ; the mass fraction of the water-based acrylic resin in the precursor spinning solution Ⅰ is 12%, and the addition amount of the alcohol-soluble hydrophobic agent and the environment-friendly cross-linking agent is 5wt of the water-based acrylic resin respectively % and 1wt%;

[0062] (2) Put the precursor spinning solution I prepared in step (1) in a syringe, spin with an electrospinning device, and receive it through the receiving substrate (aluminum foil) to prepare a hydrophobic fiber membrane with...

Embodiment 3

[0070] A method for preparing a waterproof, breathable, highly elastic, self-repairing double-layer nanofiber membrane for skin dressing, the steps are as follows:

[0071] (1) Prepare polyvinylpyrrolidone solution with absolute ethanol, add alcohol-soluble hydrophobic agent (polydimethylsiloxane emulsion), environment-friendly crosslinking agent (blocked isocyanate crosslinking agent) and functional drug (aspirin), Stir evenly to prepare precursor spinning solution I; the mass fraction of polyvinylpyrrolidone in precursor spinning solution I is 10%, and the addition amount of alcohol-soluble hydrophobic agent and environmentally friendly crosslinking agent is respectively 10wt% of polyvinylpyrrolidone and 2 wt%;

[0072] (2) Put the precursor spinning solution I prepared in step (1) in a syringe, spin it with an electrospinning device, and receive it through the receiving substrate (glossy paper) to prepare a hydrophobic fiber membrane with a thickness of 0.3 μm ; Among them...

PUM

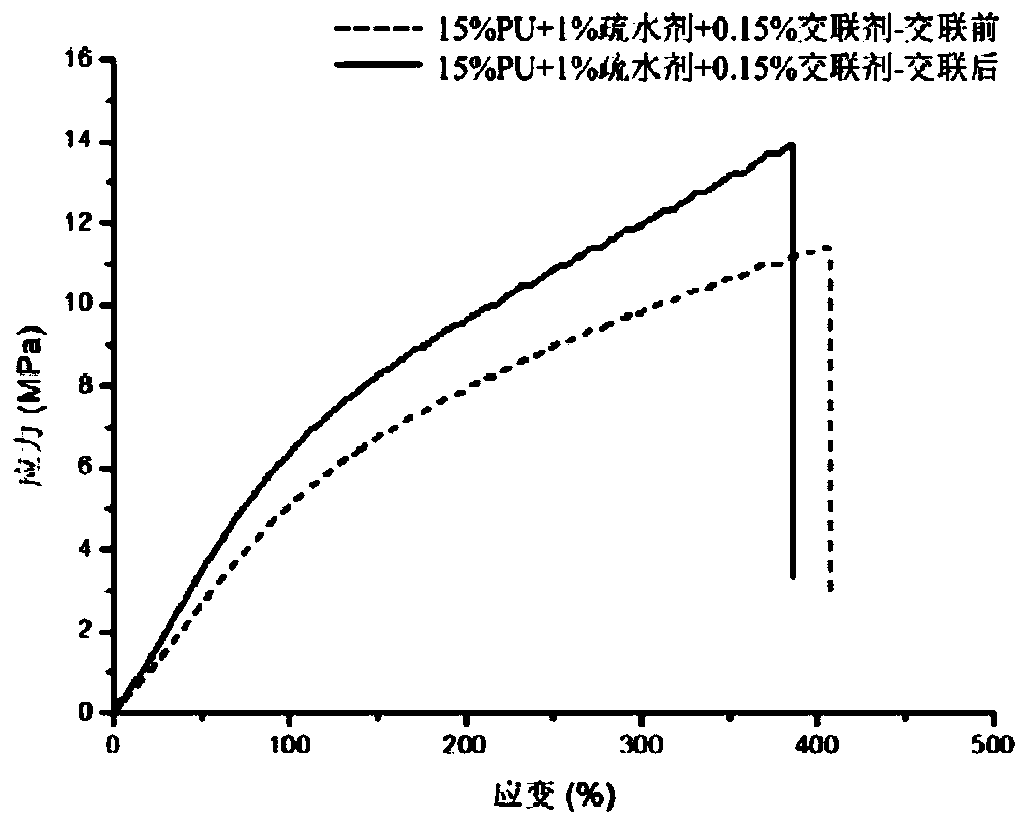

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com