Method for enhancing strength of cutting edge of tool through additive manufacturing technology

A technology for additive manufacturing and cutting tools, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement. It can solve the problems of unusable tools, waste of raw materials, tool wear, etc. The effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

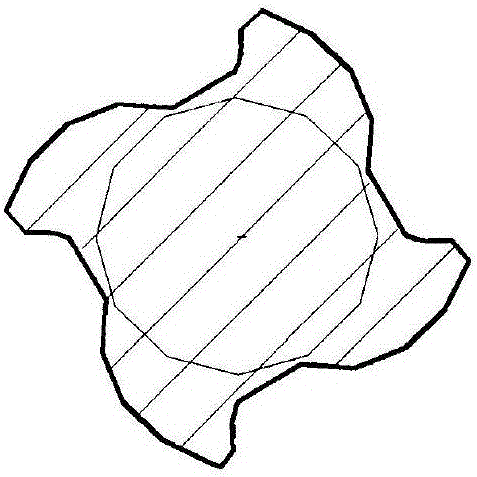

[0028] Embodiment 1 common milling cutter, wear milling cutter

[0029] First, the working edge (side edge and end edge) of the tool is evenly removed by O.8mm-1.5mm to form a basic platform, and the surface of the platform is perpendicular to the cutting direction of the tool. Figure 2b and Figure 3b shown; clean the oil, dust, water and other dirt on the surface of the tool, and wait for use; establish a digital model according to the size and shape of the tool, the size of the removed part, and the size of the platform left on the tool after the tool edge is removed, that is, Based on the remaining surface on the cutter body, use CATIA or CAD software to draw the part diagram for forming,

[0030] The size of the bottom surface of the new figure is to increase 0.5mm in all directions on the basis of the bottom surface of the original foundation, and the bottom surface is a plane or a helical surface along the axis direction of the knife. The outer surface size of the fo...

Embodiment 2

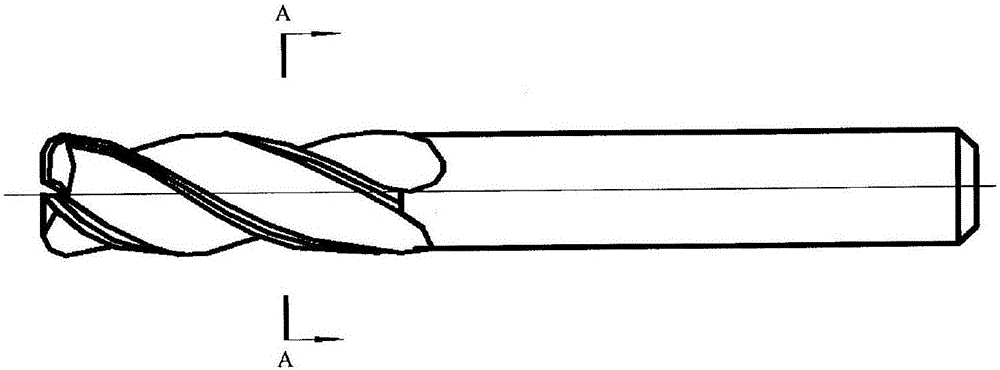

[0031] Embodiment 2 Drill bit

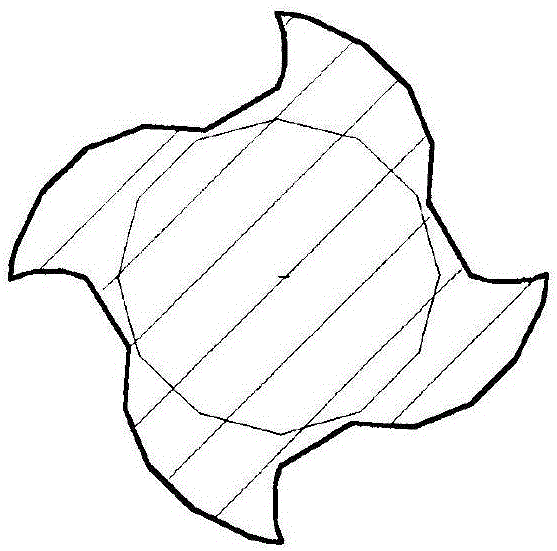

[0032] Since the working part of the drill is the front end and the front side edge of the drill, not all the side edges, when the drill is reinforced, it is not necessary to reinforce all the side edges of the drill, and only the front part of the side edge is reinforced. Can. like Figure 4 Shown is the state of the drill bit after reinforcement; Figure 5 It is the A-A view of the drill bit after reinforcement, and the shape and surface of the cutting edge after reinforcement;

[0033] The main working edge of the tool: the end edge and part of the side edge (about 15mm-20mm from the front end) are uniformly removed by 1.0mm-1.5mm, and a basic platform is established. The surface of the platform is perpendicular to the cutting direction of the tool, and the platform is in line with the unprocessed The cutting edge becomes a beveled transition; clean the oil, dust, water and other dirt on the surface of the tool for use; establish a digital...

Embodiment 3

[0034] The cutting tool of embodiment 3 chipping

[0035] For a tool with continuous chipping in multiple places, the cutting edge of the tool is polished as a whole according to the largest chipping size, and the foundation for repair is made, and then repaired by laser powder feeding additive manufacturing process; a tool with less than three and discontinuous chipping If the cutting tool with a sharp edge should be ground and cleaned, according to the size of the grinding place, use CATIA or CAD software to draw an area map for forming (the method is the same as in Example 1), which is the digital model for forming. Compile the repair program and use the laser powder feeding additive manufacturing process to repair; the repaired knives can be used again after mechanical sharpening, saving a lot of cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com