Workpiece feeding and distributing device

A material distributing device and workpiece technology, which is applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., can solve the problem of pinching fingers by workpieces with large wall thickness, and achieve the effect of preventing safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

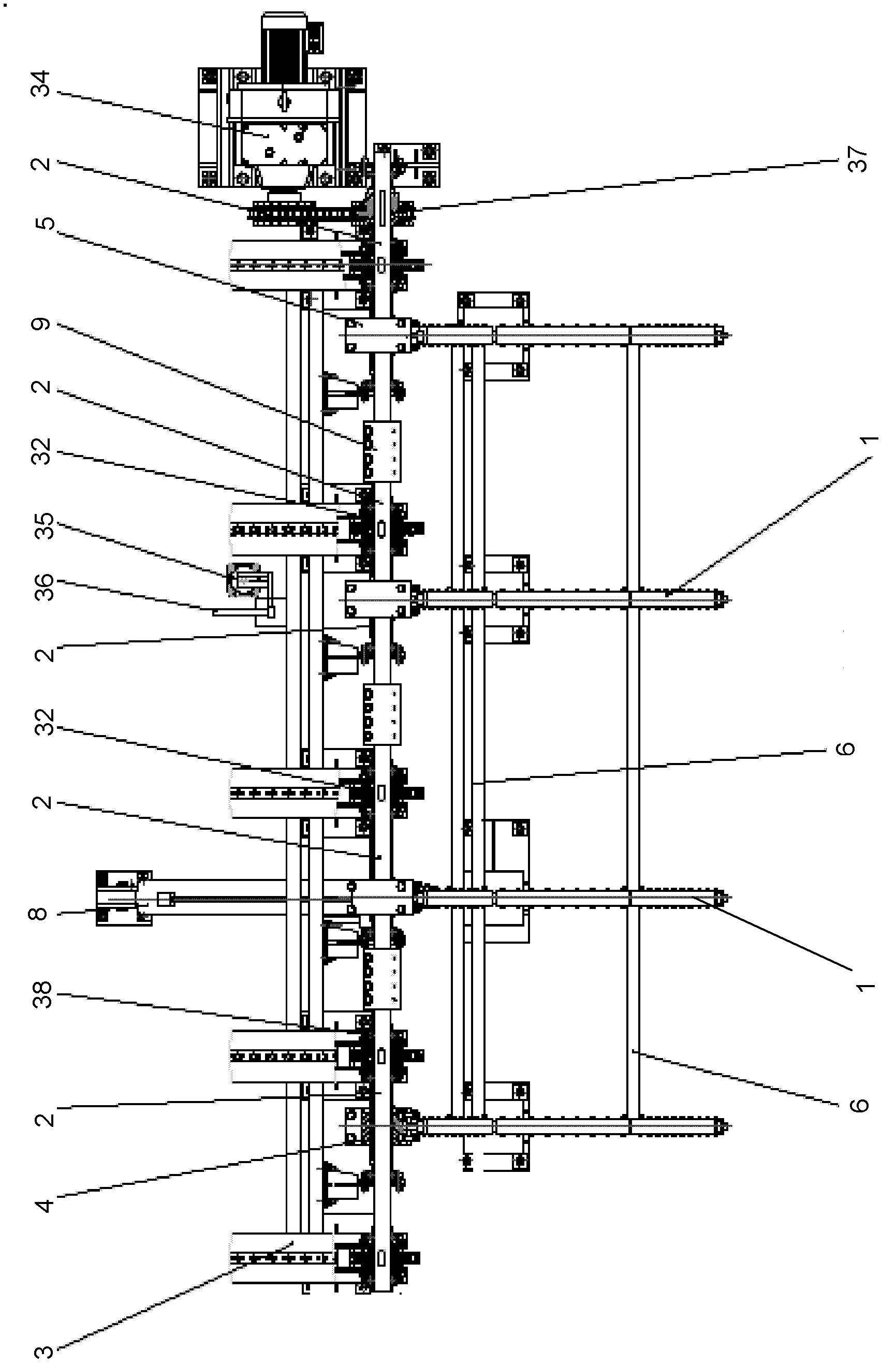

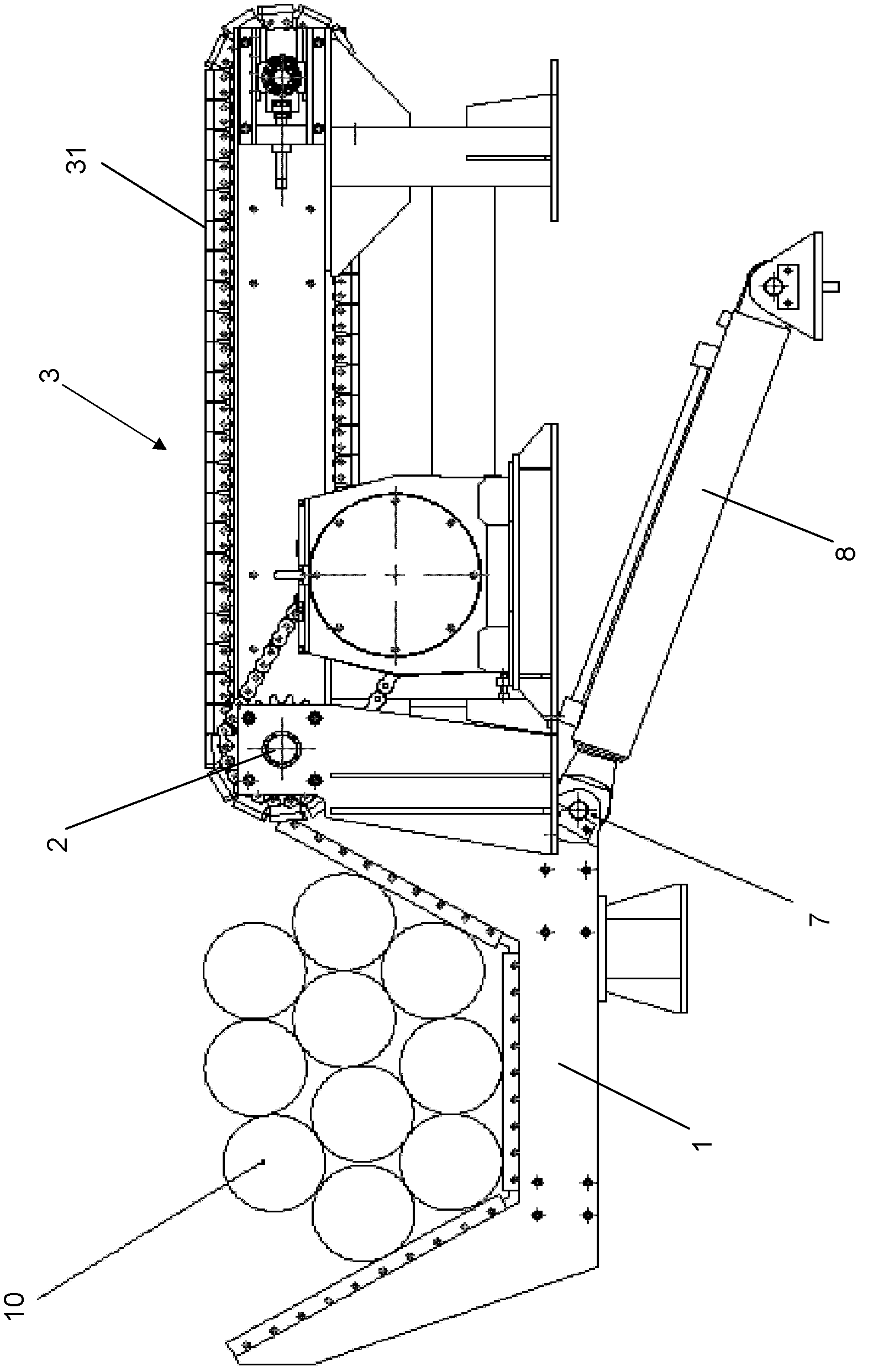

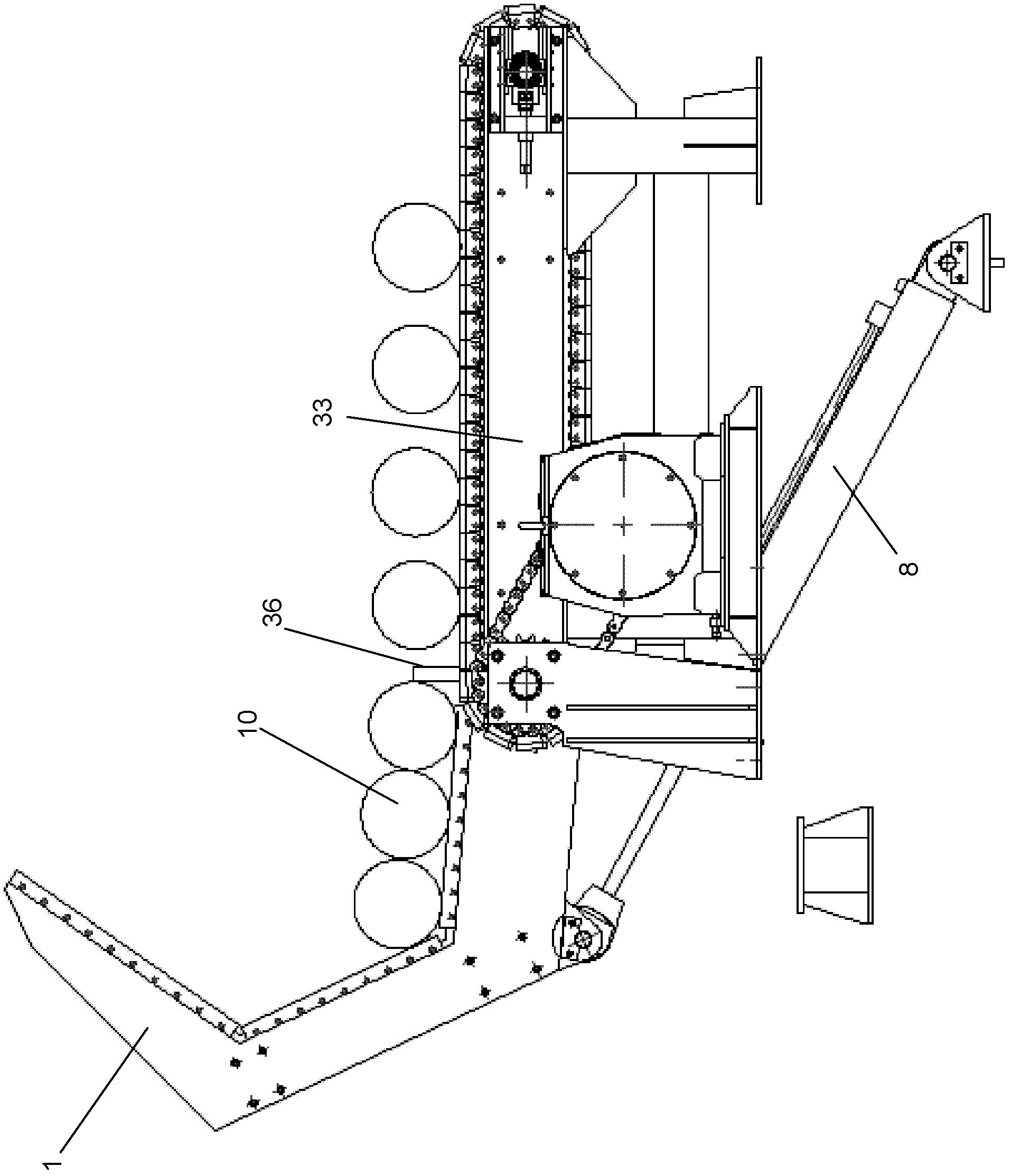

[0014] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0015] Please combine Figure 1 ~ Figure 3 As shown, the workpiece feeding and distributing device of the present invention mainly includes a U-shaped feeding trough 1 for built-in workpiece 10, a rotating shaft 2 and a chain-type distributing table 3, and several U-shaped feeding troughs 1 are arranged side by side and one end Connected to the rotating shaft 2, the specific connection method is to connect the rotating shaft 2 through the copper sleeve 4 and the gland 5, and connect the U-shaped feeding troughs 1 by setting a connecting beam 6. figure 1 The number of U-shaped feeding chute 1 shown in is two, and two connecting beams 6 are used to form a stable frame by bolting between the two. The bottom of U-shaped feeding chute 1 is also connected with oil cylinder 8 by trunnion 7, driven by oil cylinder 8, U-shaped feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com