Patents

Literature

87results about How to "No need for manual feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl chloride elastomer formula for flame-retarded mining flexible cable and its processing method

InactiveCN1676546AOvercome stickiness and blackeningOvercomes defects that can cause electrical crackingInsulated cablesInsulated conductorsElastomerRubber material

This invention relates to PVC elastomer formula for flame retarding mine use sofe cable and its processing technique. The formula includes the following contents(weight share): high polymerized PVC 100, low polymerized PVC 10-50, the plasticizer 60-120, tri-salt lead sulfate 2-5, disalt lead phosphate 2-5, disalt lead stearate 0.5-1.5 barium stearate 0.5-1.0, inflaming retarding agent 10-20, assistant retarding agent 2-7, antioxidant 0.1-1.0, bulking agent 10-30. The processing technique is as follows: match every group according to weight ratio and then past them; knead the pasting and powder under 90-110deg.C for 4-10 minutes, plasticize the kneaded mixture and particlize the processed rubber material and storage them. The elasticity of PVC of this invention can arrive the elasticity of rubber, and its electrical performance, hot endurance, inflaming retarding performance and tensile and breaking elongation are up to the standards.

Owner:JIANGWAN SPECIAL CABLE SHANGHAI

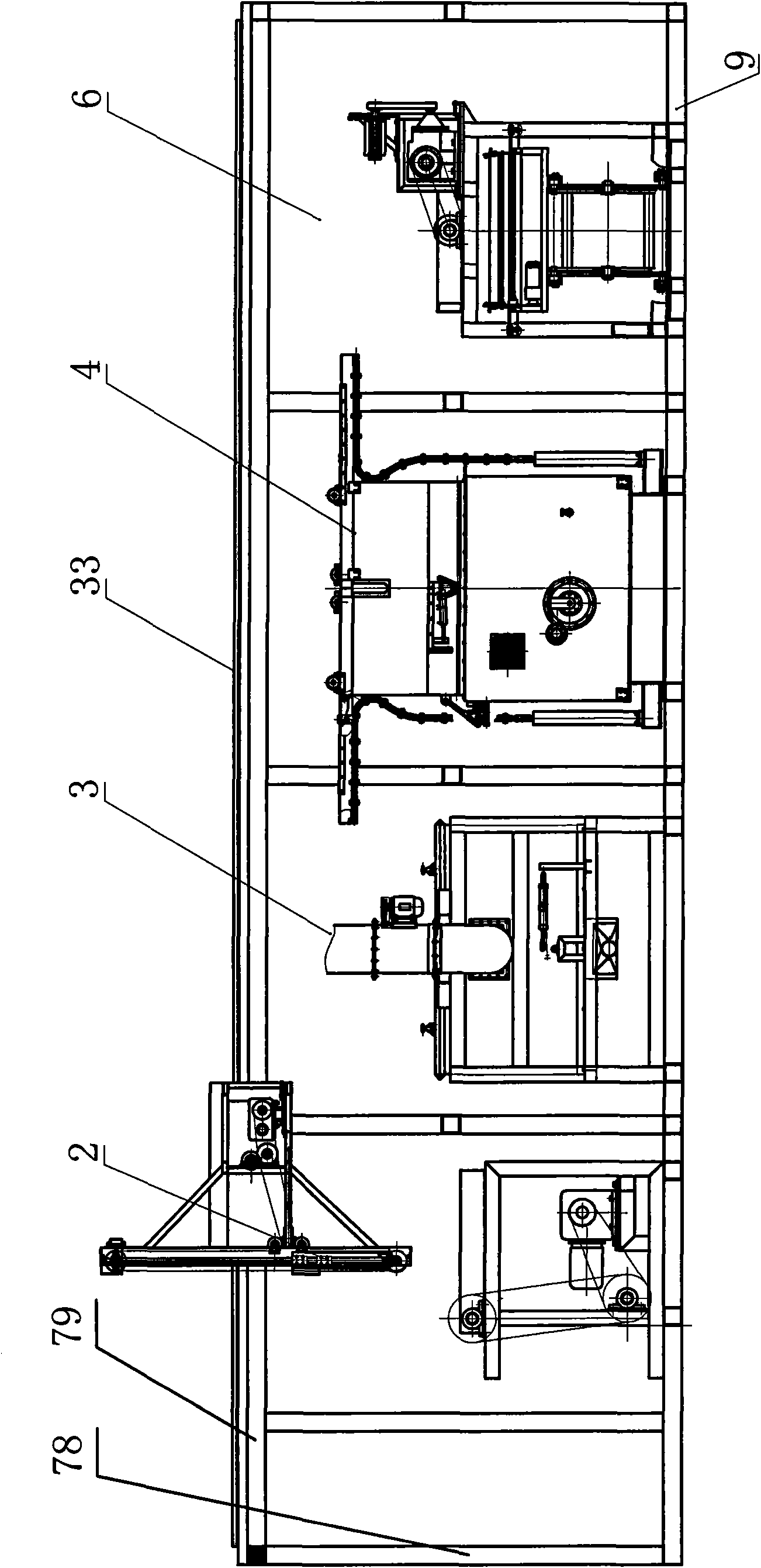

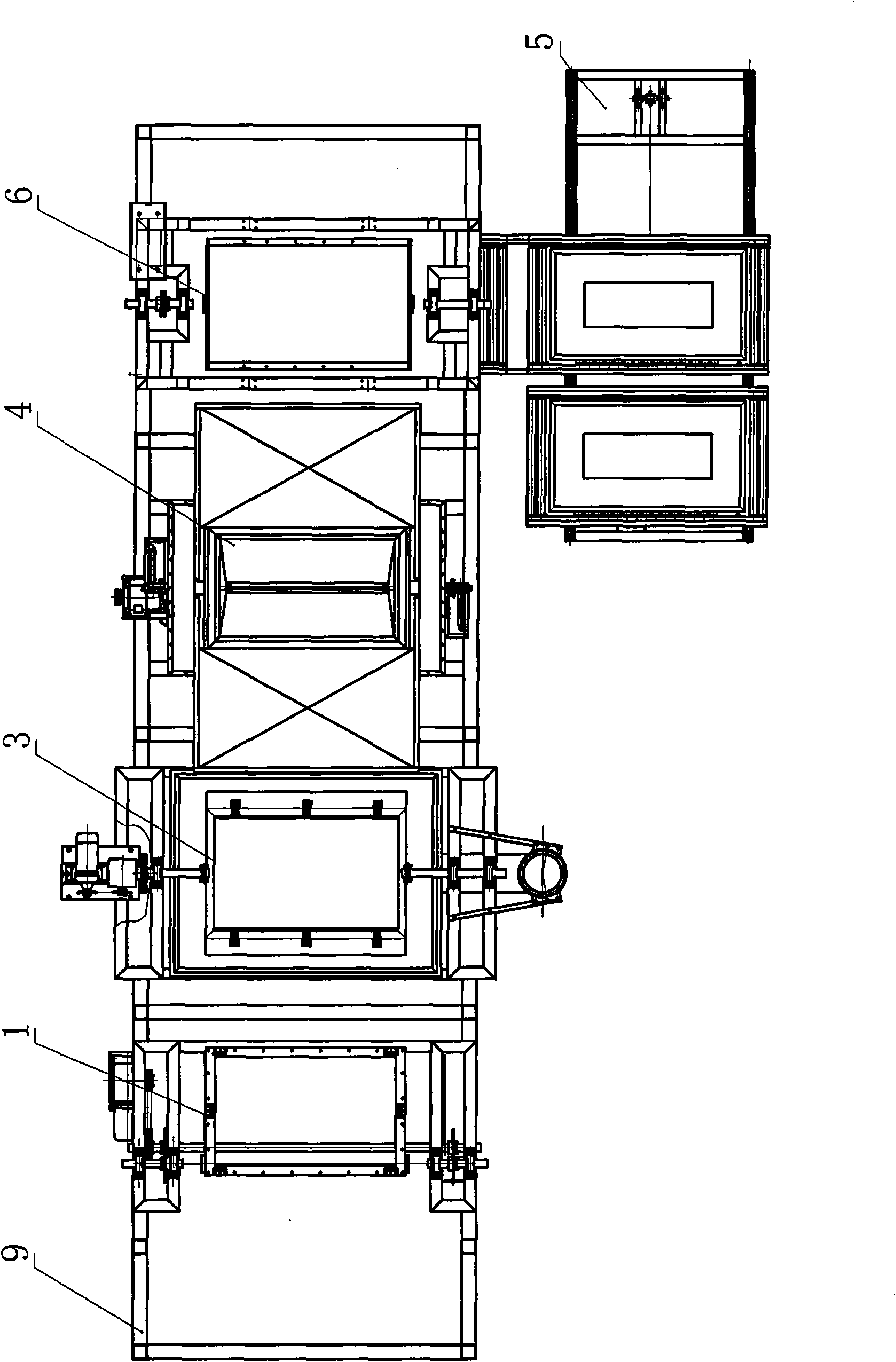

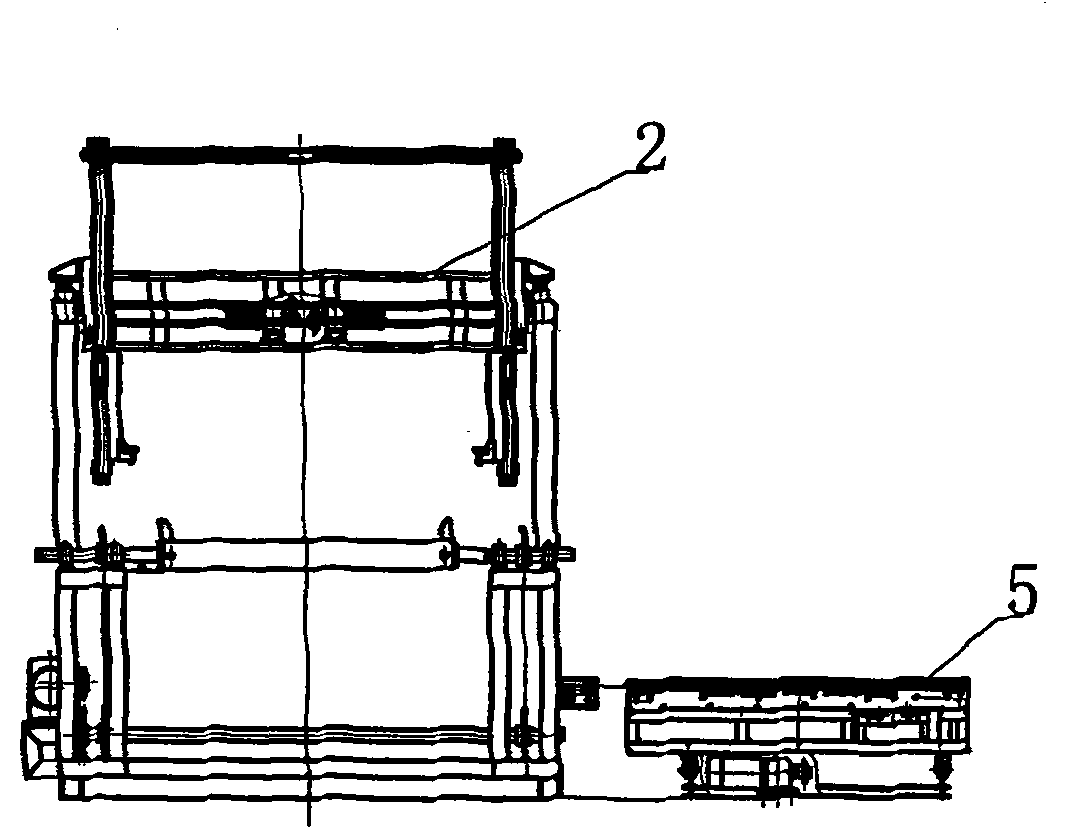

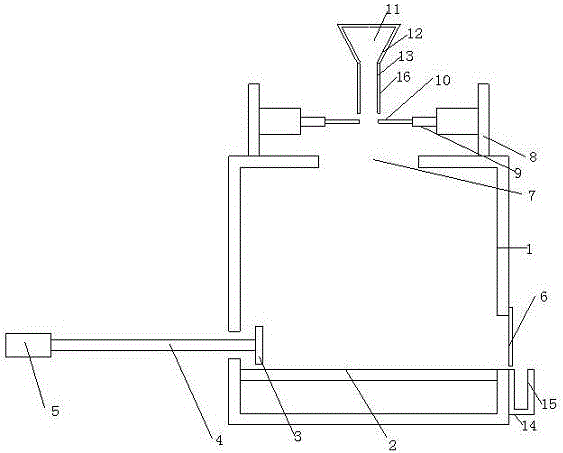

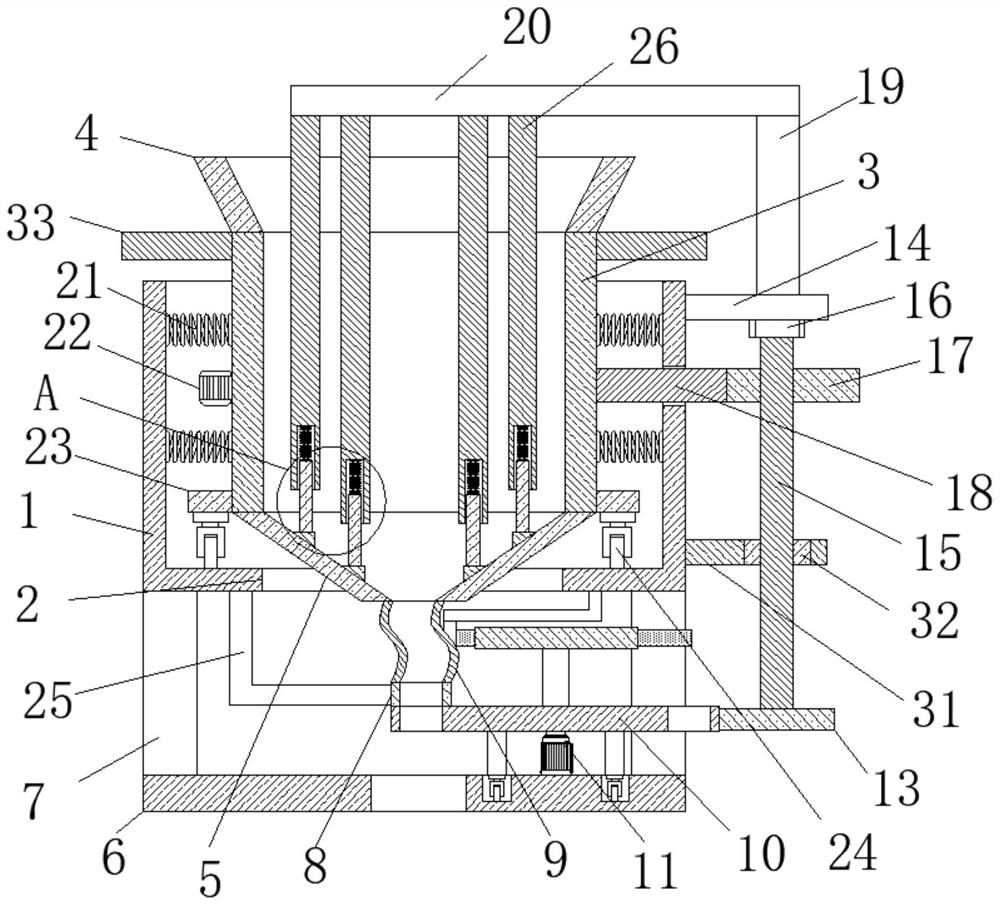

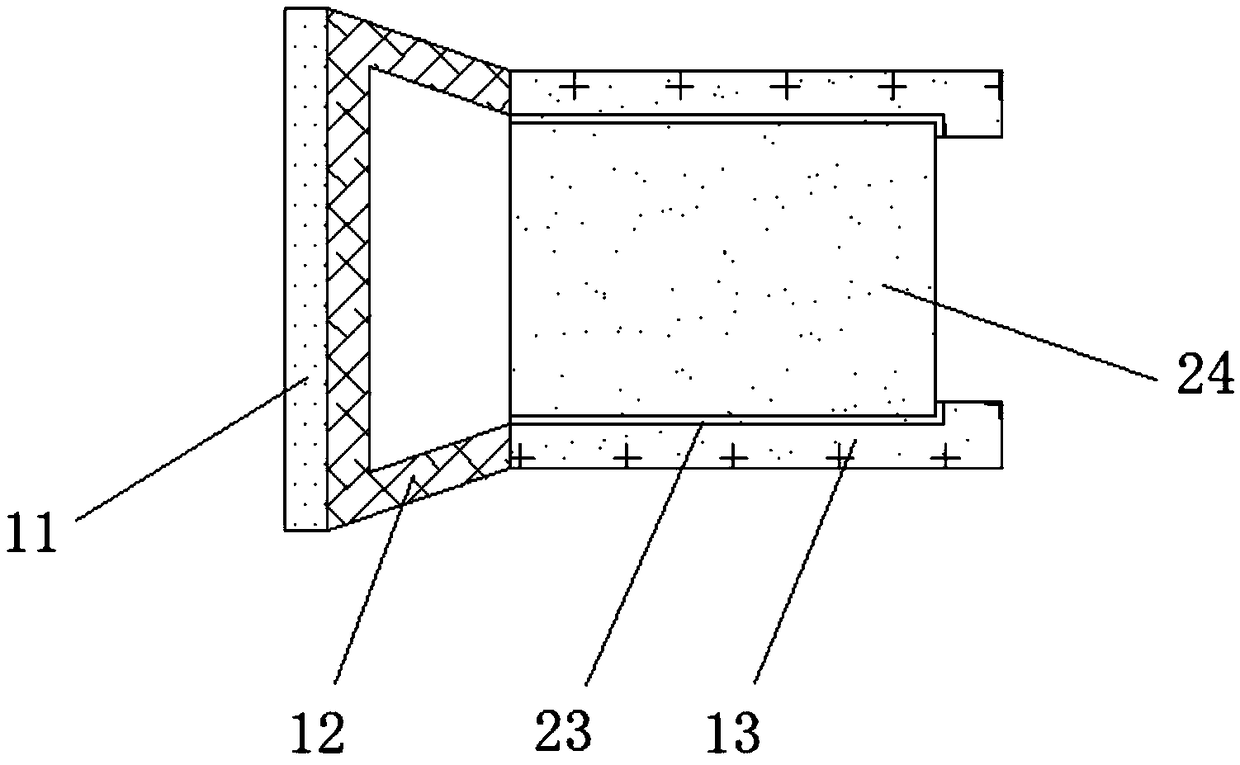

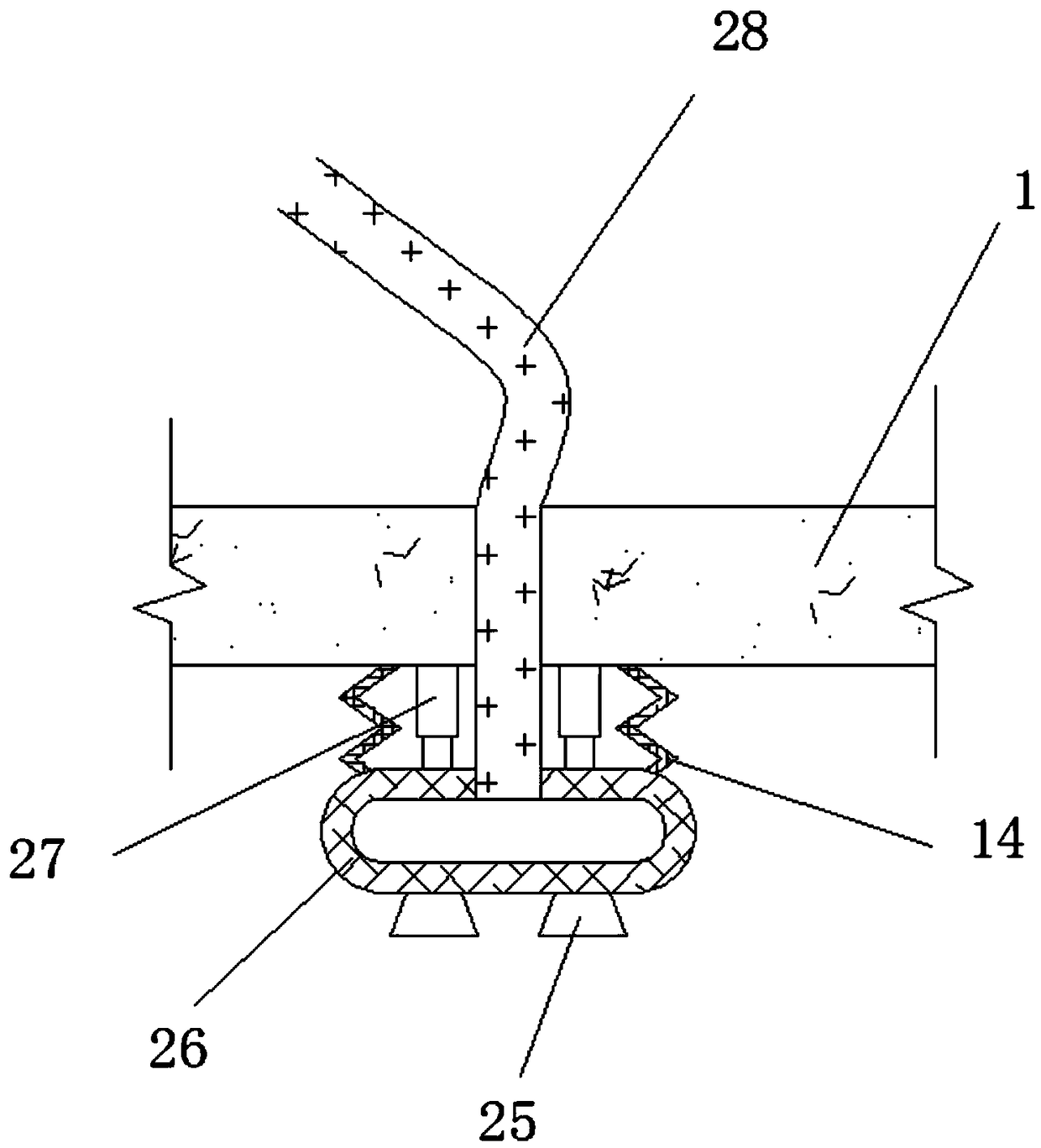

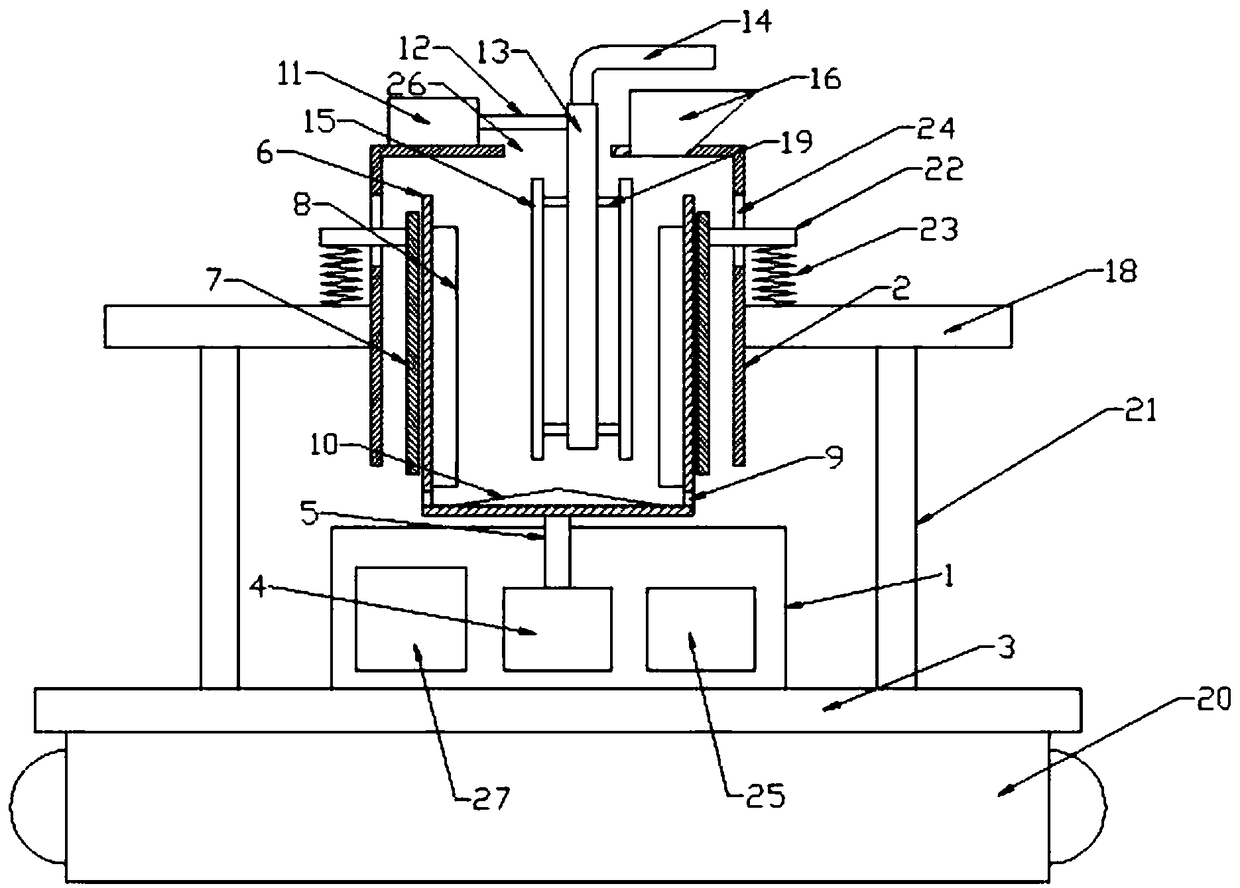

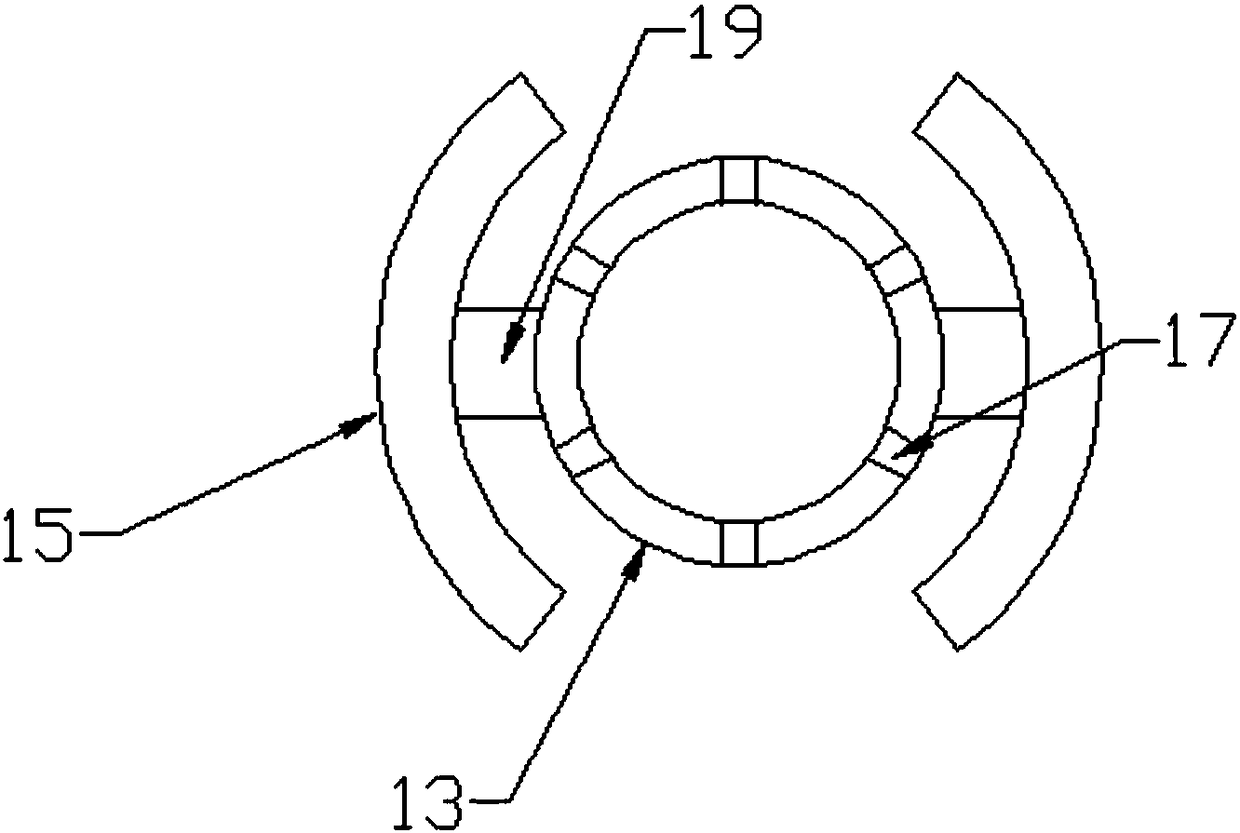

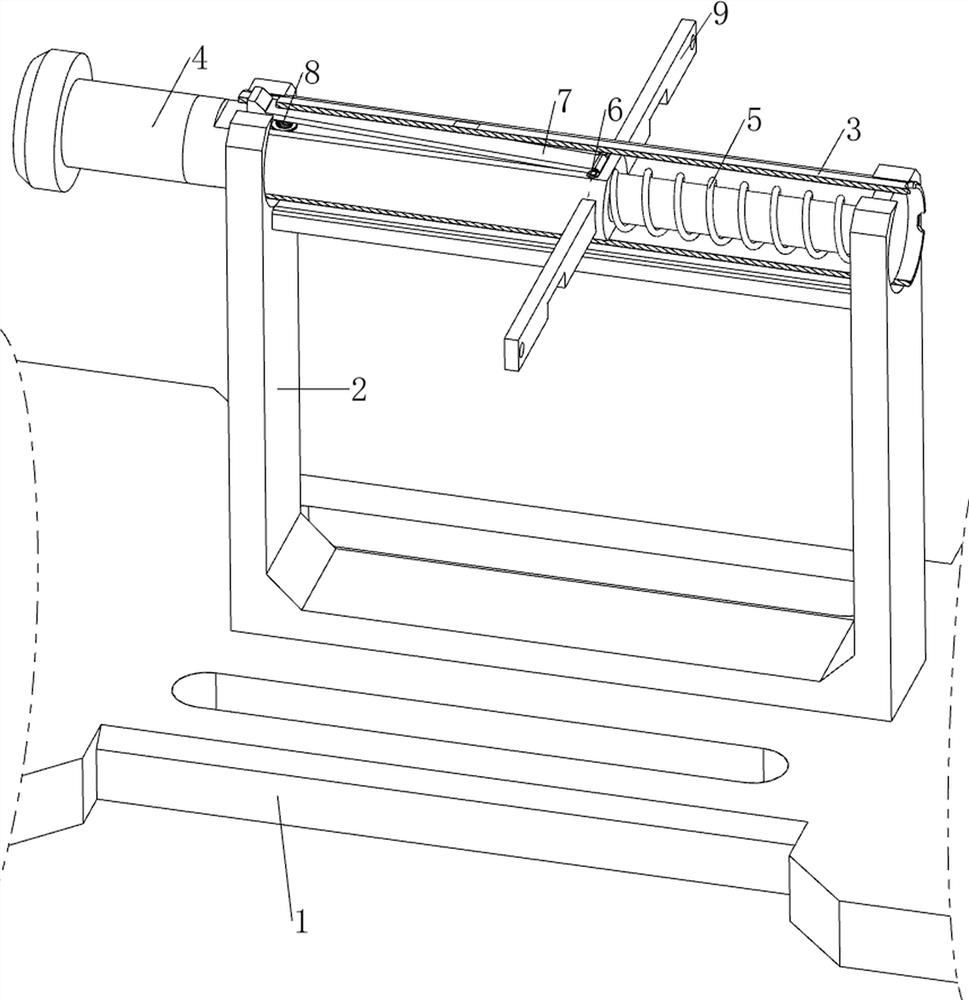

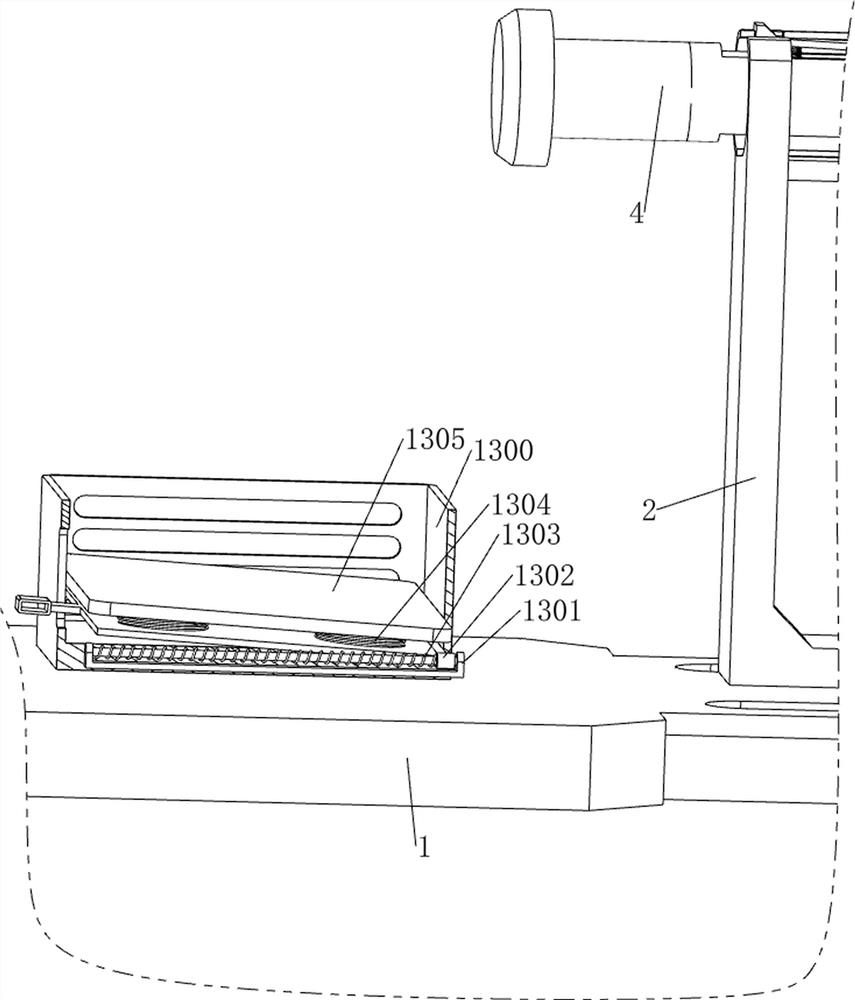

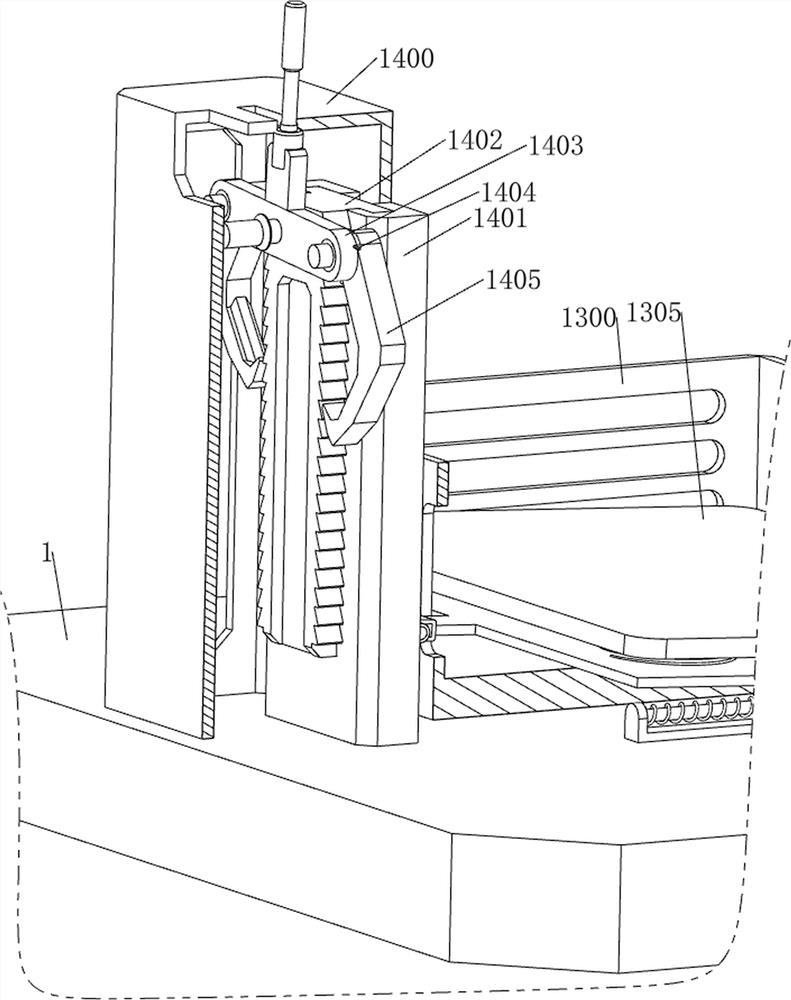

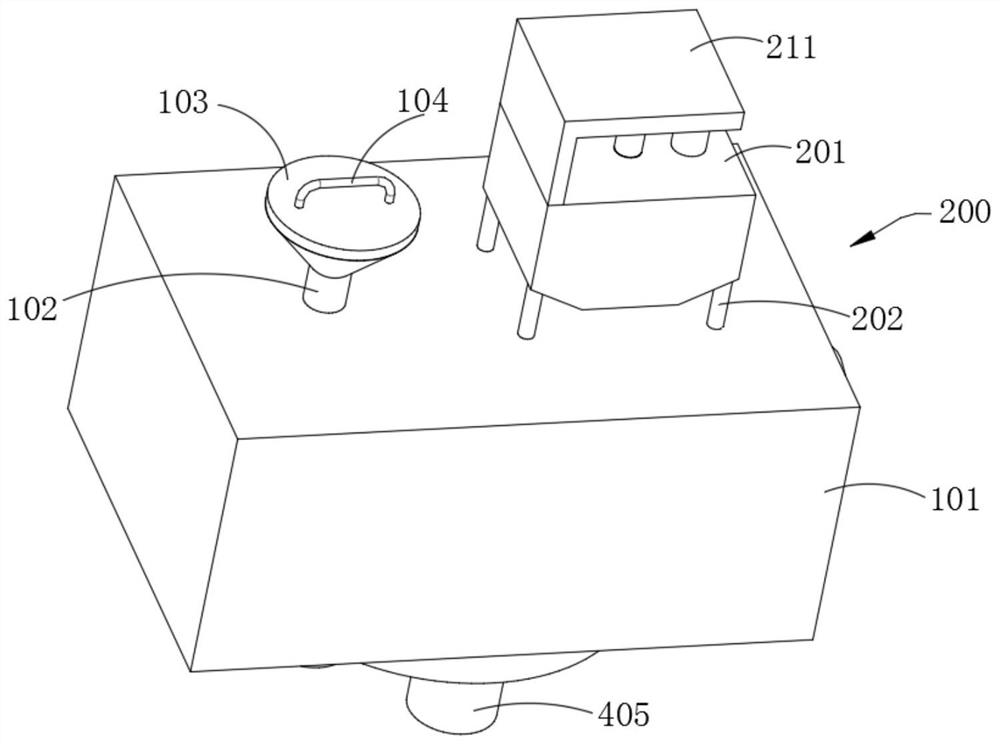

Slush molding machine

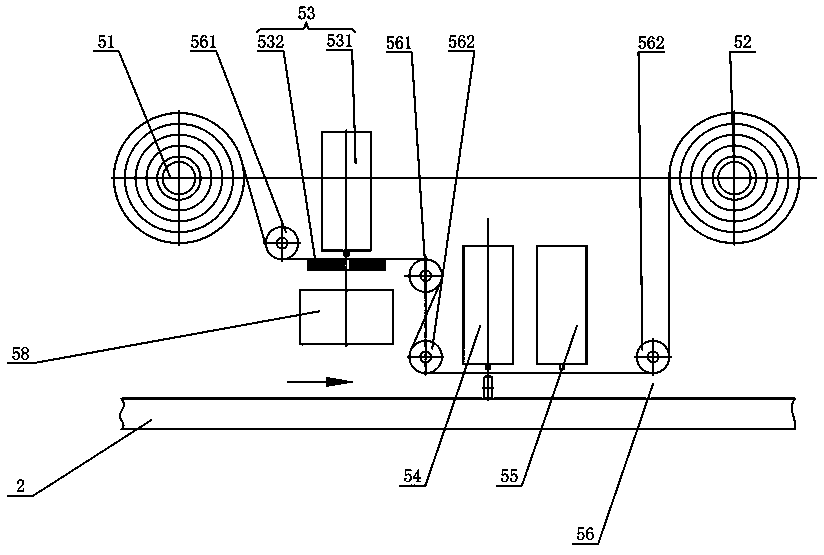

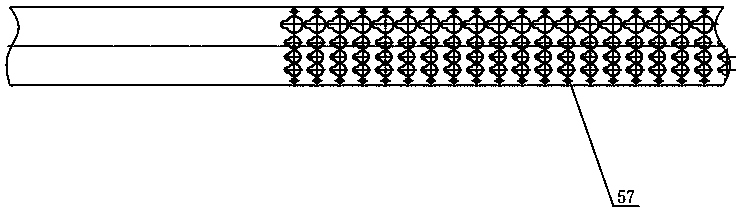

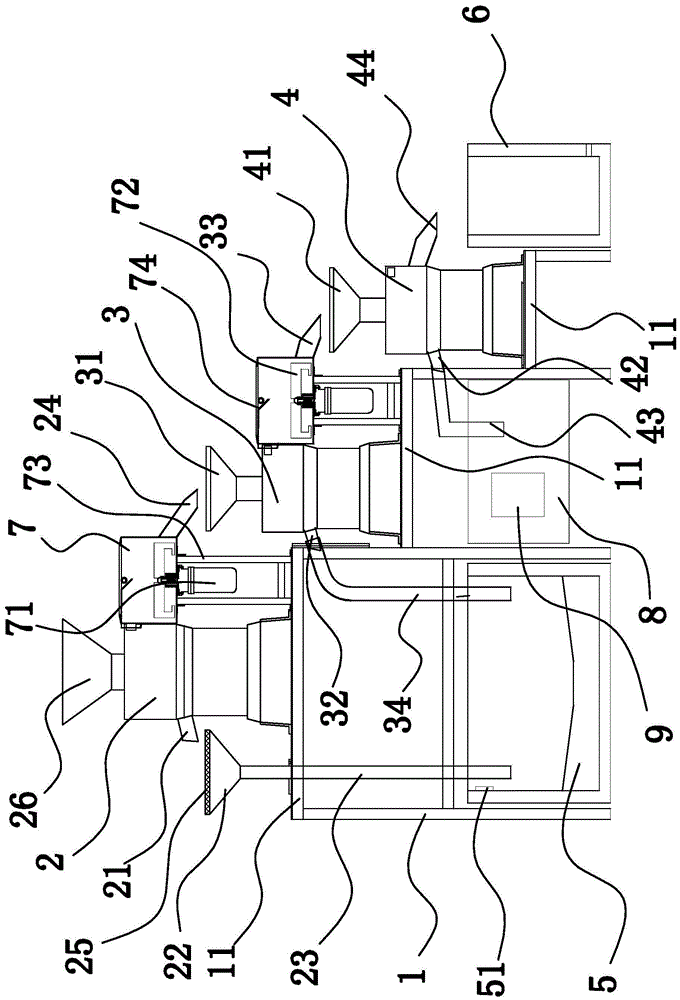

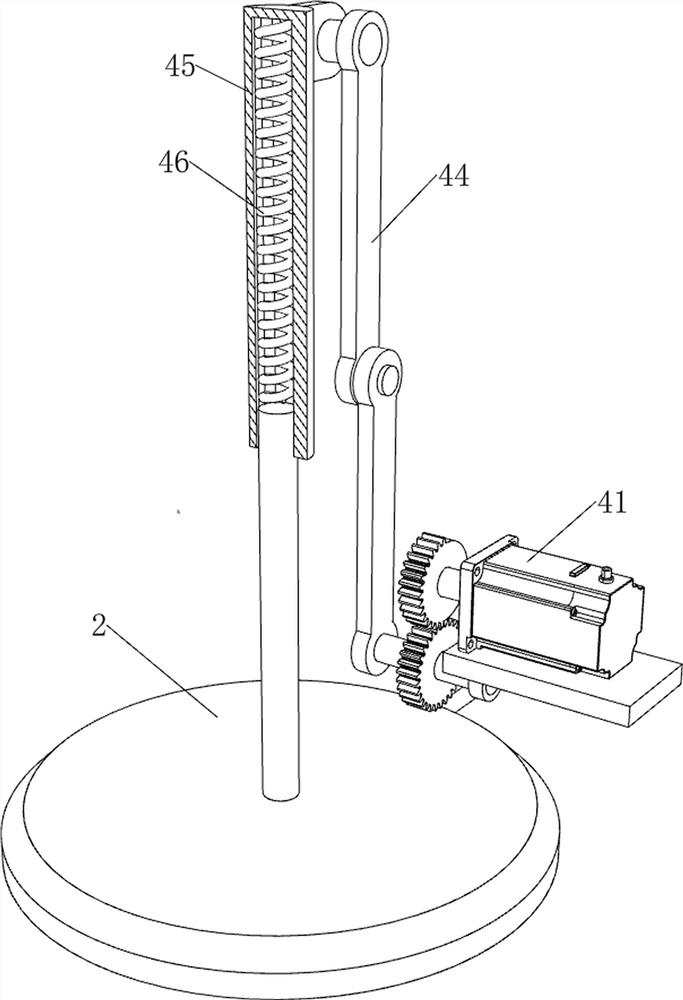

InactiveCN102001146AShorten the processing cycleNo need for manual feedingCoatingsMolding machineCooling chamber

The invention discloses a slush molding machine, which consists of 9 units including a powder exchange chamber, a molding roll-over stand, an air heater, a cooling chamber, a piece-taking roll-over stand, a manipulator, a mold frame, a powder box and a main machine frame, wherein the powder exchange chamber, the molding roll-over frame, the air heater, the cooling chamber, the piece-taking roll-over stand and the manipulator are arranged side by side in turn from one end in the main machine frame and fixedly connected with the main machine frame; the main machine frame consists of a plurality of symmetric beams on two sides and vertical sides, the beams on the two sides of the main machine frame are provided with linear sliding rails, and a slider on the manipulator is slidably connected with linear sliding rails on the main machine frame; the mold frame, the powder box and the powder exchange chamber are positioned on one side of the main machine frame and arranged in parallel to the main machine frame; and the mold frame, the powder box and the powder exchange chamber are moveably connected with the main machine frame through chain wheels or rollers. The slush molding machine is scientifically, rationally and creatively designed, completely solves the problem of localization of the slush molding machine, has the advantages of convenience of use, high practicability and the like and has a bright market prospect.

Owner:JINXING AUTOMOTIVE INTERIOR DECORATION

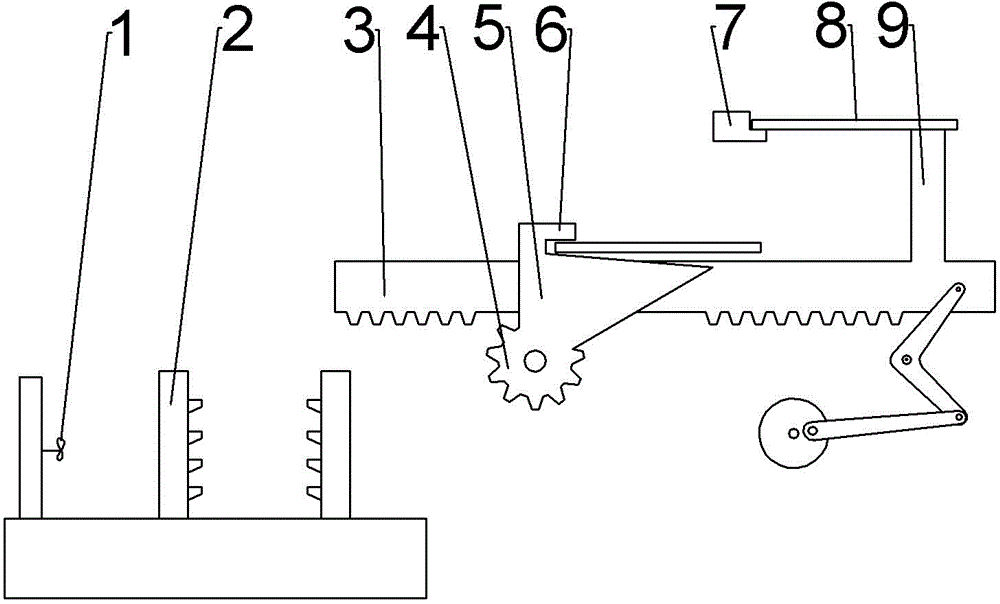

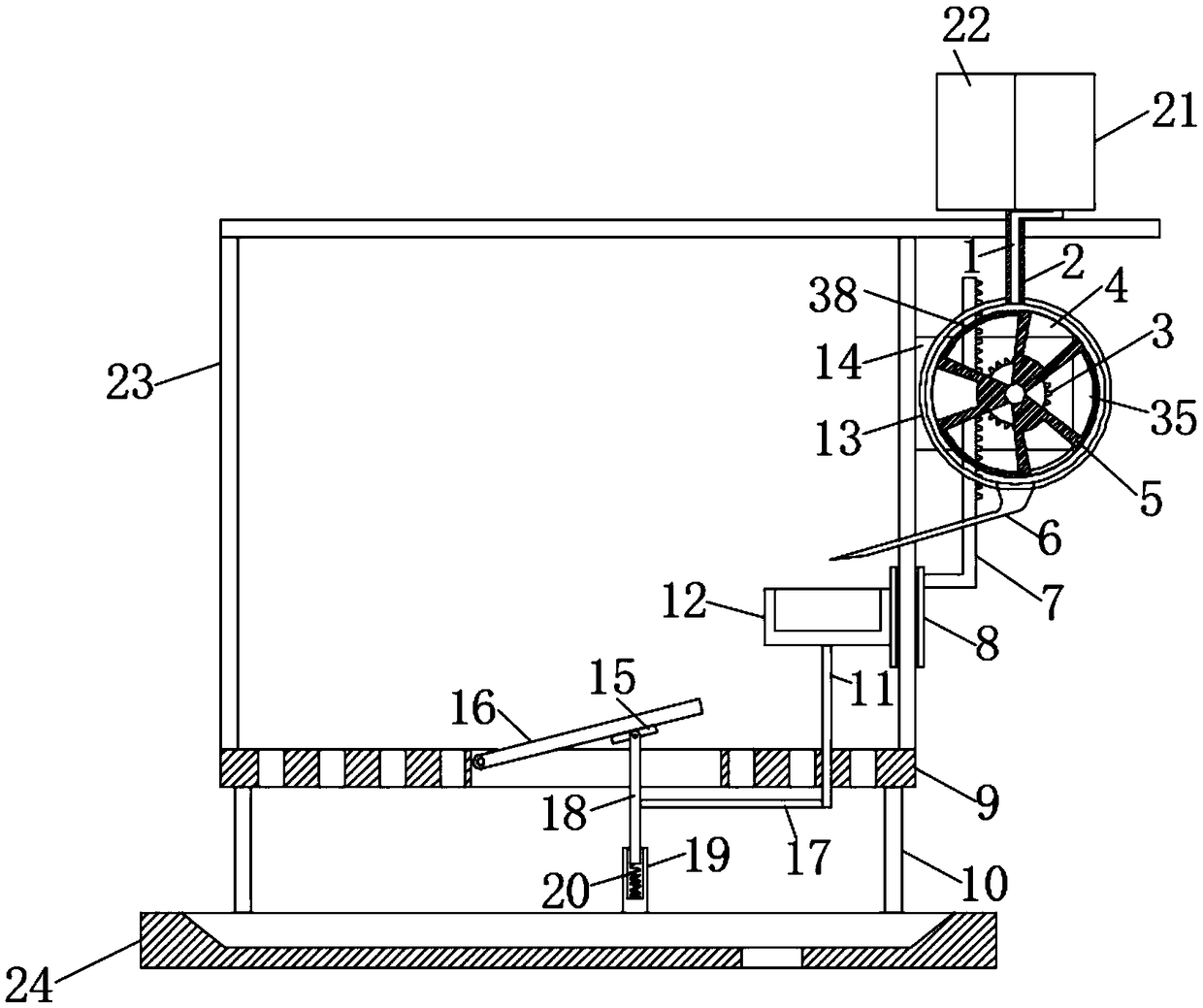

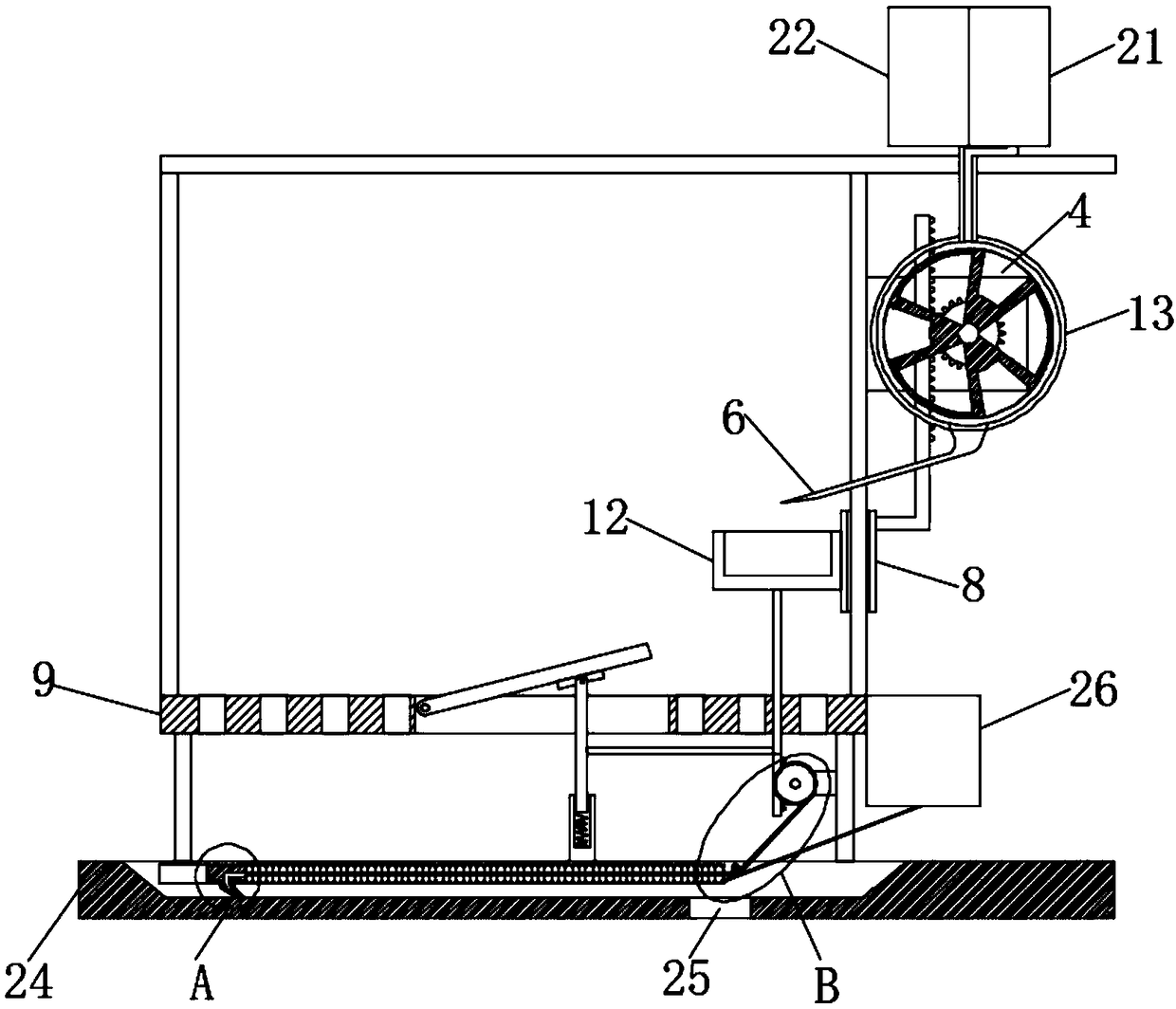

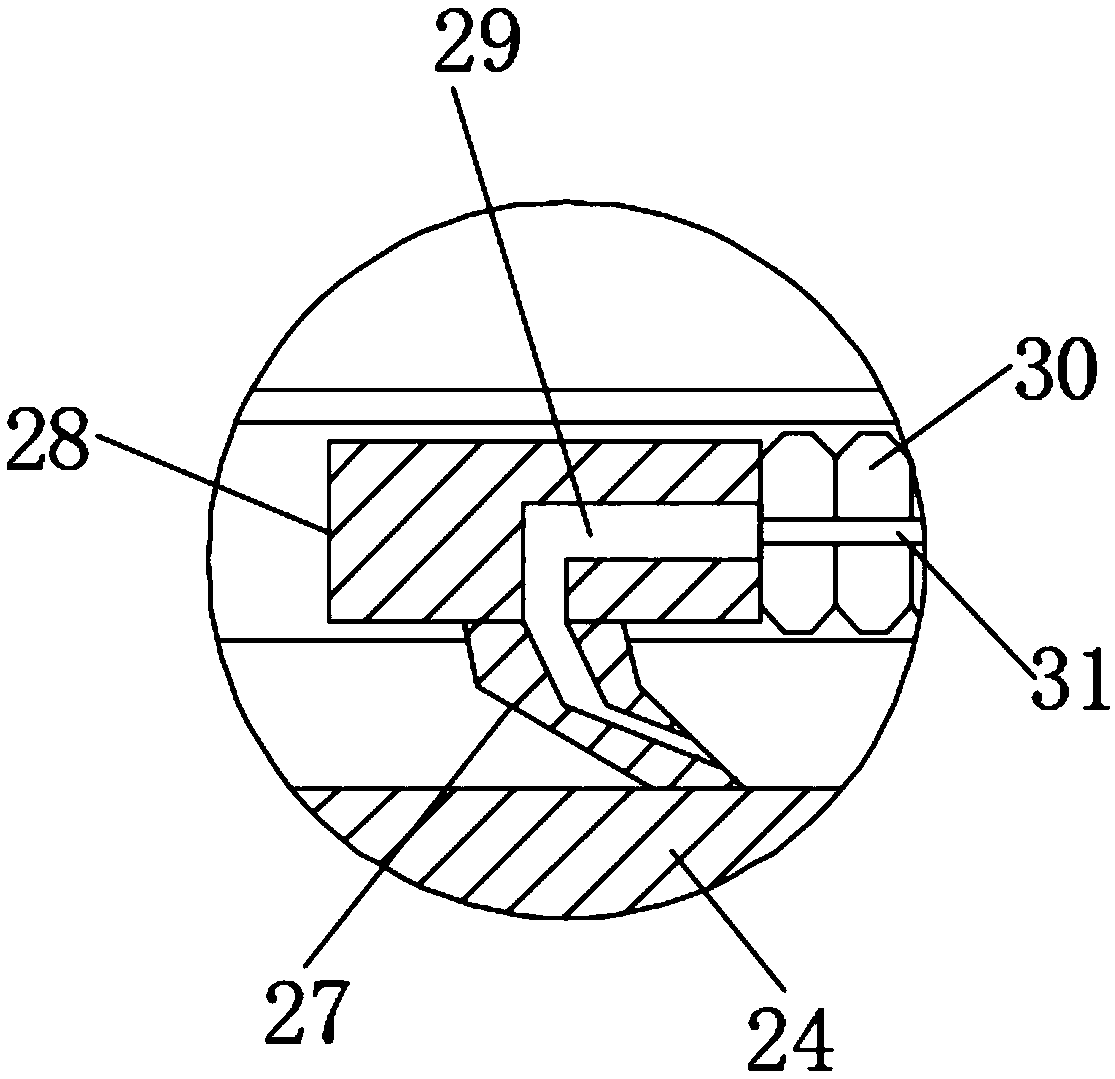

Plate turning machine

The invention discloses a plate turning machine and relates to the field of material turning. The plate turning machine comprises a turning plate, a sliding plate and a gear. The turning plate comprises a carrier and a carrying hook fixed on the carrier. The turning plate is fixed on the gear, a rack matched with the gear is arranged on the lower portion of the sliding plate, a push plate is arranged on the upper portion of the sliding plate which is hinged to a crank rocker, and the crank rocker is linked by an eccentric wheel through a connection rod. By means of the machine, the plates can be turned efficiently and continuously.

Owner:重庆新锐科技服务有限公司

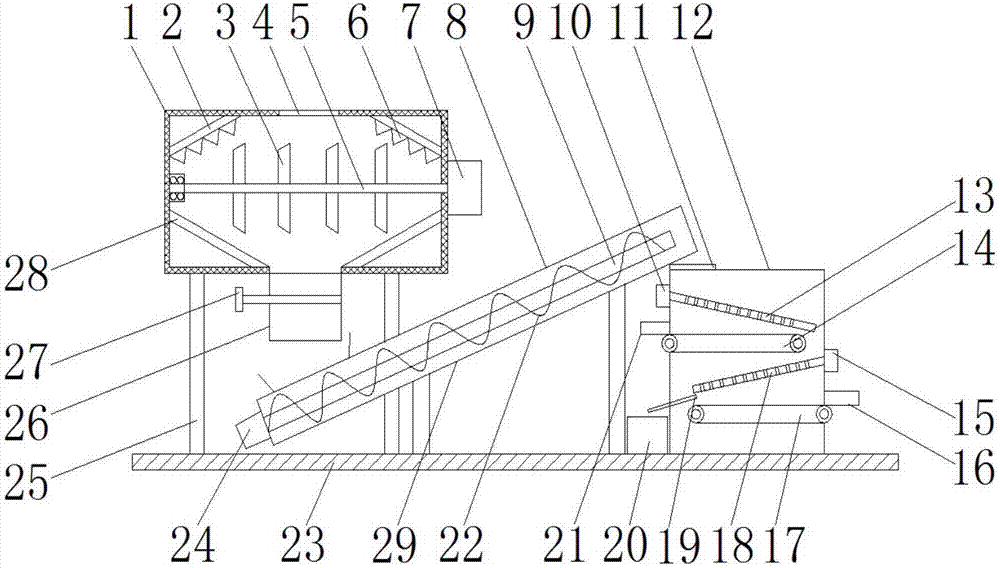

Material pulverizing and sieving device

The invention discloses a material crushing and screening device, which comprises a first motor, a rack, a slant plate, a first sieve plate, a second sieve plate, a second vibrating motor, a material guide trough and a collection trough. Drive the crushing blade on the crushing shaft to rotate, so as to crush the material, use the rack to cut the material that hits the baffle, improve the effect of material crushing, and set the inclined plate to facilitate the crushed material in the crushing box to slide to The discharge port of the crushing box realizes layered screening of materials by setting the first sieve plate and the second sieve plate, which improves the practicability of the equipment. The materials that do not fall into the second conveyor belt on the second sieve plate are Under the action of the second vibrating motor, it slides down to the material guide groove along the second sieve plate, and the collecting groove is set to collect the unscreened materials so as to be crushed again, which improves the practicability of the equipment.

Owner:CHENZHOU JINTONG INFORMATION TECH CO LTD

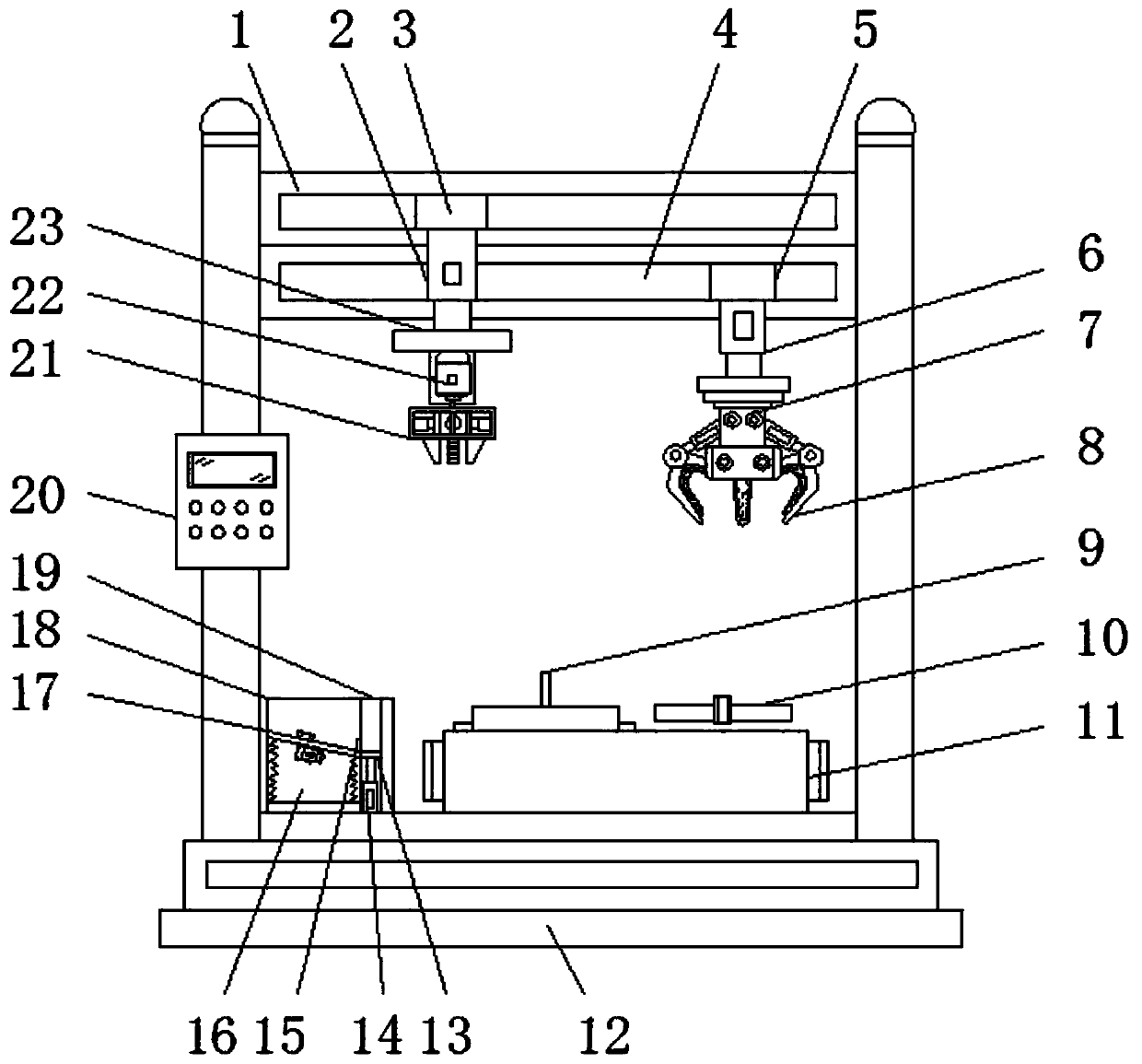

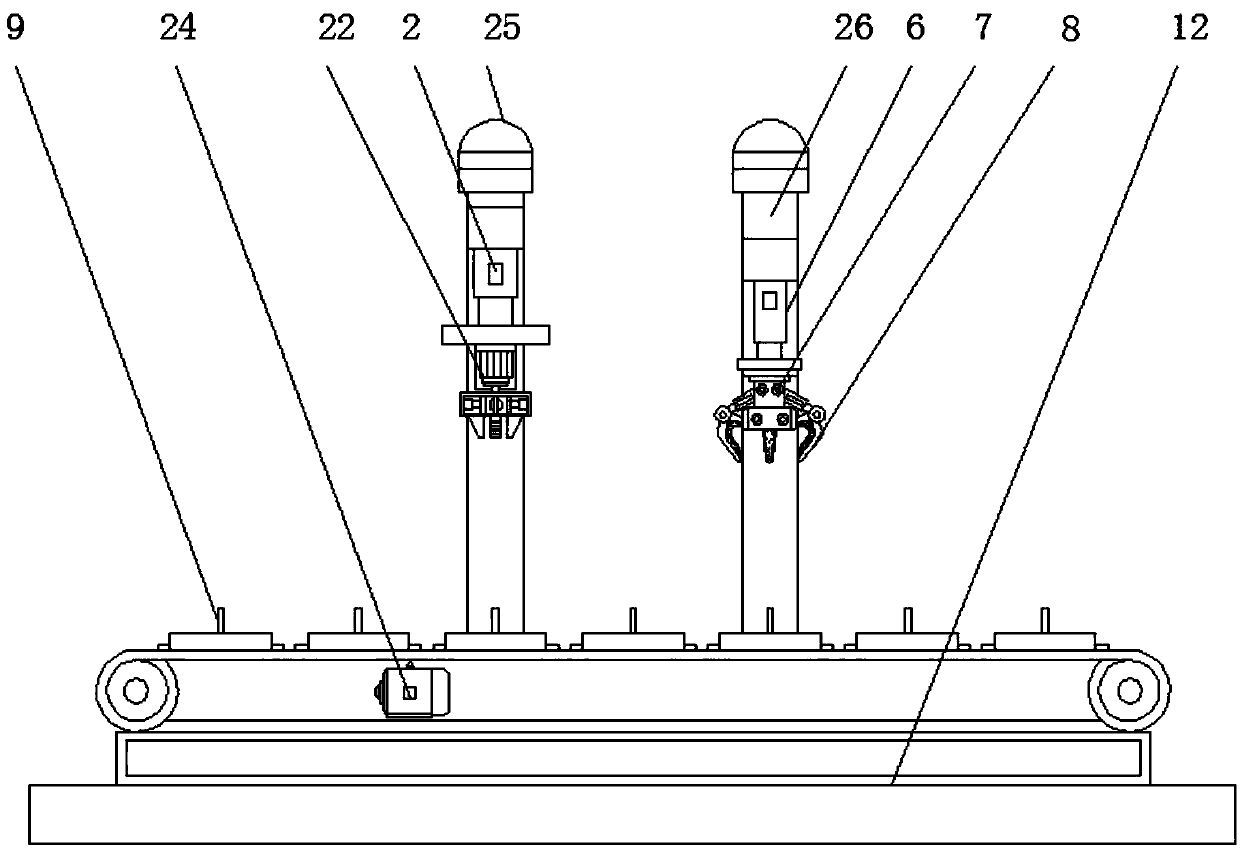

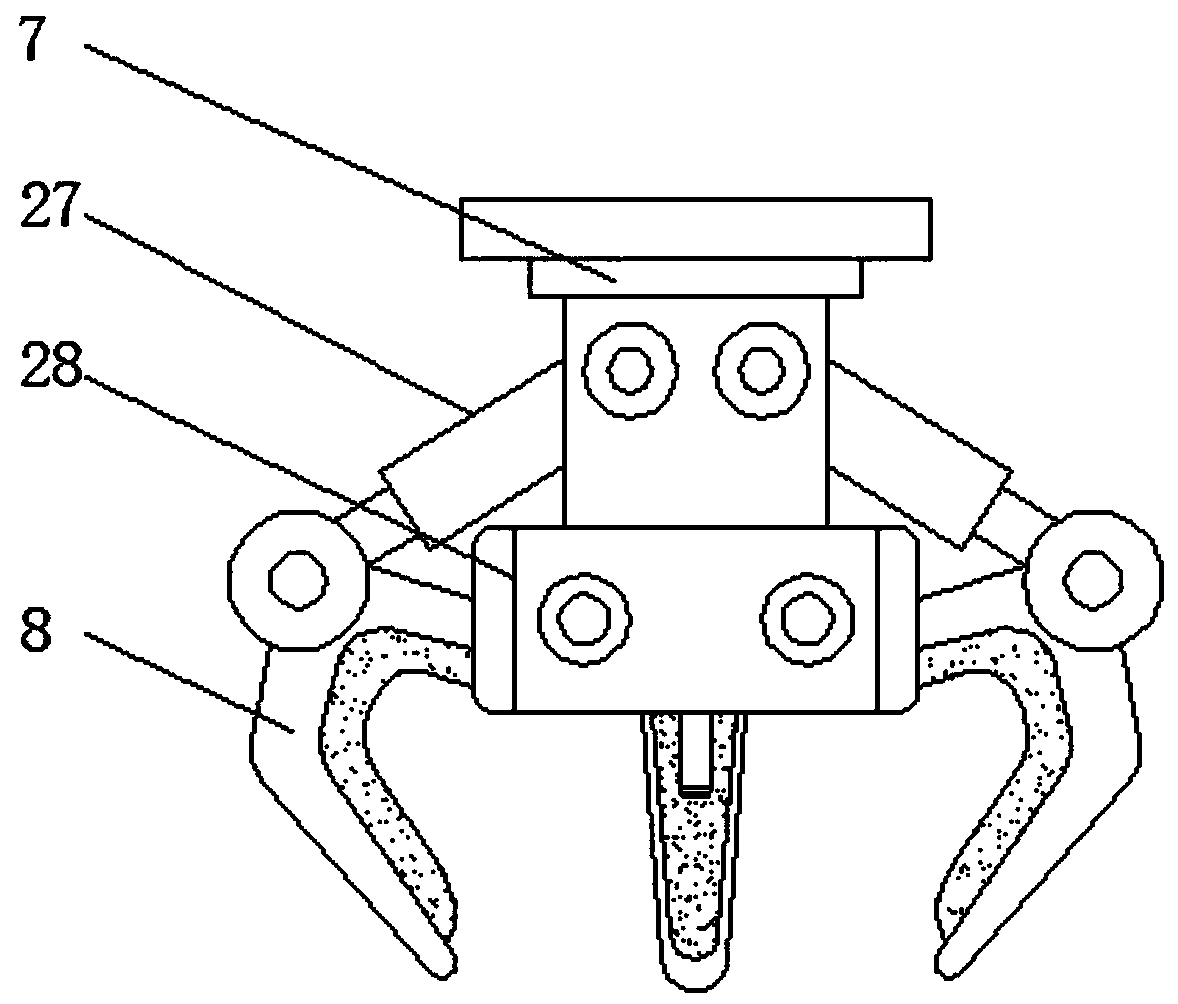

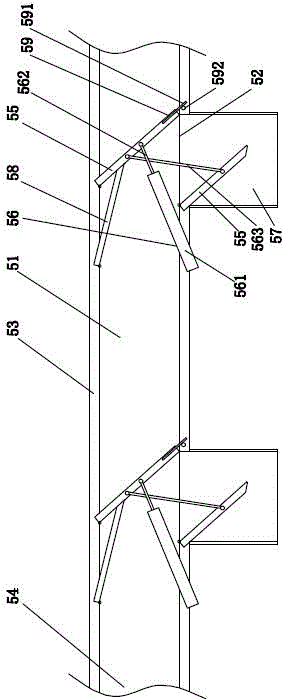

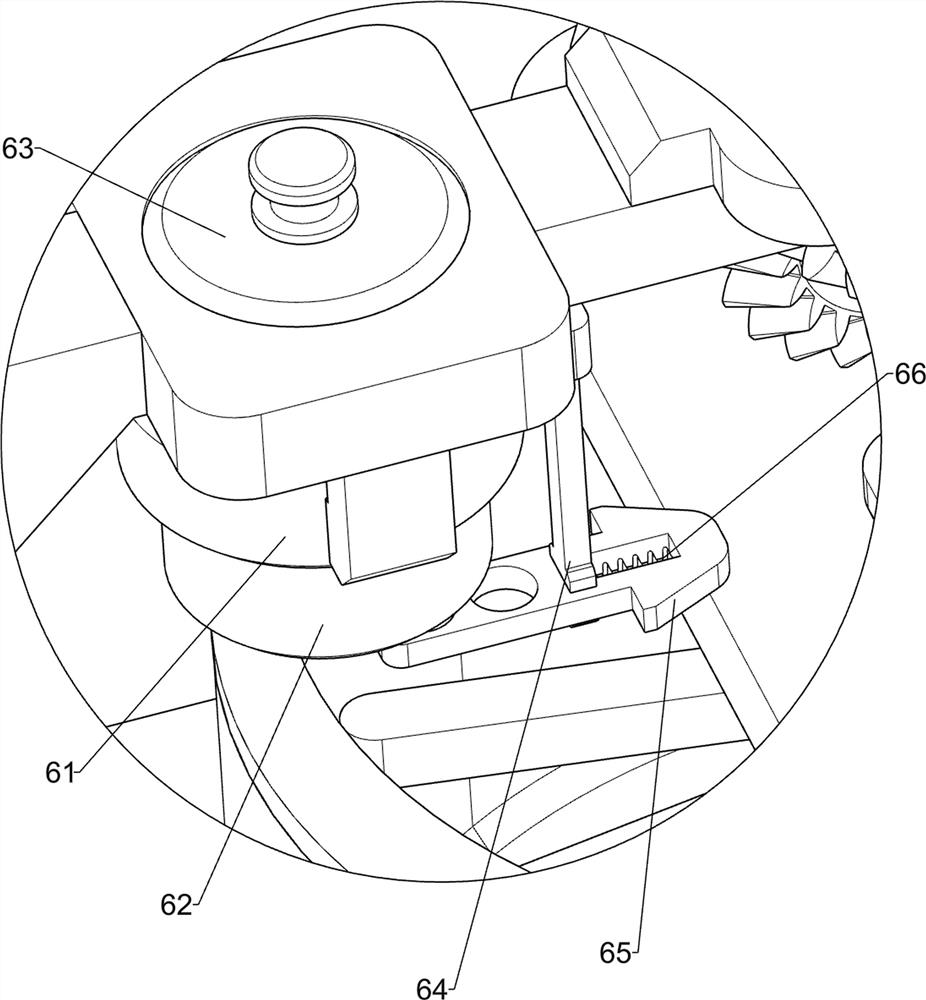

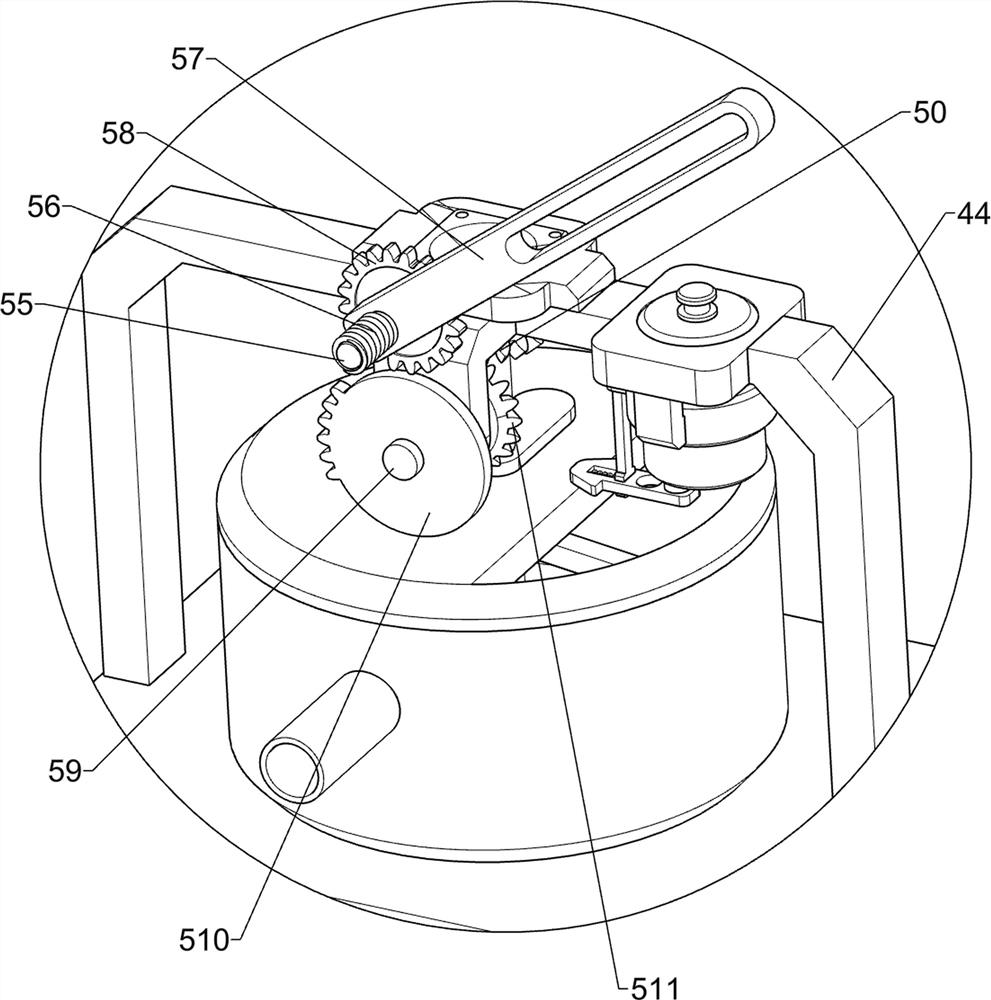

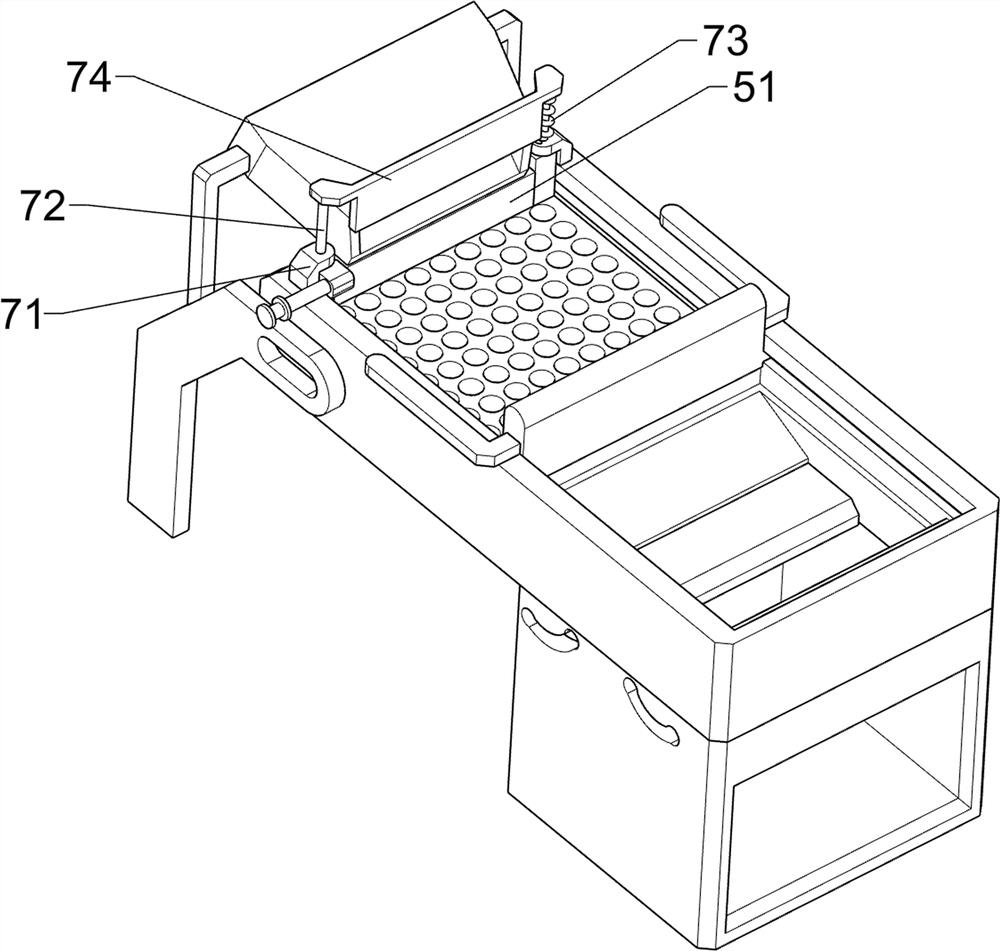

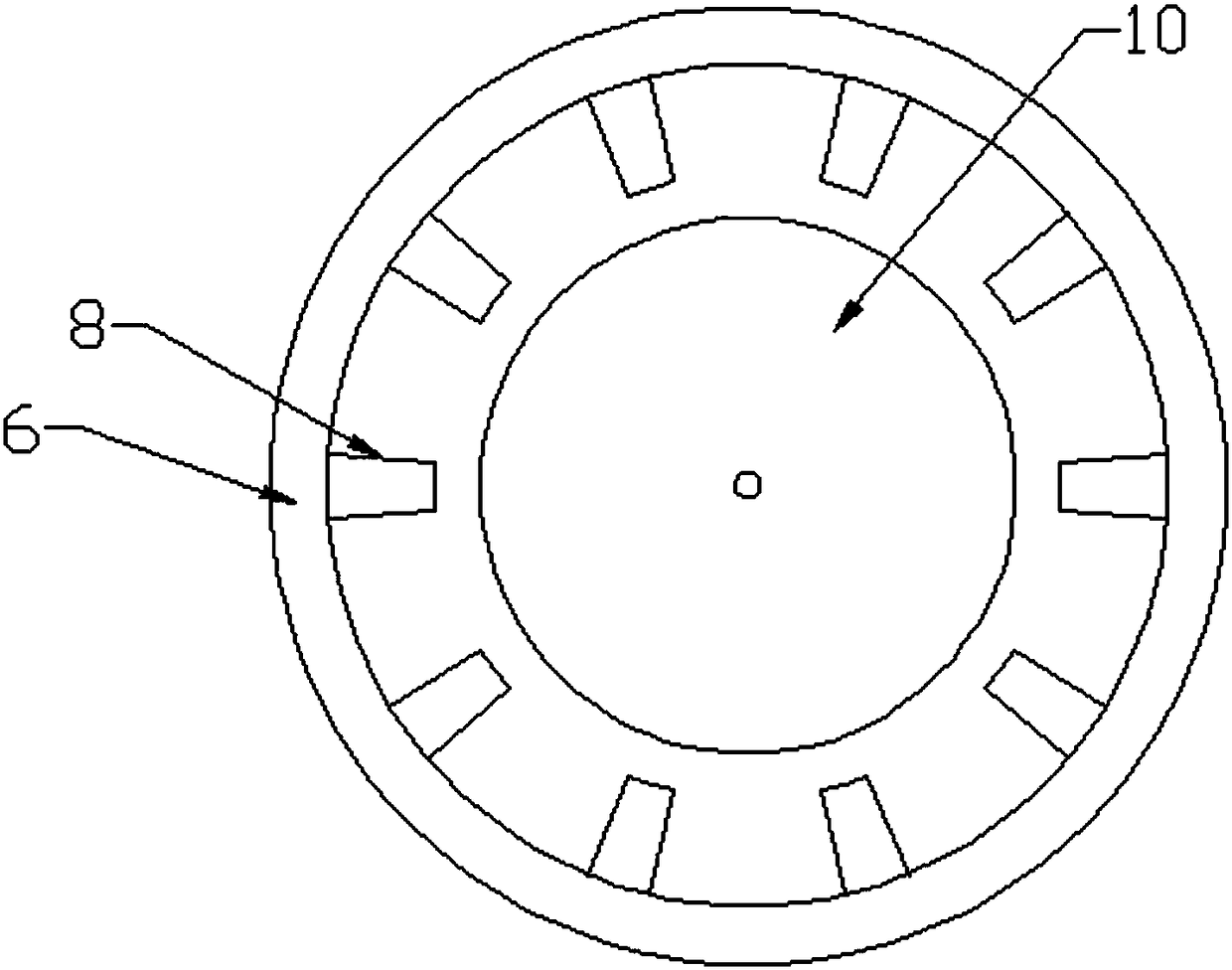

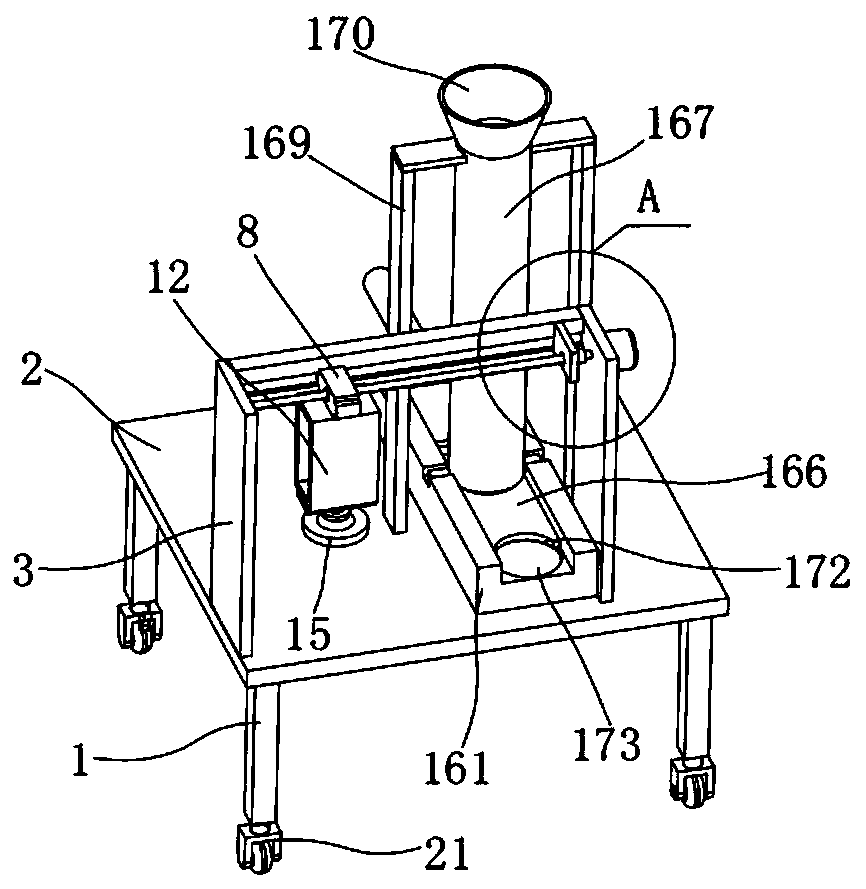

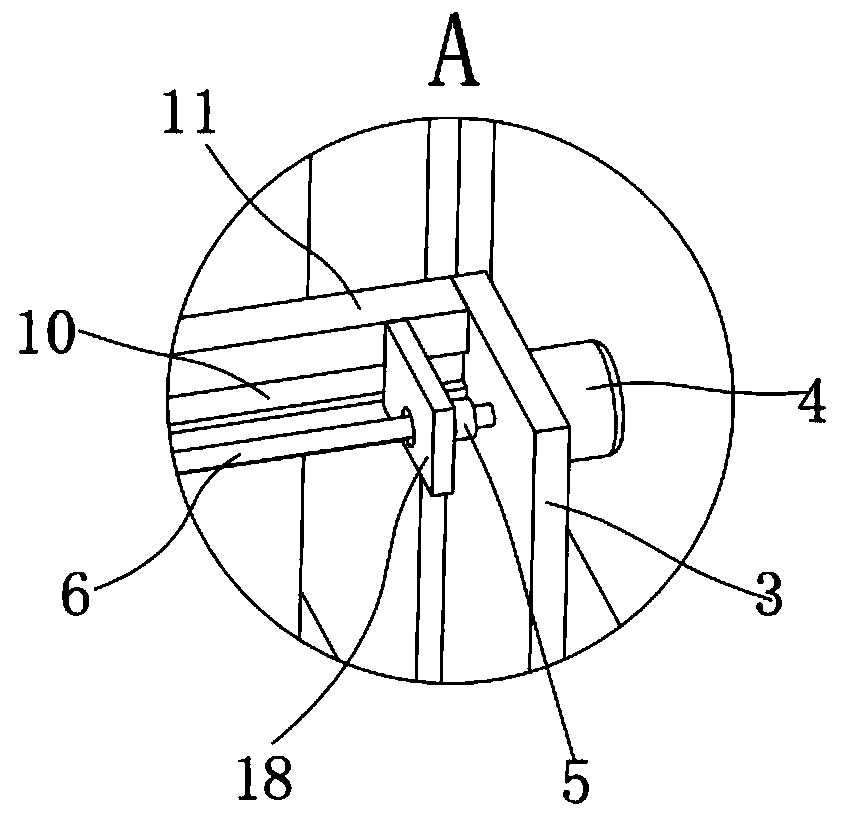

Vane wheel mounting device of water meter

InactiveCN107553099AEasy to grabEasy to installMetal working apparatusImpellerArchitectural engineering

The invention relates to a vane wheel mounting device of a water meter. The device comprises first electric slide rails, second electric slide rails, mechanical claw arms, a base and a storage box. First stand columns are mounted on the two sides of one end of the top of the base correspondingly, and the first electric slide rails are fixed at the top end of the space between the first stand columns. A first slide block is arranged in the first electric slide rails, a first hydraulic telescopic rod is fixed to the bottom end of the first slide block, a first motor is mounted at the bottom endof the first hydraulic telescopic rod through a fixing plate, and a rotating cavity is fixed to the output end of the first motor through a rotary shaft. Fifth hydraulic telescopic rods are uniformlyarranged on the inner wall of the rotary cavity, and push blocks are mounted at the output ends of the fifth hydraulic telescopic rods. According to the vane wheel mounting device provided by the invention, by mounting a conveying belt, water meter vane wheels can be mounted in a batch mode through the device, and the practicability is higher; and by mounting a vibration plate, a vibration motor and a leakage port on the device, screws are convenient to clamp and mount, and the automation degree is higher.

Owner:高卫东

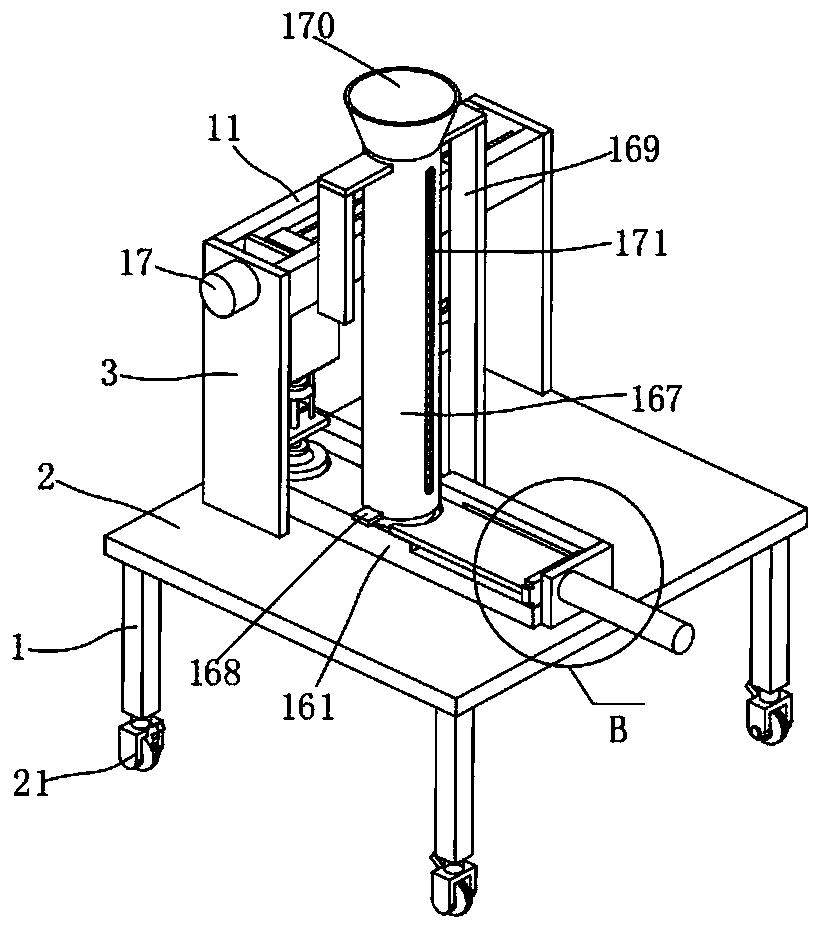

Electronic equipment product drop test device

InactiveCN106289703AImprove test efficiencyEnable continuous testingShock testingTest efficiencyDrop tests

The invention relates to an electronic equipment product drop test device. The electronic equipment product drop test device comprises a box body; the lower end of the box body is provided with an impact stage; one side of the lower end of the box body is provided with a push plate; one side of the push plate is connected with a push-pull cylinder through a connection rod, wherein the push-pull cylinder passes through one side of the box body; the other side of the lower end of the box body is provided with a sliding door which is connected through a hinge; an opening is arranged at the upper end of the box body; the left side and right side of the upper end of the box body are provided with a fixing plate respectively; the fixing plates are provided with a material discharging cylinder respectively; each material discharging cylinder is connected with a material plate; hoppers are arranged on the material plates; material tubes are arranged below the hoppers; and the lower end of one side of the sliding door is provided with a storage box. With the electronic equipment product drop test device of the invention adopted, continuous testing of products can be realized, testing efficiency can be improved, manual feeding is not required, and time and labor can be saved.

Owner:安徽云图信息技术有限公司

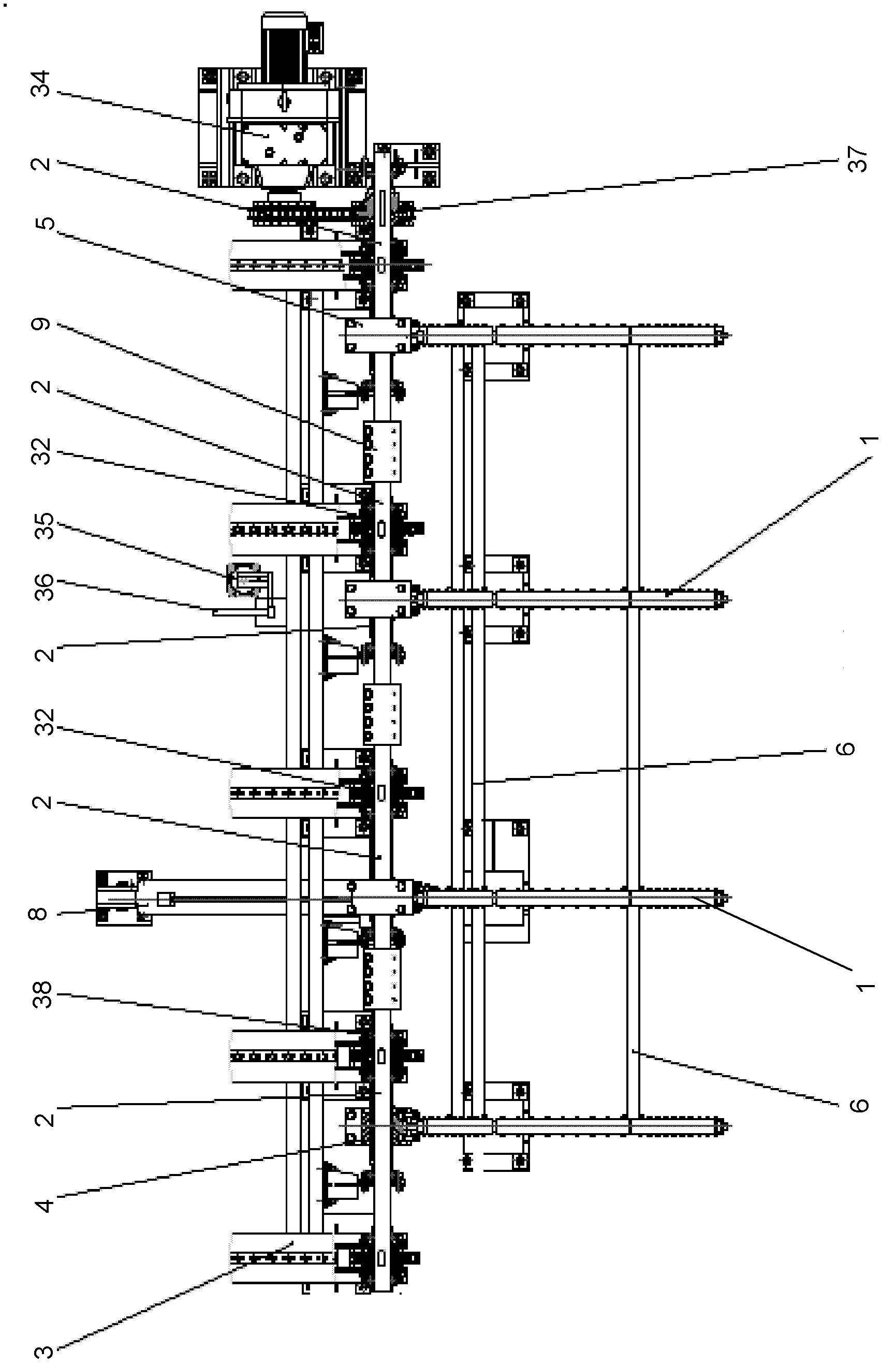

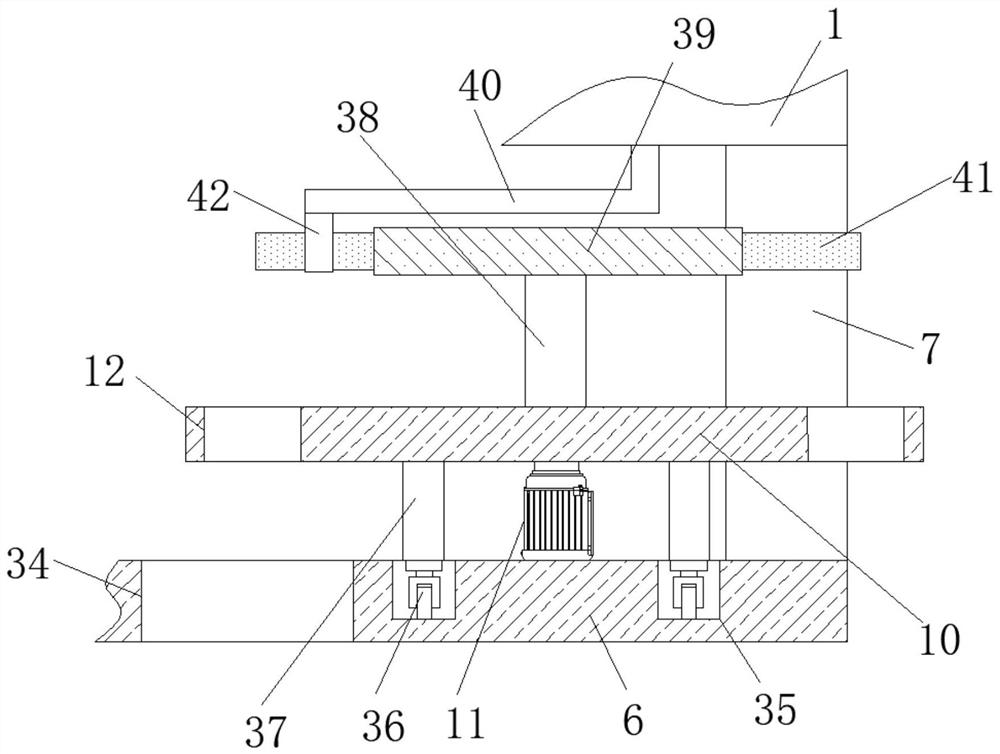

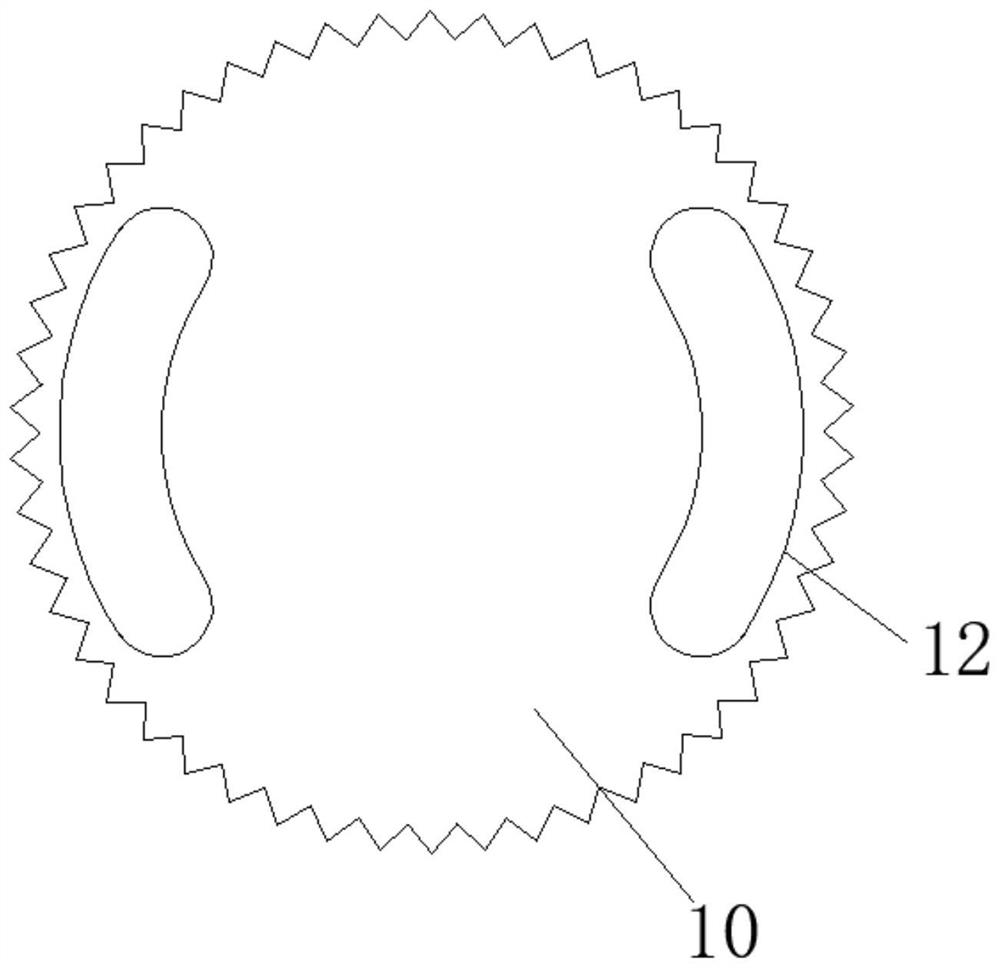

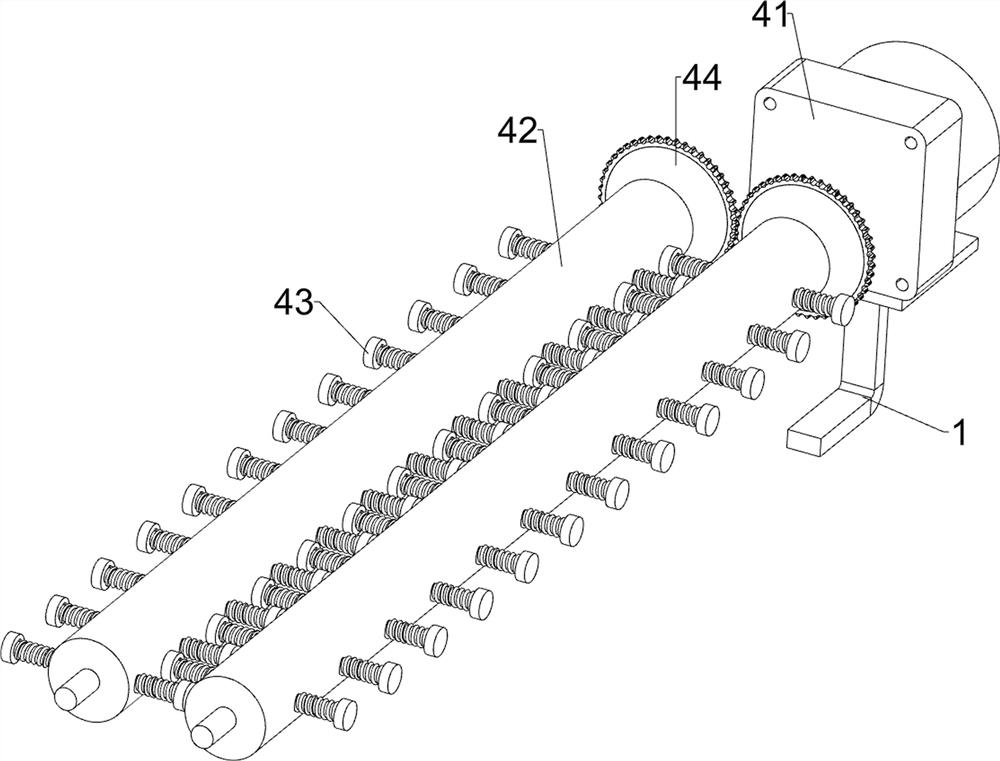

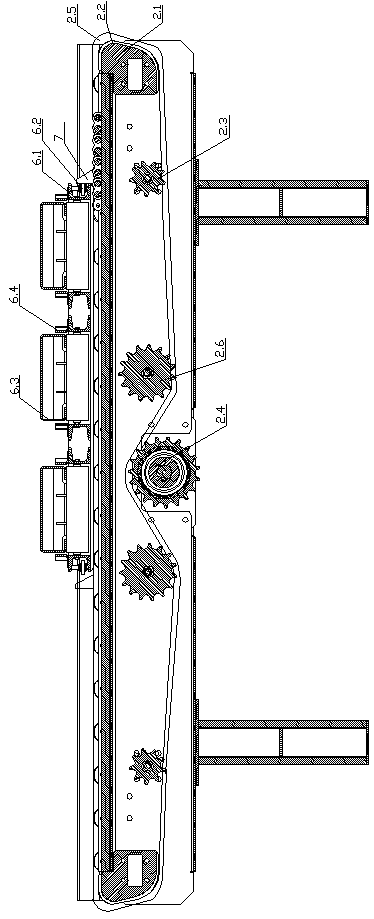

Workpiece feeding and distributing device

ActiveCN103101735ASuccessful realization of material loadingSuccessful realization of material distributionConveyor partsMechanical conveyorsEngineeringSprocket

The invention discloses a workpiece feeding and distributing device. The workpiece feeding and distributing device comprises a plurality of U-shaped feeding tanks, a rotating shaft and a chained material-distributing table, wherein the plurality of U-shaped feeding tanks are arranged in parallel and one end of each U-shaped feeding tank is connected with the rotating shaft, one bottom of each U-shaped feeding tank is connected with an oil cylinder through a trunnion, and the oil cylinders drive the U-shaped feeding tanks to conduct feeding operation. The chained material-distributing table comprises a drive sprocket which is provided with a conveying chain, a table frame and a gear motor, wherein the drive sprocket is arranged on the rotating shaft, the rotating shaft is connected on the table frame through a bearing, the gear motor is connected with the rotating shaft through a chain, a material-blocking mechanism which is driven by a cylinder to rise and fall is fixedly arranged on the table frame, the drive sprocket is driven by the gear motor, and thus an upper chain of the workpiece is enabled to conduct material distributing operation. The device is suitable for workpieces with a large scope of standards, feeding and material-distributing operations of bar materials, pipe materials and square billets can be achieved smoothly, and meanwhile, manual material-setting is of no need, and security accidents are avoided.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

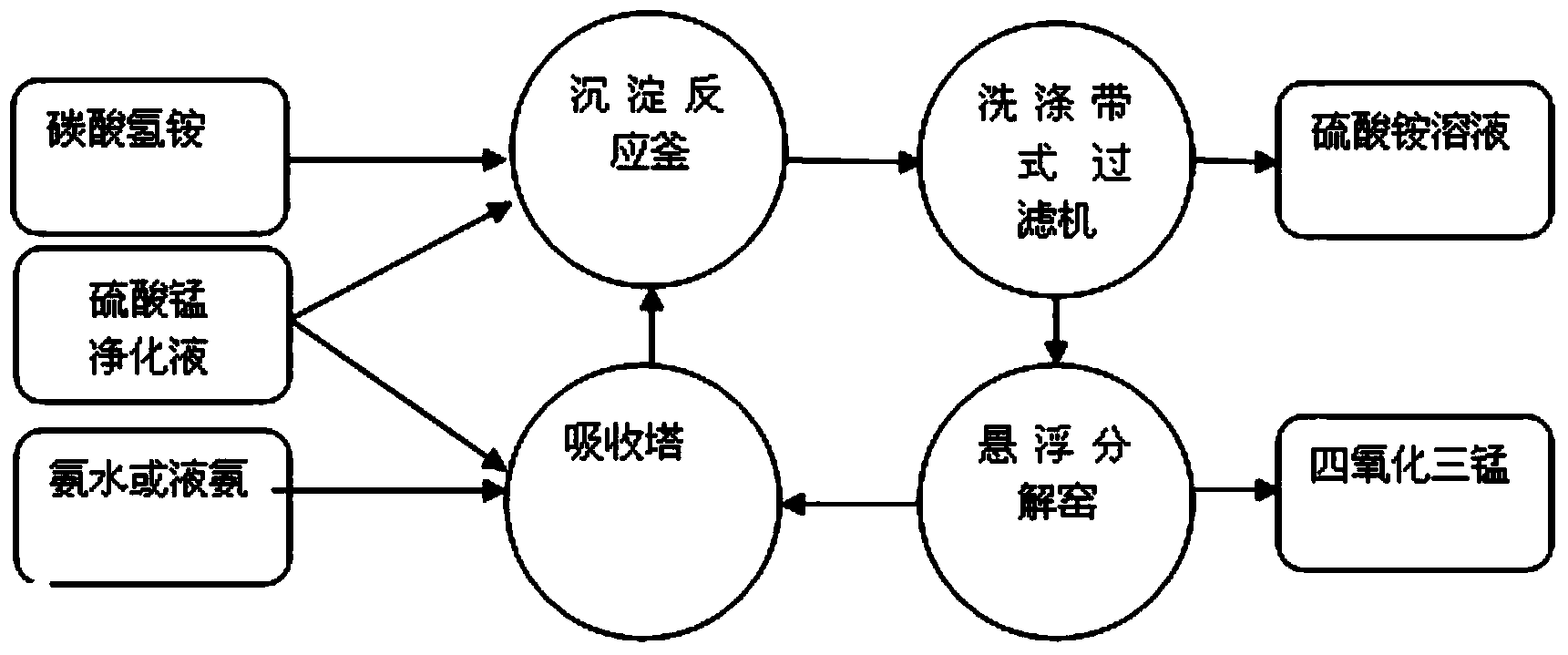

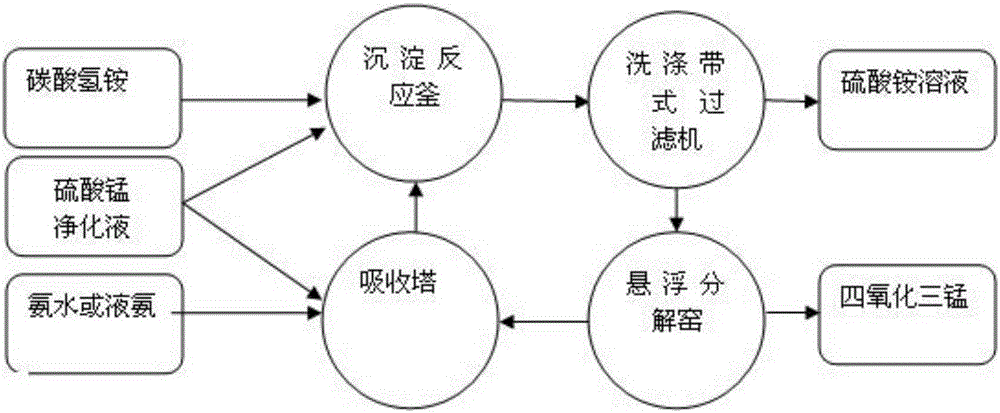

Decomposition deposition cycle technology for preparing trimanganese tetroxide through using manganese sulfate solution

ActiveCN104211122AEasy accessNo pollution in the processManganese oxides/hydroxidesSulfateDecomposition

The invention discloses a decomposition deposition cycle technology for preparing trimanganese tetroxide through using a manganese sulfate solution. The technology comprises the following steps: 1, adding a manganese sulfate solution and ammonium bicarbonate into a deposition reaction kettle to make manganese in the manganese sulfate solution fully deposited, filtering, and washing to obtain manganese carbonate; 2, sending manganese carbonate into a suspension decomposition kiln, and decomposing to obtain trimanganese tetroxide; 3, introducing the manganese sulfate solution and ammonia water or liquefied ammonia into an absorbing tower, introducing tail gas from the suspension decomposition kiln into the absorbing tower to carry out a reaction, allowing the obtained reaction liquid to flow into a deposition reaction kettle, and depositing to obtain manganese carbonate, wherein the introduction amount of the ammonia water or liquefied ammonia makes the pH value of the reaction liquid controlled at about 6.5; and 4, sending manganese carbonate into the suspension decomposition kiln, and repeating step 3. The technology using carbon dioxide decomposed by manganese carbonate and the ammonia or liquefied ammonia to deposit manganese carbonate has the advantages of environmental protection, low energy consumption and low cost.

Owner:CHONGQING SHANGJIA ELECTRONICS

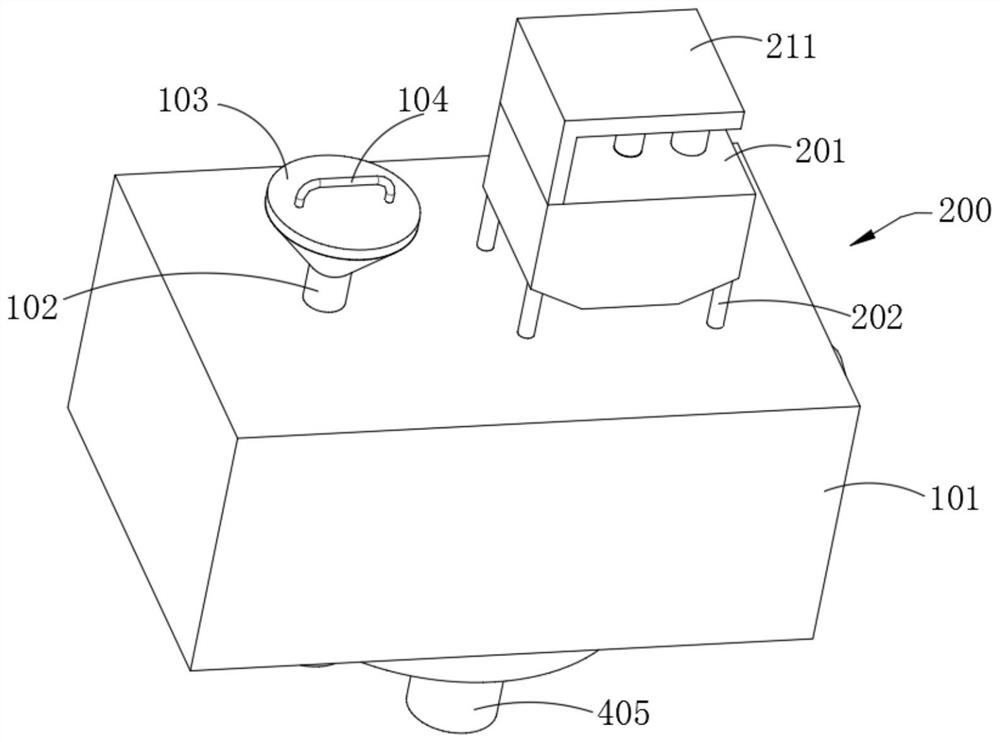

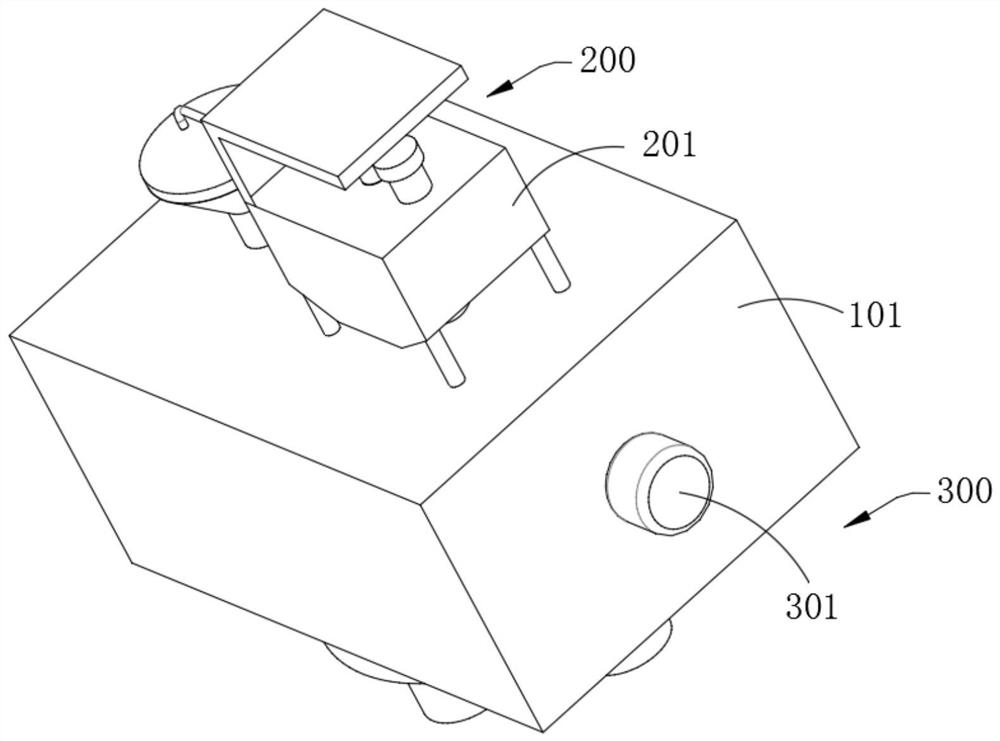

Raw material feeding device of environment-friendly food-grade cosmetic packaging hose production equipment

ActiveCN111645263AConvenient for normal dischargeImprove convenienceLarge containersProcess engineeringEngineering

The invention discloses a raw material feeding device of environment-friendly food-grade cosmetic packaging hose production equipment. The raw material feeding device comprises a fixing box, the fixing box is of a cavity structure with an opening in the top end, a through hole is formed in the inner wall of the bottom of the fixing box, a storage box is arranged in the fixing box, and the storagebox is of a cavity structure with openings in the top end and the bottom end; and the top of the storage box is fixedly connected with a feeding hopper, the bottom of the storage box is fixedly connected with a discharging hopper, and the discharging hopper penetrates through the through hole. According to the raw material feeding device of the environment-friendly food-grade cosmetic packaging hose production equipment, feeding can be quantitatively controlled, meanwhile, a raw material in the storage box is stirred, vibration is generated through a vibration motor, and a scraper moves on theinner wall of the discharging hopper, so that the possibility that the raw material adheres to the inner wall of the storage box and the inner wall of the discharging hopper is reduced, normal discharging of the discharging hopper is convenient, the possibility that the raw material is blocked in the discharging hopper is reduced, manual feeding is not needed, and convenience is improved.

Owner:浙江华橙教育科技有限公司

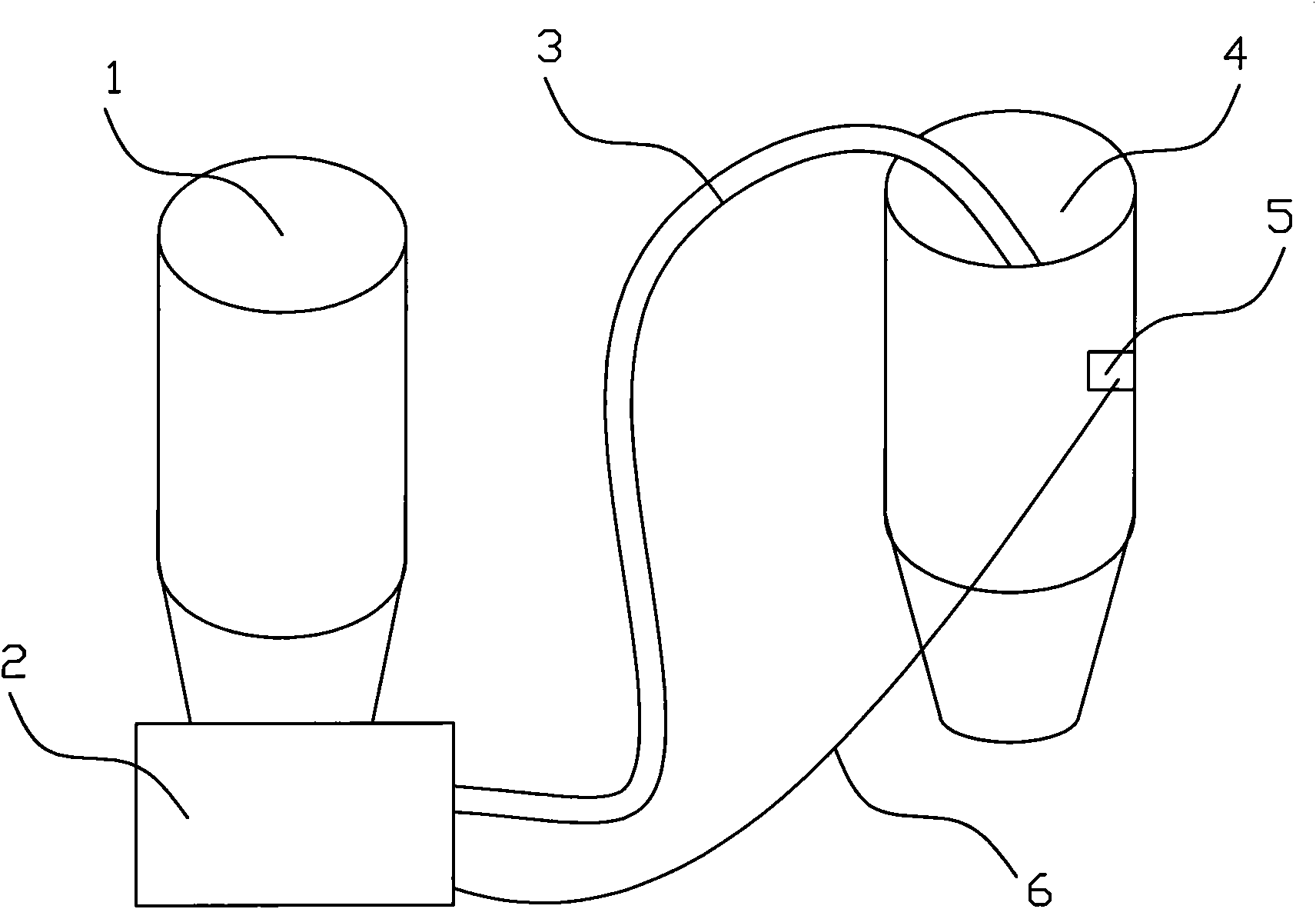

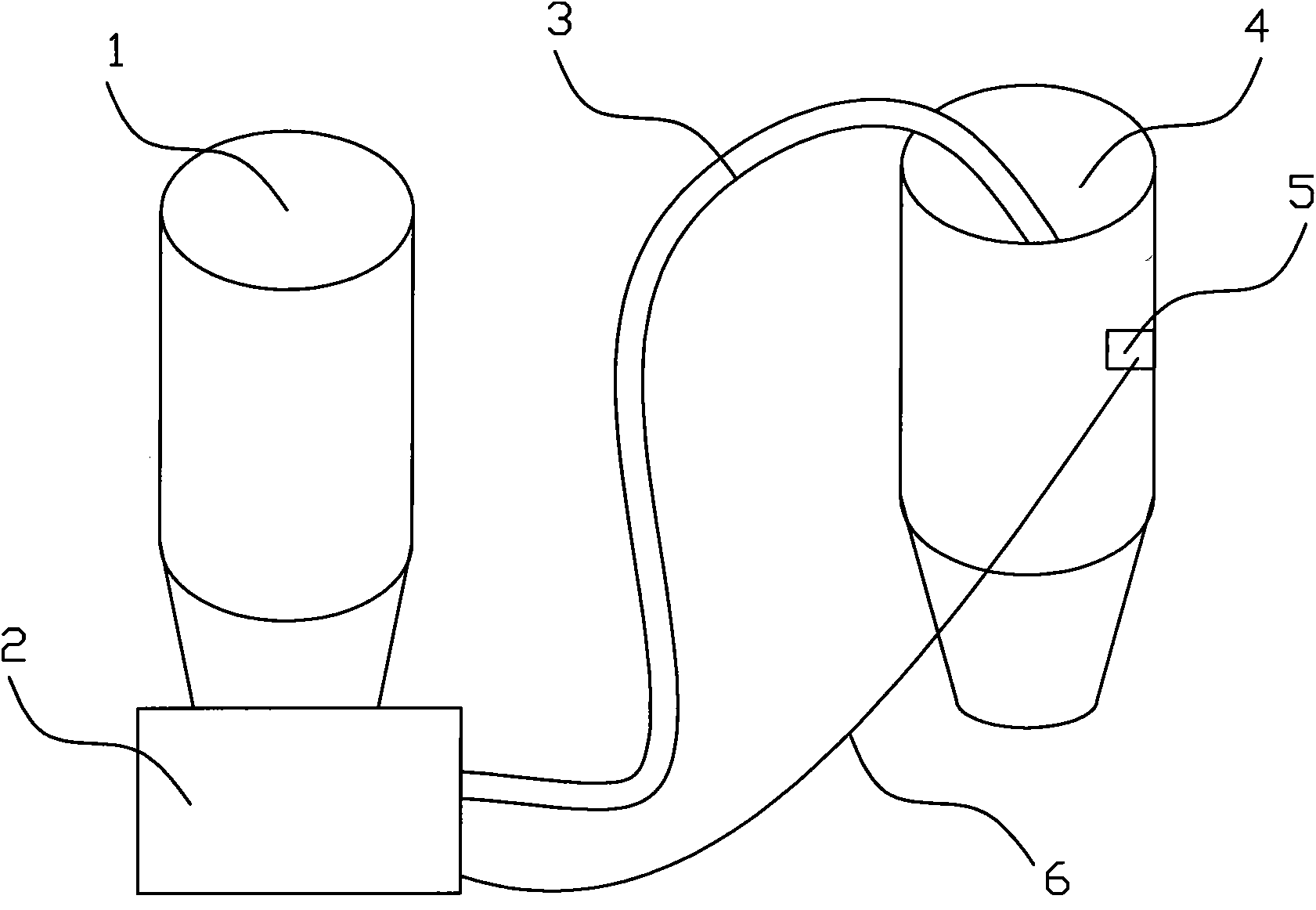

Charging device for injection molding machine

The invention discloses a charging device for an injection molding machine, comprising a raw material tank, a pneumatic transmission mechanism and a transmission hosepipe, wherein the discharging hole of the raw material tank is connected with the pneumatic transmission mechanism; the pneumatic transmission mechanism transmits raw materials from the transmission hosepipe to a charging hopper of the injection molding machine; and the charging hopper of the injection molding machine is provided with a raw material measurement sensor for measuring the amount of the raw materials in the charging hopper and feeding the raw materials information back to the pneumatic transmission mechanism in order to control the pneumatic transmission mechanism to transmit the raw materials. Because the technical scheme is adopted in the invention, the raw material tank is arranged on the ground, and the raw materials are transmitted by the pneumatic transmission mechanism to the charging hopper of the injection molding machine at a higher position via the transmission hosepipe without artificial feeding, and once the materials are insufficient, the raw materials measurement sensor feeds the material-lack information back to the pneumatic transmission mechanism, so that the pneumatic transmission mechanism can timely work to transmit the raw materials to the charging hopper of the injection molding machine.

Owner:王维东

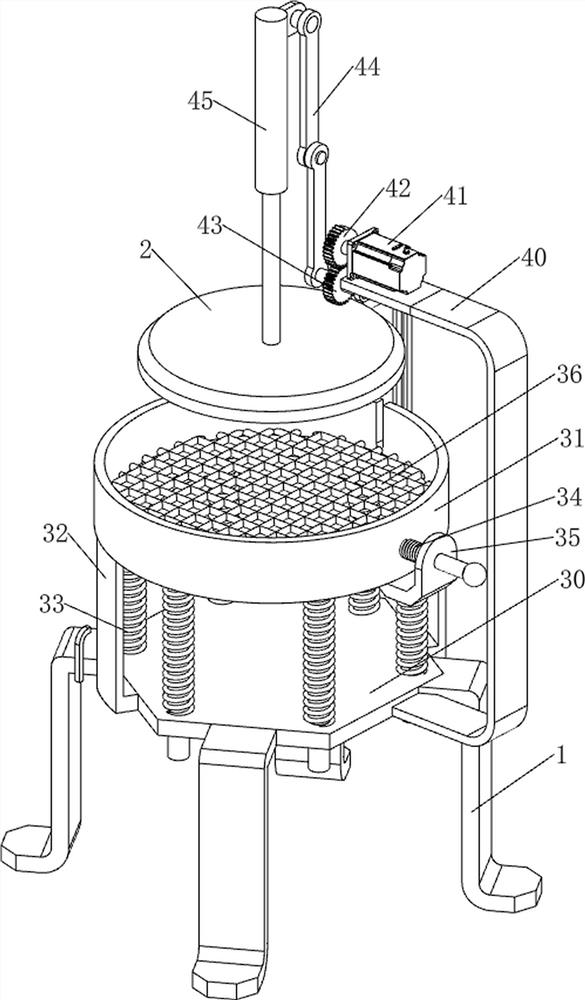

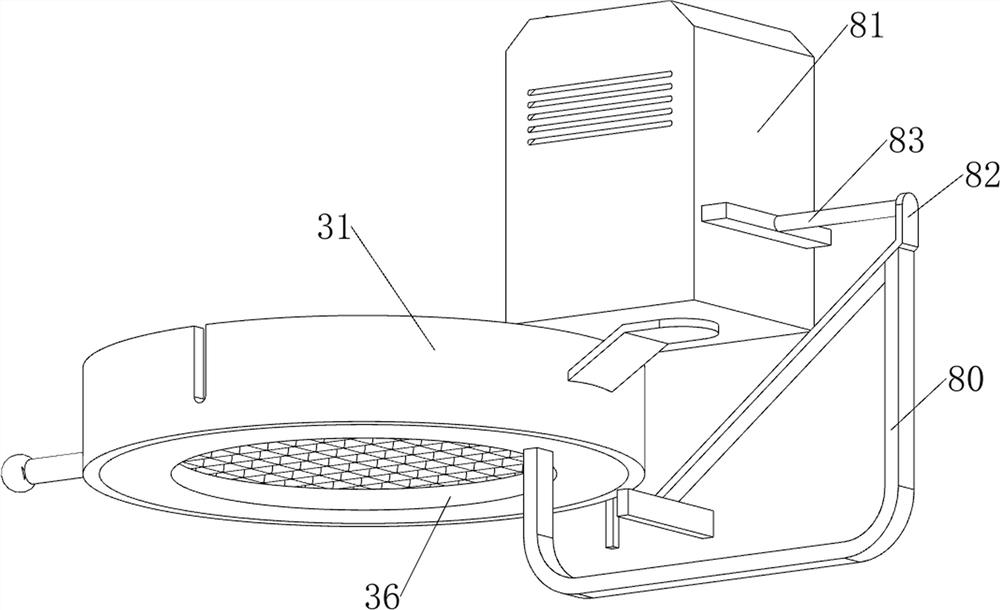

Semiautomatic settling type pickle squeezer

The invention discloses a semiautomatic settling type pickle squeezer, and belongs to the technical field of squeezing equipment. The semiautomatic settling type pickle squeezer comprises a machine frame, a squeezing platform, a bottomless filter tube, a solid squeezing tube, a feeding device, a material collecting device and a filter tube moving device, wherein the squeezing platform is arranged on the machine frame and is used for carrying the squeezing force, the bottomless filter tube is positioned on the squeezing platform, the solid squeezing tube is matched with the bottomless filter tube, the feeding device is used for feeding materials into the bottomless filter tube, the material collecting device is in seamless connection with the squeezing platform, the filter tube moving device is used for moving the bottomless filter tube to a position above the material collecting device, and the solid squeezing tube is connected with a lifting device driving the solid squeezing tube to ascend and descend. Great gravity of the solid squeezing tube per se is used for squeezing food materials and extruding water, the squeezing platform achieves a support effect on the solid squeezing tube, the pressure is greatly increased, the consumed squeezing time is short, the production efficiency is improved, the settling design is adopted, an additional pressure exertion element is not needed, and the structure is simpler and more effective.

Owner:四川红七公食品有限公司

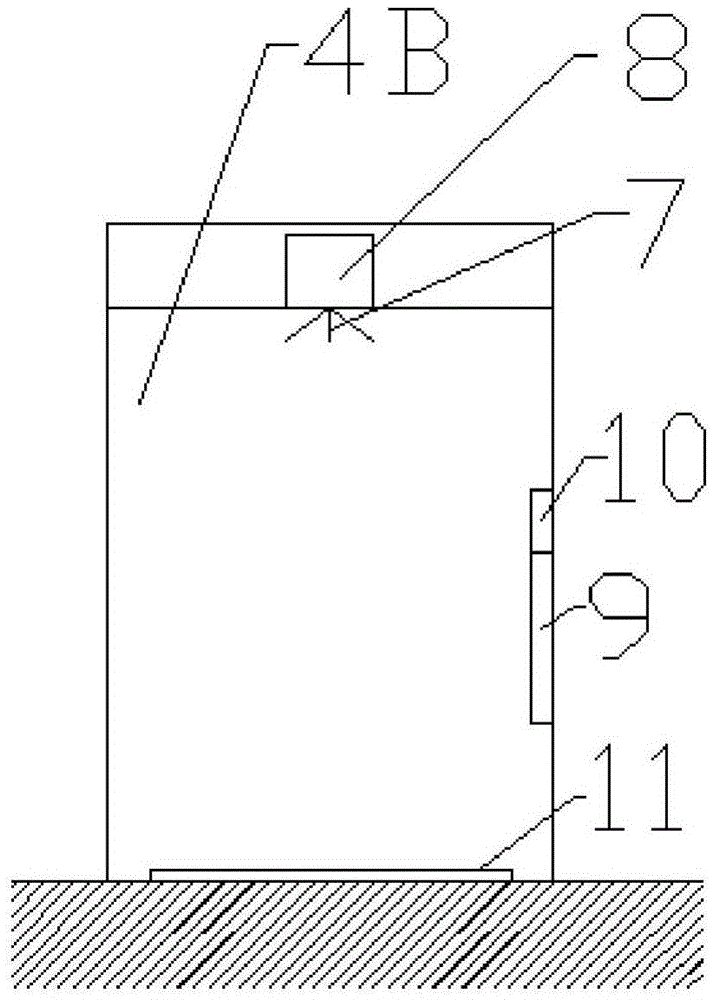

Energy-saving and environment-friendly industrial sewage treatment equipment

PendingCN113354135AEasy to handleNo need for manual feedingTreatment involving filtrationMultistage water/sewage treatmentWaste collectionSewage

The invention relates to sewage treatment equipment, in particular to energy-saving and environment-friendly industrial sewage treatment equipment. The technical problem of the invention is to provide energy-saving and environment-friendly industrial sewage treatment equipment capable of automatically filtering sewage and automatically adding chemical agents into the sewage. The energy-saving and environment-friendly industrial sewage treatment equipment comprises a bottom plate and supporting columns symmetrically arranged on one side of the top of the bottom plate; a fixed basket which is arranged on one side of the top of the bottom plate; a working basket which is arranged between the supporting columns and the upper part of the fixed basket; a filter plate which is arranged on one side in the working basket in a sliding manner; a first handle which is arranged on one side of the filter plate; and a first collection basket. Through cooperation of a waste collection mechanism, a treatment mechanism and a filter plate, industrial sewage can be automatically filtered, impurities in the sewage can be collected, and people can conveniently treat the sewage.

Owner:赖波

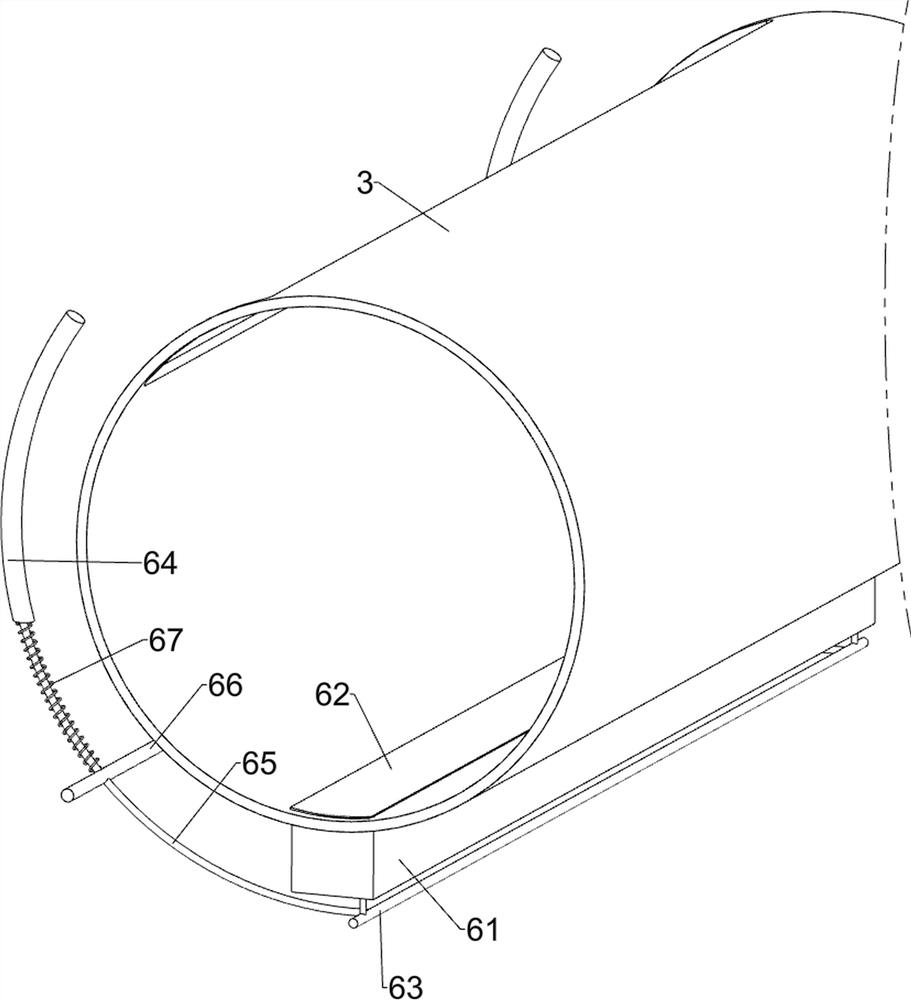

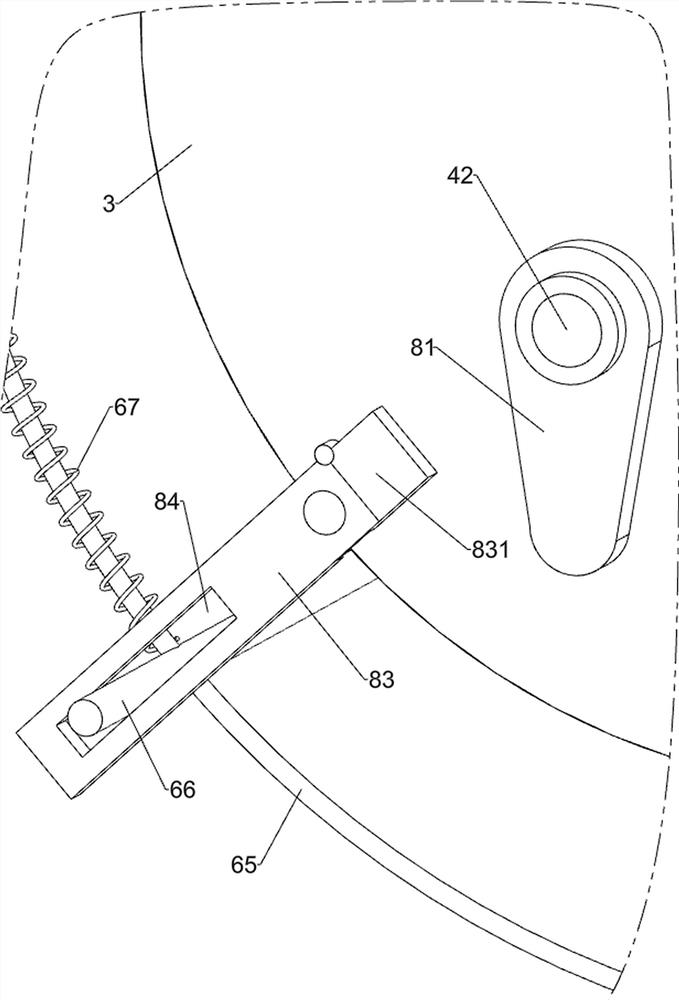

Concrete quantitative preparation and uniform mixing device

ActiveCN112207980AWill not affect the mixing effectAutomatically configure dischargeMixing operation control apparatusCement mixing apparatusEngineeringMixing effect

The invention relates to a uniform mixing device, in particular to a concrete quantitative preparation and uniform mixing device. The technical problem to be solved by the invention is to provide theconcrete quantitative preparation and uniform mixing device which can perform quantitative preparation and automatic discharging and is high in safety coefficient. The concrete quantitative preparation and uniform mixing device comprises a support; a discharging frame body mounted on the support; a mixing cylinder mounted on the support; a mixing assembly mounted on the support; a discharging assembly mounted on the mixing cylinder; and a sliding discharging assembly mounted between the mixing cylinder and the discharging frame body. A discharging stopping assembly is installed in the concretequantitative preparation and uniform mixing device, the discharging assembly can be automatically controlled to conduct discharging, and the situation that the mixing effect is affected due to the fact that the mixing cylinder is overfilled with materials is avoided; the concrete quantitative preparation and uniform mixing device can conduct automatic configuration and discharging, and manual discharging is not needed; and according to the concrete quantitative preparation and uniform mixing device, the safety coefficient is high, the discharging assembly and the mixing assembly both work inside, and only materials need to be placed in the discharging frame body.

Owner:湖北潜江顺盛建材有限公司

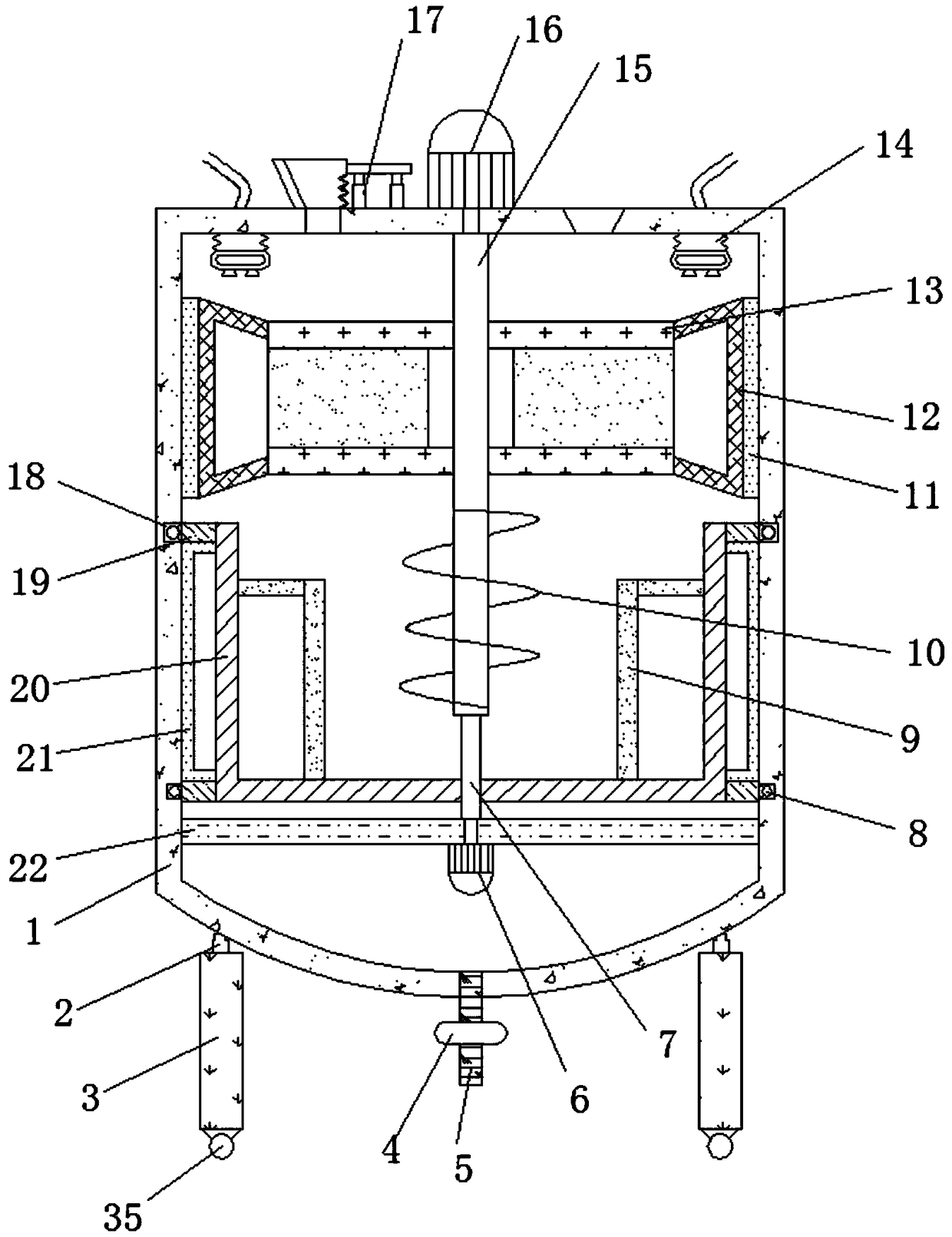

Quantitative raw material mixing device used for medicine production and convenient to clean

InactiveCN108786572AExpand the scope of cleaningEasy to cleanRotary stirring mixersTransportation and packagingMix proportionBolt connection

The invention belongs to the technical field of medicine production, particularly provides a quantitative raw material mixing device used for medicine production and convenient to clean and aims to solve the problems of simple design structure, inconvenient cleaning and difficult quantitative raw material input. At present, the scheme is proposed as follows: the quantitative raw material mixing device comprises a mixing bin, the circle center position of the outer wall of the top of the mixing bin is connected with a stirring motor through a fastening bolt, an output shaft of the stirring motor is connected with a stirring shaft through a fastening bolt, the top and middle positions of the circumference of the stirring shaft are provided with first stirring blades distributed at intervalsthrough fastening bolts, and the ends, away from the stirring shaft, of the two first stirring blades in the same vertical direction are connected with the same third stirring blade through fasteningbolts. A spray head cleaning range is widened, cleaning in the mixing bin is facilitated, quantitative raw material input is achieved, mixing proportion is ensured, manual feeding is not needed, and the quantitative raw material mixing device is convenient, prevents the raw materials from being attached to the inner wall of the mixing bin and ensures even and full mixing.

Owner:ZHENGZHOU ZHENGXIAN PHARMA CO LTD

Feed mixing and feeding device for fish breeding

InactiveCN108174812AAchieve hybridRealize deliveryRotating receptacle mixersShaking/oscillating/vibrating mixersElectricityWireless control

The invention discloses a feed mixing and feeding device for fish breeding. The device comprises a base, a housing, a bottom plate, a motor and a cylinder; a battery for storing electricity, a wireless control module for remote controlling and an upright motor are fixedly installed in the base, and a plurality of material discharging holes are formed in the side wall of the bottom of an inner tube; a floating base is fixedly installed below the bottom plate; the cylinder is horizontally fixed on the top of the housing, a fixing upright column penetrating through an opening and extending downwards is fixed at the rear end of a connecting rod, and a plurality of air spraying holes are formed in the side wall of the fixing upright column; the outer side wall of the inner tube is sleeved witha material baffling tube. According to the device, mixing and feeding of feed are achieved through a device, and only the height of the material baffling tube needs to be manually adjusted; raw materials rotate in the device, and the raw materials move left and right through a horizontally moving material pushing plate, so that the raw materials are mixed thoroughly to ensure uniform nutrition ingredients of the feed; the thrown out feed is uniformly scattered in the surrounding water, and the scattering range is wide.

Owner:王涛

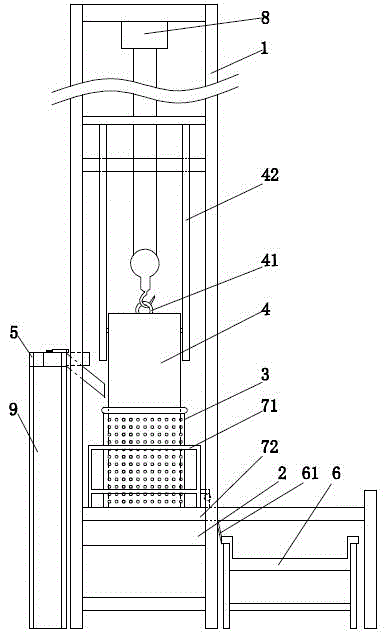

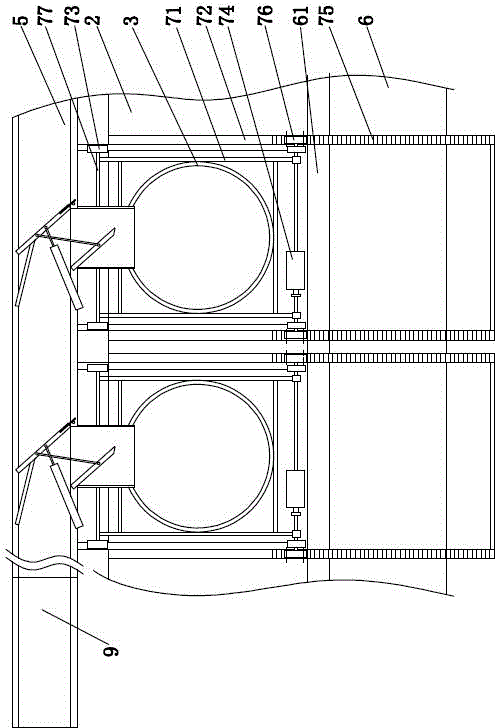

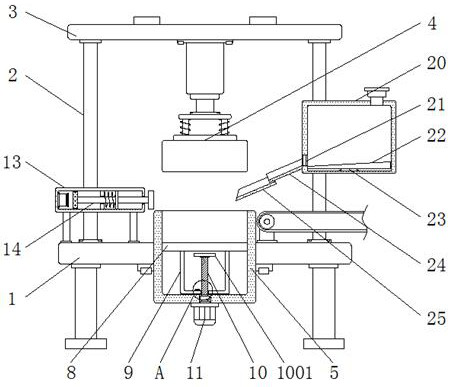

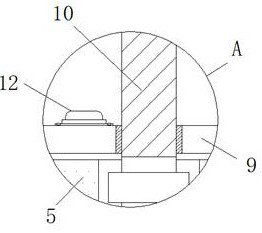

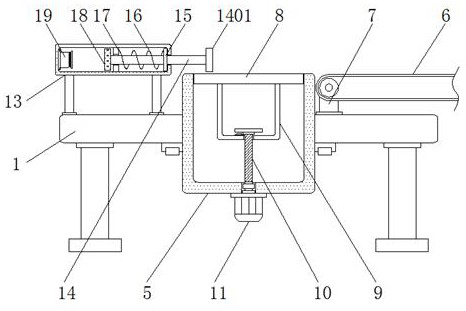

Automatic feeding press machine for refractory brick production

InactiveCN112976244AEasy to addGuaranteed accuracyDischarging arrangementFeeding arrangmentsFire brickMaterial storage

The invention discloses an automatic feeding press machine for refractory brick production. The automatic feeding press machine for refractory brick production comprises a base, supporting rods, a mounting plate, a hydraulic mechanism and an extrusion chamber, wherein the supporting rods are fixed to the upper surface of the base; the mounting plate is embedded in the upper ends of the supporting rods; the hydraulic mechanism is arranged below the mounting plate; the extrusion chamber is arranged below the hydraulic mechanism; the extrusion chamber is embedded in the base; a conveying mechanism is arranged on the right side of the extrusion chamber; and a connecting plate is installed at the left end of the conveying mechanism. The automatic feeding press machine for refractory brick production is provided with a second material guide shell and a positioning block, materials in a material storage chamber can be added into the extrusion chamber through cooperation of the second material guide shell and a first material guide shell, and the second material guide shell can slide along the first material guide shell under the action of the positioning block, so that after the materials are added, the second material guide shell can be recycled towards the right side, and subsequent work of the hydraulic mechanism is not affected; and meanwhile, manual material adding is not needed, so that automatic feeding can be achieved.

Owner:山东嘉和耐火材料有限责任公司

Captive breeding cage capable of automatically feeding livestock with water and fodder

The invention discloses a captive breeding cage capable of automatically feeding livestock with water and fodder. The cage includes a baseplate and multiple vertical rods arranged on the baseplate; atop plate is fixedly connected to the upper ends of the vertical rods, feces discharge ports are uniformly distributed in the upper end of the baseplate, a groove is formed in the upper end of the baseplate, and a footboard is rotatably connected to the inner wall of the groove; a sliding block is slidably connected to the lower end of the footboard, a tray is fixedly connected to the lower portion of the baseplate through connecting rods, and a cylinder is fixedly connected to the upper end of the tray. The activity space of poultry is increased, and convenience is provided for breeders to feed the poultry; when the poultry eat feed, a trough is moved down to be in contact with the ground, and therefore the poultry can eat the feed conveniently; the feed in a feed box is conveyed into a feed storage cavity through a feeding pipe, the feed and the water which are contained in the feed storage cavity and a water storage cavity respectively are introduced into the trough through a discharge pipe in sequence, and there is no need to manually introduce the feed and the water. Feces of the poultry on the inner bottom of the tray is scraped off by a scraping plate, and the process of manually removing the feces is omitted.

Owner:赵成书

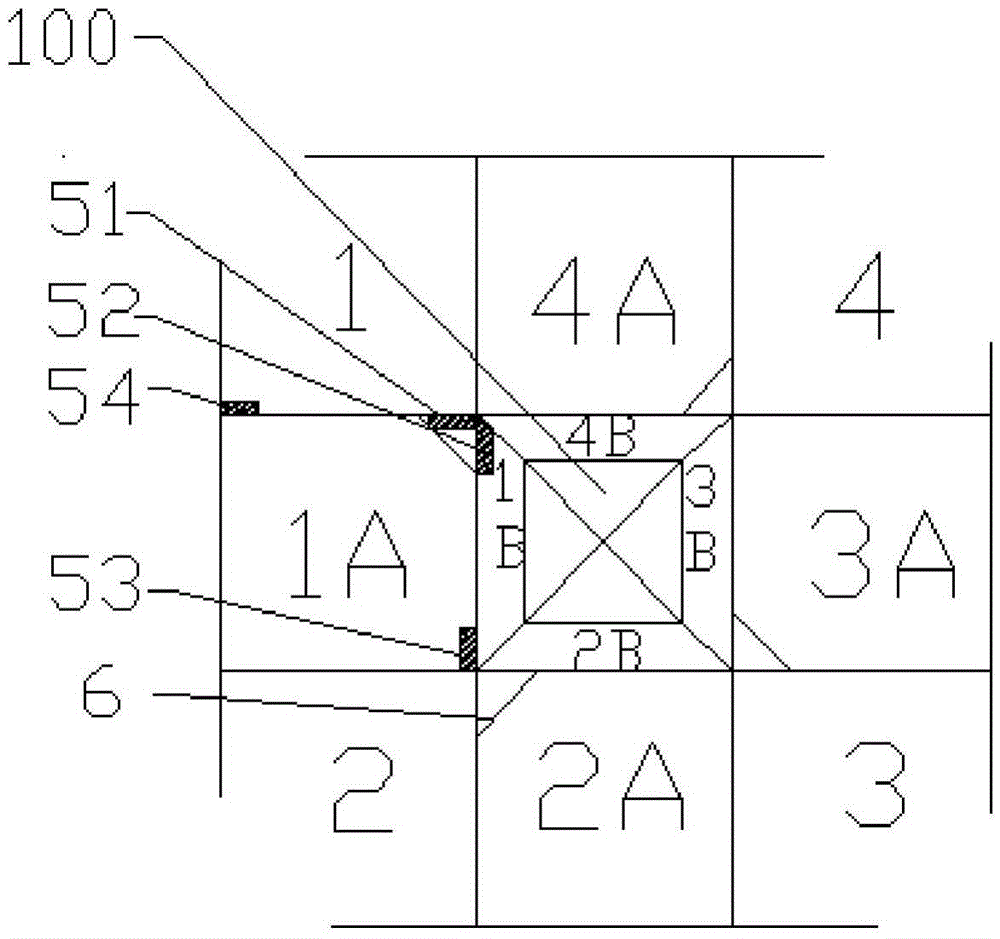

Smart feeding system for female goats

ActiveCN105409796ANo need for manual feedingPrecision Feeding ProgramAnimal feeding devicesAnimal housingEngineeringGestation

The present invention relates to a smart feeding system for female goats. The system mainly comprises a to-be-fed house, a fed house and a feeding house, wherein the to-be-fed house comprises a gestation to-be-fed house, a parturition to-be-fed house, a conservation to-be-fed house and a fattening to-be-fed house; the fed house comprises a gestation fed house, a parturition fed house, a conservation fed house and a fattening fed house; the feeding house comprises a feeding channel and a feed dispensing apparatus; the gestation to-be-fed house, the parturition to-be-fed house, the conservation to-be-fed house and the fattening to-be-fed house are sequentially distributed in the northwest, southwest, southeast and northeast directions of the feeding house, and the gestation fed house, the parturition fed house, the conservation fed house and the fattening fed house are distributed in the west, south, east, and north directions of the feeding house; and the to-be-fed house is connected to the fed house via the feeding channel. According to the smart feeding system for the female goats, fodder can be provided differentially according to different stages of the female goats, the female goats which are not fed can be separated from the fed female goats, and automatic feeding efficiency of the female goats is improved.

Owner:太湖县晋熙镇农业农村综合服务中心

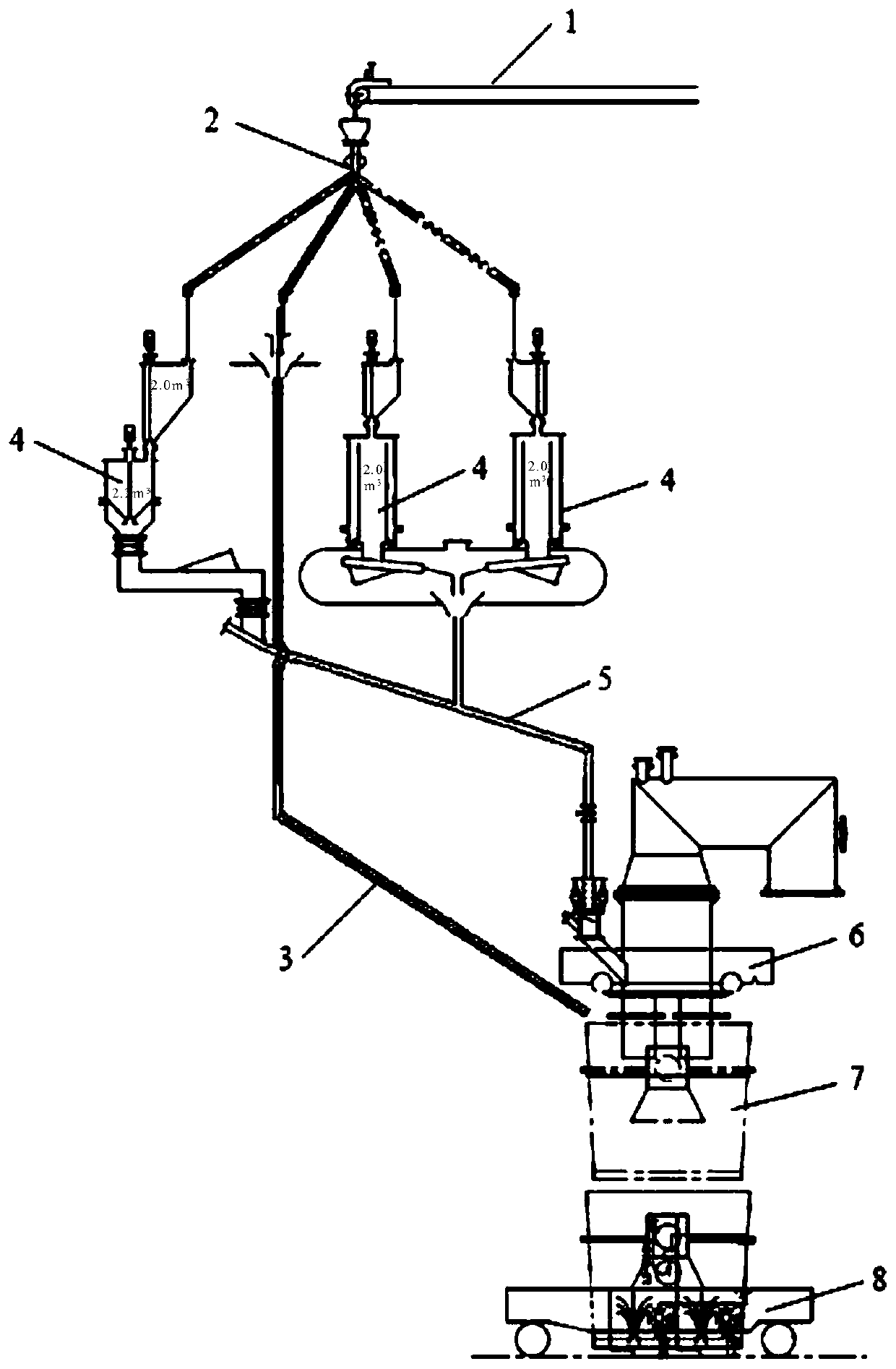

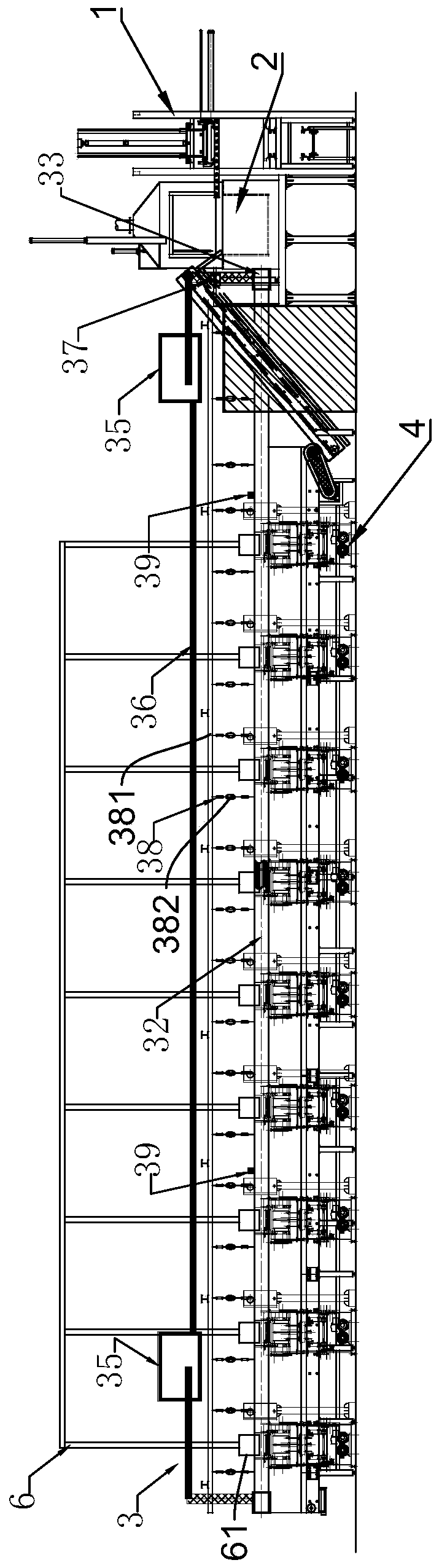

Vacuum cycle degassing furnace and feeding device thereof

InactiveCN111410062AReduce labor intensityReduce process dwell timeProcess efficiency improvementLoading/unloadingSlagProcess engineering

The invention discloses a feeding device of the vacuum cycle degassing furnace. The feeding device comprises a loading belt conveyor, a rotary distributing device and a steel ladle slag charge unloading chute. The loading belt conveyor is used for bearing adjusting slag modified slag charge, a feeding opening of the rotary distributing device is formed below the tail end of the loading belt conveyor to bear adjusting slag modified slag charge fallen from the tail end of the loading belt conveyor, and the top end of the steel ladle slag charge unloading chute is arranged below a discharging opening of the rotary distributing device to bear adjusting slag modified slag charge of a discharging opening of the rotary distributing device. The bottom end of the steel ladle slag charge unloading chute is arranged above the processing position steel ladle side of the vacuum cycle degassing furnace, and is used for adding the adjusting slag modified slag charge to steel ladle slag surface located at a processing position. By applying the feeding device of the vacuum cycle degassing furnace, automatic feeding of the adjusting slag modified slag charge is realized, manual batch charge operation is not needed, so that the labor strength of post operation personnel is reduced, and liquid steel process standing time is reduced. The feeding device is adopted to effectively trace the batch charge moment and batch charge capacity, and quality improvement control is facilitated.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

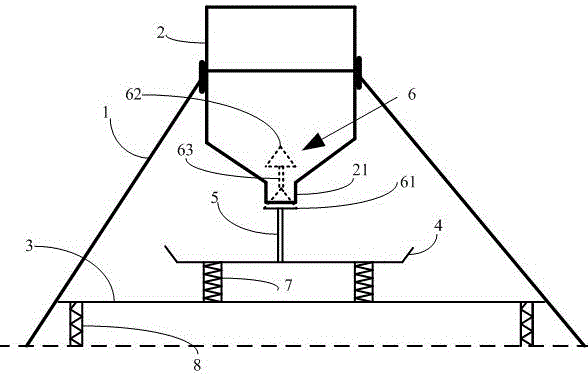

Feeding device

InactiveCN106489764ANo need for manual feedingLow costAnimal feeding devicesEngineeringElectric control

The invention provides a feeding device which is convenient for scattered feeding of feed and can avoid excessive concentration of chicken flocks. The feeding device comprises a supporting frame, a storage tank arranged at the upper part of the supporting frame, a ground mat arranged on the ground below the supporting frame, a feed basin arranged above the ground mat and right under the storage tank, a first connecting rod and a discharging mechanism; a first spring group is arranged between the ground mat and the ground; a second spring group is arranged between the feed basin and the ground mat; a discharge opening is formed in the bottom of the storage tank; the discharging mechanism is arranged in the discharge opening; the first connecting rod is vertically arranged; two ends of the first connecting rod are respectively and fixedly connected with the center of the feed basin and the discharging mechanism. The feeding devices can be putted in a breeding forest land in a scattering mode, and manual feeding is not needed; in addition, discharging can be automatically stopped when the chicken flocks are excessively concentrated or the discharging amount is over high; the feeding device adopts a simple mechanical structure and is controlled by dead weights of chickens and the return capability of the springs; an electric control device, power supply, arrangement of cables or use of a storage battery are not needed, so the cost is excessively low.

Owner:HUIZHOU JUCHUANG HUIZHI TECH DEV

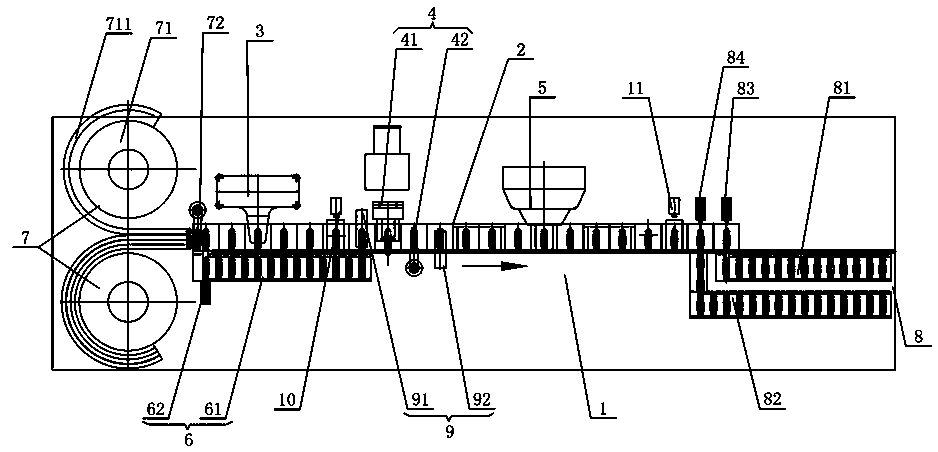

Potting system and method for abnormal-shaped container

InactiveCN109094833AOptimize layoutReduce distanceWrapping material feeding apparatusLiquid materialEngineeringAbnormal shaped

The invention discloses a potting system and method for an abnormal-shaped container. The potting system for the abnormal-shaped container comprises a machine frame. A linear type conveying line is arranged on the machine frame, a film adding station, an aluminum foil packaging station and at least one filling film pressing station are arranged on the linear type conveying line, and the film adding station, the filling film pressing station and the aluminum foil packaging station are arranged in sequence in the conveying direction of the linear type conveying line. A container input station and a film feeding station are arranged at the head end of the linear type conveying line, a container output station is arranged at the tail end of the linear type conveying line, and a measuring device used for obtaining the filling volume of the contain is further arranged on the linear type conveying line. The potting method is carried out by using the potting system for the abnormal-shaped container. The potting system for the abnormal-shaped container has the advantages of being reasonable in layout, low in cost and capable of improving the production efficiency and product percent of pass.

Owner:TRUKING TECH LTD

Efficient pulping device

InactiveCN105665108AHigh yieldHigh degree of automationGrain treatmentsPulp and paper industryDischarge rate

The invention provides an efficient pulping device and belongs to the technical field of soybean milk production equipment. The efficient pulping device comprises a base, pulping machines, a milk collecting tank and a dreg collecting tank. The milk collecting tank is located in the base, the base is provided with three stairs with the height gradually reduced, and the three pulping machines are fixed to the three stairs. A milk collecting hopper is arranged below a first milk discharging opening of the first pulping machine and communicates with the interior of the milk collecting tank through a first milk collecting pipeline. The lower portion of a first dreg discharging pipe opening of the first pulping machine exactly faces a second feeding opening of the second pulping machine. A second milk discharging opening of the second pulping machine stretches into the milk collecting tank through a second milk collecting pipeline. A liquid collecting cylinder is arranged under the second pulping machine. A third milk discharging opening of the third pulping machine stretches into the liquid collecting cylinder through a third milk collecting pipeline. A water suction pump is arranged in the liquid collecting cylinder, and an output pipeline of the water suction pump communicates with a first feeding opening of the first pulping machine. According to the device, bean dregs are cyclically pulped, and the milk discharging rate of the whole device can be increased.

Owner:浙江水磨坊智能科技有限公司

Medical traditional Chinese medicinal material grinding and mashing equipment

ActiveCN113856818AAutomatic grindingImprove work efficiencyPlastic recyclingPharmaceutical product form changeProcess engineeringMechanical engineering

The invention relates to mashing equipment, in particular to medical traditional Chinese medicinal material grinding and mashing equipment. The technical problem to be solved is to provide the medical traditional Chinese medicinal material grinding and mashing equipment which can automatically feed traditional Chinese medicinal materials and is time-saving and labor-saving. The medical traditional Chinese medicinal material grinding and mashing equipment comprises supporting plates and a material containing mechanism, and the four supporting plates are arranged on the material containing mechanism. A grinding mechanism is included and is arranged on one side of the material containing mechanism. And a grinding disc is further included and is arranged on the grinding mechanism. Through cooperation of the grinding disc, the grinding mechanism and the material containing mechanism, the traditional Chinese medicinal materials can be automatically ground in a reciprocating mode, manual operation by people is not needed, and time and labor are saved. Through cooperation of a rotating mechanism and a reset mechanism, the grinding disc can be automatically driven to rotate so that the traditional Chinese medicinal materials can be automatically ground, and the working efficiency is improved.

Owner:广东省药材公司中药饮片厂

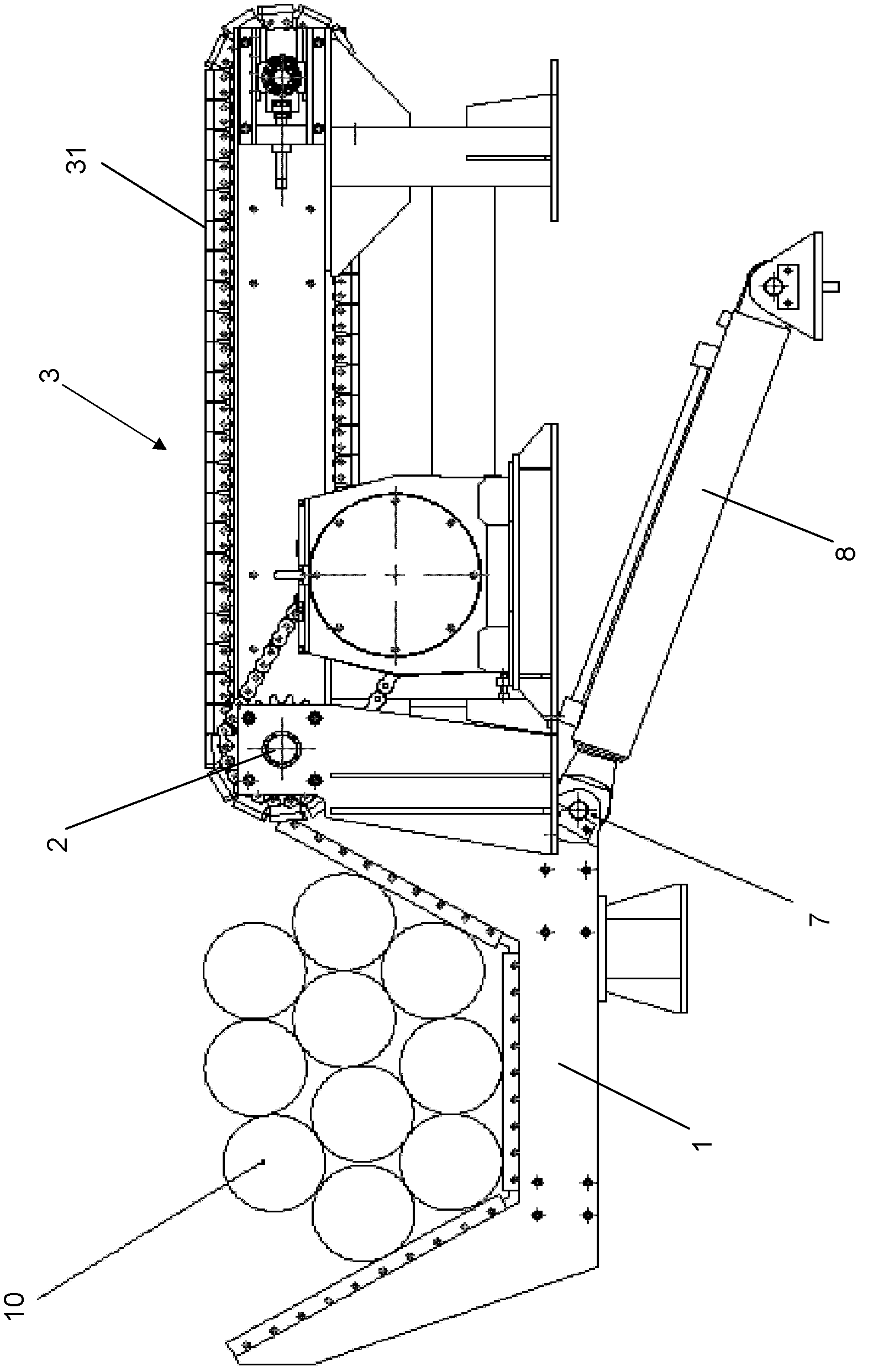

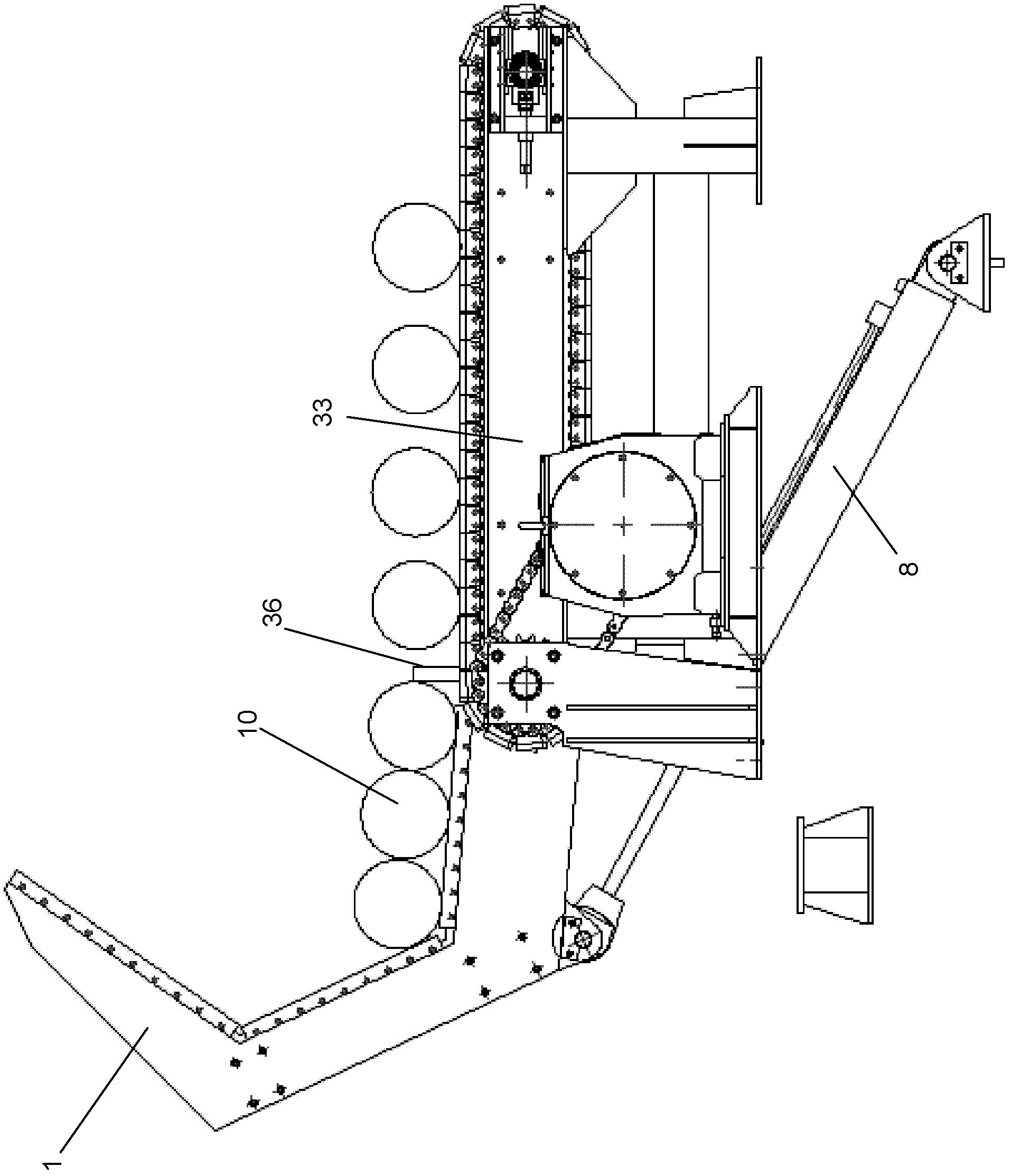

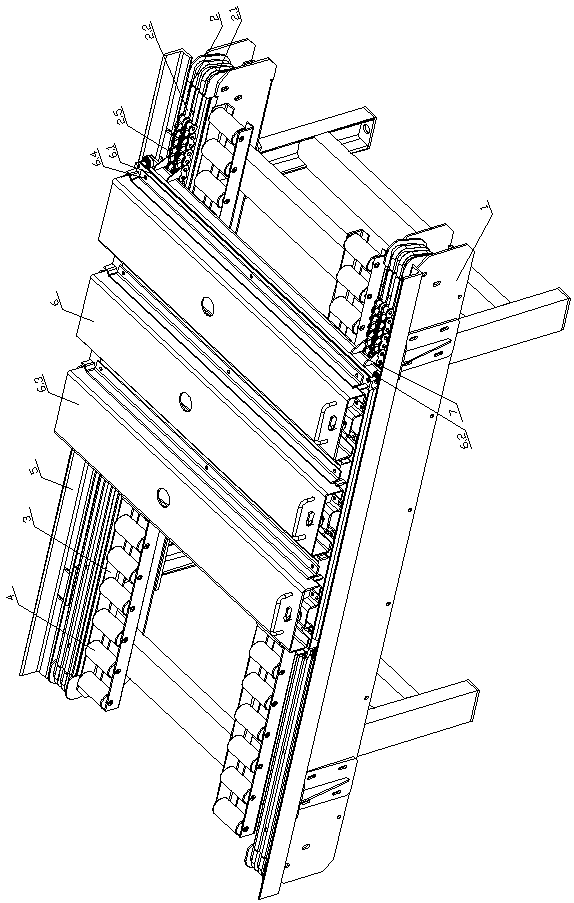

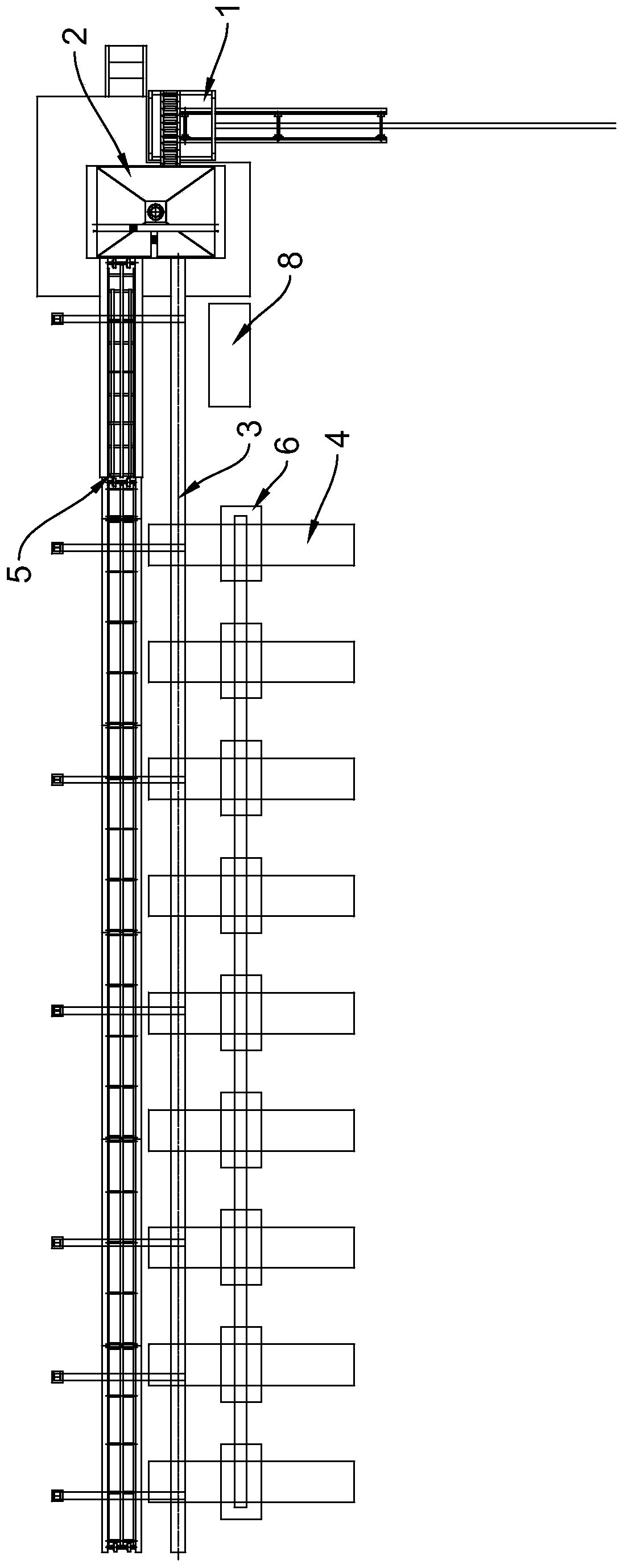

Linear warehouse suitable for automatic stacking of transformer cores

PendingCN110077798AIncrease the level of automationIncrease productivityMechanical conveyorsProduction lineTransformer

The invention discloses a linear warehouse suitable for automatic stacking of transformer cores, and relates to the field of core production equipment. The linear warehouse suitable for automatic stacking of the transformer cores comprises a conveying line support. Chain conveyors are symmetrically arranged on the two sides of the conveying line support separately. A plurality of quick-change trays are separately supported on each chain conveyor. Guide strips are separately arranged on the outer sides of the chain conveyors. Guide grooves used for guiding the quick-change trays to move in theconveying direction are formed between the guide strips. Rollers which are in rolling fit with the guide strips on the corresponding sides are separately mounted around the quick-change trays. By adoption of the linear warehouse, the automation level of a core production line is improved, the production efficiency is improved, and the labor cost is reduced.

Owner:HAIAN JIAORUI ROBOT TECH

Toughened glass impact resistance detection equipment for constructional engineering

PendingCN114136814AImprove work efficiencyConvenience to workStrength propertiesFixed frameToughened glass

The invention relates to detection equipment, in particular to tempered glass impact resistance detection equipment for constructional engineering. The tempered glass impact resistance detection equipment for constructional engineering aims at achieving the technical purposes that tempered glass can be automatically and intermittently fed, and qualified tempered glass can be collected. The tempered glass impact resistance detection equipment for constructional engineering comprises a bottom plate and a first supporting frame, and the first supporting frame is arranged on the middle side of the top of the bottom plate; the first fixing frame is arranged at the upper part of the first support frame; the impact column is arranged in the first fixing frame in a sliding manner; the beating mechanism is arranged on the first fixing frame; the power mechanism is arranged at the top of the bottom plate; and the fixing mechanism is arranged at the top of the bottom plate. Through cooperation of the striking mechanism, the power mechanism and the fixing mechanism, tempered glass can be automatically impacted, so that an impact resistance detection experiment is completed, and time and labor are saved.

Owner:谢小金

Decomposition and Precipitation Circulation Process for Preparation of Trimanganese Tetroxide with Manganese Sulfate Solution

ActiveCN104211122BEasy accessNo pollution in the processManganese oxides/hydroxidesDecompositionSulfate

The invention discloses a decomposition deposition cycle technology for preparing trimanganese tetroxide through using a manganese sulfate solution. The technology comprises the following steps: 1, adding a manganese sulfate solution and ammonium bicarbonate into a deposition reaction kettle to make manganese in the manganese sulfate solution fully deposited, filtering, and washing to obtain manganese carbonate; 2, sending manganese carbonate into a suspension decomposition kiln, and decomposing to obtain trimanganese tetroxide; 3, introducing the manganese sulfate solution and ammonia water or liquefied ammonia into an absorbing tower, introducing tail gas from the suspension decomposition kiln into the absorbing tower to carry out a reaction, allowing the obtained reaction liquid to flow into a deposition reaction kettle, and depositing to obtain manganese carbonate, wherein the introduction amount of the ammonia water or liquefied ammonia makes the pH value of the reaction liquid controlled at about 6.5; and 4, sending manganese carbonate into the suspension decomposition kiln, and repeating step 3. The technology using carbon dioxide decomposed by manganese carbonate and the ammonia or liquefied ammonia to deposit manganese carbonate has the advantages of environmental protection, low energy consumption and low cost.

Owner:CHONGQING SHANGJIA ELECTRONICS

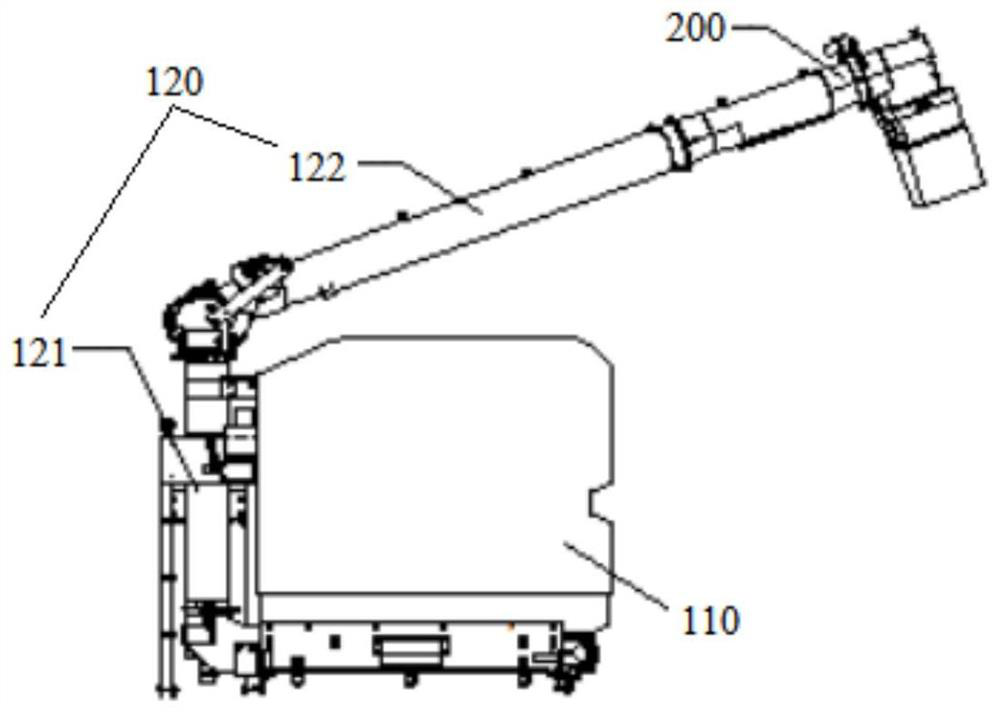

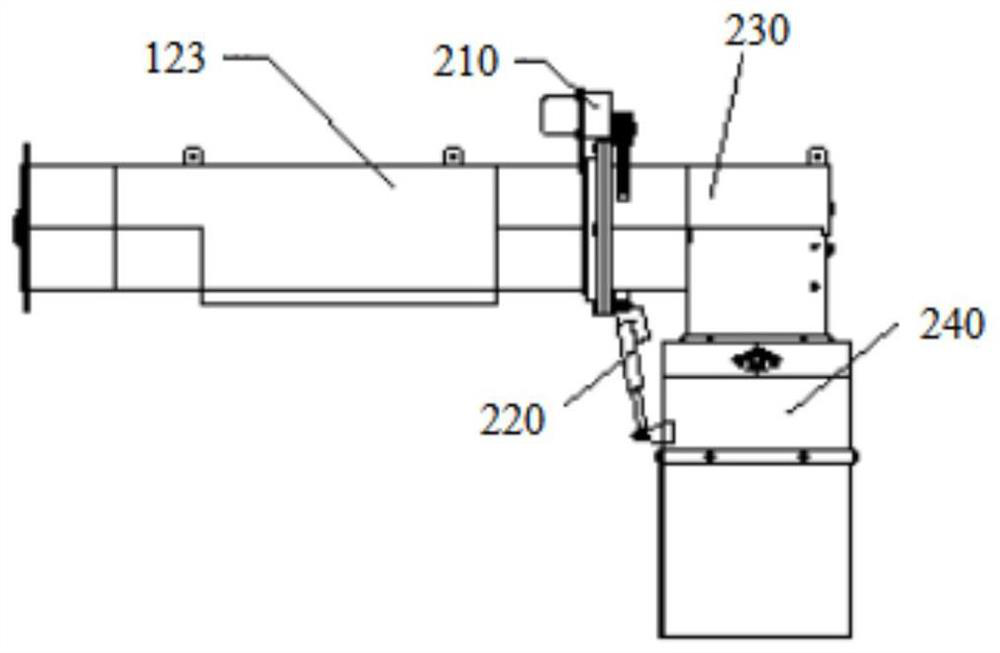

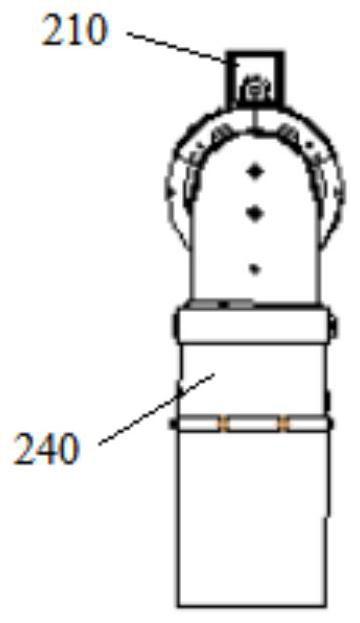

Movable grain unloading opening mechanism of combine harvester, grain unloading device and harvester

PendingCN113575100AImprove the efficiency of grain unloading operationsReduce operating costsMowersAgricultural engineeringStructural engineering

The invention discloses a movable grain unloading opening mechanism of a combine harvester, a grain unloading device and a harvester, and belongs to the technical field of harvesters. The movable grain unloading opening mechanism of the combine harvester is installed at the tail end of a grain unloading horizontal auger assembly and comprises a radial rotating assembly and an axial swinging assembly. The radial rotating assembly can rotate around the axis of the horizontal grain unloading auger assembly, and the axial swing assembly can swing in the axis direction of the horizontal grain unloading auger assembly. According to the movable (vector) grain discharging opening mechanism, during grain discharging operation, a grain discharging opening can be freely adjusted in the 360-degree direction on the horizontal projection plane, the grain discharging direction can be freely changed, grains can be evenly discharged to all corners of a dragging box of a grain transporting vehicle, the grain discharging operation efficiency of the harvester is greatly improved, the operation cost of the harvester is saved, and potential safety hazards during grain unloading are further eliminated. The movable grain unloading opening mechanism of the combine harvester is simple in principle, reasonable in structural design and convenient to popularize and use.

Owner:苏州久富农业机械有限公司

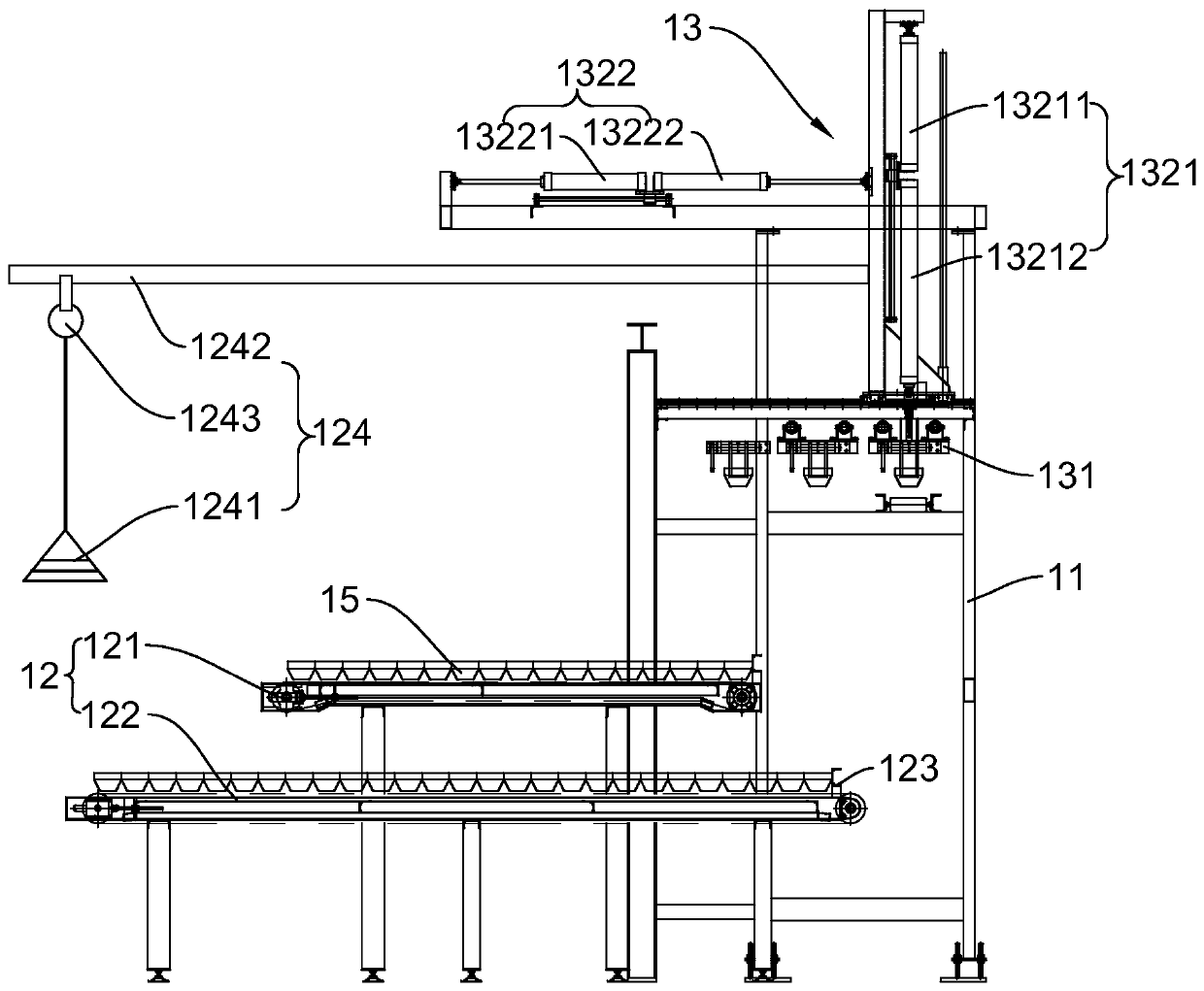

Suction lifting and releasing device for optical lens

InactiveCN110950081AReduce workloadRealize automatic feedingCharge manipulationConveyor partsEngineeringStructural engineering

The invention discloses a suction lifting and releasing device for an optical lens. The suction lifting and releasing device comprises a mounting frame, and a mounting plate is fixed to the upper endof the mounting frame. First supporting plates are fixed to one side of the mounting plate, and a servo motor is fixed to the corresponding first supporting plate. A screw rod is fixed to an output shaft of the servo motor, and a driving nut is connected to the screw rod in a screw drive mode. The driving nut is inlaid in a mounting block, and first sliding blocks are arranged on both sides of themounting block. The first sliding blocks slide in first sliding grooves in fixing plates, and the fixing plates are fixed to the first supporting plates. A mounting box is fixed to the lower end of the mounting block, and a first air cylinder is fixed into the mounting box. A first connecting plate is fixed to a piston rod of the first air cylinder, and a vacuum chuck is fixed to the lower end ofthe first connecting plate. A feeding mechanism is arranged below the vacuum chuck. The automatic feeding is realized through the above structure, optical glass is automatically moved, the working efficiency is high, and the cost is saved.

Owner:江西高佳光电科技有限公司

Raw material adding device for synthetic resin processing

PendingCN113813880AEasy to operateEasy to implementRotary stirring mixersMixer accessoriesElectric machineryProcess engineering

The invention provides a raw material adding device for synthetic resin processing. The raw material adding device comprises a material collecting box, a water inlet mechanism is arranged at the top of the material collecting box, one side of the top of the material collecting box fixedly communicates with a feeding hopper, a stirring mechanism is arranged in the material collecting box, and a quantitative discharging mechanism is arranged at the bottom of the material collecting box. The quantitative discharging mechanism comprises a second motor, the second motor is fixedly installed at the inner bottom of the material collecting box, and the output shaft end of the second motor penetrates through the bottom of the material collecting box and is fixedly connected with a rotating shaft. The second motor, a rotating shaft, a circular plate, a planetary material guide opening, a discharging pipe and a discharging opening are arranged and used in cooperation, thus the synthetic resin raw material adding device can realize adding of synthetic resin raw materials, is convenient to operate and easy to realize, can effectively control the adding speed and the adding amount of the synthetic resin raw materials, does not need manual adding, and also greatly reduces the labor intensity of workers.

Owner:清远市南星化工有限公司

Production system for slab lattice of lead-acid storage battery and method for preparing slab lattice by using the same

PendingCN109713317AHigh degree of production automationConsistent temperatureElectrode carriers/collectorsIngotSmall footprint

The invention relates to a production system for a slab lattice of a lead-acid storage battery. The system includes a lead ingot feeding device, a smelting furnace, a lead liquid heat insulation conveying device, multiple slab lattice casting devices, a waste material conveyor, and a waste gas treatment device located above the slab lattice casting devices, which are sequentially connected. The invention also provides a method for preparing the slab lattice by using the production system. The production system for the slab lattice of the lead-acid storage battery of the invention has the advantages of simple structure, low energy consumption, less pollution source, small land occupation area, and high degree of automation.

Owner:希世比能源科技(韶关)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com