Production system for slab lattice of lead-acid storage battery and method for preparing slab lattice by using the same

A lead-acid battery and production system technology, applied in the direction of electrode carrier/current collector, etc., can solve the problems of dirty and chaotic production environment, low degree of automation, high labor cost, etc., to improve the degree of production automation, reduce floor space, The effect of reducing the production cost of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with examples of implementation and accompanying drawings. The present invention can be implemented in the following ways:

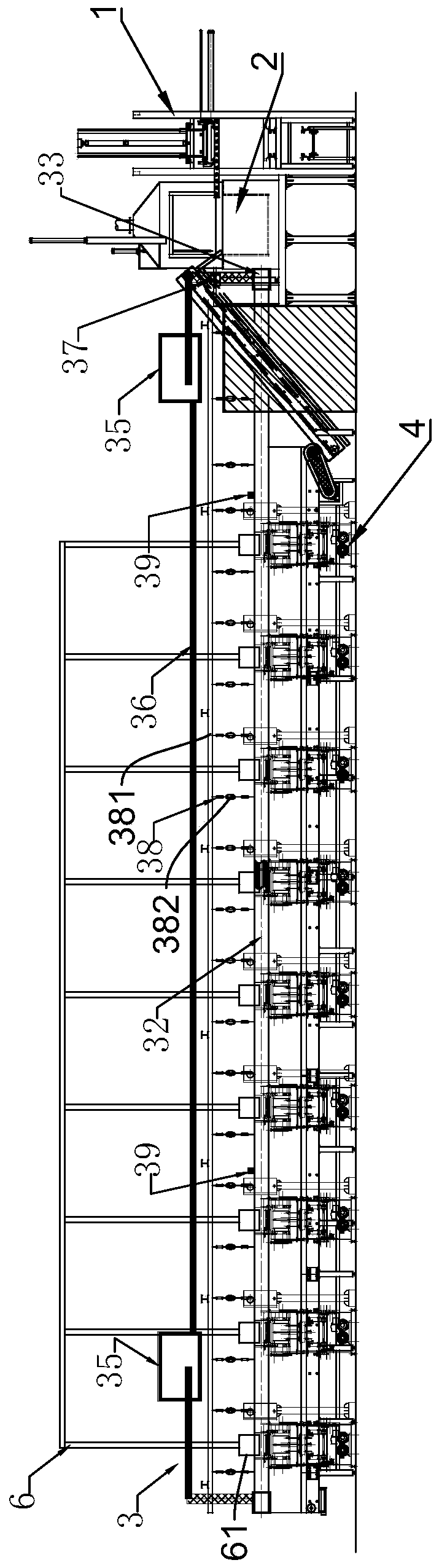

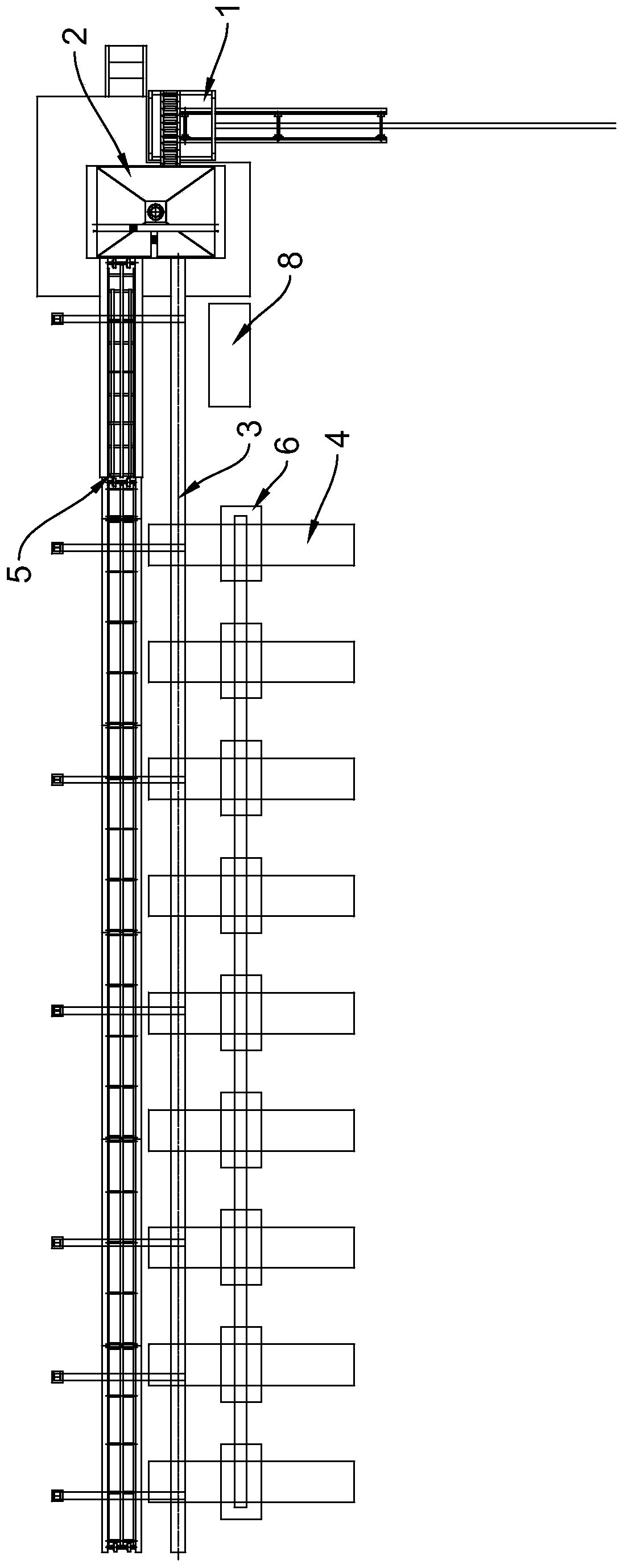

[0046] refer to Figure 1-8, a lead-acid battery grid production system, comprising a lead ingot feeding device 1, a melting furnace 2, a lead liquid heat preservation conveying device 3, a plurality of grid casting equipment 4, a waste conveyor 5 connected in sequence, and a grid casting equipment located at The upper waste gas treatment device 6; since the lead liquid heat preservation conveying device 3 can be connected to nine grid casting equipment 4 at most, this embodiment is a model of one furnace and nine machines.

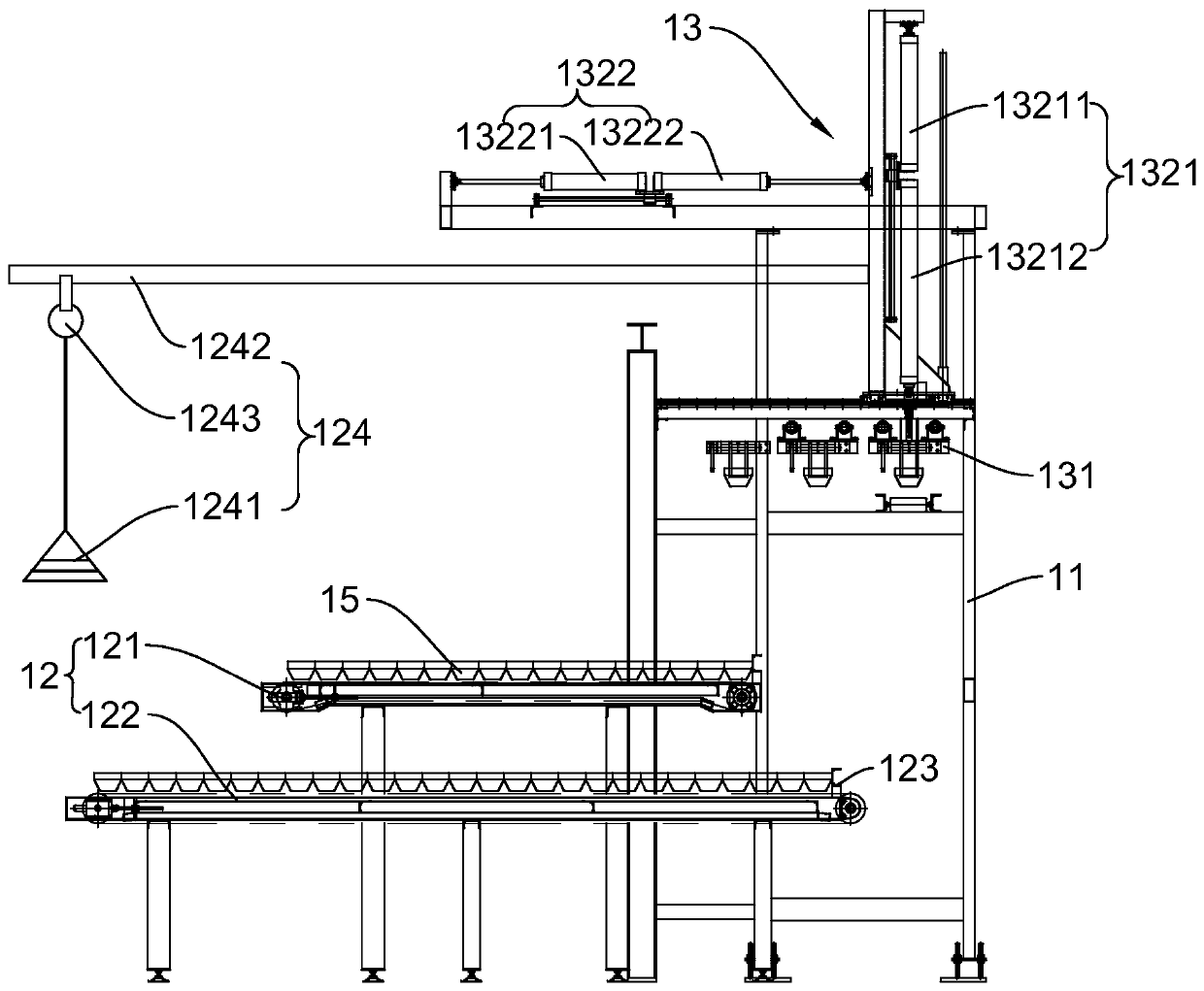

[0047] The lead ingot feeding device 1 includes a frame 11, a material conveying mechanism 12, a material clamping mechanism 13 and a pushing mechanism 14 for pushing the lead ingot in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com