Plate turning machine

A technology of turning machine and sheet material, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of the surface of the sheet material becoming flowery, not suitable for coloring operations, and low efficiency of manual turning over, and achieve the effect of high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

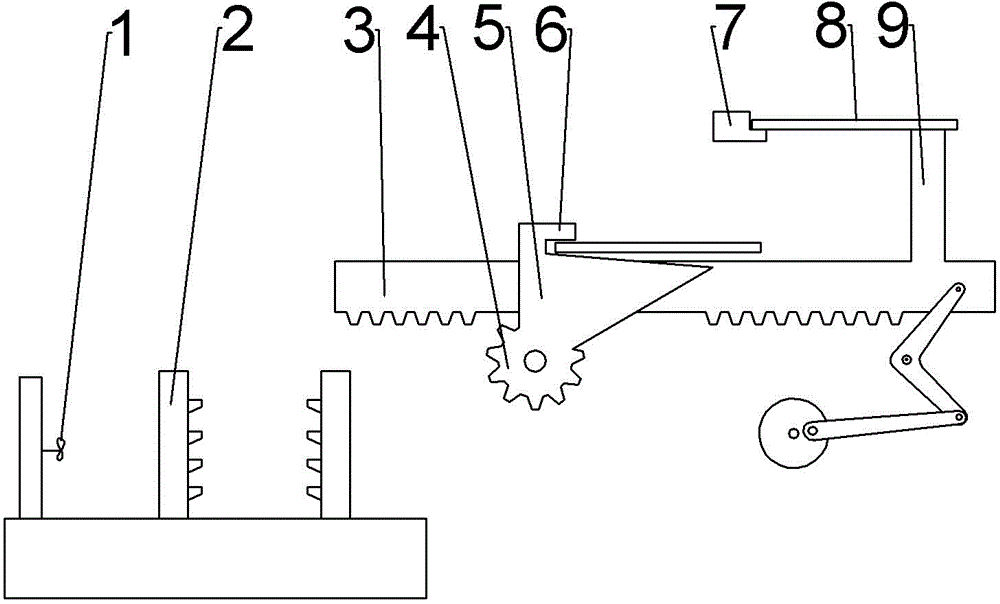

[0013] The reference signs in the accompanying drawings of the description include: fan 1 , storage rack 2 , slide plate 3 , gear 4 , turning plate 5 , hook 6 , baffle plate 7 , sheet material 8 , and push plate 9 .

[0014] The embodiment is basically as attached figure 1 Shown:

[0015] The embodiment of this program comprises flipper 5, slide plate 3 and rack 2, and slide plate 3 is horizontally arranged, is provided with push plate 9 on slide plate 3 top, and baffle plate 7 is set above slide plate 3, and the storage surface of this baffle plate 7 and push plate 9 The upper surface level of the upper surface is consistent, and the plate 8 to be turned over can be placed on the top of the baffle plate 7 and the push plate 9.

[0016] A rack is provided under the slide plate 3, and the rack is engaged with a gear 4 arranged below the slide plate 3, and a turning plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com