Linear warehouse suitable for automatic stacking of transformer cores

A transformer and iron core technology, applied in the field of linear material storage, can solve the problems of low equipment utilization rate, long material turnover time, human and financial resources consumption, etc., and achieve the effect of ensuring stable transportation, reducing labor costs and improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

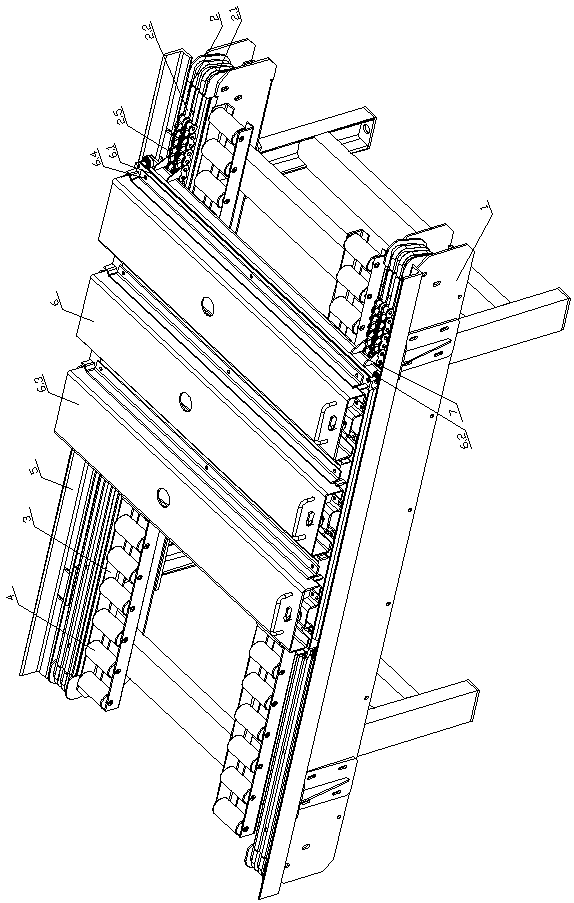

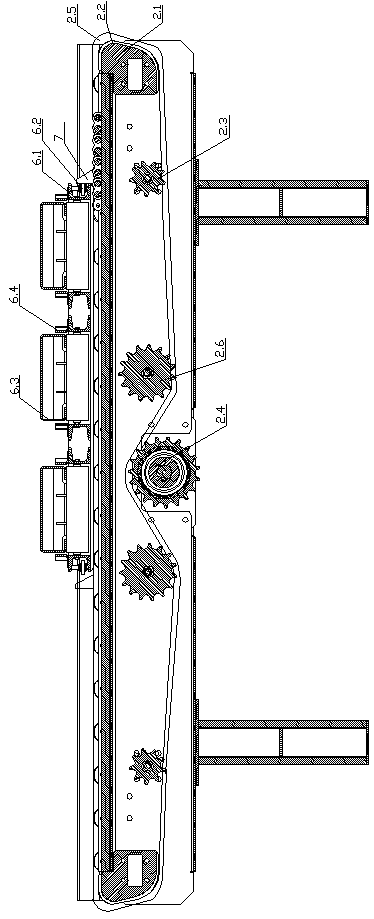

[0020] Such as figure 1 , 2 As shown, the present invention includes a conveyor line support 1, and symmetrically arranged chain conveyors 2 are respectively installed on both sides of the conveyor line support 1. The chain conveyor 2 includes a chain support seat 2.1 fixedly installed on the conveyor line support 1, and the chain support The seat 2.1 is provided with a chain guide rail 2.2, and a transmission wheel 2.3 is respectively installed on the conveyor line support 1 on both sides below the chain support seat 2.1, and a drive wheel 2.4 is installed between the two transmission wheels 2.4, and the transmission wheels 2.3 on both sides A chain tensioning wheel 2.6 is respectively arranged between the drive wheel 2.4, and the drive wheel 2.4 is correspondingly connected with a drive motor (not shown in the figure), and a chain 2.5 is arranged on the chain guide rail 2.2, and the chain 2.5 is ring-shaped. Go around driving wheel 2.3, tensioning wheel 2.6, driving wheel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com