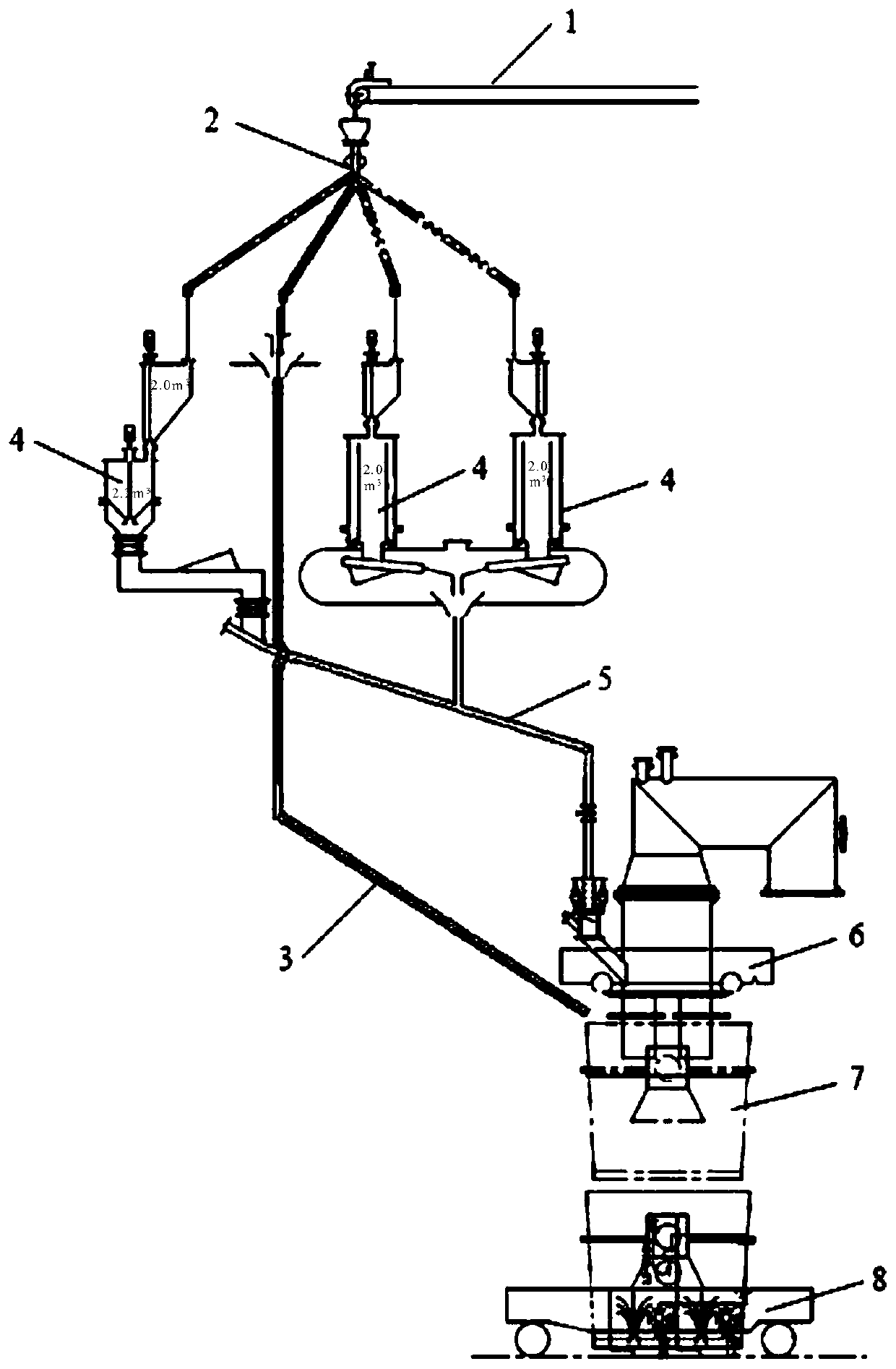

Vacuum cycle degassing furnace and feeding device thereof

A technology of feeding device and vacuum circulation, which is applied in the field of smelting, can solve the problems of difficulty in ensuring feeding accuracy and high labor intensity, and achieve the effects of reducing labor intensity, reducing residence time, and facilitating quality improvement and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The RH refining furnace processes low-carbon aluminum series micro-carbon steel, the molten steel temperature at the RH station is 1610-1630°C, [C]%: 0.02%-0.05%, the slag surface of ladle 7 is about 500-1000kg, and the FeO% content in slag is 15 ~18%, after being treated by RH furnace, the composition and temperature of molten steel meet the requirements of continuous casting in the subsequent process.

[0040] The RH treatment position uses the ladle slag discharge chute 3. After the molten steel treatment is completed, the ladle slag discharge chute 3 is used to add the required amount of slag to the ladle 7 slag surface in time. Low-carbon aluminum series micro-carbon steel grades, the molten steel temperature after RH treatment is 1590°C, the slag content on the slag surface of ladle 7 is about 500-1000kg, the FeO% content in slag is 15-18%, and the Als burning loss is 60-120ppm. Using this invention, after the molten steel treatment is completed, the slag adjusted...

Embodiment 2

[0042] The RH refining furnace of a steelmaking plant processes IF series ultra-low carbon steel. The molten steel temperature at the RH station is 1630-1650°C, [C]%: 0.02%-0.05%. The FeO% content is 15-18%. After being treated by the RH furnace, the composition and temperature of the molten steel meet the requirements of continuous casting in the subsequent process.

[0043] The RH treatment position uses the ladle slag discharge chute 3. After the molten steel treatment is completed, the ladle slag discharge chute 3 is used to add the required amount of slag to the ladle 7 slag surface in time. IF ultra-low carbon series steel grades, the molten steel temperature after RH treatment is 1590-1600°C, the slag content on the slag surface of ladle 7 is about 500-1000kg, the FeO% content in slag is 15-18%, and the Als burning loss is 60-120ppm. Using this invention, after the molten steel treatment is completed, the slag adjusted and modified slag in the ladle 7 is weighed by vibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com